Hydraulic cylinder position system controlled by piezoelectric high-speed on-off valve

-

摘要:

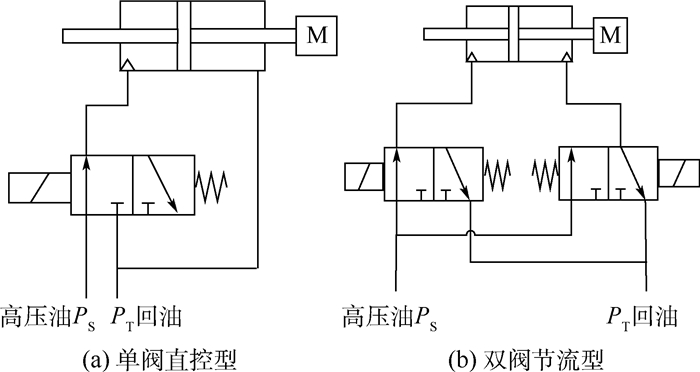

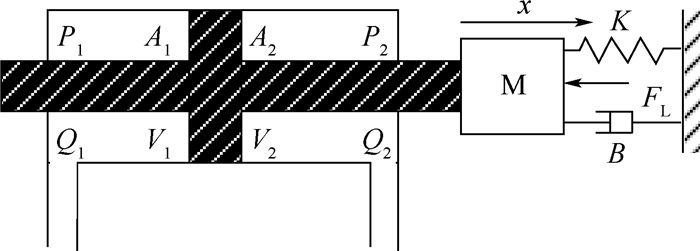

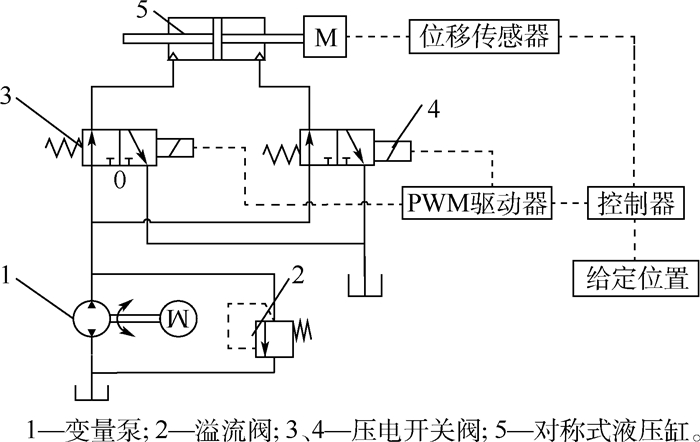

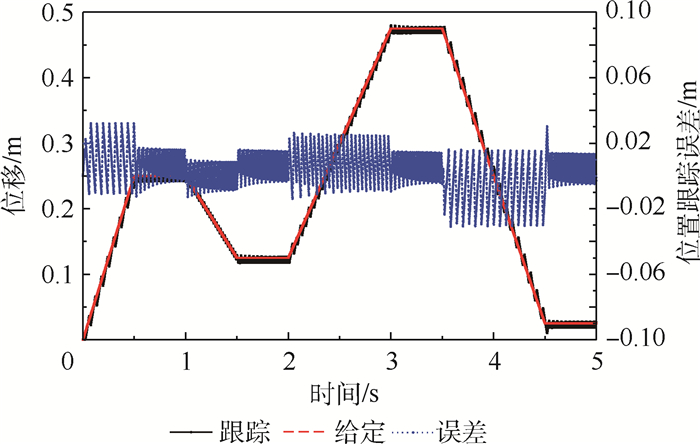

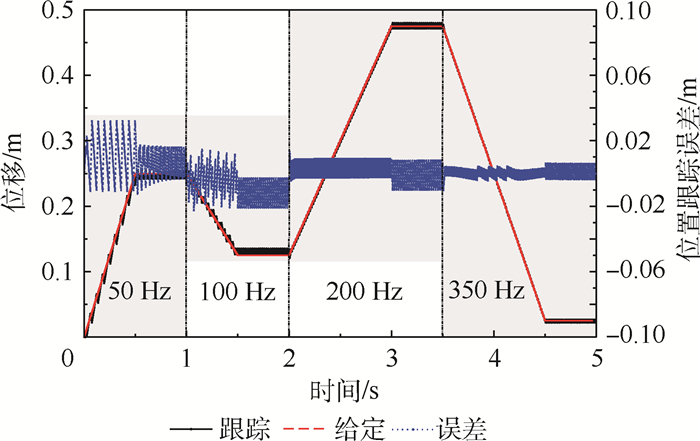

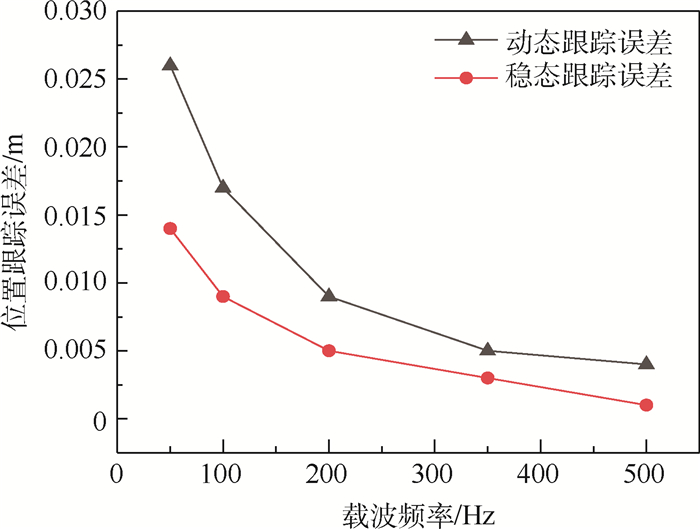

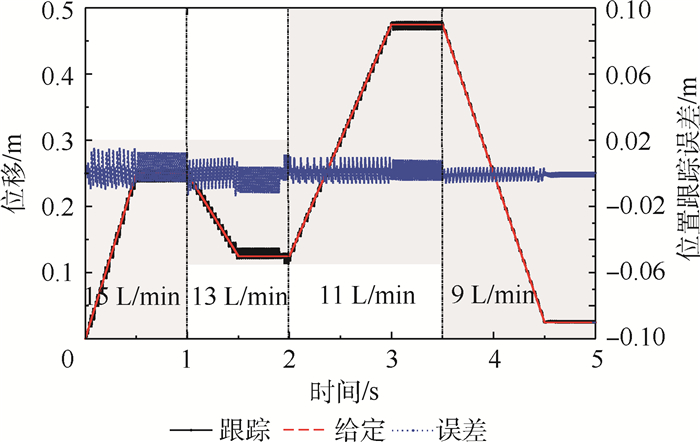

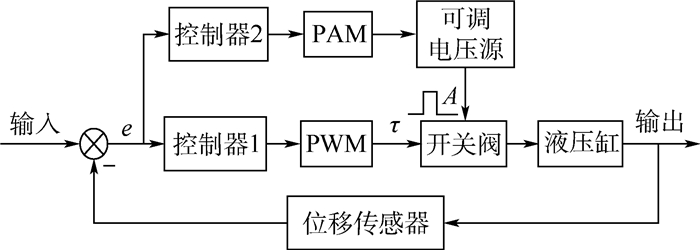

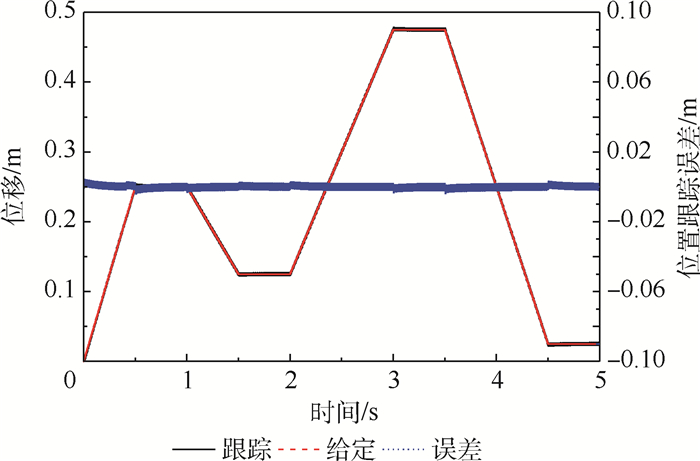

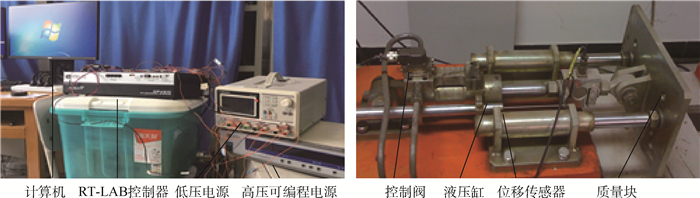

针对开关阀控液压缸位置分辨率低、响应慢的问题,设计了压电式高速开关阀控液压缸位置系统。首先,建立开关阀控液压缸位置系统模型,分析了PWM载波频率对开关阀流量特性的影响规律,采用基于差动流量的双阀结构,实现液压缸负载流量的非线性补偿,减小开关阀死区对系统静、动态性能的影响。然后,分析双阀控制式液压缸系统负载脉冲流量的影响因素,得到了开关阀控液压缸位置抖振的产生机理,比较基于脉冲流量的PWM、PAM、PFM控制方法。最后,依据压电式高速开关阀流量特性,提出了PWM+PAM的复合控制方法,根据误差信号及其变化,调节占空比和流量幅值,实现液压缸位置的快速、精确控制。仿真及实验结果表明:系统定位精度将近1%,为高速开关阀及其控制系统应用提供了理论基础。

Abstract:Aimed at low position resolution and slow response of on-off valve controlled cylinder, a hydraulic cylinder position system controlled by piezoelectric high-speed on-off valve was designed. Firstly, the position system model of on-off valve was built in order to analyze the influence of PWM carrier frequency on the on-off valve flow characteristics. The system structure based on differential flow of double valve is adopted to realize the nonlinear compensation of hydraulic cylinder load flow, which reduced the influence of dead zone on the static and dynamic performance. Then, mechanism and principle of on-off valve controlled hydraulic cylinder position chattering are obtained by analyzing the influence factors of load pulse flow of double valve controlled hydraulic cylinder system, and PWM, PAM and PFM control methods based on the pulse flow are compared.Finally, considering the piezoelectric high-speed on-off valve flow characteristics, a composite control method with PWM and PAM is proposed, which helps the system realize fast and accurate position control by adjusting the duty cycle and flow amplitude according to the error signal and change. Simulation and experimental results show that the positioning accuracy is nearly 1%, which provides a theoretical basis for the application of high-speed on-off valve and control system.

-

Key words:

- high-speed on-off valve /

- flow characteristics /

- position control /

- PWM /

- PFM /

- PAM /

- position resolution

-

表 1 压电式高速开关阀参数

Table 1. Parameters of piezoelectric high-speed on-off valve

参数 数值 压电叠堆外尺寸/(mm×mm×mm) 32(长)×10×8 位移放大倍数 4.3 锥阀角α/(°) 45 阀口直径d/mm 12 开关阀流量幅值Qmax/(L·min-1) 16.8 死区时间t0/ms 0.22 完全开启时间ton/ms 1.15 完全关闭时间toff/ms 0.85 表 2 压电式高速开关阀控液压缸参数

Table 2. Parameters of hydraulic cylinder controlled by piezoelectric high-speed on-off valve

参数 数值 液压缸负载等效质量m/kg 1.5 活塞直径d0/mm 25 活塞杆直径d1/mm 15 液压缸最大行程xmax/m 0.5 泄漏系数C/((L·min-1)·bar-1) 0.000 2 阻尼系数B/(N·(m·s-1)-1) 350 静摩擦/N 15 摩擦系数/(N·(m·s-1)-1) 150 PWM驱动电压U/V 120 PWM载波频率f/Hz 100 供油压力PS/MPa 7 表 3 模糊控制规则

Table 3. Fuzzy control rules

B M S B B B B M B M M S M S S -

[1] 杨华勇, 王双, 张斌, 等. 数字液压阀及其阀控系统发展和展望[J]. 吉林大学学报(工学版), 2016, 46(5): 1494-1505.YANG H Y, WANG S, ZHANG B, et al. Development and prospect of digital hydraulic valve and valve control system[J]. Journal of Jilin University (Engineering and Technology Edition), 2016, 46(5): 1494-1505(in Chinese). [2] YANG H Y, PAN M. Engineering research in fluid power: A review[J]. Journal of Zhejiang University-SCIENCE A, 2015, 16(6): 427-442. doi: 10.1631/jzus.A1500042 [3] 罗樟, 朱玉川. 智能材料驱动的高速开关阀[J]. 压电与声光, 2019, 41(4): 575-581.LUO Z, ZHU Y C. High speed on-off valve driven by smart material[J]. Piezoelectrics & Acoustooptics, 2019, 41(4): 575-581(in Chinese). [4] JIAO Z X, LIU X C, SHANG Y X, et al. An integrated self-energized brake system for aircrafts based on a switching valve control[J]. Aerospace Science and Technology, 2017, 60: 20-30. doi: 10.1016/j.ast.2016.10.021 [5] PAN M, PLUMMER A. Digital switched hydraulics[J]. Frontiers of Mechanical Engineering, 2018, 13(2): 225-231. doi: 10.1007/s11465-018-0509-7 [6] BRUNO N, ZHU Y C, LIU C, et al. Development of a piezoelectric high speed on/off valve and its application to pneumatic closed-loop position control system[J]. Journal of Mechanical Science and Technology, 2019, 33(6): 2747-2759. doi: 10.1007/s12206-019-0521-9 [7] ZHONG Q, ZHANG B, YANG H Y, et al. Performance analysis of a high-speed on/off valve based on an intelligent pulse-width modulation control[J]. Advances in Mechanical Engineering, 2017, 9(11): 1-11. [8] ZHANG B, ZHONG Q, MA J E, et al. Self-correcting PWM control for dynamic performance preservation in high-speed on/off valve[J]. Mechatronics, 2018, 55: 141-150. doi: 10.1016/j.mechatronics.2018.09.001 [9] WU S, ZHAO X Y, LI C F, et al. Multi-objective optimization of a hollow plunger type solenoid for high-speed on/off valve[J]. IEEE Transactions on Industrial Electronics, 2017, 65(4): 3115-3124. [10] 高强, 朱玉川, 罗樟, 等. 高速开关阀的复合PWM控制策略分析与优化[J]. 北京航空航天大学学报, 2019, 45(6): 1129-1136. doi: 10.13700/j.bh.1001-5965.2018.0565GAO Q, ZHU Y C, LUO Z, et al. Analysis and optimization on compound PWM control strategy of high-speed on/off valve[J]. Journal of Beijing University of Aeronautics and Astronautics, 2019, 45(6): 1129-1136(in Chinese). doi: 10.13700/j.bh.1001-5965.2018.0565 [11] 高强, 朱玉川. 基于均匀切换的并联数字阀控系统位置控制策略[J]. 中国机械工程, 2020, 31(12): 1461-1468.GAO Q, ZHU Y C. Position control strategy of parallel digital valve-controlled system based on uniform switching method[J]. China Mechanical Engineering, 2020, 31(12): 1461-1468(in Chinese). [12] 陈晓明, 朱玉川, 吴昌文, 等. 数字开关液压系统管路压力波传播建模与分析[J]. 北京航空航天大学学报, 2020, 46(7): 1335-1344. doi: 10.13700/j.bh.1001-5965.2019.0478CHEN X M, ZHU Y C, WU C W, et al. Modeling and analysis of pressure wave propagation inside pipeline of digital switched hydraulic system[J]. Journal of Beijing University of Aeronautics and Astronautics, 2020, 46(7): 1335-1344(in Chinese). doi: 10.13700/j.bh.1001-5965.2019.0478 [13] YAO B, BU F P, REEDY J, et al. Adaptive robust motion control of single-rod hydraulic actuators: Theory and experiments[J]. IEEE/ASME Transactions on Mechatronics, 1998, 5(1): 79-91. [14] 曹晓明, 姚静, 沙桐, 等. 多级压力源切换负载口独立控制系统能耗特性实验研究[J]. 西安交通大学学报, 2019, 53(12): 63-71.CAO X M, YAO J, SHA T, et al. Experimental research on energy consumption characteristics for multi-level pressure switching control[J]. Journal of Xi'an Jiaotong University, 2019, 53(12): 63-71(in Chinese). [15] 高钦和, 刘志浩, 牛海龙, 等. 高速开关阀控液压缸的位置控制[J]. 中国机械工程, 2014, 25(20): 2775-2781. doi: 10.3969/j.issn.1004-132X.2014.20.014GAO Q H, LIU Z H, NIU H L, et al. Position control of hydraulic cylinder controlled by high-speed on/off valve[J]. China Mechanical Engineering, 2014, 25(20): 2775-2781(in Chinese). doi: 10.3969/j.issn.1004-132X.2014.20.014 [16] 刘志浩, 高钦和, 管文良. 高速开关阀流量非线性分析及补偿控制验证[J]. 兵工学报, 2015, 36(1): 163-174. doi: 10.3969/j.issn.1000-1093.2015.01.024LIU Z H, GAO Q H, GUAN W L. Flow nonlinear analysis and compensation control validation for high-speed on/off valve[J]. Acta Armamentarii, 2015, 36(1): 163-174(in Chinese). doi: 10.3969/j.issn.1000-1093.2015.01.024 [17] 俞军涛, 焦宗夏, 吴帅. 大流量压电式高速开关阀设计与仿真测试[J]. 机械工程学报, 2020, 56(18): 226-234.YU J T, JIAO Z X, WU S. Design, simulation and test of high-flow high-speed on/off valve driven by piezoelectric[J]. Journal of Mechanical Engineering, 2020, 56(18): 226-234(in Chinese). [18] 苏明. 高速电磁开关阀控缸位置控制系统的纹波抑制[J]. 液压与气动, 2012(1): 92-94. doi: 10.3969/j.issn.1000-4858.2012.01.033SU M. Ripple suppression of the cylinder position control system with high-speed switching solenoid valve[J]. Chinese Hydraulics & Pneumatics, 2012(1): 92-94(in Chinese). doi: 10.3969/j.issn.1000-4858.2012.01.033 期刊类型引用(15)

1. 姚静,杨帅,王梦阳,王佩. 一种低功耗数字阀建模、性能分析及试验验证. 航空学报. 2025(02): 324-339 .  百度学术

百度学术2. 徐纯洁,谢方伟,凡镕瑞,魏汝路,田祖织. 考虑电磁铁线圈构型的高速开关阀动态特性分析. 西安交通大学学报. 2024(04): 211-220 .  百度学术

百度学术3. 刘广阔. 负载口独立控制的压铸机比例插装压射速度系统研究. 液压气动与密封. 2024(06): 73-79 .  百度学术

百度学术4. 吴会刚,韦文术,徐龙. 高速开关阀动态响应特性研究及性能优化. 机床与液压. 2024(12): 119-126 .  百度学术

百度学术5. 朱牧之,黄兴溶,张杰,刘勇. 电机直驱式高速开关阀及其系统特性研究. 南京工程学院学报(自然科学版). 2024(01): 24-32 .  百度学术

百度学术6. 陈楠,魏汝路,谢方伟. 高速开关阀阀芯频响及流量输出特性研究. 机床与液压. 2024(19): 159-164 .  百度学术

百度学术7. 何新军,何小群. 基于普通换向阀的高精度油缸位置控制. 液压与气动. 2023(01): 167-174 .  百度学术

百度学术8. 马克凡,王立勇,唐长亮,贾然. 基于高速开关阀的湿式离合器缓冲控制系统研究. 机床与液压. 2023(02): 174-179 .  百度学术

百度学术9. 高强,朱勇,钱鹏飞,张兵,王杰. 阵列压电叠堆驱动高速开关阀的设计与仿真分析. 液压与气动. 2023(09): 56-62 .  百度学术

百度学术10. 熊志文,崔玉国,蔡永根,马剑强,杨依领. 压电执行器输出位移的精密自感知. 仪器仪表学报. 2023(07): 28-36 .  百度学术

百度学术11. 赵天宇,吴帅,李文顶,房成,傅俊勇. 基于模型的数字式电液作动器智能控制方法. 飞控与探测. 2022(01): 48-56 .  百度学术

百度学术12. 张啸甫,施光林. 基于变溢流压力的电液机械臂节能控制策略. 液压与气动. 2022(07): 25-30 .  百度学术

百度学术13. 毛景禄,王聪,张彦伟,苗峰,崔雷. 复杂时变环境高速开关阀自适应控制算法. 液压与气动. 2022(12): 109-114 .  百度学术

百度学术14. 赵凯平,何涛,王传礼,史瑞. 双弹簧电液激振缸振幅补偿性能的研究. 工程设计学报. 2021(06): 737-745 .  百度学术

百度学术15. 刘伟静,赵超泽,王东,徐文丽,姚宁,王小涛. 基于CC430F6137的工业手柄摇杆优化模型研究. 自动化仪表. 2021(12): 77-81 .  百度学术

百度学术其他类型引用(12)

-

下载:

下载:

百度学术

百度学术