Design and verification of an adjustable length safety tether for astronaut extravehicular activities

-

摘要:

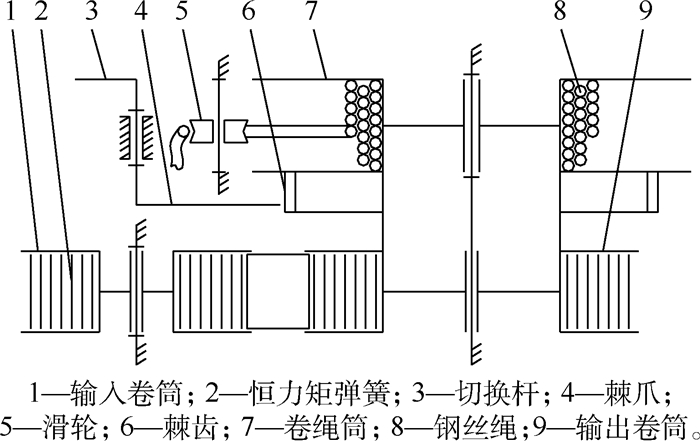

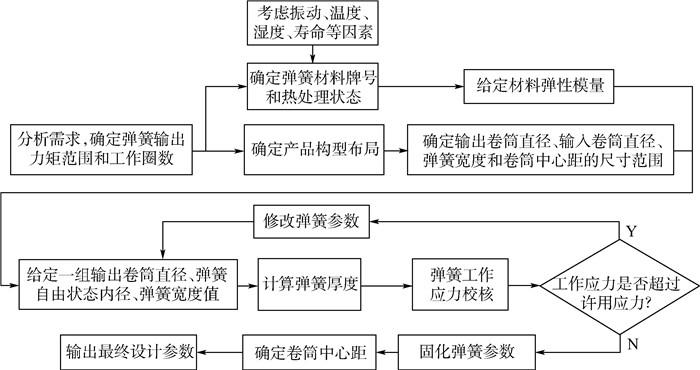

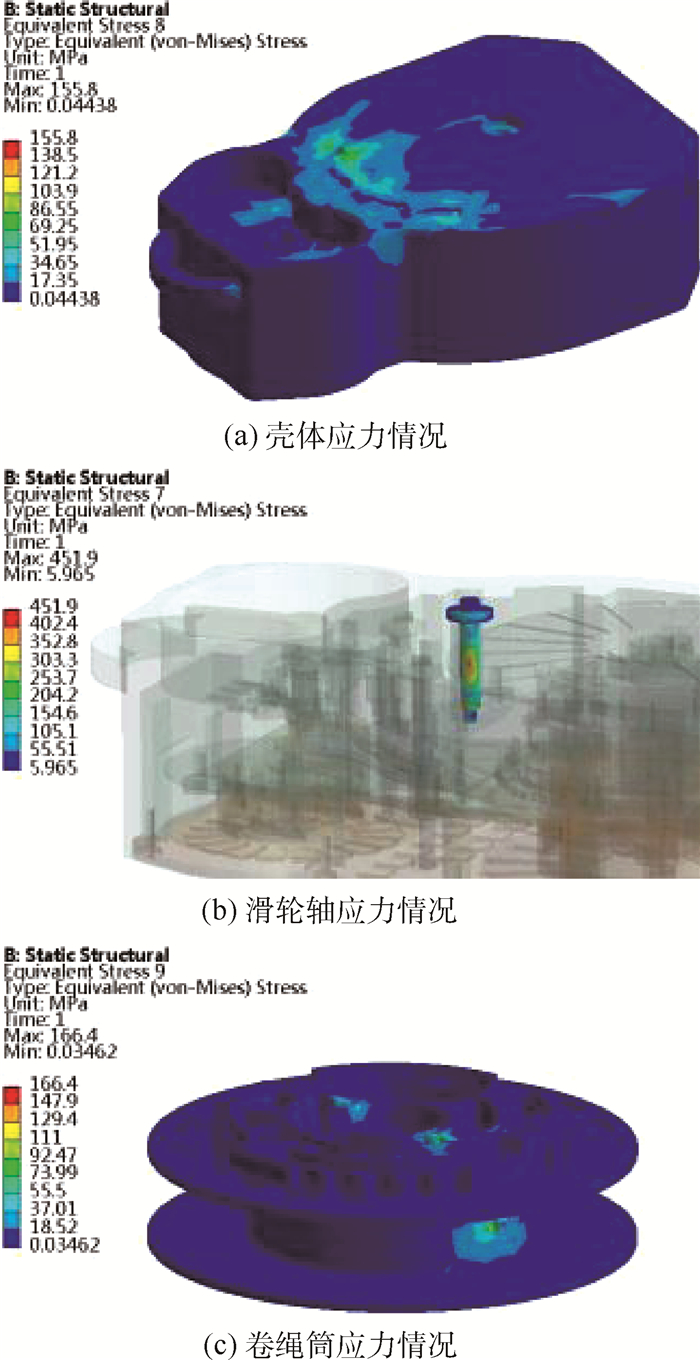

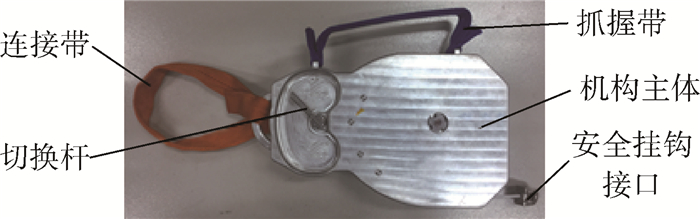

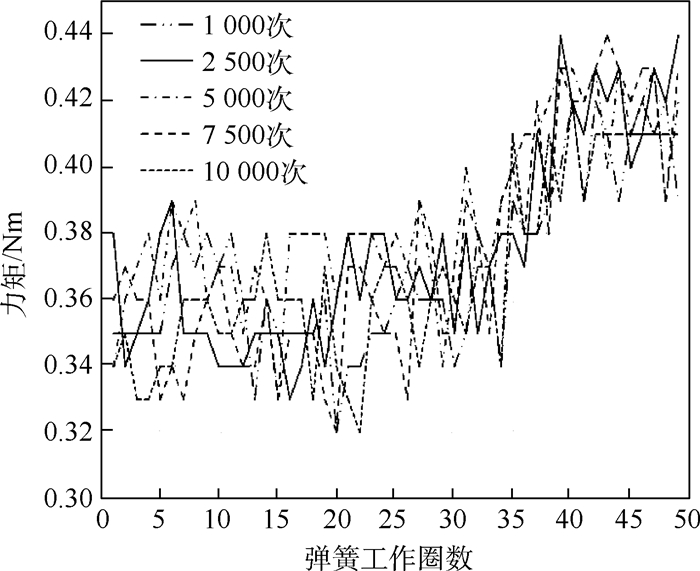

随着中国神舟飞船系列任务和空间站建设任务的稳步进行,中国航天员将面临频繁的在轨出舱作业任务,航天员出舱活动范围将逐渐增大,作业位置也将频繁变换,传统安全绳已无法满足使用要求。提出了一种基于恒力矩弹簧驱动的航天员出舱可伸缩安全系绳设计方案,并优化设计方法。对可伸缩安全系绳的核心部分——驱动单元进行设计,研制航天员出舱可伸缩安全系绳样机,并完成功能性能、环境适应性和驱动单元寿命试验验证。结果表明:所提方案可顺利完成钢丝绳收放,且实测收绳力、放绳力与理论值基本吻合。方案具有体积小、质量轻、可耐大量级振动和高低温环境等优点,其驱动单元满足10 000次的长寿命使用要求,可用于后续工程产品中。

Abstract:With the steady progress of Shenzhou spaceship series tasks and space station construction tasks in China, Chinese astronauts are facing frequent extravehicular activities, the range of astronauts' extravehicular activities will gradually increase, and the operation position of astronauts will change frequently. The traditional safety tether can not operation the requirements. In this paper, a design scheme of an adjustable length safety tether for astronaut extravehicular activities driven by constant force spring is put forward, the design method is optimized, and the detailed design of the driving unit which is the core part of the safety tether is performed. Finally, the prototype of safety tether is developed, and the functional performance test, environmental adaptability test and driving unit life test are completed. The results show that the scheme of the safety tether can successfully complete the retraction and release of steel wire rope, and the measured retracting force and pulling force are basically consistent with the theoretical values. It has the advantages of small volume, light weight, and resistance to a large number of levels of vibration and high and low temperature environment. The driving unit can meet the requirements of 10 000 times of long-life use. The scheme of the safety tether can be used in subsequent engineering products.

-

Key words:

- astronaut /

- safety tether /

- adjustable length /

- constant force spring /

- long service life

-

表 1 恒力矩弹簧设计参数

Table 1. Design parameters of constant torque spring

参数 数值 输出卷筒直径/mm 80 弹簧自由状态下的内径/mm 44 弹簧厚度/mm 0.25 弹簧宽度/mm 16 第1圈输出力矩/(N·m) 0.393 第45圈输出力矩/(N·m) 0.428 输入卷筒直径/mm 46 卷筒中心距/mm 116 弹簧工作应力/ MPa 1 544~1 672 表 2 部分参数实测值

Table 2. Measured values of some parameters

参数 数值 卷绳筒卷绕直径/mm 第1~3圈 75 第4~9圈 80 第10~15圈 85 第16~21圈 90 第22~27圈 96 第28~33圈 101 第34~38圈 106 滑轮平均阻力/N 1.32 绳口平均阻力/N 0.85 棘轮平均阻力/N 1.13 表 3 收绳力、拉绳力理论值

Table 3. Theoretical values of rope pulling force and rope pulling force

拉出绳长/m 弹簧工作圈数 卷绳筒卷绕直径/mm “收放”模式收绳力/N “收放”模式拉绳力/N “只放”模式拉绳力/N 1.1 5 0.106 5.3 9.7 10.8 1.9 8 0.101 5.7 10.1 11.2 3.0 12 0.096 6.2 10.5 11.7 4.1 16 0.096 6.3 10.6 11.7 5.1 20 0.09 6.9 11.2 12.4 5.9 23 0.09 6.9 11.3 12.4 7.0 27 0.085 7.6 11.9 13.0 8.1 31 0.08 8.2 12.6 13.7 8.9 34 0.08 8.3 12.6 13.8 10.0 38 0.075 9.1 13.4 14.6 注:随拉出钢丝绳长度增加,弹簧工作圈数增加,卷绳筒卷绕直径减小,因此收绳力与拉绳力会发生变化。 表 4 正弦振动试验条件

Table 4. Sinusoidal vibration test conditions

频率范围/Hz 幅值 验收级 鉴定级 4~10 14.7 mm 22 mm 10~17 3.6 g 5.4 g 17~60 8 g 12 g 60~100 3.8 g 5.6 g 加载扫描率 4 oct/min 2 oct/min 加载方向 3个轴向 注:oct为倍频程。 表 5 随机振动试验条件

Table 5. Random vibration test conditions

频率范围/Hz 鉴定级 验收级 10~50 3 dB/oct 3 dB/oct 50~300 0.25 g2/Hz 0.1 g2/Hz 300~2 000 -12 dB/oct 总均方根加速度(grms) 9.68 6.11 加载时间(s·轴-1) 120 60 加载方向 3个轴向 注:g为重力加速度,rms为均方根。 -

[1] 朱仁璋, 王鸿芳, 王晓光. 舱外活动系统述评[J]. 航天器工程, 2008, 17(6): 7-32. doi: 10.3969/j.issn.1673-8748.2008.06.002ZHU R Z, WANG H F, WANG X G. A review of EVA system[J]. Spacecraft Engineering, 2008, 17(6): 7-32(in Chinese). doi: 10.3969/j.issn.1673-8748.2008.06.002 [2] MINOR M A, HIRSCHI C R. Automated tether management system for extravehicular activities[J]. Journal of Field Robotics, 2007, 24(4): 311-335. doi: 10.1002/rob.20188 [3] ATWELL W. Extra vehicular activity (EVA) operations in the geostationary environment: AIAA 2012-3646[R]. Reston: AIAA, 2012. [4] VOGT G L. Suited for spacewalking. Teacher's guide with activities, mathematics and science: EG-1998-03-112[R]. Washington D.C. : NASA, 1998. [5] BORTHWICK D E, CRONCH D F, NIXON G R. Design of a reusable kinetic energy absorber for an astronaut safety tether to be used during extravehicular activities on the space station: NASA-CR-192015[R]. Wshington, D.C. : NASA, 1991. [6] MINOR M A, HIRSCHI C R, AMBROSE R O. An automated tether management system for microgravity extravehicular activities[C]//Proceedings of 2002 IEEE International Conference on Robotics and Automation. Piscataway: IEEE Press, 2002: 7379378. [7] HIRSCHI C R, MINOR M A. Testing and evaluation of an automated tether management system for microgravity extravehicular activities[C]//Proceedings of 2004 IEEE International Conference on Robotics and Automation. Piscataway: IEEE Press, 2004: 8330186. [8] VAN PELT M. Space tethers and space elevators[M]. Berlin: Springer, 2009. [9] 陈学文, 黄鹏, 张炎, 等. 航天员舱外活动安全绳虚拟现实操作仿真方法研究[J]. 载人航天, 2018, 24(6): 724-739.CHEN X W, HUANG P, ZHANG Y, et al. Study on simulation methods of safety rope operation in virtual reality during astronaut extravehicular activity[J]. Manned Spaceflight, 2018, 24(6): 724-739(in Chinese). [10] 杨锋, 丁立, 杨春信, 等. 舱外活动中航天员利用扶手移动的路径规划[J]. 北京航空航天大学学报, 2005, 31(3): 326-330. doi: 10.3969/j.issn.1001-5965.2005.03.014YANG F, DING L, YANG C X, et al. Path planning for astronaut translation by means of continuous handrails during extravehicular cativity[J]. Journal of Beijing University of Aeronautics and Astronautics, 2005, 31(3): 326-330(in Chinese). doi: 10.3969/j.issn.1001-5965.2005.03.014 [11] 付铁, 陈杰, 丁洪生. 恒力弹簧的载荷-变形特性分析[J]. 北京理工大学学报, 2011, 3(8): 905-908.FU T, CHEN J, DING H S. Analysis on load-deflection behaviors of constant force springs[J]. Transactions of Beijing Institute of Technology, 2011, 3(8): 905-908(in Chinese). [12] 张英会, 刘辉航, 王德成. 弹簧手册[M]. 北京: 机械工业出版社, 2008.ZHANG Y H, LIU H H, WANG D C. Spring handbook[M]. Beijing: China Machine Press, 2008(in Chinese). [13] 李占华, 韩静涛, 于春宇, 等. 拉压复合连续弯曲成形恒力弹簧工艺研究[J]. 锻压技术, 2016, 41(4): 49-53.LI Z H, HAN J T, YU C Y, et al. Research on the constant force spring process in tension-compression composite progressive bending[J]. Foring & Stamping Technology, 2016, 41(4): 49-53(in Chinese). [14] 曹树谦, 张文德, 萧龙翔. 振动结构模态分析: 理论、实验与应用[M]. 2版. 天津: 天津大学出版社, 2014.CAO S Q, ZHANG W D, XIAO L X. Modal analysis of vibration structure: Theory, experiment and application[M]. 2nd ed. Tianjin: Tianjin University Press, 2014(in Chinese). [15] 马兴瑞, 韩增尧, 邹元杰, 等. 航天器力学环境分析与条件设计研究进展[J]. 宇航学报, 2012, 33(1): 1-12. doi: 10.3873/j.issn.1000-1328.2012.01.001MA X R, HAN Z Y, ZOU Y J, et al. Review and assessment of spacecraft mechanical environment analysis and specification determination[J]. Journal of Astronautics, 2012, 33(1): 1-12(in Chinese). doi: 10.3873/j.issn.1000-1328.2012.01.001 [16] 孟光, 周徐斌, 苗军. 航天重大工程中的力学问题[J]. 力学进展, 2016, 46(1): 267-322.MENG G, ZHOU X B, MIAO J. Mechanical problems in momentous projects of aerospace engineering[J]. Progress in Mechanics, 2016, 46(1): 267-322(in Chinese). -

下载:

下载: