Experimental and computational study on blade surface pressure measurement of coaxial rigid rotor in hovering state

-

摘要:

针对共轴刚性模型旋翼悬停状态,开展了桨叶表面压力测量试验与数值模拟研究。试验采用微型压力传感器进行桨叶表面压力测量,不仅获得了桨叶表面压力的试验数据,同时为CFD计算方法计算桨叶表面压力提供了验证数据。计算与试验结果对比吻合度良好,验证了CFD计算方法的有效性。研究获得了共轴刚性旋翼上下旋翼桨叶表面的流动情况和压力特性,结果表明:对于上下各4片桨叶的共轴刚性旋翼,桨叶表面压力随着桨叶旋转呈周期性变化,旋转一周出现8个小周期;在上下旋翼扭矩配平的悬停状态,下旋翼桨叶大部分区域受下洗流影响,下旋翼剖面拉力低于上旋翼;在桨尖区域,下旋翼的桨距角大于上旋翼,受各自上洗流的影响,下旋翼剖面拉力高于上旋翼。

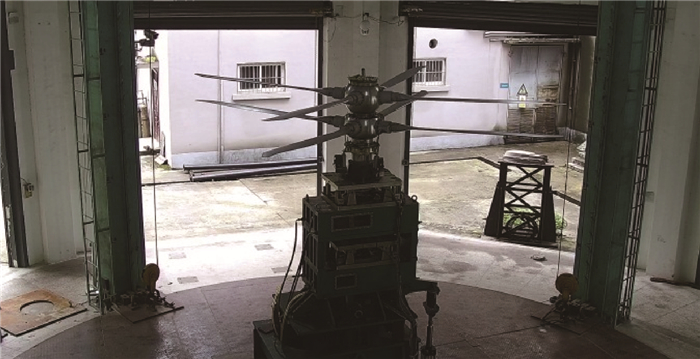

Abstract:For the coaxial rigid model rotor in hovering state, the experimental and numerical simulation research on blade surface pressure measurement were carried out. The micro pressure sensor was used to measure the blade surface pressure, which not only obtains the experimental data of blade surface pressure, but also provides verification data for CFD method to calculate the blade surface pressure. The calculation results are in good agreement with the experimental results, which verifies the effectiveness of CFD method. The flow and pressure characteristics of the upper and lower rotor blade surface of the coaxial rigid rotor were obtained. The results show that, for coaxial rigid rotor with 4 upper blades and 4 lower blades, the blade surface pressure changes periodically with the rotation of the blade, and there are eight small cycles in one rotation cycle. In the hovering state of the upper and lower torque balancing, most of the area of the lower rotor blade is affected by the downwash flow, and the profile pull of the lower rotor is lower than that of the upper rotor; total pitch angle of the lower rotor in the tip region is larger than that of the upper rotor, and affected by respective upwash flow, the profile pull of the lower rotor is higher than that of the upper rotor.

-

表 1 旋翼参数

Table 1. Rotor parameters

参数 数值 桨毂半径/mm 272 桨叶片数 4+4 旋翼旋转方向 上旋翼:逆时针; 下旋翼:顺时针 旋翼半径R/m 2 旋翼转速N/(r·min-1) 778 旋翼间距 0.15R 翼型 OA3/4系列 -

[1] 吴希明. 高速直升机发展现状、趋势与对策[J]. 南京航空航天大学学报2015, 47(2): 173-179. https://www.cnki.com.cn/Article/CJFDTOTAL-NJHK201502002.htmWU X M. Current status, development trend and countermeasure for high-speed rotorcraft[J]. Journal of Nanjing University of Aeronautics & Astronautics, 2015, 47(2): 173-179(in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-NJHK201502002.htm [2] GREG L P, ANGSHUMAN B S. JMR development[C]//American Helicopter Society 72th Annual Forum, 2016: 389-399. [3] 邓景辉. 高速直升机前行桨叶概念旋翼技术[J]. 航空科学技术, 2012(3): 9-14. doi: 10.3969/j.issn.1007-5453.2012.03.003DENG J H. The ABC rotor technology for high speed helicopter[J]. Aeronautical Science & Technology, 2012(3): 9-14(in Chinese). doi: 10.3969/j.issn.1007-5453.2012.03.003 [4] RUDDELL J A, MACRINO J A. Advancing blade concept(ABC)TM high speed development[C]// American Helicopter Society 36th Annual Forum, 1980: 1-13. [5] PAGLINO V M, BENO E A. Full-scale wind tunnel investigation of the advancing blade concept rotor system[R]. United Aircraft Corp Stratford Conn Sikorsky Aircraft Div, 1971: 1-13. [6] KIM H W, KENYON A R, BROWN R E, et al. Interactional aerodynamics and acoustics of a hingeless coaxial helicopter with an auxiliary propeller in forward flight[J]. Aeronautical Journal, 2009, 113(1140): 65-78. doi: 10.1017/S0001924000002797 [7] WALSH G, JACOBELLIS G. An acoustic investigation of a coaxial helicopter in high-speed flight[C] //American Helicopter Society 72th Annual Forum, 2016: 322-354. [8] SCHATZMAN N L. Aerodynamics and aeroacoustic sources of a coaxial rotor[D]. Atlanta: Georgia Institute of Technology, 2018: 67-90. [9] SHAMA K, BRENTNER K S, JIA Z, et al. Aeroacoustic study of lift offset coaxial rotor using free wake analysis[C] //American Helicopter Society 75th Annual Forum, 2019: 400-417. [10] LORBER P, LAW G, O'NEILL J, et al. Overview of S-97 RAIDRTM scale modle tests[C] //American Helicopter Society 72th Annual Forum, 2016: 143-160. [11] 张昆. 基于CFD方法的高速直升机共轴刚性双旋翼的气动特性研究[D]. 南京: 南京航空航天大学. 2012: 74-84.ZHANG K. Researches on aerodynamic characteristics of rigid coaxial rotor of high-speed helicopter based on CFD method[D]. Nanjing: Nanjing University of Aeronautics and Astronautics, 2012: 74-84(in Chinese). [12] 叶靓, 徐国华. 共轴式双旋翼悬停流场和气动力的CFD计算[J]. 空气动力学学报, 2012, 30(4): 437-442. doi: 10.3969/j.issn.0258-1825.2012.04.003YE L, XU G H. Calculation on flow field and aerodynamic force of coaxial rotors in hover with CFD method [J]. Acta Aerodynamica Sinica, 2012, 30(4): 437-442(in Chinese). doi: 10.3969/j.issn.0258-1825.2012.04.003 [13] 谭剑锋, 孙义鸣, 王浩文, 等. 共轴刚性双旋翼非定常气动干扰载荷分析[J]. 北京航空航天大学学报, 2018, 44(1): 50-62. doi: 10.13700/j.bh.1001-5965.2017.0033TAN J F, SUN Y M, WANG H W, et al. Analysis of rigid coaxial rotor unsteady interactional aerodynamic loads[J]. Journal of Beijing University of Aeronautics and Astronautics, 2018, 44(1): 50-62(in Chinese). doi: 10.13700/j.bh.1001-5965.2017.0033 [14] 吴希明, 祁浩天, 马率, 等. 共轴刚性旋翼气动干扰数值计算方法研究[J]. 南京航空航天大学学报, 2019, 51(2): 147-153. https://www.cnki.com.cn/Article/CJFDTOTAL-NJHK201902003.htmWU X M, QI H T, MA S, et al. Research on numerical method of coaxial rigid rotor aerodynamic interaction[J]. Journal of Nanjing University of Aeronautics & Astronautics, 2019, 51(2): 147-153(in Chinese). https://www.cnki.com.cn/Article/CJFDTOTAL-NJHK201902003.htm [15] DENG J H, FAN F, LIU P A, et al. Aerodynamic characteristics of rigid coaxial rotor by wind tunnel test and numerical calculation[J]. Chinese Journal of Aeronautics, 2019, 32(3): 568-576. http://www.sciencedirect.com/science/article/pii/S1000936119300421 [16] 杨永飞, 林永峰, 樊枫, 等, 共轴刚性旋翼流场测量试验研究[J]. 南京航空航天大学学报, 2019, 51(2): 178-187. https://www.cnki.com.cn/Article/CJFDTOTAL-NJHK201902008.htmYANG Y F, LIN Y F, FAN F, et al. Flow field measurement investigation on rigid coaxial rotor[J]. Journal of Nanjing University of Aeronautics & Astronautics, 2019, 51(2): 178-187(in Chinese). https://www.cnki.com.cn/Article/CJFDTOTAL-NJHK201902008.htm [17] 章贵川, 彭先敏, 车兵辉, 等. 共轴刚性旋翼试验自动配平技术研究[J]. 南京航空航天大学学报, 2019, 51(2): 227-232. https://www.cnki.com.cn/Article/CJFDTOTAL-NJHK201902015.htmZHANG G C, PENG X M, CHE B H, et al. Research on automatic trim technology of coaxial rigid rotor test[J]. Journal of Nanjing University of Aeronautics & Astronautics, 2019, 51(2): 227-232(in Chinese). https://www.cnki.com.cn/Article/CJFDTOTAL-NJHK201902015.htm [18] 樊枫. 直升机非定常干扰流场与声场的计算方法研究及应用[D]. 南京: 南京航空航天大学, 2013: 25-59.FAN F. Research on numerical methods for unsteady interaction flowfield and aerocoustics of helicopters and their applications[D]. Nanjing: Nanjing University of Aeronautics and Astronautics, 2013: 25-59(in Chinese). [19] QI H T, XU G H, LU C, et al. A study of coaxial rotor aerodynamic interaction mechanism in hover with high-efficient trim model[J]. Aerospace Science and Technology, 2019, 84: 1116-1130. http://www.onacademic.com/detail/journal_1000041581724899_29d8.html -

下载:

下载: