-

摘要:

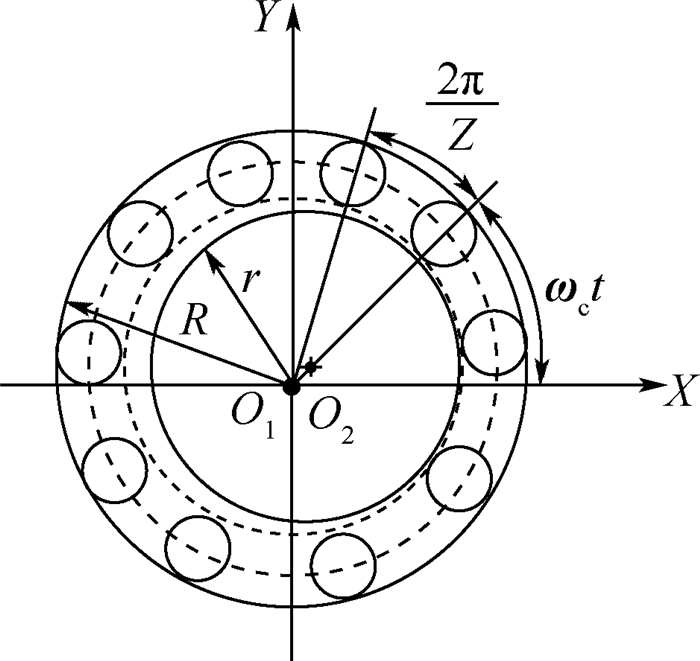

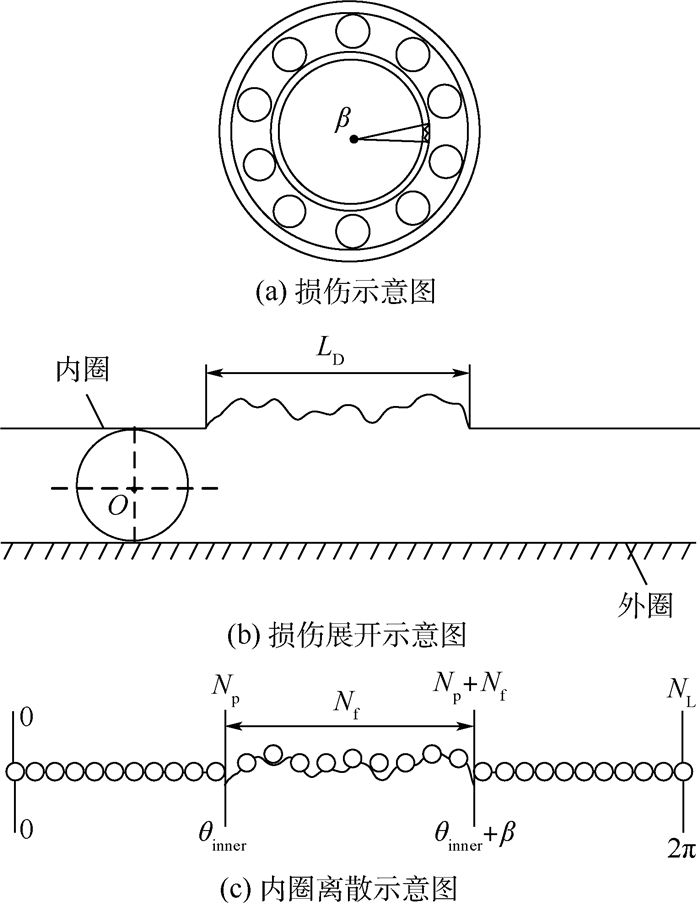

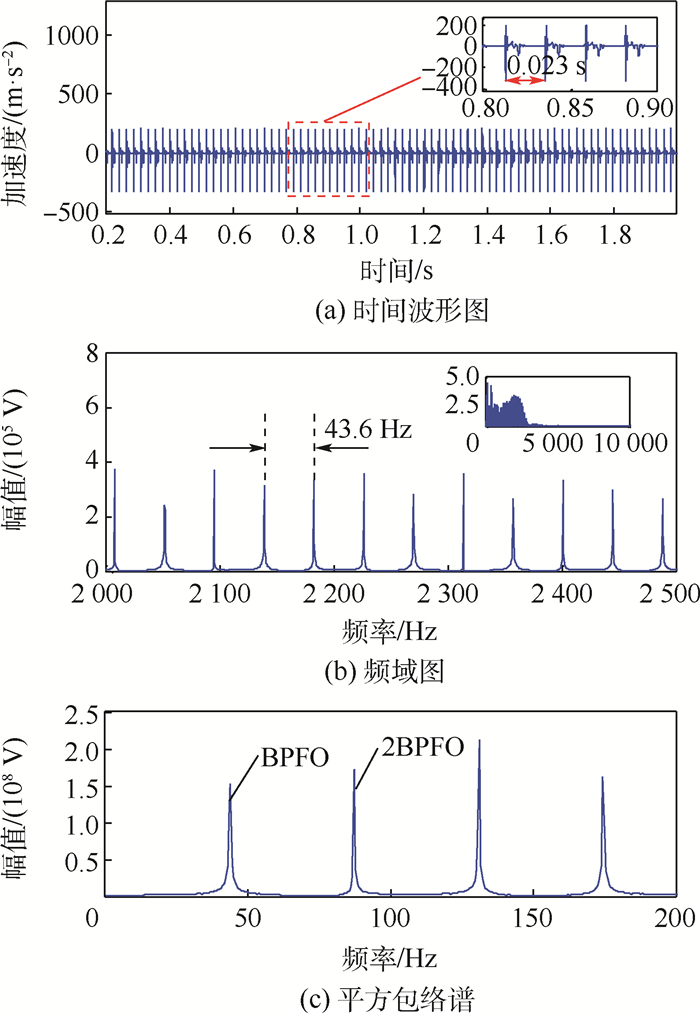

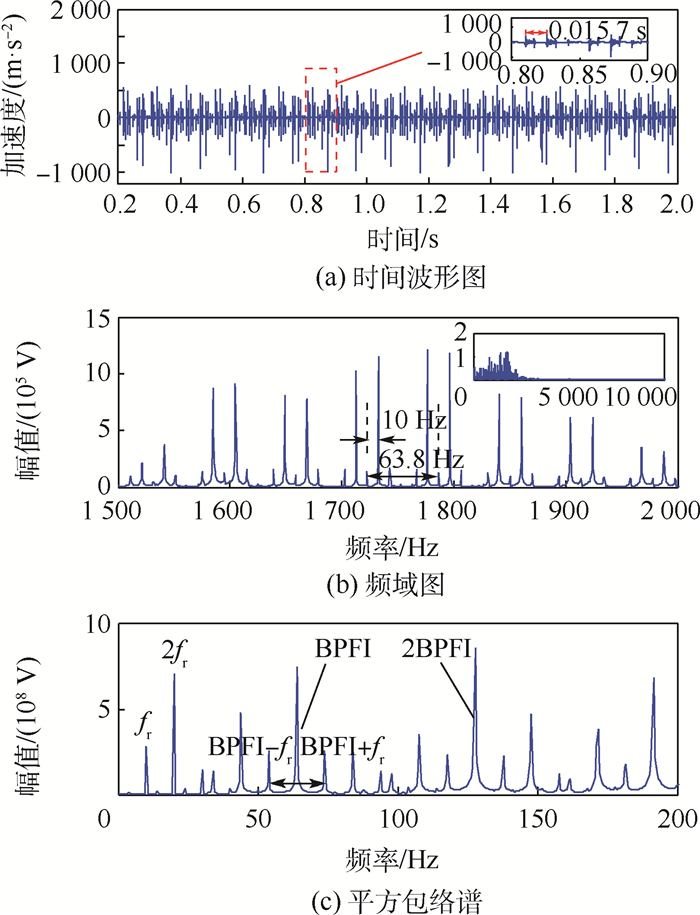

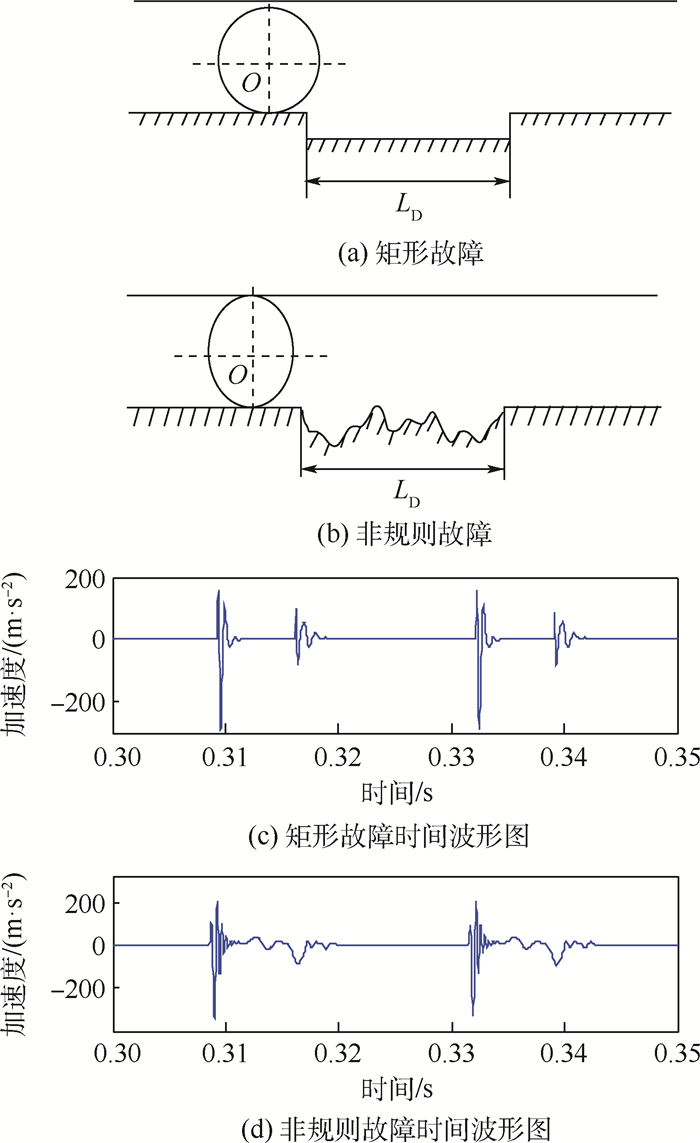

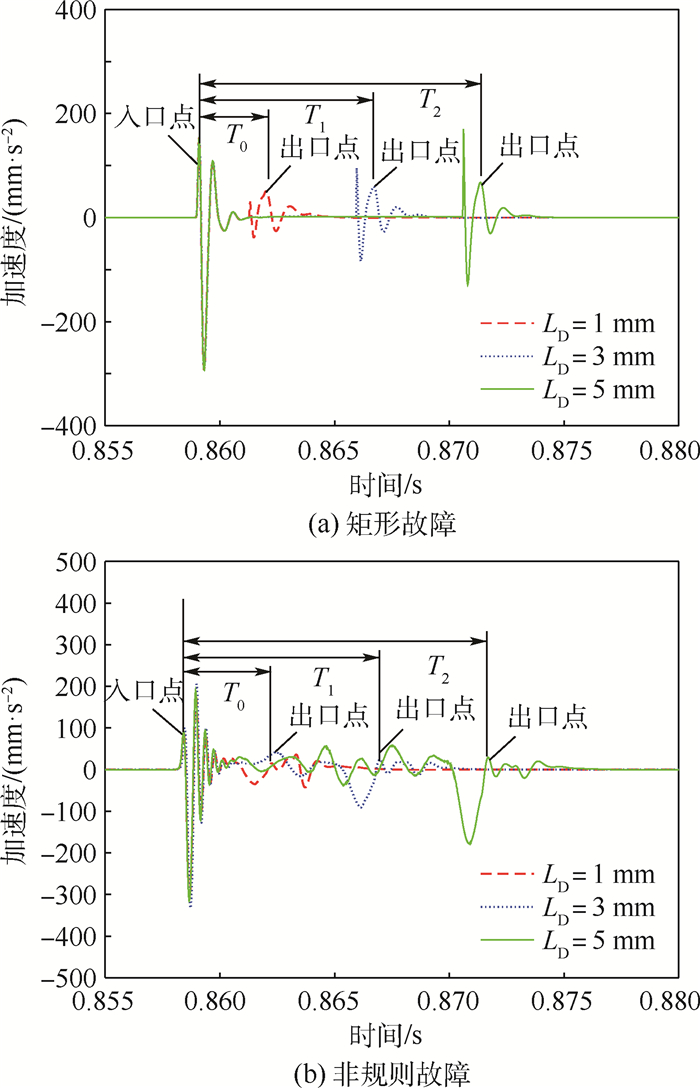

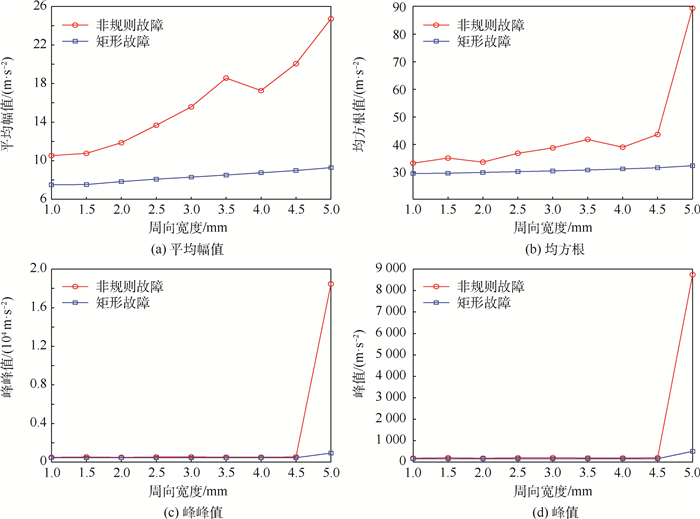

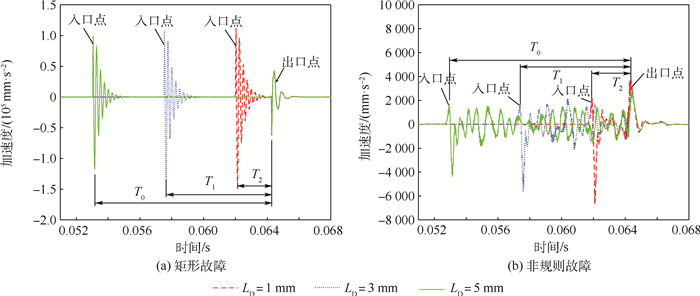

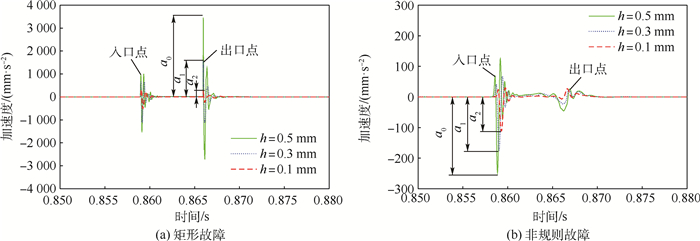

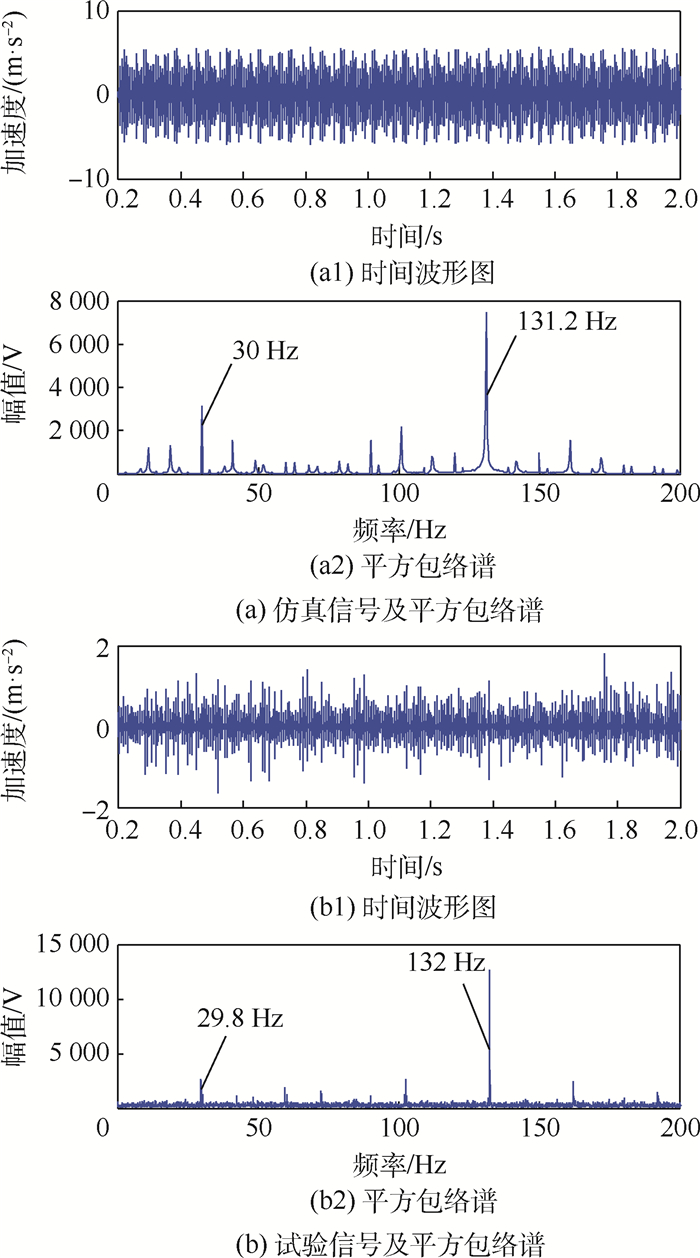

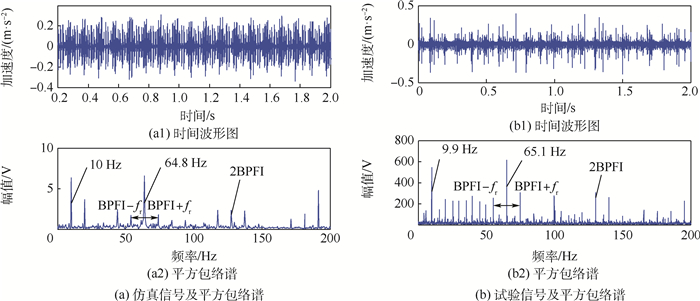

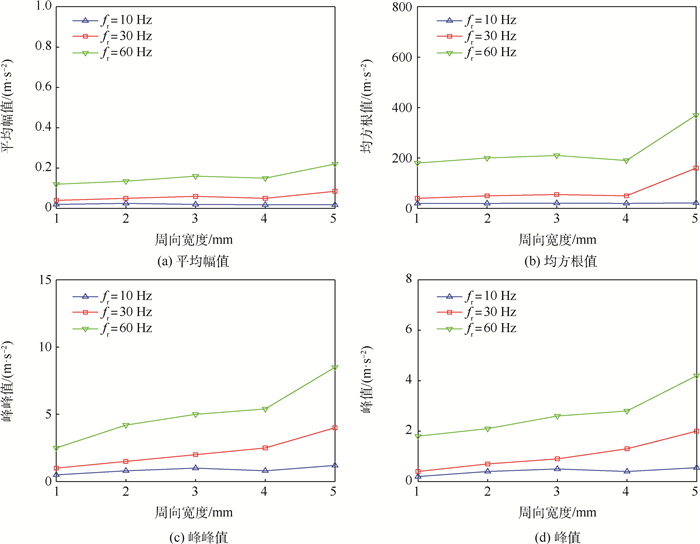

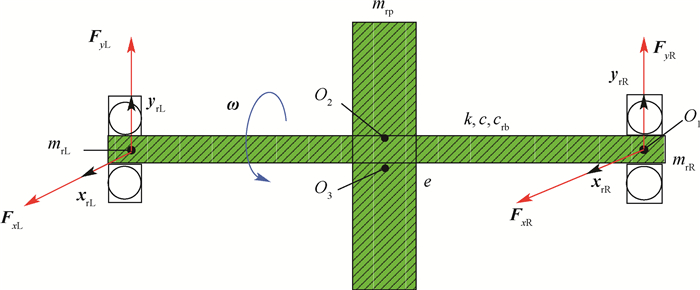

针对现有轴承故障研究大多将故障简化为矩形凹槽或圆形凹坑等规则形状,与实际故障形貌存在较大差别的问题,以航空发动机转子系统为研究对象,从滚动轴承的实际故障形貌和复杂转子系统中主轴轴承易失效的客观实际出发,提出了非规则轴承故障的表征方法,并将其引入单转子-轴承系统动力学模型,建立了轴承内外圈非规则故障模型。利用数值计算的方法对含故障轴承转子系统的振动响应进行了分析,并研究了系统轴承在内外圈含有矩形故障和非规则故障的情况下,故障的周向宽度和深度对系统振动的影响规律。针对滚动轴承内外圈中存在的故障轴承损伤,制作了不同位置、大小的故障轴承,并将其引入转子系统开展试验研究,采集了不同旋转频率和故障尺寸下的系统振动数据,通过与数值仿真结果的比较,充分验证了非规则轴承故障动力学模型的正确性。

Abstract:Most of the existing bearing failure researches simplified the failure to regular shapes such as rectangular grooves or circular pits, which were quite different from the actual failure morphology, taking the aero-engine rotor system as the research object, starting from the actual fault morphology of the rolling bearing and the objective reality of the main shaft bearing being prone to failure in the complex rotor system, a method for characterizing the irregular bearing fault was proposed and introduced into the single rotor-bearing system dynamic model, and the irregular failure model of bearing inner and outer rings was established. Using the method of numerical calculation, the vibration response of the rotor system with faults was analyzed, and the influence of the circumferential width and depth of the faults on the system vibration was studied when the system bearings contained rectangular faults and irregular faults in the inner and outer rings. Finally, for the fault damage existing in the inner and outer rings of the rolling bearing, fault bearings with different positions and sizes were made and introduced into the rotor system to conduct experimental research, and the system vibration data at different rotation frequencies and fault sizes were collected. The comparison with the numerical simulation results fully verified the correctness of the irregular bearing failure dynamic model.

-

Key words:

- aero-engine /

- rolling bearing /

- irregular failure /

- vibration response /

- kinetic model

-

表 1 滚动轴承主要计算参数

Table 1. Rolling bearing main calculation parameters

参数 2204K NJ204E 外圈滚道半径R/mm 23.5 23.5 内圈滚道半径r/mm 10 10 滚动体直径d/mm 14 14 滚珠数目Z 15 9 赫兹接触刚度Cb/(N·m-3/2) 13.34×109 13.34×109 轴承初始间隙δ0/μm 0 0 -

[1] LU Z Y, WANG X D, HOU L, et al. Nonlinear response analysis for an aero engine dual-rotor system coupled by the inter-shaft bearing[J]. Archive of Applied Mechanics, 2019, 89(7): 1275-1288. doi: 10.1007/s00419-018-01501-0 [2] 史修江. 航空发动机主轴轴承动态性能和热弹流润滑状态耦合分析[D]. 哈尔滨: 哈尔滨工业大学, 2018: 1-7.SHI X J. Coupling analysis of dynamic performance and tehl state of aeroengine main shaft bearing[D]. Harbin: Harbin Institute of Technology, 2018: 1-7(in Chinese). [3] 路振勇. 航空发动机转子系统的动力学建模及非线性振动研究[D]. 哈尔滨: 哈尔滨工业大学, 2017: 17-24.LU Z Y. Dynamical modeling and nonlinear vibration study of aero-engine rotor system[D]. Harbin: Harbin Institute of Technology, 2017: 17-24(in Chinese). [4] KANKAR P K, SHARMA S C, HARSHA S P. Fault diagnosis of high speed rolling element bearings due to localized defects using response surface method[J]. Journal of Dynamic Systems, Measurement and Control, 2011, 133(3): 031007. doi: 10.1115/1.4003371 [5] 东亚斌, 廖明夫, 高琦. 滚动体具有局部缺陷滚动轴承的动力学分析[J]. 重型机械, 2012(3): 148-152.DONG Y B, LIAO M F, GAO Q. Dynamics analysis on rolling element bearings with localized defects[J]. Heavy Machinery, 2012(3): 148-152(in Chinese). [6] SAWALHI N, RANDALL R B. The combined gear bearing dynamic model and the simulation of localised bearing faults[J]. Mechanical Systems & Signal Processing, 2008, 22(8): 1924-1951. [7] SAWALHI N, RANDALL R B. Simulation of the vibrations produced by extended bearing faults[J]. Mechanical Systems & Signal Processing, 2008, 22(8): 1952-1966. [8] 陈果. 转子-滚动轴承-机匣耦合系统中滚动轴承故障的动力学分析[J]. 振动工程学报, 2008, 21(6): 577-587. doi: 10.3969/j.issn.1004-4523.2008.06.008CHEN G. Dynamic analysis of ball bearing faults in rotor-ball bearing-stator coupling system[J]. Journal of Vibration Engineering, 2008, 21(6): 577-587(in Chinese). doi: 10.3969/j.issn.1004-4523.2008.06.008 [9] 廖明夫. 航空发动机转子动力学[M]. 西安: 西北工业大学出版社, 2015: 163-170.LIAO M F. Aeroengine rotor dynamics[M]. Xi'an: Northwestern Polytechnical University Press, 2015: 163-170(in Chinese). [10] CAO H R, NIU L K, XI S T, et al. Mechanical model development of rolling bearing-rotor systems: A review[J]. Mechanical Systems & Signal Processing, 2018, 102: 37-58. [11] 张智勇. 球轴承-转子系统变柔度振动的分岔与滞后行为[D]. 哈尔滨: 哈尔滨工业大学, 2015: 18-23.ZHANG Z Y. Bifurcations and hysteresis of varying compliance vibrations of a ball bearing-rotor system[D]. Harbin: Harbin Institute of Technology, 2015: 18-23(in Chinese). [12] 何浩浩. 含非规则轴承故障的航空发动机双转子系统动力学建模与特性分析[D]. 西安: 火箭军工程大学, 2017: 11-18.He H H. Dynamic Modeling and characteristic analysis of aeroengine dual rotor system with irregular bearing faults[D]. Xi'an: Rocket Force University of Engineering, 2017: 11-18(in Chinese). [13] 关贞珍, 郑海起, 王彦刚, 等. 滚动轴承局部损伤故障动力学建模及仿真[J]. 振动·测试与诊断, 2012, 32(6): 950-955.GUAN Z Z, ZHENG H Q, WANG Y G, et al. Fault dynamic modeling and simulating of rolling bearing with localized defect[J]. Journal of Vibration, Measurement & Diagnosis, 2012, 32(6): 950-955(in Chinese). [14] 徐可君, 任帅, 秦海勤, 等. 滚动轴承内圈故障的动力学模型建立及仿真[J]. 航空发动机, 2015, 41(4): 8-11.XU K J, REN S, QIN H Q, et al. Dynamics model establishment and simulation of rolling bearing element with inner race defect[J]. Aeroengine, 2015, 41(4): 8-11(in Chinese). [15] 罗茂林, 郭瑜, 伍星. 考虑冲击力的球轴承外圈剥落缺陷双冲击现象动力学建模[J]. 振动与冲击, 2019, 38(14): 48-54.LUO M L, GUO Y, WU X. Dynamic modeling of the dual-impulse behavior produced by a spall on the outer race of a ball bearing considering impact forces[J]. Journal of Vibration and Shock, 2019, 38(14): 48-54(in Chinese). [16] CHEN G. A new rotor-ball bearing-stator coupling dynamics model for whole aero-engine vibration[J]. Journal of Vibration and Acoustics, Transactions of the ASME, 2009, 131(6): 0610091-0610099. -

下载:

下载: