Three-dimensional vibration measurement method for lightweight beam based on machine vision

-

摘要:

振动测量是状态检测和故障诊断的方法之一,针对传统接触式测量方法中存在负载效应等问题,对基于机器视觉的三维振动测量方法进行了研究。首先,基于视频相位的二维振动测量方法,提取出相机所采集图像中被测目标的二维振动数据。然后,在二维振动测量方法的基础上,结合双目立体视觉,设计了一种基于机器视觉的三维振动测量方法。最后,进行了悬臂梁的振动测量实验。结果表明:所提方法可以实现无接触和无标记的振动测量,并能准确测量出三维的振动信息。

Abstract:Vibration measurement is one of the methods of state detection and fault diagnosis. In view of the loading effect in the current contact vibration measurement method and other problems, this paper studies the three-dimensional vibration measurement method based on machine vision. First, based on the two-dimensional vibration measurement method of video phase, the two-dimensional vibration data of the measured object in the image collected by the camera is extracted. Then, on the basis of two-dimensional vibration measurement method, combined with binocular stereo vision, a three-dimensional vibration measurement method based on machine vision is designed. Finally, the vibration measurement experiment of cantilever beam is performed. The experimental results show that the proposed method can realize non-contact and label free vibration measurement, and can accurately measure the three-dimensional vibration information.

-

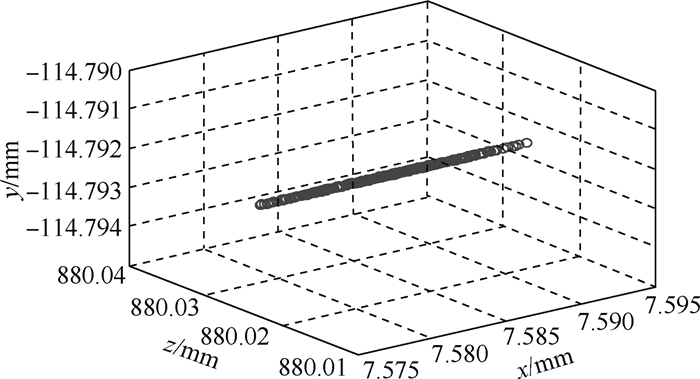

表 1 重投影误差计算结果

Table 1. Reprojection error calculation results

帧数 重建所得的坐标/mm 重投影误差/pixel x y z 左相机 右相机 1 7.584 -114.794 880.039 0.043 0.051 2 7.590 -114.792 880.037 0.045 0.052 3 7.583 -114.791 880.036 0.042 0.051 4 7.579 -114.793 880.037 0.044 0.053 5 7.587 -114.793 880.037 0.041 0.051 6 7.589 -114.791 880.036 0.043 0.052 7 7.581 -114.792 880.039 0.044 0.054 8 7.581 -114.794 880.038 0.041 0.053 9 7.589 -114.793 880.037 0.046 0.052 10 7.586 -114.790 880.039 0.044 0.052 -

[1] LEE J J, SHINOZUKA M A. Vision-based system for remote sensing of bridge displacement[J]. NDT & E International, 2006, 39(5): 425-431. [2] LI J, HAO H, FAN K Q, et al. Development and application of a relative displacement sensor for structural health monitoring of composite bridges[J]. Structural Control and Health Monitoring, 2015, 22(4): 726-742. doi: 10.1002/stc.1714 [3] POOZESH P, BAQERASD J, NIZERECKI C, et al. Large-area photogrammetry based testing of wind turbine blades[J]. Mechanical Systems and Signal Processing, 2017, 86: 98-115. doi: 10.1016/j.ymssp.2016.07.021 [4] HUANG H, BADDOUR N, LIANG M. Bearing fault diagnosis under unknown time-varying rotational speed conditions via multiple time-frequency curve extraction[J]. Journal of Sound and Vibration, 2018, 414: 43-60. doi: 10.1016/j.jsv.2017.11.005 [5] DILEK A U, OGUZ A D, SATIS F, et al. Condition monitoring of wind turbine blades and tower via an automated laser scanning system[J]. Engineering Structures, 2019, 189: 25-34. doi: 10.1016/j.engstruct.2019.03.065 [6] MORLIER J, SALOM P, BOS F. New image processing tools for structural dynamic monitoring[J]. Key Engineering Materials, 2007, 347: 239-244. doi: 10.4028/www.scientific.net/KEM.347.239 [7] BLACK J T, PITCHER N A, REEDER M F, et al. Videogrammetry dynamics measurements of a lightweight flexible wing in a wind tunnel[J]. Journal of Aircraft, 2010, 47(1): 172-180. doi: 10.2514/1.44545 [8] CHANG C C, JI Y F. Flexible videogrammetric technique for three-dimensional structural vibration measurement[J]. Journal of Engineering Mechanics, 2007, 133(6): 656-664. doi: 10.1061/(ASCE)0733-9399(2007)133:6(656) [9] WANG W Z, MOTTERSHEAD J E, IHIE A, et al. Finite element model updating from full-field vibration measurement using digital image correlation[J]. Journal of Sound and Vibration, 2011, 330(8): 1599-1620. doi: 10.1016/j.jsv.2010.10.036 [10] 孙伟, 何小元, 胥明, 等. 数字图像相关方法在膜材拉伸试验中的应用[J]. 工程力学, 2007, 24(2): 34-38.SUN W, HE X Y, XU M, et al. Study on the tension test of membrane materials using digital image correlation method[J]. Engineering Mechanics, 2007, 24(2): 34-38(in Chincese). [11] HA N S, JIN T, GOO N S. Modal analysis of an artificial wing mimicking an Allomyrina dichotoma beetle's hind wing for flapping-wing micro air vehicles by noncontact measurement techniques[J]. Optics and Lasers in Engineering, 2013, 51(5): 560-570. doi: 10.1016/j.optlaseng.2012.12.012 [12] HA N S, VANG H M, GOO N S. Modal analysis using digital image correlation technique: An application to artificial wing mimicking beetle-s hind wing[J]. Experimental Mechanics, 2015, 55(5): 989-998. doi: 10.1007/s11340-015-9987-2 [13] HUNADY R, PAVELKA P, LENGVARSKY P. Vibration and modal analysis of a rotating disc using high-speed 3D digital image correlation[J]. Mechanical Systems and Signal Processing, 2019, 121: 201-214. doi: 10.1016/j.ymssp.2018.11.024 [14] BAKER S, MATTHEWS I. Lucas-Kanade 20 years on: A unifying framework[J]. International Journal of Computer Vision, 2004, 56(3): 221-255. doi: 10.1023/B:VISI.0000011205.11775.fd [15] HORN B K P, SCHUNCK B G. Determining optical flow[J]. Artificial Intelligence, 1981, 17(1-3): 185-203. doi: 10.1016/0004-3702(81)90024-2 [16] CAETANO E, SILVA S, BATEIRA J. A vision system for vibration monitoring of civil engineering structures[J]. Experimental Techniques, 2011, 25(4): 74-82. [17] AOYAMA T, LI L, JIANG M, et al. Vibration sensing of a bridge model using a multithread active vision system[J]. IEEE/ASME Transactions on Mechatronics, 2018, 23(1): 179-189. doi: 10.1109/TMECH.2017.2764504 [18] YU Q B, YIN A J, ZHANG Q, et al. Optical flow tracking method for vibration identification of out-of-plane vision[J]. Journal of Vibroengineering, 2017, 19(4): 2363-2374. doi: 10.21595/jve.2017.17771 [19] FLEET D J, JEPSON A D. Computation of component image velocity from local phase information[J]. International Journal of Computer Vision, 1990, 5(1): 77-104. doi: 10.1007/BF00056772 [20] CHEN J G, WADHWA N, CHA Y J, et al. Modal identification of simple structures with high-speed video using motion magnification[J]. Journal of Sound and Vibration, 2015, 345: 58-71. doi: 10.1016/j.jsv.2015.01.024 [21] CHEN J G, DAVIS A, WADHWA N, et al. Video camera-based vibration measurement for civil infrastructure applications[J]. Journal of Infrastructure Systems, 2017, 23(3): 1-11. [22] PENG C, ZENG C, WANG Y G. Camera-based micro-vibration measurement for lightweight structure using an improved phase-based motion extraction[J]. IEEE Sensors Journal, 2020, 20(5): 2590-2599. doi: 10.1109/JSEN.2019.2951128 [23] PENG C, ZHU M T, WANG Y, et al. Phase-based video measurement for active vibration suppression performance of the magnetically suspended rotor system[J]. IEEE Transactions on Industrial Electronics, 2021, 68(2): 1497-1505. doi: 10.1109/TIE.2020.2967725 -

下载:

下载: