Judgment method of circumferential relative sliding of air film seal between shafts

-

摘要:

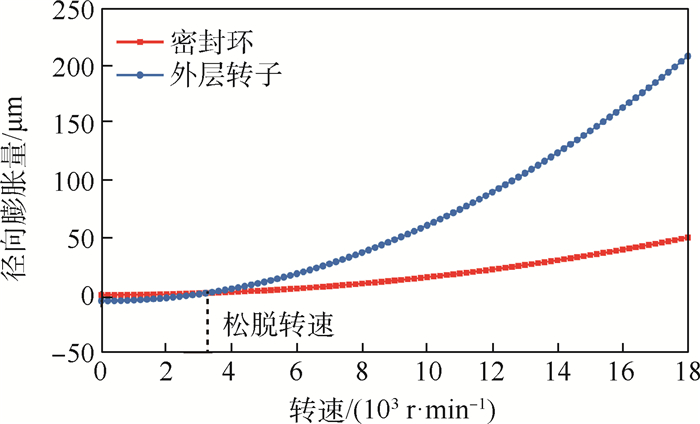

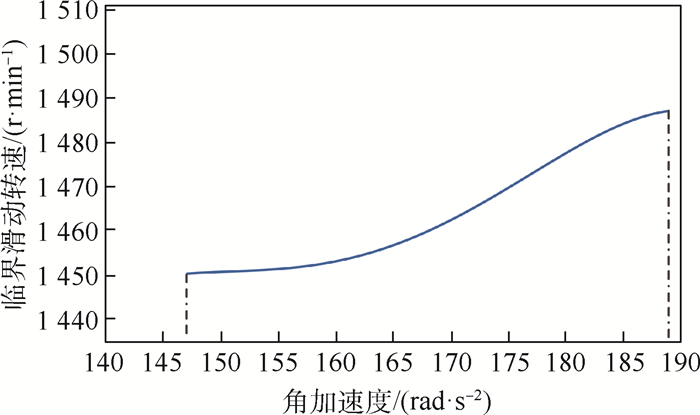

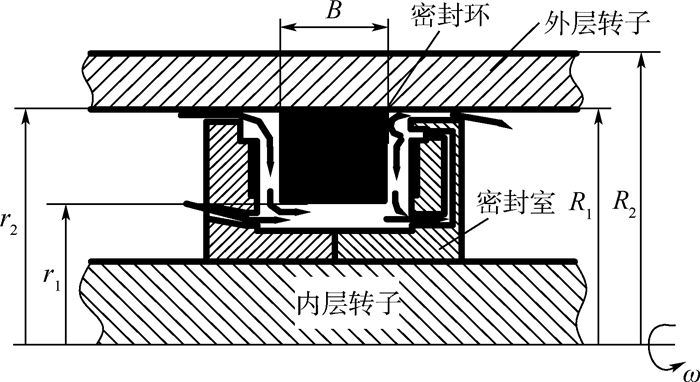

为预判端面轴间气膜密封中密封环与外层转子之间是否产生周向相对滑动,提出了一种考虑离心膨胀效应的轴间气膜密封周向相对滑动判定方法。分析了密封环与外层转子之间产生周向相对滑动的力学机制,将密封环和外层转子离心膨胀简化为轴对称平面应力问题和轴对称平面应变问题。计算了密封环和外层转子的弹性变形刚度差异对膨胀变形及连接关系的影响,得到了密封环与外层转子产生临界滑动的工况区域。所提判定方法对工程中密封环的周向滑动问题提供了预测及指导。

Abstract:In order to predict whether there is relative sliding in the circumferential direction between the seal ring and the outer rotor in air film seal between shafts, a method for determining the circumferential sliding of air film seal between shafts considering centrifugal expansion effect is proposed. The mechanical mechanism of the circumferential sliding between seal ring and outer rotor is analyzed. The centrifugal expansion of seal ring and outer rotor is simplified into axisymmetric plane stress and axisymmetric plane strain. The influence of the difference of elastic deformation stiffness between seal ring and outer rotor on the expansion deformation and the connection relationship is calculated, and the critical sliding operating area between seal ring and rotor is obtained. The research method provides a prediction and guidance method for circumferential sliding of seal ring in engineering.

-

表 1 密封环参数

Table 1. Parameters of seal ring

参数 符号 摩擦因数 μ 密封环宽度 B 无旋转时密封环外边界上的正压力 p 旋转时密封环外边界上的正压力 pe 密封环的转动惯量 J 外层转子在ω角速度时的瞬时角加速度 α 密封环外半径 r2 密封环内半径 r1 密封环外圆周面积 S 密封环质量 m 最大静摩擦力与滑动摩擦力之间的比例系数 K 外层转子内半径 R1 外层转子外半径 R2 参数 数值 摩擦因数μ 0.15 密封环外半径r2/mm 76 密封环内半径r1/mm 69 密封环宽度B/mm 10 外层转子最高转速n/(r·min-1) 18 000 外层转子角加速度α/(rad·s-2) 188.5 外层转子外半径R2/mm 82 外层转子内半径R1/mm 76 表 3 材料性能参数一

Table 3. Material property parameters Ⅰ

参数 数值 密封环弹性模量E1/GPa 14 密封环泊松比ν1 0.25 密封环密度ρ1/(g·cm-3) 1.8 外层转子弹性模量E2/GPa 209 外层转子泊松比ν2 0.3 外层转子密度ρ2/(g·cm-3) 7.85 表 4 材料性能参数二

Table 4. Material property parameters Ⅱ

参数 数值 密封环弹性模量E1/GPa 209 密封环泊松比ν1 0.3 密封环密度ρ1/(g·cm-3) 7.85 外层转子弹性模量E2/GPa 14 外层转子泊松比ν2 0.25 外层转子密度ρ2/(g·cm-3) 1.8 表 5 材料性能参数三

Table 5. Material property parameters Ⅲ

参数 数值 密封环弹性模量E1/GPa 209 密封环泊松比ν1 0.3 密封环密度ρ1/(g·cm-3) 7.85 外层转子弹性模量E2/GPa 209 外层转子泊松比ν2 0.3 外层转子密度ρ2/(g·cm-3) 7.85 -

[1] STEINETZ B M, HENDRICKS R C. Engine seal technology requirements to meet NASA's advanced subsonic technology program goals[J]. Journal of Propulsion and Power, 1996, 12(4): 786-793. doi: 10.2514/3.24102 [2] STEINETZ B M, HENDRICKS R C, MUNSON J. Advanced seal technology role in meeting next generation turbine engine goals[C]//NASA Technical Memorandum Toulouse, 1998: 1-12. [3] 胡绚, 罗贵火, 高德平. 航空发动机中介轴承的特性分析[J]. 航空动力学报, 2007, 22(3): 439-443. doi: 10.3969/j.issn.1000-8055.2007.03.019HU X, LUO G H, GAO D P. Performance analysis of aero-engine intershaft bearing[J]. Journal of Aerospace Power, 2007, 22(3): 439-443(in Chinese). doi: 10.3969/j.issn.1000-8055.2007.03.019 [4] HOLLOWAY G, MEHTA J, ROSADO L, et al. Rotating brush seal-experimental performance evaluation[C]//44th AIAA/ASME/SAE/ASEE Joint Propulsion Conference & Exhibit. Reston: AIAA, 2008: 21-23. [5] HOLLOWAY G, MEHTA J, ROSADO L, et al. Rotating intershaft brush seal for sealing between rotating shafts: Part 1-Experimental performance evaluation compared to mechanical design analysis[C]//43rd AIAA/ASME/SAE/ASEE Joint Propulsion Conference & Exhibit. Reston: AIAA, 2007: 1-19. [6] MEHTA J, HOLLOWAY G, ROSADO L, et al. Innovative rotating intershaft brush seal for sealing between rotating shafts. Part Ⅱ: Modeling of the brush seal leakage flows[C]//42nd AIAA/ASME/SAE/ASEE Joint Propulsion Conference & Exhibit. Reston: AIAA, 2006: 1-14. [7] HOLLOWAY G, MEHTA J, ROSADO L, et al. Innovative rotating intershaft brush seal for sealing between rotating shafts. Part Ⅰ-Mechanical design of the rotating brush seal[C]//42nd AIAA/ASME/SAE/ASEE Joint Propulsion Conference & Exhibit. Reston: AIAA, 2006: 1-21. [8] 王之栎, 刘国西, 郭艳丽. 反转轴间气膜密封振动过程分析[J]. 振动与冲击, 2011, 30(2): 181-185.WANG Z L, LIU G X, GUO Y L. Vibration process analysis of a gas film seal in counter-rotating shafts[J]. Journal of Vibration and Shock, 2011, 30(2): 181-185(in Chinese). [9] 王之栎, 侯景仁, 信琦. 反转轴间气密封研究[C]//第五届中日机械技术史及机械设计国际学术会议, 2005: 159-162.WANG Z L, HOU J R, XIN Q. Research for an air film seal between two contraty rotation shafts[C]//Proceedings of the Fifth China-Japan International Conference on History of Mechanical Technology and Mechanical Design, 2005: 159-162(in Chinese). [10] DIRUSSO E. Feasibility analysis of a spiral groove ring seal for counter-rotating shafts[J]. Journal of Aircraft, 1984, 21(8): 618-622. doi: 10.2514/3.45032 [11] GAMBLE W L. Counterrotating intershaft seals for advanced engines[J]. Journal of Propulsion and Power, 1985, 1(6): 437-440. doi: 10.2514/3.22825 [12] 刘雨川. 端面气膜密封特性研究[D]. 北京: 北京航空航天大学, 1999: 33-35. https://d.wanfangdata.com.cn/thesis/Y336381LIU Y C. Behavior of gas film face seal[D]. Beijing: Beihang University, 1999: 33-35(in Chinese). https://d.wanfangdata.com.cn/thesis/Y336381 [13] 吴宁兴, 赵宗坚. 反转轴间气膜密封可行性试验研究[J]. 航空发动机, 2001, 27(4): 20-25.WU N X, ZHAO Z J. Feasibility test study of counter-rotating intershaft gas film seal[J]. Aeroengine, 2001, 27(4): 20-25(in Chinese). [14] 王之栎, 刘国西, 郭艳丽. 反转轴间气膜密封动特性分析[J]. 北京航空航天大学学报, 2010, 36(5): 509-512. https://bhxb.buaa.edu.cn/CN/Y2010/V36/I5/509WANG Z L, LIU G X, GUO Y L. Dynamic characteristic analysis of the gas film seal in counter-rotating shafts[J]. Journal of Beijing University of Aeronautics and Astronautics, 2010, 36(5): 509-512(in Chinese). https://bhxb.buaa.edu.cn/CN/Y2010/V36/I5/509 [15] 王之栎, 郭艳丽, 侯景仁. 反转轴间气膜密封的结构参数与密封性能分析[J]. 润滑与密封, 2008, 33(1): 68-72.WANG Z L, GUO Y L, HOU J R. Configuration parameters and sealing performances analysis of gas film seal in counter-rotating shafts[J]. Lubrication Engineering, 2008, 33(1): 68-72(in Chinese). [16] 刘晓玉, 王之栎, 丁蕾, 等. 反转轴间双端面气膜密封性能分析[J]. 北京航空航天大学学报, 2017, 43(3): 608-614. doi: 10.13700/j.bh.1001-5965.2016.0216LIU X Y, WANG Z L, DING L, et al. Seal performance analysis of double-faced gas film in counter-rotating intershafts[J]. Journal of Beijing University of Aeronautics and Astronautics, 2017, 43(3): 608-614(in Chinese). doi: 10.13700/j.bh.1001-5965.2016.0216 [17] 徐芝纶. 弹性力学(上册)[M]. 4版. 北京: 高等教育出版社, 2006.XU Z L. Elastic mechanics. Volume I[M]. 4th ed. Beijing: Higher Education Press, 2006(in Chinese). [18] 曹宏瑞, 李兵, 陈雪峰, 等. 高速主轴离心膨胀及对轴承动态特性的影响[J]. 机械工程学报, 2012, 48(19): 59-64.CAO H R, LI B, CHEN X F, et al. Centrifugal expansion of high-speed spindle and its influences on bearing dynamic characteristics[J]. Journal of Mechanical Engineering, 2012, 48(19): 59-64(in Chinese). [19] 张峻晖, 黄红武, 熊万里. 高速电主轴轴承配合过盈量的计算方法研究[J]. 机械与电子, 2004, 22(7): 7-10.ZHANG J H, HUANG H W, XIONG W L. Calculation method research of the interference fit for high speed motorized spindle bearings[J]. Machinery & Electronics, 2004, 22(7): 7-10(in Chinese). [20] 濮良贵, 陈国定, 吴立言. 机械设计[M]. 9版. 北京: 高等教育出版社, 2013: 132-133.PU L G, CHEN G D, WU L Y. Mechanical design[M]. 9th ed. Beijing: Higher Education Press, 2013: 132-133(in Chinese). -

下载:

下载: