-

摘要:

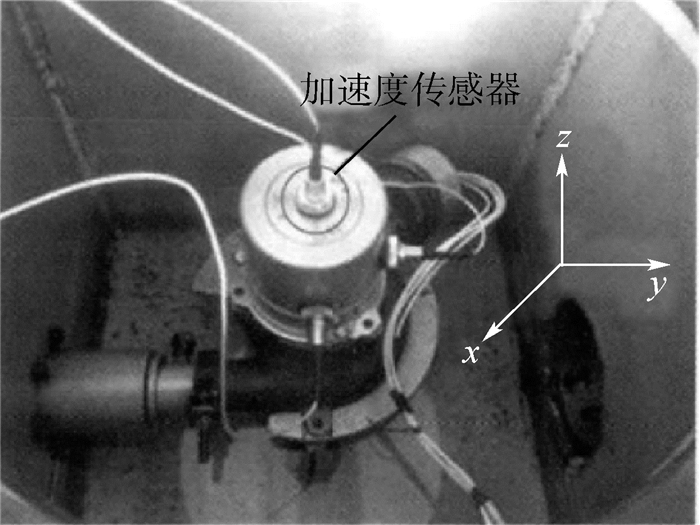

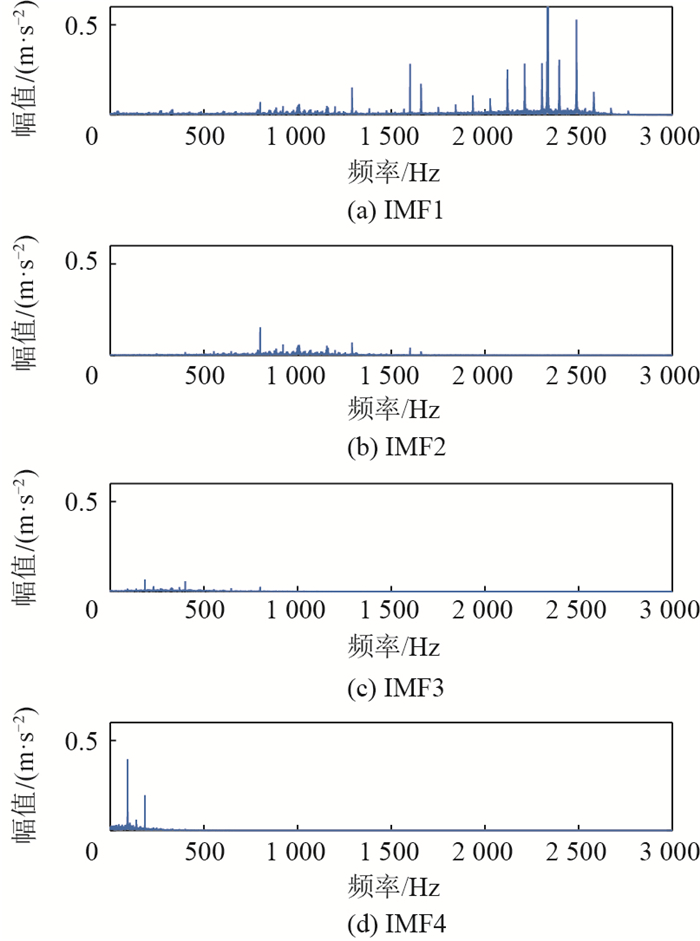

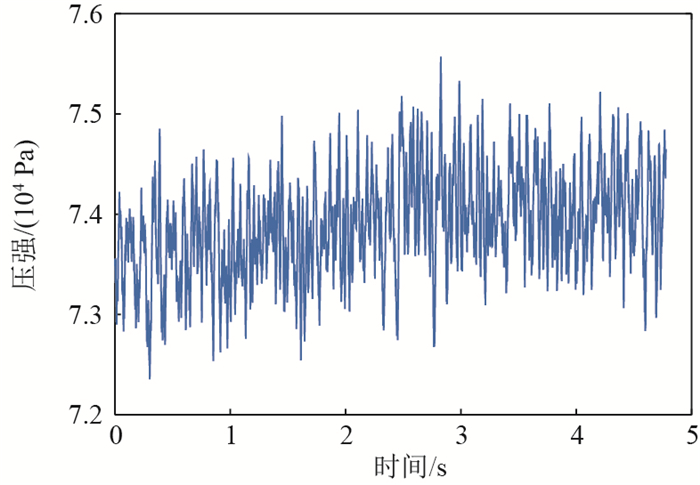

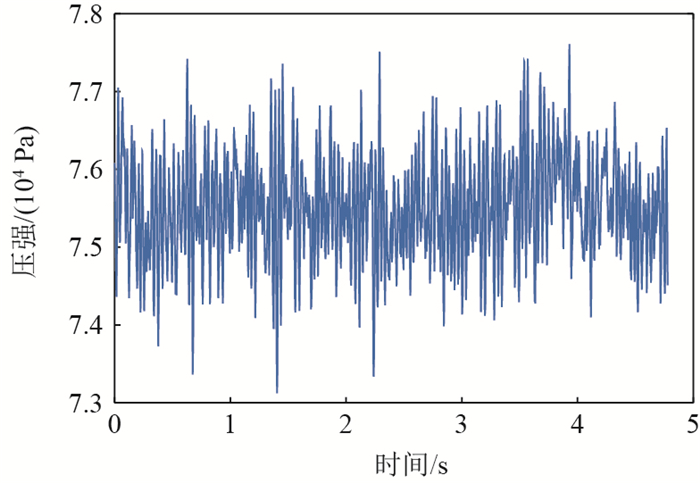

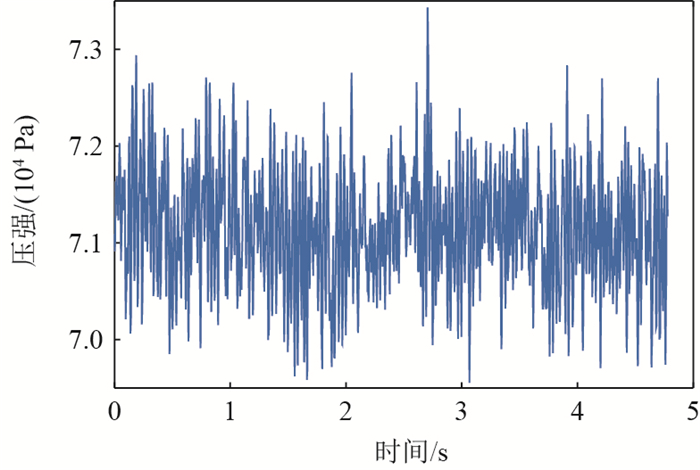

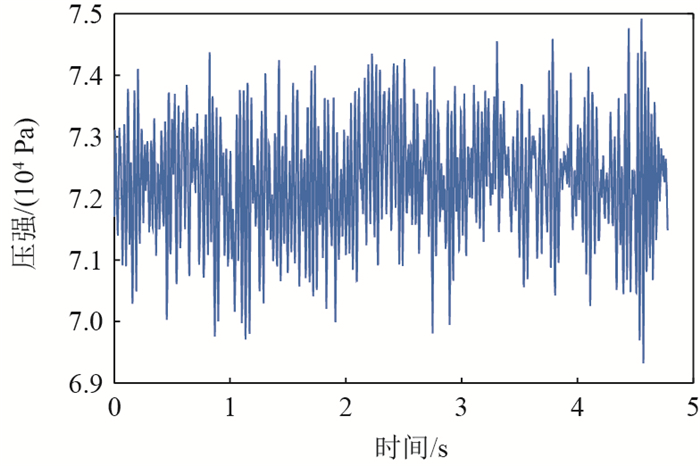

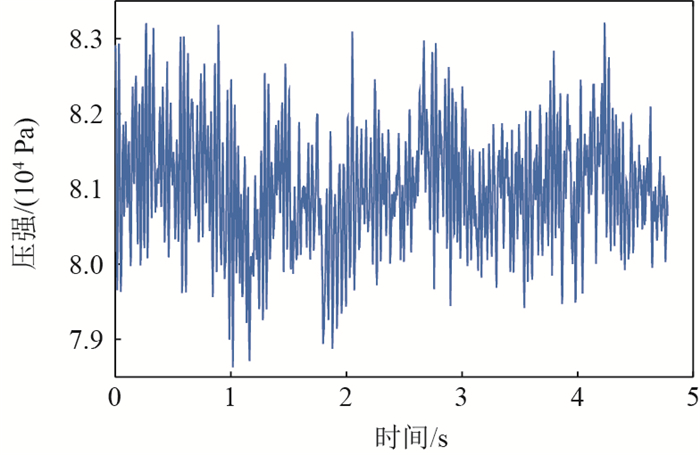

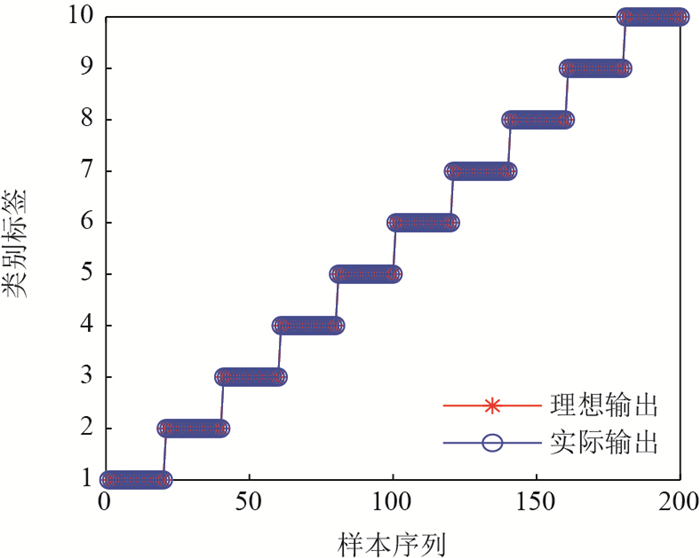

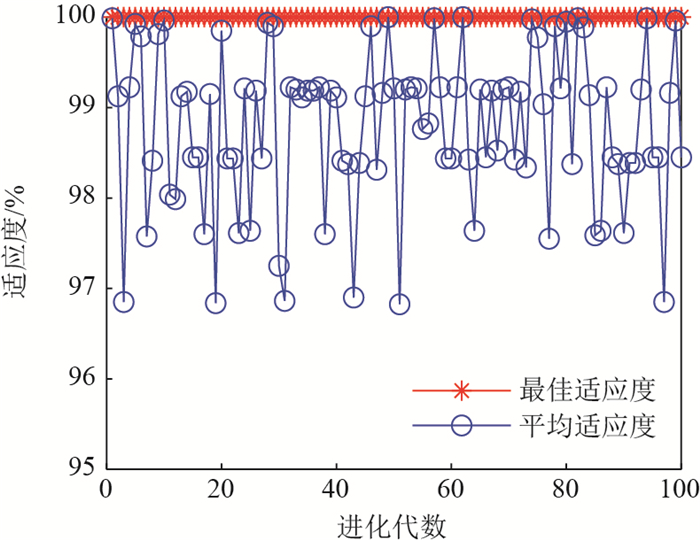

针对机载燃油泵故障数据来源较少、诊断效率较低、维护费用较高、缺乏有效故障特征的问题,利用机载燃油转输系统实验平台收集的振动信号和压力信号,提出了一种基于经验模态分解(EMD)和支持向量机(SVM)的机载燃油泵故障诊断方法。首先,利用EMD提取振动信号不同频段的能量值作为特征参量,并结合压力信号均值构造故障特征向量;其次,分别采用遗传算法(GA)、粒子群优化算法(PSO)、樽海鞘群算法(SSA)、网格搜索算法(GS)对SVM的惩罚参数和径向基函数(RBF)参数进行优化,并对优化后的SVM诊断性能进行了评估;最后,分别采用SVM、极限学习机(ELM)、BP神经网络作为分类器,并对3种分类器的诊断性能进行了评估。结果表明:采用3种群智能优化算法的SVM故障诊断率均能达到100%,寻优过程中均未陷入局部最优解,且寻优时间相当,其中GA的训练时间最短,可以采用GA对SVM参数进行寻优;当采用GA_SVM作为故障分类器时,用时较短,且故障诊断率较高,可以选用GA_SVM分类模型实现机载燃油泵的高效故障诊断。

-

关键词:

- 燃油泵 /

- 实验平台 /

- 经验模态分解(EMD) /

- 支持向量机(SVM) /

- 遗传算法(GA)

Abstract:For the problems of less onboard fuel pump fault data source, low diagnosis efficiency, high maintenance costs, and lack of effective fault characteristics, we use vibration signals and pressure signals collected from onboard fuel transfer system experimental platform, and put forward an onboard fuel pump fault diagnosis method based on Empirical Mode Decomposition (EMD) and Support Vector Machine (SVM). First, EMD is used to extract values of vibration signals energy as characteristic parameters at different frequency bands, and fault characteristic vectors are constructed by combining with the mean value of port pressure signals. Then, Genetic Algorithm (GA), Particle Swarm Optimization (PSO), Salp Swarm Algorithm (SSA) and Grid Search (GS) algorithm are used to optimize the penalty parameters c and Radial Basis Function (RBF) parameters g of SVM, and the optimized SVM diagnostic performance is evaluated. Finally, SVM, Extreme Learning Machine (ELM) and BP neural network are used as classifiers, and the diagnostic performance of the three classifiers is evaluated. The results show that the fault diagnosis rates of the SVM using the three-population intelligent optimization algorithm can reach 100%, none of them fall into the local optimal solution during the optimization process, and the optimization time is equal. Among them, the training time of GA is the shortest, so GA can be used to optimize the SVM parameters. When GA_SVM is used as the fault classifier, the time is shorter and the fault diagnosis rate is higher. Therefore, the GA_SVM classification model can be used to realize the efficient fault diagnosis of airborne fuel pump.

-

表 1 产品主要工作参数

Table 1. Main working parameters of product

参数 数值 泵流量/(L·h-1) 12 000 泵增压/kPa ≥73 电压/V 27 电流/A ≤5.5 漏油量/(mL·min-1) 0 表 2 不同故障状态的归一化IMF能量

Table 2. Normalized IMF energy in different fault states

故障模式 IMF1 IMF2 IMF3 IMF4 叶片损伤1片 0.012 6 0.549 4 0.017 8 0.072 3 叶片损伤2片 0.484 6 0.121 3 0.012 2 0.096 0 表 3 各工作状态下压力信号均值

Table 3. Average pressure under different working conditions

机载燃油泵工作状态 压力信号均值/kPa 正常 74.094 叶片损伤1片 75.379 叶片损伤2片 73.788 叶片损伤10片 56.660 扩散管损伤 71.208 叶片损伤10片+扩散管损伤 52.354 扩散管与叶轮刮蹭 72.480 泵口与叶轮刮蹭 81.212 渗漏 72.284 轴承磨损0.02 mm 72.379 表 4 燃油泵数据采集参数

Table 4. Fuel pump data acquisition parameters

参数 数值 燃油泵转速/(r·min-1) 5 000 采样频率/kHz 6 采样时间/s 5 测量通道 3振动 1压力 记录组数 100 表 5 归一化特征参数

Table 5. Normalized partial characteristic parameters

状态 EV1 EV2 EV3 EV4 EP 正常状态 0.204 6 0.028 5 0.102 6 0.010 7 0.730 7 0.404 2 0.091 1 0.042 0 0.033 2 0.643 0 … 叶片损伤1片 0.975 0 0.952 3 0.012 1 0.010 0 0.673 2 0.201 4 0.023 5 0.079 9 0.008 9 0.748 0 … 叶片损伤2片 0.983 6 0.921 8 0.021 5 0.079 9 0.682 7 0.441 6 0.111 7 0.018 4 0.092 8 0.747 6 … ⋮ 轴承磨损0.02 mm 0.978 3 0.940 5 0.017 0 0.093 0 0.688 1 0.973 5 0.897 1 0.017 1 0.085 2 0.685 7 … 表 6 故障特征参数

Table 6. Fault characteristic parameters

状态 训练样本编号 EV1 EV2 EV3 EV4 EP 分类标签 正常状态 1~80 0.192 0 0.005 5 0.070 8 0.013 8 0.749 2 1 0.192 3 0.016 1 0.069 5 0.011 6 0.749 2 … 叶片损伤1片 81~160 0.002 6 0.479 7 0.025 8 0.060 6 0.806 2 2 0.002 3 0.433 7 0.025 6 0.058 2 0.795 4 … 叶片损伤2片 161~240 0.437 3 0.098 9 0.023 0 0.091 5 0.742 0 3 0.550 3 0.218 6 0.012 0 0.091 2 0.749 4 … ⋮ 轴承磨损0.02mm 721~800 0.965 3 0.866 8 0.017 7 0.089 6 0.675 5 10 0.975 2 0.901 2 0.012 8 0.101 8 0.672 1 … 表 7 算法寻优性能对比

Table 7. Comparison of algorithm optimization performance

优化算法 训练时间/s 故障诊断率/% PSO 54.15 100 GA 19.86 100 SSA 47.55 100 GS 88.57 100 表 8 各分类器评估指标

Table 8. Evaluation index of each classifier

分类器 用时/s 故障诊断率/% 诊断方差 BP神经网络 3.000 0 97.95 16.006 4 ELM 0.006 7 86.95 11.907 5 常规SVM 0.005 0 99.95 0.020 3 GA_SVM 0.005 1 100 0 -

[1] HAYLOCK J A, MECROW B C, JACK A G, et al. Operation of a fault tolerant PM drive for an aerospace fuel pump application[J]. IEE Proceedings Electric Power Applications, 1998, 145(5): 441-448. doi: 10.1049/ip-epa:19982164 [2] 冯威, 于劲松, 袁海文, 等. 机载燃油系统在线实时健康管理[J]. 北京航空航天大学学报, 2013, 39(12): 1639-1643. https://bhxb.buaa.edu.cn/CN/Y2013/V39/I12/1639FENG W, YU J S, YUAN H W, et al. Online real-time health management for aerial fuel delivery system[J]. Journal of Beijing University of Aeronautics and Astronautics, 2013, 39(12): 1639-1643(in Chinese). https://bhxb.buaa.edu.cn/CN/Y2013/V39/I12/1639 [3] MURALIDHARAN V, SUGUMARAN V. Rough set based rule learning and fuzzy classification of wavelet features for fault diagnosis of monoblock centrifugal pump[J]. Measurement, 2013, 46(9): 3057-3063. doi: 10.1016/j.measurement.2013.06.002 [4] TIAN J W, GAO M J, LI K, et al. Fault detection of oil pump based on classify support vector machine[C]//2007 IEEE International Conference on Control and Automation. Piscataway: IEEE Press, 2007: 549-553. [5] HANCOCK K M, ZHANG Q. A hybrid approach to hydraulic vane pump condition monitoring and fault detection[J]. Transactions of the ASABE, 2006, 49(4): 1203-1211. doi: 10.13031/2013.21720 [6] GAO Y, ZHANG Q, KONG X. Comparison of hydraulic faults diagnosis methods: Avelet vs. spectral analyses[C]//Proceedings of the ASME Fluid Power Systems and Technology Division, 2005: 73-78. [7] 焦晓璇, 景博, 黄以锋, 等. 基于小波包BP_AdaBoost算法的机载燃油泵故障诊断研究[J]. 仪器仪表学报, 2016, 37(9): 1978-1988. doi: 10.3969/j.issn.0254-3087.2016.09.008JIAO X X, JING B, HUANG Y F, et al. Research on fault diagnosis for airborne fuel pump based on wavelet package and BP_AdaBoost algorithm[J]. Chinese Journal of Scientific Instrument, 2016, 37(9): 1978-1988(in Chinese). doi: 10.3969/j.issn.0254-3087.2016.09.008 [8] ZHANG X D, TANG L, DECASTRO J. Robust fault diagnosis of aircraft engines: A nonlinear adaptive estimation-based approach[J]. IEEE Transactions on Control Systems Technology, 2013, 21(3): 861-868. doi: 10.1109/TCST.2012.2187057 [9] 孔凡国, 张永孝, 宋剑虹. 经验模态分解在密封轴承故障诊断中的应用[J]. 机械设计与研究, 2011, 27(3): 70-72.KONG F G, ZHANG Y X, SONG J H. Sealed bearing fault diagnosis method based on empirical mode decomposition[J]. Machine Design & Research, 2011, 27(3): 70-72(in Chinese). [10] 焦晓璇, 景博, 羌晓清, 等. 机载燃油泵故障诊断及实验平台研究[J]. 振动与冲击, 2017, 36(1): 120-128.JIAO X X, JING B, QIANG X Q, et al. Fault diagnosis and test platform for airborne fuel pumps[J]. Journal of Vibration and Shock, 2017, 36(1): 120-128(in Chinese). [11] 彭喜元, 彭宇, 戴毓丰. 群智能理论及应用[J]. 电子学报, 2003, 31(S1): 1982-1988.PENG X Y, PENG Y, DAI Y F. Swarm intelligence theory and applications[J]. Acta Electronica Sinica, 2003, 31(S1): 1982-1988(in Chinese). [12] 张超, 陈建军, 徐亚兰. 基于EMD分解和奇异值差分谱理论的轴承故障诊断方法[J]. 振动工程学报, 2011, 24(5): 539-545. doi: 10.3969/j.issn.1004-4523.2011.05.012ZHANG C, CHEN J J, XU Y L. A bearing fault diagnosis method based on EMD and difference spectrum theory of singular value[J]. Journal of Vibration Engineering, 2011, 24(5): 539-545(in Chinese). doi: 10.3969/j.issn.1004-4523.2011.05.012 [13] 张超, 陈建军, 郭迅. 基于EMD能量熵和支持向量机的齿轮故障诊断方法[J]. 振动与冲击, 2010, 29(10): 216-220. doi: 10.3969/j.issn.1000-3835.2010.10.045ZHANG C, CHEN J J, GUO X. A gear fault diagnosis method based on EMD energy entropy and SVM[J]. Journal of Vibration and Shock, 2010, 29(10): 216-220(in Chinese). doi: 10.3969/j.issn.1000-3835.2010.10.045 [14] 陈晋音, 熊晖, 郑海斌. 基于粒子群算法的支持向量机的参数优化[J]. 计算机科学, 2018, 45(6): 203-209.CHEN J Y, XIONG H, ZHENG H B. Parameters optimization for SVM based on particle swarm algorithm[J]. Computer Science, 2018, 45(6): 203-209(in Chinese). [15] 戴邰武, 陈强强, 戴浩然, 等. 基于MFE-GASVM的机载燃油泵故障诊断[J]. 计算机测量与控制, 2020, 28(1): 8-10.DAI T W, CHEN Q Q, DAI H R, et al. Airborne fuel pumps diagnosis based on MFE-GASVM[J]. Computer Measurement & Control, 2020, 28(1): 8-10(in Chinese). -

下载:

下载: