Performance of oxygen-consuming catalytic inerting system of fuel tank under flight envelope

-

摘要:

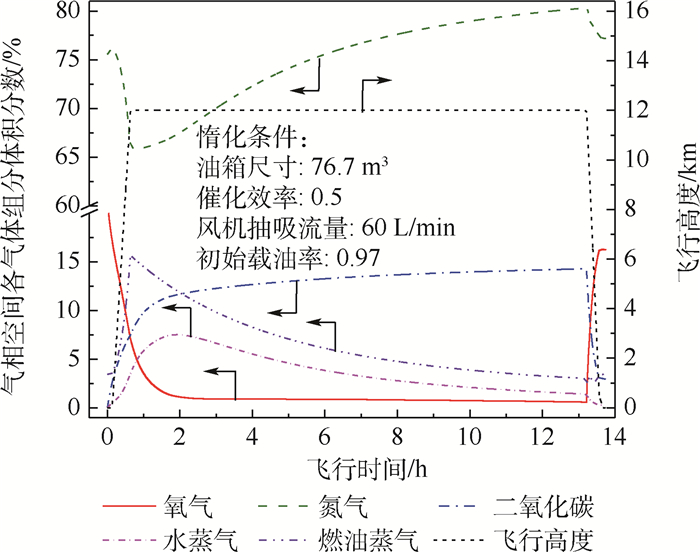

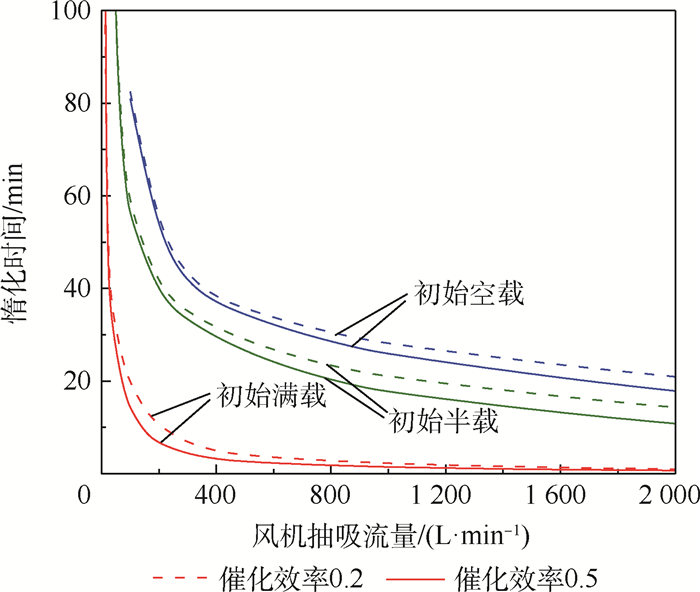

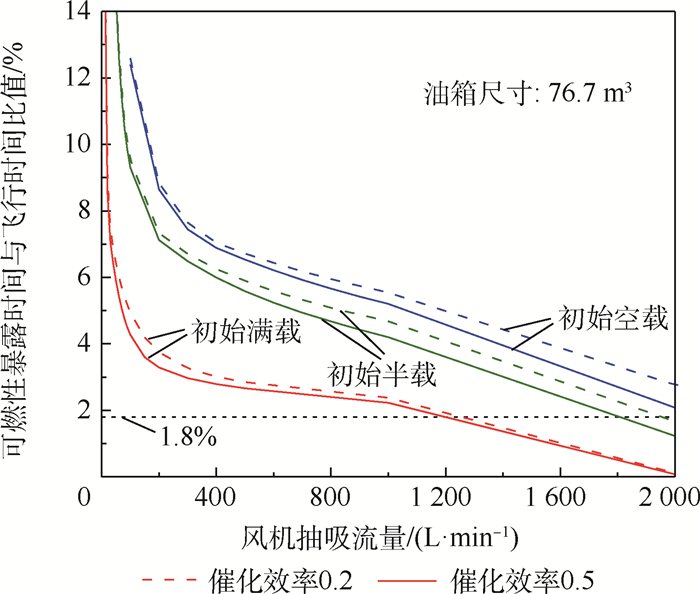

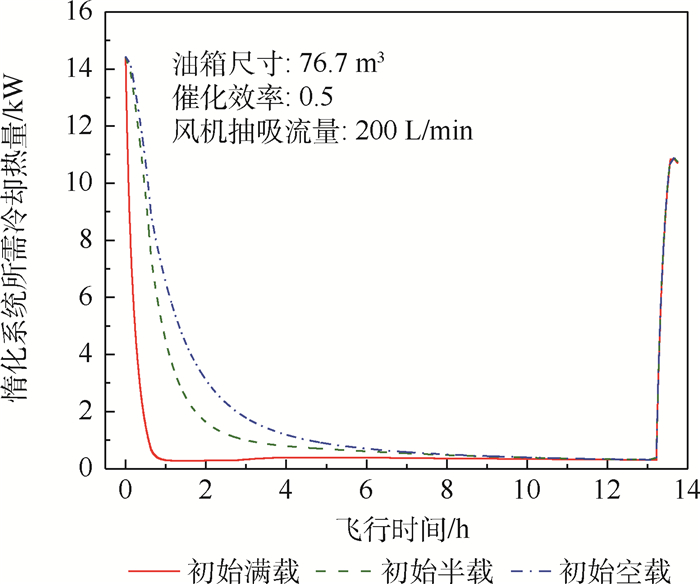

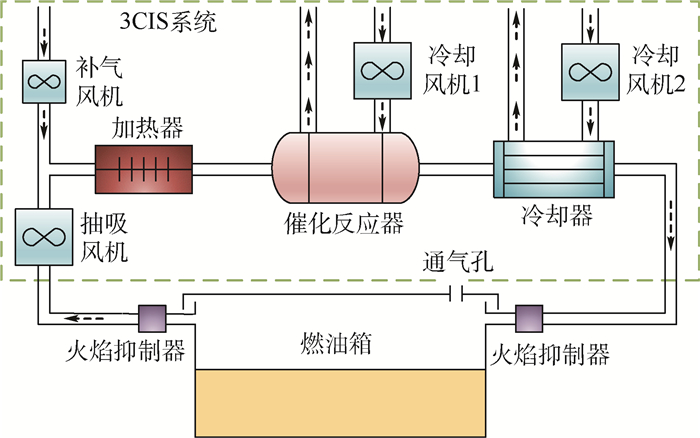

为给新型耗氧催化惰化系统部件设计提供输入参数,在提出低温可控耗氧催化惰化系统流程基础上,以燃油箱出口抽吸流量为基准,基于质量守恒和能量守恒方程,建立了系统流程模型。以中央燃油箱为对象,仿真研究了全飞行包线下惰化系统的重要性能变化,以及关键参数对其影响。结果表明:惰化系统可以有效降低氧体积分数,如在初始满载、催化效率0.5、风机抽吸流量60 L/min条件下,24 min后氧体积分数即降至12%以下;在飞行过程中,燃油箱气相氧氧体积分数在下降及进场阶段上升,其他阶段均呈下降趋势;催化效率越高、风机抽吸流量越大,所需惰化时间越小,且催化效率一定时,达到相同惰化时间,初始空载时所需风机抽吸流量最大。应按最不利的空载工况来设计耗氧型催化惰化系统。

Abstract:In order to provide input parameters for the design of new types of oxygen-consuming inerting system components, based on the proposed low-temperature controllable oxygen-consuming catalytic inerting system flow, the system mathematical model is established based on the mass conservation and energy conservation equations with the suction flow rate at the outlet of fuel tank as the benchmark. Taking the central fuel tank as the object, the important performance changes of the inerting system under the full flight envelope and the influence of key parameters on it are simulated. The results show that: inerting system can effectively reduce the oxygen volume fraction. For example, under the condition of initial full load, 0.5 catalytic efficiency and 60 L/min suction flow, the oxygen volume fraction will reach below 12% after 24 minutes. During the flight, the volume fraction of gas phase oxygen in the fuel tank rises during the declining and approaching phases, while it is decreasing in other phases. The higher the catalytic efficiency is and the larger the fan flow is, the shorter the inerting time is required. When the catalytic efficiency is fixed, the same inerting time is achieved, and the maximum fan suction flow is required when there is no fuel load. Therefore, the oxygen-consuming catalytic inert system should be designed according to the most unfavorable no fuel load working conditions.

-

表 1 飞行包线信息

Table 1. Flight envelope information

状态 轮档时间/min 高度/m 轮档耗油/kg 滑出 7 0 189 起飞 2 0→457 630 爬升 29 457→12 000 4 992 巡航 755 12 000 67 987 下降 21 120 00→457 373 进场 6 457 240 滑入 5 0 135 -

[1] 冯诗愚, 刘冠男, 江荣杰, 等. 飞机燃油箱机载惰化技术研究现状与发展趋势[J]. 航空动力学报, 2021, 36(3): 616-625.FENG S Y, LIU G N, JIANG R J, et al. Research status and development trend of aircraft fuel tank on-board inerting technology[J]. Journal of Aerospace Power, 2021, 36(3): 616-625(in Chinese). [2] LI J, YANG W, PEI Y. Vulnerability assessment for fire and explosion suppression measures of aircraft fuel system[J]. Advanced Materials Research, 2012, 510: 64-69. doi: 10.4028/www.scientific.net/AMR.510.64 [3] 张瑞华, 刘卫华, 彭孝天, 等. 昼夜温度变化对燃油箱空余空间氧浓度的影响[J]. 北京航空航天大学学报, 2020, 46(5): 1018-1023. doi: 10.13700/j.bh.1001-5965.2019.0331ZHANG R H, LIU W H, PENG X T, et al. Influence of diurnal temperature changes on oxygen concentration in free space of fuel tank[J]. Journal of Beijing University of Aeronautics and Astronautics, 2020, 46(5): 1018-1023(in Chinese). doi: 10.13700/j.bh.1001-5965.2019.0331 [4] LANGTON R, CLARK C, HEWITT M, et al. Aircraft fuel systems[M]. New York: Wiley, 2009: 32-40. [5] SMITH D E. Fuel tank inerting systems for civil aircraft[D]. Fort Collins: Colorado State University, 2014: 32. [6] 冯诗愚, 卢吉, 刘卫华, 等. 机载制氮系统中空纤维膜分离特性[J]. 航空动力学报, 2012, 27(6): 1332-1339.FENG S Y, LU J, LIU W H, et al. Separation performance of hollow fiber membrane for on-board inerting gas generating system[J]. Journal of Aerospace Power, 2012, 27(6): 1332-1339(in Chinese). [7] 刘夙春, 邱献双. 一种新型的飞机油箱催化惰化系统[J]. 航空科学技术, 2011(4): 27-29.LIU S C, QIU X S. A new fuel tank catalytically inerting system[J]. Aeronautical Science and Technology, 2011(4): 27-29(in Chinese). [8] 谢辉辉, 冯诗愚, 彭孝天, 等. 耗氧型惰化系统反应器性能理论[J]. 北京航空航天大学学报, 2019, 45(11): 2312-2319. doi: 10.13700/j.bh.1001-5965.2019.0117XIE H H, FENG S Y, PENG X T, et al. Theoretical of reactor performance in oxygen consumption based inerting system[J]. Journal of Beijing University of Aeronautics and Astronautics, 2019, 45(11): 2312-2319(in Chinese). doi: 10.13700/j.bh.1001-5965.2019.0117 [9] WALKER S, JUNG W, ROBERTSON S. Demonstration of a novel catalyst based green on board inert gas generation system (GOBIGGSTM)for fuel tank inerting[C]//AHS 69th Annual Forum, 2013: 1-10. [10] MORRIS R, MILLER J, LIMAYE S. Fuel deoxygenation and aircraft thermal management[C]//4th International Energy Conversion Engineering Conference and Exhibit (IECEC). Reston: AIAA, 2006: 1-13. [11] 王苏明, 冯诗愚, 李宗祺, 等. 燃油箱耗氧惰化与中空膜惰化的数值模拟及比较[J]. 北京航空航天大学学报, 2020, 46(5): 1032-1038. doi: 10.13700/j.bh.1001-5965.2019.0332WANG S M, FENG S Y, LI Z Q, et al. Numerical simulation and comparison of oxygen consumption inerting and hollow membrane inerting in fuel tank[J]. Journal of Beijing University of Aeronautics and Astronautics, 2020, 46(5): 1032-1038(in Chinese). doi: 10.13700/j.bh.1001-5965.2019.0332 [12] SHAO L, LIU W H, LI C Y, et al. Experimental comparison of aircraft fuel tank inerting process using NEA and MIG[J]. Chinese Journal of Aeronautics, 2018, 31(7): 1515-1524. doi: 10.1016/j.cja.2018.04.016 [13] 陈伟, 卢京潮, 袁燎原, 等. 基于高增益观测器的航迹角自适应反步控制[J]. 北京航空航天大学学报, 2013, 39(10): 1414-1420. https://bhxb.buaa.edu.cn/CN/Y2013/V39/I10/1414CHEN W, LU J C, YUAN L Y, et al. Adaptive backstepping control for flight path angle based on high gain observer[J]. Journal of Beijing University of Aeronautics and Astronautics, 2013, 39(10): 1414-1420(in Chinese). https://bhxb.buaa.edu.cn/CN/Y2013/V39/I10/1414 [14] 冯诗愚, 邵垒, 李超越, 等. 航空燃油类型对催化惰化系统性能的影响[J]. 航空学报, 2016, 37(6): 1819-1826.FENG S Y, SHAO L, LI C Y, et al. Performance of catalytic inerting system affected by various aviation jet fuels[J]. Acta Aeronautica et Astronautica Sinica, 2016, 37(6): 1819-1826(in Chinese). [15] 冯诗愚, 李超越, 刘卫华. 一种催化燃烧惰化油箱的装置及其方法:CN104843189A[P]. 2015-08-19. FENG S Y, LI C Y, LIU W H. A device and method of catalytic combustion inerting oil tank: CN104843189A[P]. 2015-08-19(in Chinese). [16] 彭孝天, 冯诗愚, 李超越. 一种带补气催化燃烧惰化飞行器燃油箱及控制方法:CN107856869A[P]. 2018-03-30. PENG X T, FENG S Y, LI C Y. Fuel tank and control method of inert vehicle with supplementary gas catalytic combustion: CN107856869A[P]. 2018-03-30(in Chinese). [17] CAI Y, BU X, LIN G, et al. Experimental study of an aircraft fuel tank inerting system[J]. Chinese Journal of Aeronautics, 2015, 28(2): 394-402. http://www.cnki.com.cn/Article/CJFDTotal-HKXS201502007.htm [18] 冯诗愚, 李超越, 邵垒, 等. 一种燃油箱绿色惰化系统地面惰化性能分析[J]. 航空动力学报, 2017, 32(2): 268-274.FENG S Y, LI C Y, SHAO L, et al. Analysis on ground-based inerting performance of a fuel tank green on-board inert gas generation system[J]. Journal of Aerospace Power, 2017, 32(2): 268-274(in Chinese). [19] 温博, 陆中. 民用飞机燃油箱可燃性评估方法研究[J]. 中国民航大学学报, 2016, 34(2): 6-9.WEN B, LU Z. Research on fuel tank flammability assessment for civil aircraft[J]. Journal of Civil Aviation University of China, 2016, 34(2): 6-9(in Chinese). [20] 康振烨, 刘振侠, 任国哲, 等. 基于MATLAB/Simulink的飞机燃油箱内燃油温度仿真计算[J]. 推进技术, 2014, 35(1): 62-69.KANG Z Y, LIU Z X, REN G Z, et al. Simulation and calculation of fuel temperature in aircraft fuel tank based on MATLAB/Simulink[J]. Journal of Propulsion Technology, 2014, 35(1): 62-69(in Chinese). [21] 中国民用航空局. 中国民用航空规章. 第25部. 运输类飞机适航标准: CCAR-25-R4[S]. 北京: 中国民用航空局, 2011.Civil Aviation Administration of China. China civil aviation regulation: 25-Airworthiness standard of transport aircraft: CCAR-25-R4[S]. Beijing: Civil Aviation Administration of China, 2011(in Chinese). -

下载:

下载: