-

摘要:

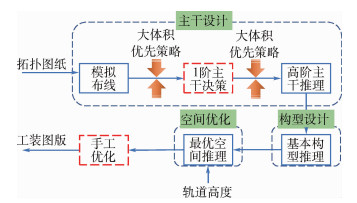

针对飞机线束工装图版设计效率低、出错率高的问题,研究了各设计阶段的核心内容和谓词逻辑,提出了具备无向图和多叉树双重特征的干枝树(TBT)模型,取代了传统的无向无环图建模方法。基于模拟布线的统计结果,利用大体积优先(LVF)策略实现了1阶主干的辅助决策。基于谓词逻辑,设计了高阶主干推理、基本构型推理和最优空间推理方法,实现了高阶主干的自动决策、线束构型的自动设计和布局空间的自动优化。搭建了线束智能工艺辅助设计系统,并开展了12组实物实验,对于边数大于200的超大型图纸,能够在30 s内完成自动设计过程,设计总时长不超过30 min,未出现1阶主干选择不合理和边长度错误的问题。实验结果表明,所提方法大幅度提高了设计效率和可靠性。

-

关键词:

- 飞机线束 /

- 工装图版设计 /

- 干枝树(TBT) /

- 谓词逻辑 /

- 大体积优先(LVF)策略

Abstract:Aimed at the problems of low efficiency and high error rate of aircraft harness tooling drawing design, the core content and predicate logic of each design phase were studied. The Trunk-Branch Tree (TBT) model, which has the characteristics of undirected graph and multi-way tree, was proposed to replace the traditional undirected acyclic graph modeling method. Based on the simulative wiring statistical results, the Large Volume First (LVF) policy was used to realize the auxiliary decision making of the 1-order trunk. The higher-order trunk reasoning, the basic structure reasoning and the best space reasoning based on predicate logic were used to realize the automatic higher-order trunks' decision making, the automatic harness structure design and the automatic space optimization. The harness intelligent process aided design system was developed and used successfully in 12 actual experiments. The tooling drawings can always be designed automatically in 30 seconds, and total design time is no more than 30 minutes for the super-large design drawings with more than 200 edges, excluding the problems of the incorrect 1-order trunk selection and the incorrect edge length. The experimental results show that the design efficiency and reliability are improved significantly by the proposed method.

-

图 1 拓扑图 1∶1展开示意图

Figure 1. Schematic diagram of topology 1∶1 expansion

表 1 高阶主干推理逻辑谓词

Table 1. Logic predicates of higher-order trunk reasoning

逻辑谓词 符号 释义 参数 NodeContains(ns, v) NC 结点包含在结点集中 ns为结点集合,n为结点 TreeNodes(t, ns) TN 结点集合属于树 t为树,ns为结点集合 TreeTrunk(t, es) TT 边集是树的主干 t为树,es为边集 TreeBranch(t, b) TB 分枝属于干枝树 t为干枝树,b为分枝 TreeRoot(t, n) TR 结点是树的根 t为树,n为结点 TreeLeaf(t, f) TL 结点是树的叶子 t为树,f为叶子结点 TreeRoute(rt, r, f) TRT 路径是由两结点确定的 rt为路径,r为根结点,f为叶子结点 TreeTrunkNodes(t, ns) TTN 结点集合是树的主干结点集 t为树,ns为结点集合 TreeTrunkCandidate(t, R) TTC 路径是候选主干 t为树,R为路径 TreeTrunkCandidateSet(t, RS) TTCS 属于候选主干集合 t为树,RS为候选主干集合 MaxProbability(rt, RS) MP 决策概率最高 rt为候选主干,RS为候选主干集合 表 2 基本构型推理逻辑谓词

Table 2. Logic predicates of basic structure reasoning

逻辑谓词 符号 释义 参数 Own(t, x) O 归属于 t为树,x可以是段、边、主干或子树 Cross(x, y) C 处于交叠状态 x和y可以是段、边、主干或树 FixedShapeState(t) FSS 定形态 t为树 FactState(t) FS 事实态 t为树 LocationAngle(t, α) LA 是树的位置角 t为树,α为位置角 Between(α, min, max) B 位置角范围 α为位置角,min为最小容许角度,max为最大容许角度 LegalLA(t, α) LLA 位置角合法 t为树,α为位置角 表 3 最优空间推理逻辑谓词

Table 3. Logic predicates of the best space reasoning

逻辑谓词 符号 释义 参数 OnTrackState(t) OTS 是在轨态 t为树 CompressState(t) CS 是压缩态 t为树 KneePoint(t, p) KP 是拐点 t为树,p为拐点 LegalKP(t, p) LKP 拐点合法 t为树,p为拐点 表 4 实验结果

Table 4. Experimental results

实验编号 设计图纸 主干设计 构型设计 空间优化 自动过程总时长/s 累计交叠失效次数 手工优化时间/min 总时长/s 图纸规模 边数 模拟布线耗时/s 高阶主干耗时/s 耗时/s 交叠失效次数 耗时/s 交叠失效次数 1 19 2.062 0.722 0.989 0 1.069 0 4.842 0 4 245 2 小型 33 2.494 1.371 2.353 0 2.668 0 8.886 0 2 129 3 42 2.757 1.269 2.675 0 2.545 0 9.246 0 5 309 4 67 3.192 1.583 2.698 1 2.984 1 10.457 2 11 670 5 中型 80 3.217 1.663 2.825 1 3.204 2 10.909 3 12 731 6 83 3.173 1.934 2.833 0 3.197 1 11.137 1 18 1 091 7 114 3.334 1.964 2.986 1 3.277 4 11.561 5 25 1 512 8 大型 121 3.940 1.895 3.673 0 3.384 4 12.892 4 17 1 033 9 123 3.698 2.053 2.748 0 2.976 2 11.475 2 12 731 10 203 4.378 3.629 3.474 0 5.107 0 16.588 0 19 1 157 11 超大型 204 4.407 2.983 4.996 0 6.854 3 19.240 3 24 1 459 12 242 6.260 3.112 6.026 1 7.341 4 22.739 5 21 1 283 表 5 使用Auto CAD设计的工时统计

Table 5. Hours statistics of tooling drawing design by Auto CAD software

图纸规模 消耗工时/h 小型 1~3 中型 3~8 大型 8~16 超大型 16~30 表 6 设计可靠性对比分析

Table 6. Comparative analysis of design reliability

实验编号 图纸规模 1阶主干选择 边的长度错误/次 手工 系统 手工 系统 1 √ √ 0 0 2 小型 √ √ 0 0 3 √ √ 0 0 4 √ √ 0 0 5 中型 × √ 0 0 6 √ √ 0 0 7 × √ 1 0 8 大型 √ √ 0 0 9 × √ 0 0 10 √ √ 3 0 11 超大型 × √ 0 0 12 × √ 2 0 -

[1] NG F M, RITCHIE J M, SIMMONS J. Cable harness design and planning using immersive virtual reality-A novel concurrent engineering approach[J]. Journal of Computing in Civil Engineering, 1999, 9(1): 91-92. [2] 章文. 基于CHS的航空线束工艺设计系统[J]. 航空精密制造技术, 2018, 54(6): 55-58.ZHANG W. Harness process design system based on CHS[J]. Aviation Precision Manufacturing Technology, 2018, 54(6): 55-58(in Chinese). [3] 刘睿, 范秀敏, 尹旭悦, 等. 面向手工装配的线缆目标图像分割方法[J]. 计算机辅助设计与图形学学报, 2018, 30(4): 666-672.LIU R, FAN X M, YIN X Y, et al. Cable target image segmentation method for manual cable laying process[J]. Journal of Computer-Aided Design & Computer Graphics, 2018, 30(4): 666-672(in Chinese). [4] GAO P, WEN J Q. Process optimization for wiring technology of aircraft harness based on ECRS principle[C]//Proceedings of the 21st International Conference on Industrial Engineering and Engineering Management 2014. Paris: Atlantis Press, 2015: 349-353. [5] 孔瑞莲. 航空发动机可靠性工程[M]. 北京: 航空工业出版社, 1996: 493-496.KONG R L. Aeroengine reliability engineering[M]. Beijing: Aviation Industry Press, 1996: 493-496(in Chinese). [6] CONRU A B. A genetic approach to the cable harness routing problem[C]//IEEE Conference on Evolutionary Computation. Piscataway: IEEE Press, 1994: 200-205. [7] NG F M, RITCHIE J M, SIMMONS J, et al. Designing cable harness assemblies in virtual environments[J]. Journal of Materials Processing Technology, 2000, 107(1): 37-43. [8] 刘晓平, 吴黄, 何士双, 等. 线束工艺图的建模研究[J]. 工程图学学报, 2009, 30(2): 155-161.LIU X P, WU H, HE S S, et al. The research on wire harness technological graph modeling[J]. Journal of Engineering Graphics, 2009, 30(2): 155-161(in Chinese). [9] 刘检华, 万毕乐, 孙刚, 等. 线缆虚拟布线与敷设过程仿真技术[J]. 计算机集成制造系统, 2012, 18(4): 787-795.LIU J H, WAN B L, SUN G, et al. Cable harness virtual wiring and assembly process simulation technology[J]. Computer Integrated Manufacturing Systems, 2012, 18(4): 787-795(in Chinese). [10] 刘检华, 赵涛, 王春生, 等. 虚拟环境下的活动线缆物理特性建模与运动仿真技术[J]. 机械工程学报, 2011, 47(9): 117-124.LIU J H, ZHAO T, WANG C S, et al. Motional cable harness physical characteristic oriented modeling and kinetic simulation technology in virtual environment[J]. Journal of Mechanical Engineering, 2011, 47(9): 117-124(in Chinese). [11] 崔伟, 王勐. 基于Pro/E电缆模块的变速器线束设计[J]. 农业技术与装备, 2015(7): 32-34. doi: 10.3969/j.issn.1673-887X.2015.07.012CUI W, WANG M. Design of the transmission harness based on Pro/E cable module[J]. Agricultural Technology & Equipment, 2015(7): 32-34(in Chinese). doi: 10.3969/j.issn.1673-887X.2015.07.012 [12] 吴保胜, 郭宇, 王发麟, 等. 基于改进蚁群算法的线缆路径规划技术研究[J]. 计算机工程与应用, 2018, 54(10): 236-241. doi: 10.3778/j.issn.1002-8331.1612-0323WU B S, GUO Y, WANG F L, et al. Research on path planning of cable harness based on improved ant colony optimization[J]. Computer Engineering and Applications, 2018, 54(10): 236-241(in Chinese). doi: 10.3778/j.issn.1002-8331.1612-0323 [13] WANG H, FU X D, WANG G Q. Multi-tree coding method (MCM) for drainage networks supporting high-efficient search[J]. Computers & Geosciences, 2013, 52: 300-306. [14] 严蔚敏, 李冬梅, 吴伟民. 数据结构(C语言版)[M]. 北京: 清华大学出版社, 1997: 118-121.YAN W M, LI D M, WU W M. Data structure (C language version)[M]. Beijing: Tsinghua University Press, 1997: 118-121(in Chinese). [15] 汪亚文, 李未. 开放逻辑及其实现技术[J]. 北京航空航天大学学报, 1992, 18(3): 122-129.WANG Y W, LI W. An open logic system and its implementation[J]. Journal of Beijing University of Aeronautics and Astronautics, 1992, 18(3): 122-129(in Chinese). [16] 何自强. 离散数学中与量词有关的推理规则[J]. 北京航空航天大学学报, 2000, 26(4): 432-434. https://bhxb.buaa.edu.cn/CN/Y2000/V26/I4/432HE Z Q. Rules of inference for quantifiers in discrete mathematics[J]. Journal of Beijing University of Aeronautics and Astronautics, 2000, 26(4): 432-434(in Chinese). https://bhxb.buaa.edu.cn/CN/Y2000/V26/I4/432 [17] YING M S. A logic for approximate reasoning[J]. Journal of Symbolic Logic, 1994, 59(3): 830-837. [18] MAGDALINOS P, KOUSARIDAS A, SPAPIS P, et al. Enhancing a fuzzy logic inference engine through machine learning for a self-managed network[J]. Mobile Networks and Applications, 2011, 16(4): 475-489. [19] BARTOLI A, DE LORENZO A, MEDVET E, et al. Predicting the effectiveness of pattern-based entity extractor inference[J]. Applied Soft Computing, 2016, 46: 398-406. [20] PARNAS D L. Predicate logic for software engineering[J]. IEEE Transactions on Software Engineering, 1993, 19(9): 856-862. [21] PETR H, PETR C. On theories and models in fuzzy predicate logics[J]. Journal of Symbolic Logic, 2006, 71(3): 863-880. -

下载:

下载: