-

摘要:

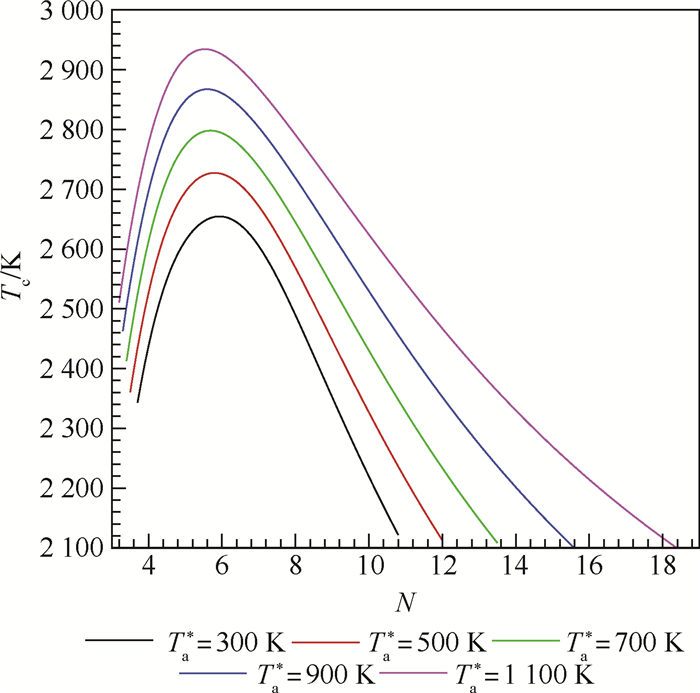

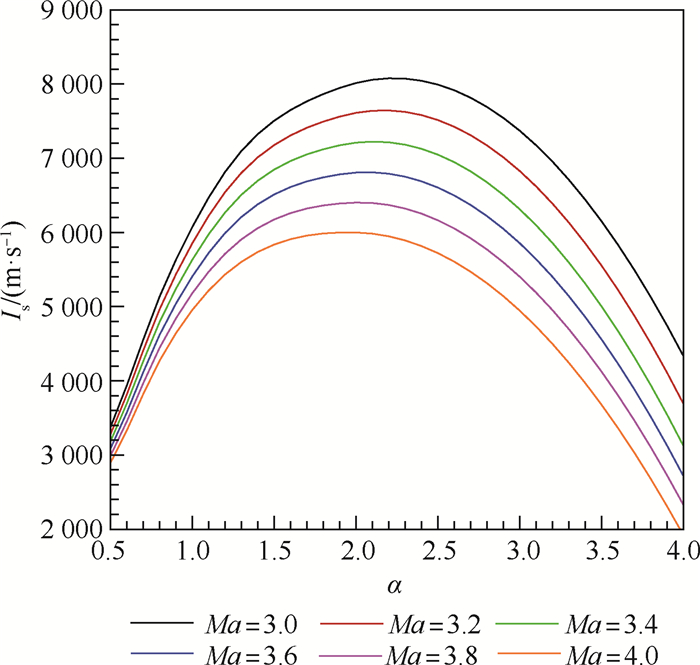

针对冲压动力飞行器射程优化总体需求,提出了基于飞行器-发动机性能因子的评估方法,建立了固体火箭冲压发动机性能模型及优化设计流程,为总体与动力一体化优化设计提供了支撑。根据典型含硼贫氧推进剂性能分析结果可知,相同马赫数及余气系数下,高度对比冲的影响不明显;相同马赫数下,比冲随余气系数的增加先增加后减小;相同余气系数下,比冲随马赫数的增加而降低;飞发性能因子随马赫数、余气系数的增加先增加后降低,在一定条件下达到最大值。

Abstract:Aimed at range optimization requirements of vehicle with ramjet, an evaluation method based on the vehicle-ramjet performance factor is proposed. Performance prediction model and optimization design process of ducted rocket are developed. These provide support for the integrated optimization design of vehicle and ramjet. According to the analysis results of ramjet performance with boron-based fuel rich propellant, under the same Mach number and excess air coefficient, the change of specific impulse caused by height variation is not obvious. Under the same Mach number, the specific impulse increases first and then decreases with the increase of excess air coefficient. Under the same excess air coefficient, the specific impulse decreases with the increase of Mach number. With the increase of the Mach number and excess air coefficient, vehicle-ramjet performance factor increases first and then decreases. The vehicle-ramjet performance factor reaches a maximum under certain Mach number and excess air coefficient.

-

Key words:

- ducted rocket /

- design point /

- specific impulse /

- range /

- performance optimization

-

-

[1] 鲍福廷, 黄熙君, 张振鹏, 等. 固体火箭冲压组合发动机[M]. 北京: 中国宇航出版社, 2006: 1-44.BAO F T, HUANG X J, ZHANG Z P, et al. Integral solid propellant ramjet rocket motor[M]. Beijing: China Astronautic Publishing House, 2006: 1-44(in Chinese). [2] 夏智勋, 陈斌斌, 黄利亚, 等. 固体火箭冲压发动机技术研究进展[J]. 上海航天, 2019, 36(6): 11-18.XIA Z X, CHEN B B, HUANG L Y, et al. Research progresses in solid rocket-ramjet engine[J]. Aerospace Shanghai, 2019, 36(6): 11-18(in Chinese). [3] FRY R S. A century of ramjet propulsion technology evolution[J]. Journal of Propulsion and Power, 2004, 20(1): 27-58. doi: 10.2514/1.9178 [4] BESSER H L. History of duct rocket development at Bayern-Chemine: AIAA 2008-5261[R]. Reston: AIAA, 2008. [5] 叶定友. 固体火箭冲压发动机的若干技术问题[J]. 固体火箭技术, 2007, 30(6): 470-473. doi: 10.3969/j.issn.1006-2793.2007.06.003YE D Y. Some technological problems of solid rocket ramjet[J]. Journal of Solid Rocket Technology, 2007, 30(6): 470-473(in Chinese). doi: 10.3969/j.issn.1006-2793.2007.06.003 [6] 喻银飞, 陈雄, 李宏文. 固冲发动机燃气发生器性能分析及参数优化[J]. 计算机仿真, 2014, 31(4): 73-77. doi: 10.3969/j.issn.1006-9348.2014.04.017YU Y F, CHEN X, LI H W. Performance analysis and parameter optimization of gas-generator on ducted rocket[J]. Computer Simulation, 2014, 31(4): 73-77(in Chinese). doi: 10.3969/j.issn.1006-9348.2014.04.017 [7] 张炜, 方丁酉, 夏智勋, 等. 固体火箭冲压发动机的工作特性分析[J]. 国防科技大学学报, 2000, 22(4): 19-22. doi: 10.3969/j.issn.1001-2486.2000.04.006ZHANG W, FANG D Y, XIA Z X, et al. Operating characteristics of solid ducted rocket[J]. Journal of National University of Defense Technology, 2000, 22(4): 19-22(in Chinese). doi: 10.3969/j.issn.1001-2486.2000.04.006 [8] 王友银. 宽马赫数运行冲压发动机的热力性能优化分析[D]. 哈尔滨: 哈尔滨工业大学, 2016.WANG Y Y. Optimal analysis of the scramjet thermodynamic performance in wide Mach numbers[D]. Harbin: Harbin Institute of Technology, 2016(in Chinese). [9] 朱美军. 超燃冲压发动机内流道设计与优化研究[D]. 杭州: 浙江大学, 2017.ZHU M J. Research on design and optimization of scramjet engine flowpaths[D]. Hangzhou: Zhejiang University, 2017(in Chinese). [10] 王青, 谷良贤, 龚春林. 超燃冲压发动机可调尾喷管多目标优化设计[J]. 推进技术, 2013, 34(3): 294-299.WANG Q, GU L X, GONG C L. Multi-objective optimization design of geometry-variable nozzle for scramjet[J]. Journal of Propulsion Technology, 2013, 34(3): 294-299(in Chinese). [11] 曹军伟, 何国强, 王希亮, 等. 空空导弹固体火箭冲压发动机设计参数优化[J]. 航空动力学报, 2015, 30(8): 2018-2024.CAO J W, HE G Q, WANG X L, et al. Parameter optimization design of air-ducted rocket for airborne missile[J]. Journal of Aerospace Power, 2015, 30(8): 2018-2024(in Chinese). [12] 王超. 超燃冲压发动机总体方案设计与优化研究[D]. 长沙: 国防科学技术大学, 2011.WANG C. Design and optimization research on scramjet system scheme[D]. Changsha: National University of Defense Technology, 2011(in Chinese). [13] 李建平, 宋文艳, 肖隐利. 超燃冲压发动机/机体一体化优化设计[J]. 航空动力学报, 2011, 26(4): 874-879.LI J P, SONG W Y, XIAO Y L. Research on the optimization design of integrated scframjet/airframe[J]. Journal of Aerospace Power, 2011, 26(4): 874-879(in Chinese). [14] 刘恒军, 沙建科, 王华. 冲压发动机导弹弹道多目标优化[J]. 系统仿真学报, 2009, 21(9): 2764-2766.LIU H J, SHA J K, WANG H. Trajectory multi-objective optimization of missile propelled by liquid rocket ramjet[J]. Journal of System Simulation, 2009, 21(9): 2764-2766(in Chinese). [15] 吴先宇. 超燃冲压发动机一体化流道设计优化研究[D]. 长沙: 国防科学技术大学, 2007.WU X Y. Research on design and optimization of integrated scramjet flowpath[D]. Changsha: National University of Defense Technology, 2007(in Chinese). [16] 张旭, 王利, 林言中, 等. 超燃冲压发动机总体化性能分析[J]. 推进技术, 2014, 35(2): 157-165.ZHANG X, WANG L, LIN Y Z, et al. Analysis of overall scramjet performance[J]. Journal of Propulsion Technology, 2014, 35(2): 157-165(in Chinese). [17] 李俊红, 程晓丽, 沈清. 超燃冲压发动机性能预测工程方法[J]. 推进技术, 2009, 30(2): 129-134. doi: 10.3321/j.issn:1001-4055.2009.02.001LI J H, CHENG X L, SHEN Q. Engineering method of scramjet engine performance prediction based on nozzle exit pressure[J]. Journal of Propulsion Technology, 2009, 30(2): 129-134(in Chinese). doi: 10.3321/j.issn:1001-4055.2009.02.001 [18] 谢爱元, 武晓松, 于栋梁. 固体燃料冲压发动机性能预示[J]. 推进技术, 2014, 35(1): 8-14.XIE A Y, WU X S, YU D L. Prediction model of performance for solid fuel ramjet[J]. Journal of Propulsion Technology, 2014, 35(1): 8-14(in Chinese). [19] 龚玉元. 固体火箭冲压发动机性能预估方法研究与导弹弹道仿真[D]. 长沙: 国防科学技术大学, 2010.GONG Y Y. Research on the way of solid-propellant ducted rocket performance estimate and simulation of missile trajectory[D]. Changsha: National University of Defense Technology, 2010(in Chinese). -

下载:

下载: