-

摘要:

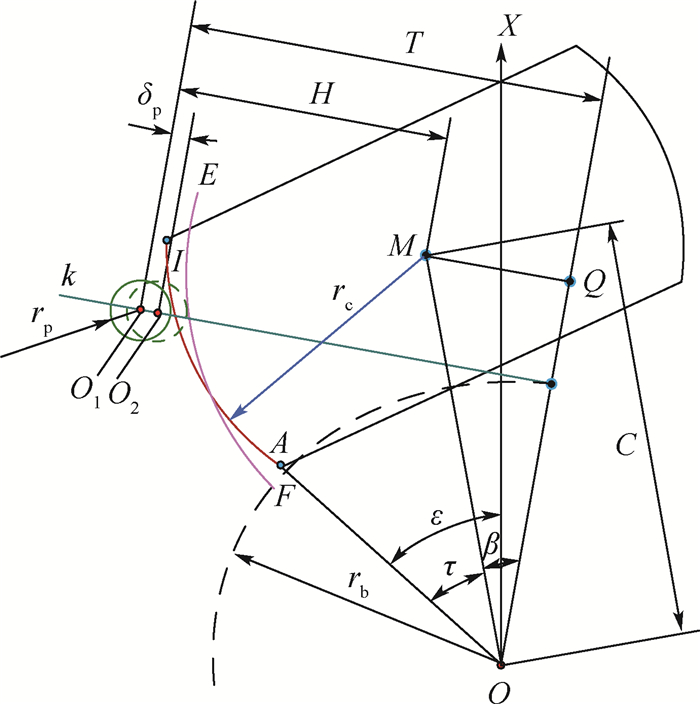

大尺寸渐开线样板加工困难,测量更加困难,导致大齿轮的量值传递成为难题。采用圆弧代替渐开线齿廓,构造了新型大尺寸渐开线样板——双轴式圆弧型大尺寸渐开线样板。提出了新型大尺寸渐开线样板的工作原理,研究了样板的设计方法,建立了样板的原理误差模型,提出了双轴式圆弧型大尺寸渐开线样板可评定的齿轮测量仪器单项误差项,以及使用样板评定齿轮测量仪器的齿面偏差测量性能的方法。为验证所提工作原理的可行性,加工了原理验证样板,实验结果表明:加工的双轴式圆弧型大尺寸渐开线样板,其测量得到的原理误差曲线与理论的原理误差曲线整体趋势一致,都为驼峰状,证明了双轴式圆弧型大尺寸渐开线样板的原理误差模型建立的准确性和可行性;在评定范围内,整个评定偏差曲线幅值为45.5 μm,对应产生的压力角误差为1.34 μm/rad;证明了双轴式圆弧型大尺寸渐开线样板的圆弧选取准则、中心距的设计模型和圆弧半径的设计模型的正确性。研究成果为大齿轮的量值传递提供了研究思路。

Abstract:Due to the difficulty of machining large-size involute artifact, it is even more difficult to measure, and as a result, the transmission of values in large gears has always been a problem. In this paper, an arc is used instead of involute tooth profile to construct a new type of large-size involute artifact—the double-axis arc-shaped large-size involute artifact. The principle of the new large-size involute artifact is introduced, the design method of the artifact is studied, the principle error model of the artifact is established, the single error of the gear measuring instrument which can be evaluated by the double-axis arc-shaped large-size involute artifact is proposed, and the method of evaluating the tooth surface deviation measuring performance of the gear measuring instrument by using the artifact is presented. In order to verify the feasibility, an artifact for testing principle was processed, and the experimental results show that the measured principle error curve of the processed double-axis arc-shaped large-size involute artifact is consistent with the overall trend of the theoretical principle error curve, which is hump-shaped, proving the accuracy and feasibility of the establishment of the principle error model of the artifact. The magnitude of the entire assessment deviation curve is 45.5 μm within the assessment range, corresponding to a resulting pressure angle error of 1.34 μm /rad. The experimental results also demonstrate the correctness of the arc selection criterion, the design model of center distance and the design model of arc radius for the double-axis arc-shaped large-size involute artifact. The paper provides theoretical support for establishing the value transfer of the large gear.

-

Key words:

- involute artifact /

- gear measuring instruments /

- gear measurement method /

- large gear /

- value transfer

-

表 1 不同样板参数对应的绝对值最大原理误差

Table 1. Absolute maximum principle error corresponding to different artifact parameters

齿数 模数/mm 绝对值最大原理误差/mm 28 4 0.231 2 28 8 0.379 2 28 12 0.532 2 28 16 0.686 4 28 20 0.841 0 28 24 0.995 9 28 28 1.151 0 28 32 1.306 2 -

[1] 石照耀, 林虎, 林家春, 等. 大齿轮测量: 现状与趋势[J]. 机械工程学报, 2013, 49(10): 35-44. https://www.cnki.com.cn/Article/CJFDTOTAL-JXXB201310008.htmSHI Z Y, LIN H, LIN J C, et al. Current status and trends of large gears metrology[J]. Journal of Mechanical Engineering, 2013, 49(10): 35-44(in Chinese). https://www.cnki.com.cn/Article/CJFDTOTAL-JXXB201310008.htm [2] 王长路, 王伟功, 张立勇, 等. 中国风电产业发展分析[J]. 重庆大学学报, 2015, 38(1): 148-154. https://www.cnki.com.cn/Article/CJFDTOTAL-FIVE201501020.htmWANG C L, WANG W G, ZHANG L Y, et al. The analysis of China wind power industry[J]. Journal of Chongqing University, 2015, 38(1): 148-154(in Chinese). https://www.cnki.com.cn/Article/CJFDTOTAL-FIVE201501020.htm [3] RUDOLF O. History of gear measuring machines and traceability 1900—2006[J]. Gear Product News, 2006(10): 20-25. [4] HARTIG F, ROST K, GOCH G. Large gear material standard for the traceability of gears for transmission manufacturing[C]//International Conference on Gears, 2010: 1-14. [5] WIEMANN A K, STEIN M, KNIEL K. Traceable metrology for large involute gears[J]. Precision Engineering, 2019, 55: 330-338. doi: 10.1016/j.precisioneng.2018.10.001 [6] CARMIGNATO S, CHIFFRE L D, BOSSE H, et al. Dimensional artefacts to achieve metrological traceability in advanced manufacturing[J]. CIRP Annals, 2020, 69(2): 693-716. doi: 10.1016/j.cirp.2020.05.009 [7] KOMORI M, TAKEOKA F, KONDO K, et al. Design method of double ball artifact for use in evaluating the accuracy of a gear-measuring instrument[J]. Journal of Mechanical Design, 2010, 132(7): 071010. doi: 10.1115/1.4001875 [8] OSAWA S, SATO O, KONDO Y, et al. A novel artifact for evaluating accuracies of gear profile and pitch measurements of gear measuring instruments[C]//19th IMEKO World Congress, 2009, 3: 1574-1578. [9] KONDO Y, SASAJIMA K, OSAWA S, et al. Traceability strategy for gear-pitch-measuring instruments: Development and calibration of a multiball artifact[J]. Measurement Science and Technology, 2009, 20(6): 152-154. [10] ISO. Code of inspection practice. Part 1: Measurement of cylindrical gear tooth flanks: ISO/TR 10064-1[S]. Geneva: ISO, 2019. [11] ZELENY V, LINKEOVA I, SYKORA J, et al. Mathematical approach to evaluate involute gear profile and helix deviations without using special gear software[J]. Mechanism and Machine Theory, 2019, 135: 150-164. doi: 10.1016/j.mechmachtheory.2019.01.030 [12] WANG Q, PENG Y, WIEMANN A K, et al. Improved gear metrology based on the calibration and compensation of rotary table error motions[J]. CIRP Annals, 2019, 68(1): 511-514. doi: 10.1016/j.cirp.2019.04.078 [13] KONDO K, TAKADA J. Study on tooth profiles of the harmonic drive[J]. Journal of Mechanical Design, 1990, 112(1): 131-137. doi: 10.1115/1.2912570 [14] 凌四营, 陈义磊, 凌明, 等. 齿轮渐开线样板安装偏心对齿廓倾斜偏差的影响[J]. 光学精密工程, 2019, 27(12): 2581-2588. https://www.cnki.com.cn/Article/CJFDTOTAL-GXJM201912011.htmLING S Y, CHEN Y L, LING M, et al. Influence of installation eccentricity on profile slope deviation of gear involute artifacts[J]. Optics and Precision Engineering, 2019, 27(12): 2581-2588(in Chinese). https://www.cnki.com.cn/Article/CJFDTOTAL-GXJM201912011.htm [15] 杨国梁, 薛梓, 刘春杰, 等. 齿轮测量中心的校准方法探究[J]. 计量学报, 2009, 30(5A): 128-131.YANG G L, XUE Z, LIU C J, et al. Study on the calibration methods of gear measuring center[J]. Acta Metrologica Sinica, 2009, 30(5A): 128-131(in Chinese). [16] MICHAEL T H. Big gears better inspection[J]. Gear Solutions, 2010(2): 34-36. -

下载:

下载: