-

摘要:

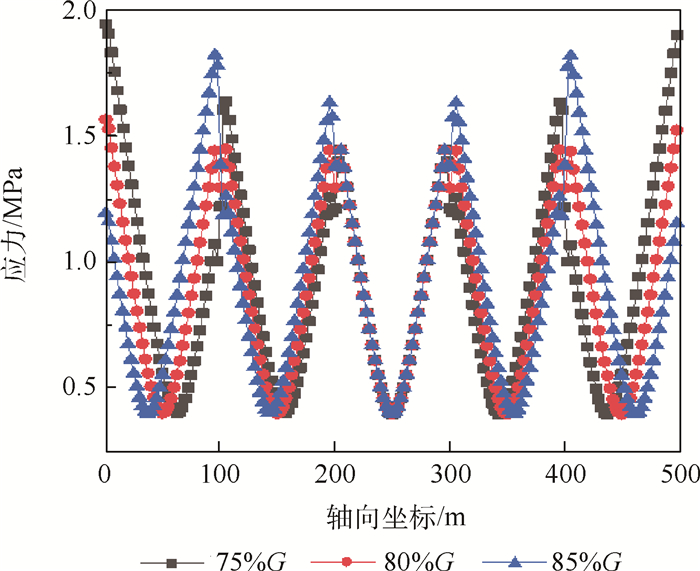

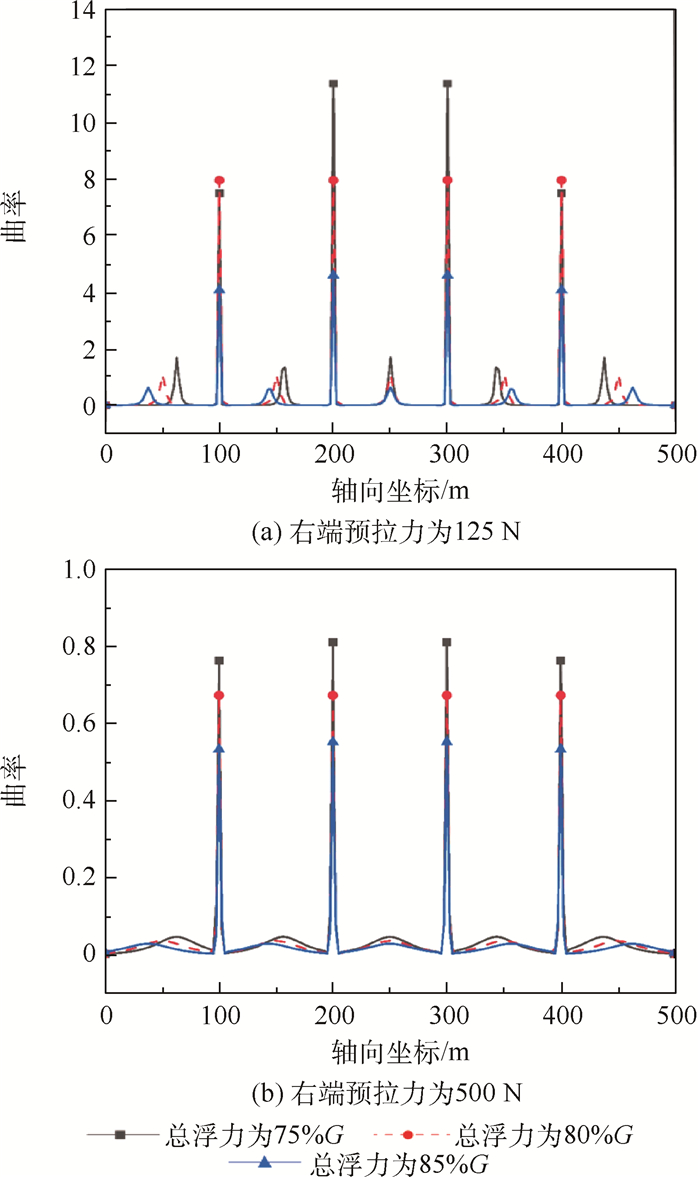

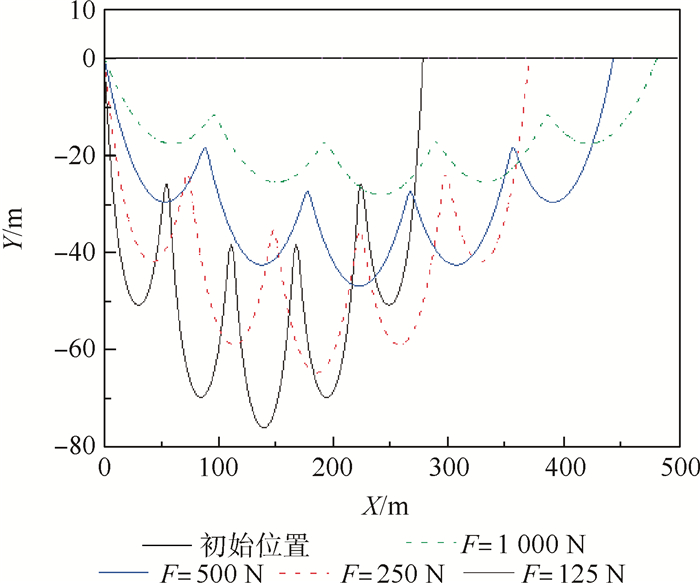

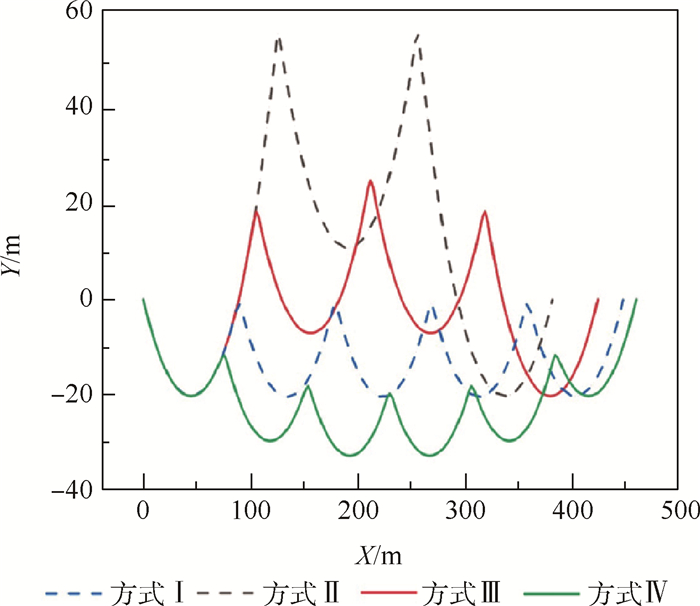

随着现代工业的消耗,有限的陆地资源已经难以支撑未来人类社会的可持续发展,因而对海洋资源的开发越来越受到重视。扬矿管作为深海采矿系统中的关键部件,连接了海面矿船和海底矿车。为避免长而柔的扬矿管道在深海作业时发生触地或打结等现象,影响作业效率,通常在管道上布置浮力块进行提升。考虑浮力提升装置布局的几个设计参数,包含总提升浮力、水平拉力、浮力段段数以及浮力段分布长度,通过有限元计算评价扬矿管的静态构型,探究几个参数对结构构型一般性的影响规律,从而提出合理的浮力分布方案。

Abstract:With the consumption of modern industry, the limited land resources have been unable to support the sustainable development of human society in the future, so more and more attention has been paid to the exploitation of marine resources. Marine riser is a key component in deep-sea mining system, which connects mining ship on the sea surface and the mining car on the seabed. In order to avoid the long and soft lifting mine pipeline in the deep-sea operation to touch the seabed or tie up and other phenomena, which will affect the operation efficiency, buoyancy modules are usually used to lift the riser. Considering several design parameters of the buoyancy lifting modules layout, including the total lifting buoyancy, horizontal tension, number of buoyancy segments and the distribution length of buoyancy segments, the static configuration of the marine riser is evaluated by finite element method, and the general influence law of these parameters on the structure configuration is explored, so as to propose a reasonable buoyancy distribution scheme.

-

Key words:

- deep-sea mining system /

- marine risers /

- buoyancy modules /

- lifting scheme /

- finite element method

-

表 1 工程文件中给出的深海缆线参数

Table 1. Deep-sea cable parameters given in project documents

参数 数值 在空气中的线密度/(kg·km-1) 1 319 在海水中的线密度/(kg·km-1) 991 破坏强度/kN 206.0 工作载荷/kN 56.5 曲率半径限制/cm 44 表 2 缆线待提升段的几何和材料参数

Table 2. Geometric and material parameters of cable segment to be lifted

参数 数值 管线总长度/m 500 管线截面半径/m 0.01 材料密度/(kg·m-3) 3 156 材料弹性模量/GPa 120 表 3 求解的各个工况参数

Table 3. Parameters of each working condition

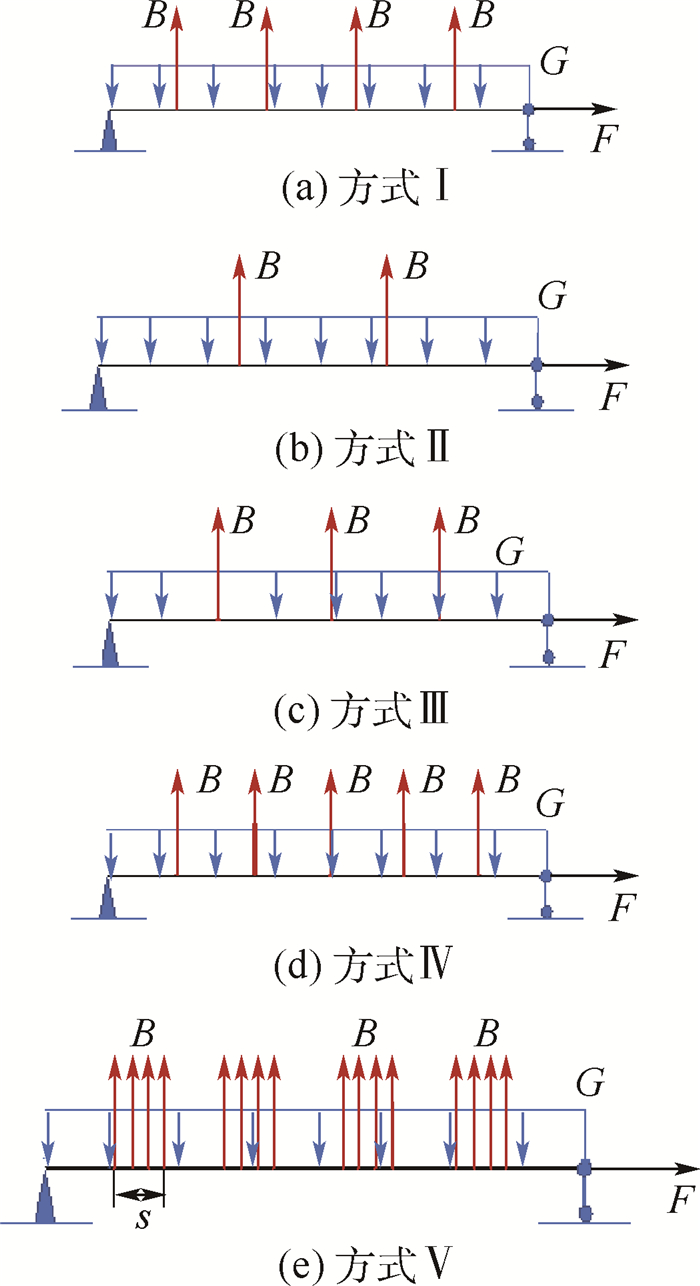

工况编号 浮力分布方式 预拉力F/N

1 Ⅰ 1 000 75 2 Ⅰ 500 75 3 Ⅰ 250 75 4 Ⅰ 125 75 5 Ⅰ 500 80 6 Ⅰ 250 80 7 Ⅰ 125 80 8 Ⅰ 500 85 9 Ⅰ 250 85 10 Ⅰ 125 85 11 Ⅱ 500 80 12 Ⅲ 500 80 13 Ⅳ 500 80 14 Ⅴ(s=10 m) 500 80 15 Ⅴ(s=20 m) 500 80 16 Ⅴ(s=30 m) 500 80 注:Ⅰ~Ⅴ为不同的浮力分布方式,在图 3中给出。 表 4 浮力固定为80%G时提升点的位移情况

Table 4. Displacement of lifting point when buoyancy is fixed at 80%G

工况编号 中间提升点纵向位移/m 两侧提升点纵向位移/m 纵向最大位移/m 5 -0.9 -0.81 -20.3 6 -1.19 -1.07 -30.8 7 -1.22 -1.09 -38.9 表 5 各控制因素对结构特性的影响

Table 5. Influence of discussed parameters on structural characteristics

结构特性 右端拉力 总浮力 浮力点个数 浮力分布长度 向下最大位移 - -- + 0 右端水平位移 -- 0 - - 结构最大应力 ++ 0 -- 0 结构曲率 - - - -- 注:++代表强正相关;+代表弱正相关;--代表强负相关;-代表弱负相关;0代表其影响关系微小可忽略,或影响关系不确定。 表 6 理想的浮力分布参数

Table 6. Ideal buoyancy distribution parameter

参数 数值 结构右端预拉力 12%G 总浮力 80%G 浮力分布段数 3或4 每段浮力段长度 2%~4%L 注:G为结构总重;L为结构总长度。 -

[1] 深海矿产资源[EB/OL]. [2020-06-01].Deep sea mineral resources[EB/OL]. [2020-06-01]. (in Chinese). [2] 于淼, 邓希光, 姚会强, 等. 世界海底多金属结核调查与研究进展[J]. 中国地质, 2018, 45(1): 29-38.YU M, DENG X G, YAO H Q, et al. The progress in the investigation and study of global deep-sea polumetallic nodules[J]. Geology in China, 2018, 45(1): 29-38(in Chinese). [3] 肖林京, 方湄, 张文明. 大洋多金属结核开采研究进展与现状[J]. 金属矿山, 2000(8): 11-14. doi: 10.3321/j.issn:1001-1250.2000.08.004XIAO L J, FANG M, ZHANG W M. Advance and present state of the research in oceanic metalliferous nodule mining[J]. Metal Mine, 2000(8): 11-14(in Chinese). doi: 10.3321/j.issn:1001-1250.2000.08.004 [4] 肖林京, 曾庆良, 张文明. 深海采矿扬矿管非线性偏移特性研究[J]. 机械工程学报, 2002, 38(8): 94-99. doi: 10.3321/j.issn:0577-6686.2002.08.020XIAO L J, ZENG Q L, ZHANG W M. Analysis of nonlinear offsetting characteristics on deep ocean mining pipe[J]. Chinese Journal of Mechanical Engineering, 2002, 38(8): 94-99(in Chinese). doi: 10.3321/j.issn:0577-6686.2002.08.020 [5] 肖林京, 左帅, 宋庆辉, 等. 深海采矿扬矿管的静态特性分析[J]. 矿业研究与开发, 2020, 40(4): 130-135.XIAO L J, ZUO S, SONG Q H, et al. Analysis on static characteristics of lifting pipe in deep sea mining[J]. Mining Research and Development, 2020, 40(4): 130-135(in Chinese). [6] 徐海良, 周刚, 吴万荣, 等. 深海采矿扬矿管几何非线性静力分析[J]. 中南大学学报(自然科学版), 2011, 42(11): 3352-3358.XU H L, ZHOU G, WU W R, et al. Geometry nonlinear static force analysis of transporting pipe in deep-sea mining[J]. Journal of Central South University (Science and Technology), 2011, 42(11): 3352-3358(in Chinese). [7] 许兆美. 深海采矿扬矿管非线性变形分析[J]. 金属矿山, 2010(5): 47-50.XU Z M. Nonlinear deformation analysis of lifting pipe of deep seabed mining[J]. Metal Mine, 2010(5): 47-50(in Chinese). [8] 兰四清. 深水钢悬线立管触地区力学特性数值模拟分析[J]. 应用力学学报, 2019, 36(6): 1478-1483.LAN S Q. Numerical simulation of the mechanical interactions between the deepwater steel catenary riser and the touchdown zone of seabed[J]. Chinese Journal of Applied Mechanics, 2019, 36(6): 1478-1483(in Chinese). [9] 凌胜, 肖林京, 申焱华, 等. 深海采矿开采系统运动状态和动态特性影响因素分析研究[J]. 中国工程科学, 2002, 4(3): 78-83. doi: 10.3969/j.issn.1009-1742.2002.03.013LING S, XIAO L J, SHEN Y H, et al. A study of the factors influencing the kinematic condition and dynamic characteristics of deep seabed mining systems[J]. Engineering Science, 2002, 4(3): 78-83(in Chinese). doi: 10.3969/j.issn.1009-1742.2002.03.013 [10] 戴瑜, 刘少军. 深海采矿系统整体联动作业模式动力学分析[J]. 华中科技大学学报(自然科学版), 2012, 40(S2): 39-43.DAI Y, LIU S J. Dynamic analysis of the integrated motion operation mode of the total deep ocean mining system[J]. Journal of Huazhong University of Science and Technology (Natural Science Edition), 2012, 40(S2): 39-43(in Chinese). [11] 刘建浩, 杨启. 深海采矿扬矿管的横向运动响应分析[J]. 矿山机械, 2012, 40(2): 5-9.LIU J H, YANG Q. Analysis on lateral motion response of deep-sea mining riser[J]. Mining & Processing Equipment, 2012, 40(2): 5-9(in Chinese). [12] LIU Z, GUO H Y. Dynamic response study of steel catenary riser based on slender rod model[J]. China Ocean Engineering, 2019, 33(1): 57-64. doi: 10.1007/s13344-019-0006-8 [13] 徐海良, 饶星, 杨放琼. 横向摆动对深海采矿扬矿管输送特性的影响[J]. 中南大学学报(自然科学版), 2019, 50(10): 2395-2402. doi: 10.11817/j.issn.1672-7207.2019.10.008XU H L, RAO X, YANG F Q. Influence of lateral swing on transportation characteristics of deep sea mining pipeline[J]. Journal of Central South University (Science and Technology), 2019, 50(10): 2395-2402(in Chinese). doi: 10.11817/j.issn.1672-7207.2019.10.008 [14] GUO S X, LI Y L, LI M, et al. Dynamic response analysis on flexible riser with different configurations in deep-water based on FEM simulation[C]//Proceedings of ASME 2018 37th International Conference on Ocean. Madrid: Offshore and Arctic Engineering, Spain. 2018. [15] ZHAO T F, FU S X, WU T H. Seabed stiffness influences and water damping effects on vibration of the touchdown zone in a steel catenary riser[J]. International Journal of Pressure Vessels and Piping, 2019, 170: 30-39. doi: 10.1016/j.ijpvp.2018.12.006 期刊类型引用(2)

1. 单新有,李映坤,许进升,朱敏,陈雄,何勇. 膏体推进剂近燃面区域的热解与燃烧过程. 火炸药学报. 2024(09): 830-839 .  百度学术

百度学术2. 单新有,李映坤,武炎,陈雄,何勇. 基于MAC方法的膏体推进剂管道流动特性. 航空动力学报. 2023(10): 2430-2440 .  百度学术

百度学术其他类型引用(1)

-

下载:

下载:

百度学术

百度学术