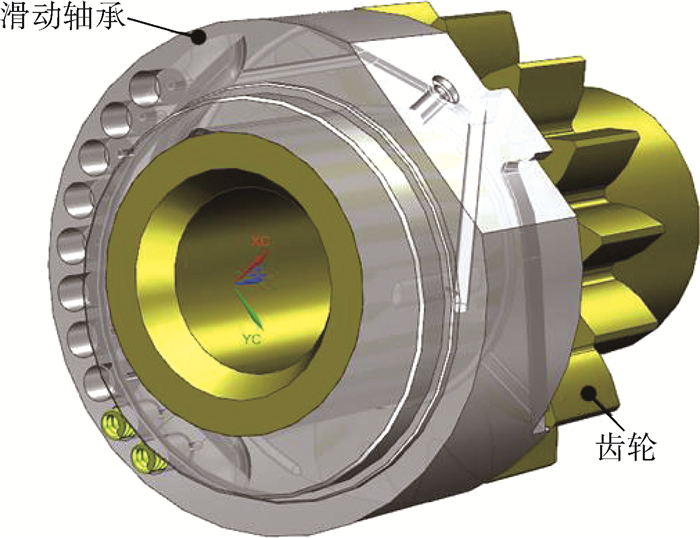

Reliability analysis of journal bearings inside aero-gear pump based on AK-IS method

-

摘要:

为研究高转速、低介质黏度运行的航空齿轮泵滑动轴承动压润滑可靠性,通过将Reylonds润滑方程与影响矩阵耦合,建立了考虑轴瓦弹性变形的航空齿轮泵滑动轴承弹流润滑(EHL)模型。考虑滑动轴承尺寸公差和运行工况等引起的不确定性,将与滑动轴承润滑特性密切相关的动压润滑的压力峰值作为可靠性判据,采用自适应Kriging和重要抽样法相结合的AK-IS法对滑动轴承动压润滑特性进行了可靠性及灵敏度计算。研究结果表明:考虑轴瓦弹性变形的压力峰值比刚性轴瓦压力峰值降低15.04%,表明滑动轴承弹流润滑对轴承动压润滑的影响不能忽略;基于AK-IS法的航空齿轮泵滑动轴承动压润滑可靠性分析具有准确性和高效性;各不确定因素对动压润滑可靠性的影响程度不同,其中轴承的半径间隙对可靠性最敏感,转速对可靠性最不敏感。

Abstract:To study the hydrodynamic lubrication reliability of journal bearings inside aero-gear pumps running at high speed and with low medium viscosity, an elastohydrodynamic lubrication (EHL) model considering elastic deformation of bearing bush is established by coupling Reynolds lubrication equation with influence matrix. Considering the uncertainty caused by the size tolerance and operating conditions of journal bearings, the peak pressure of hydrodynamic lubrication, which is closely related to the lubrication characteristics of journal bearings, is taken as the reliability criterion. The AK-IS method combining adaptive Kriging and importance sampling is used to calculate the reliability and sensitivity of the hydrodynamic lubrication characteristics of journal bearings. The results show that considering bearing deformation, the pressure peak value of journal bearings is 15.04% lower than that of rigid bearings, and hence the influence of EHL on hydrodynamic lubrication of bearings cannot be neglected. The results also show the accuracy and efficiency of the AK-IS based reliability analysis of hydrodynamic lubrication of journal bearings. Moreover, the degree of the effect of various uncertainties on the reliability of hydrodynamic lubrication is different, with the radius clearance of bearings being the most sensitive to reliability, and the rotational speed the least.

-

表 1 滑动轴承随机变量分布参数

Table 1. Random variable distribution parameters of journal bearing

参数 分布形式 平均值 标准差 轴承宽度B/mm Normal 30 0.011 齿轮轴半径R/mm Normal 9.97 0.01 半径间隙C/mm Normal 0.03 0.005 转速n/(r·min-1) Normal 7 000 500 介质黏度η/(Pa·s) Normal 9.66×10-4 0.1 偏心率ε Normal 0.8 0.01 表 2 滑动轴承可靠度计算结果

Table 2. Calculation resucts of reliability of sliding bearing

方法 Ncall N

ξ/% MCS 107 3.22 0 IS 103 3.230 2 0.317 AK-MCS 200 1 290 000 3.233 2 0.41 AK-IS 49 11 000 3.233 9 0.432 表 3 滑动轴承灵敏度计算结果

Table 3. Calculation of results of sensitivity analysis of sliding bearing

参数 数值 参数 数值 ∂Pf/∂μB 1.55×10-2 ∂Pf/∂σB 7.68×10-6 ∂Pf/∂μR 0.261 ∂Pf/∂σR 1.97×10-3 ∂Pf/∂μC -2.32×102 ∂Pf/∂σC 7.78×102 ∂Pf/∂μn 2.15×10-7 ∂Pf/∂σn 6.66×10-8 ∂Pf/∂μη 1.422 476 ∂Pf/∂ση 0.625 ∂Pf/∂με 0.012 163 ∂Pf/∂σε 3.57×10-3 -

[1] HUANG P. Numerical calculation of lubrication[M]. Singapore: John Wiley & Sons Singapore Pte. Ltd., 2013. [2] TAKABI J, KHONSARI M M. On the dynamic performance of roller bearings operating under low rotational speeds with consideration of surface roughness[J]. Tribology International, 2015, 86: 62-71. doi: 10.1016/j.triboint.2015.01.011 [3] 符江锋, 李华聪, 樊丁, 等. 一种自冷却结构燃油泵滑动轴承润滑特性分析[J]. 北京航空航天大学学报, 2018, 44(10): 2052-2062. doi: 10.13700/j.bh.1001-5965.2017.0762FU J F, LI H C, FAN D, et al. Lubrication characteristics analysis of a type of self-cooling structure fuel pump sliding bearings[J]. Journal of Beijing University of Aeronautics and Astronautics, 2018, 44(10): 2052-2062(in Chinese). doi: 10.13700/j.bh.1001-5965.2017.0762 [4] CHENG F, JI W X. A new model of water-gas turbulent lubrication for analysis of the static and dynamic characteristics in a journal bearing[J]. Proceedings of the Institution of Mechanical Engineers, Part J: Journal of Engineering Tribology, 2016, 230(12): 1439-1451. doi: 10.1177/1350650116635927 [5] LIN Q Y, BAO Q K, LI K J, et al. An investigation into the transient behavior of journal bearing with surface texture based on fluid-structure interaction approach[J]. Tribology International, 2018, 118: 246-255. doi: 10.1016/j.triboint.2017.09.026 [6] 王琳, 张瑜, 陈国定. 高速高比压织构滑动轴承热弹流润滑分析[J]. 西北工业大学学报, 2019, 37(4): 751-756. doi: 10.3969/j.issn.1000-2758.2019.04.015WANG L, ZHANG Y, CHEN G D. Thermo-elastohydrodynamic study on textured journal bearing with high-speed and high-specific-pressure[J]. Journal of Northwestern Polytechnical University, 2019, 37(4): 751-756(in Chinese). doi: 10.3969/j.issn.1000-2758.2019.04.015 [7] 金燕, 刘少军. 基于人工神经网络的航空轴承疲劳可靠性分析[J]. 东北大学学报(自然科学版), 2018, 39(6): 850-855. https://www.cnki.com.cn/Article/CJFDTOTAL-DBDX201806018.htmJIN Y, LIU S J. Fatigue reliability analysis of aviation bearings based on ANN[J]. Journal of Northeastern University (Natural Science), 2018, 39(6): 850-855(in Chinese). https://www.cnki.com.cn/Article/CJFDTOTAL-DBDX201806018.htm [8] 冯吉路, 孙志礼, 赵坚, 等. 基于AK-MCS法的主轴系统振动可靠性分析[J]. 振动与冲击, 2019, 38(18): 135-140. https://www.cnki.com.cn/Article/CJFDTOTAL-ZDCJ201918019.htmFENG J L, SUN Z L, ZHAO J, et al. Vibration reliability analysis on a spindle system based on AK-MCS method[J]. Journal of Vibration and Shock, 2019, 38(18): 135-140(in Chinese). https://www.cnki.com.cn/Article/CJFDTOTAL-ZDCJ201918019.htm [9] 胡明用, 李昌, 韩兴, 等. 基于Monte-Carlo法的滚动轴承-转子系统非线性随机振动可靠性分析[J]. 轴承, 2018(8): 27-31. https://www.cnki.com.cn/Article/CJFDTOTAL-CUCW201808007.htmHU M Y, LI C, HAN X, et al. Reliability analysis on nonlinear random vibration of rolling bearing-rotor system based on Monte-Carlo method[J]. Bearing, 2018(8): 27-31(in Chinese). https://www.cnki.com.cn/Article/CJFDTOTAL-CUCW201808007.htm [10] 李洪双, 马远卓. 结构可靠性分析与随机优化设计的统一方法[M]. 北京: 国防工业出版社, 2015: 51-55.LI H S, MA Y Z. Unified methods for structural reliability analysis and stochastic optimization design[M]. Beijing: National Defense Industry Press, 2015: 51-55(in Chinese). [11] ZHANG F, LU Z Z, CUI L J, et al. Reliability sensitivity algorithm based on stratified importance sampling method for multiple failure modes systems[J]. Chinese Journal of Aeronautics, 2010, 23(6): 660-669. doi: 10.1016/S1000-9361(09)60268-5 [12] TSIRIKOGLOU P, ABRAHAM S, CONTINO F, et al. A hyperparameters selection technique for support vector regression models[J]. Applied Soft Computing, 2017, 61: 139-148. doi: 10.1016/j.asoc.2017.07.017 [13] 洪林雄, 李华聪, 彭凯, 等. 基于高效搜索方法的可靠性分析改进响应面法[J]. 北京航空航天大学学报, 2020, 46(1): 95-102. doi: 10.13700/j.bh.1001-5965.2019.0169HONG L X, LI H C, PENG K, et al. Improved response surface method of reliability analysis based on efficient search method[J]. Journal of Beijing University of Aeronautics and Astronautics, 2020, 46(1): 95-102(in Chinese). doi: 10.13700/j.bh.1001-5965.2019.0169 [14] KAYMAZ I. Application of Kriging method to structural reliability problems[J]. Structural Safety, 2005, 27(2): 133-151. doi: 10.1016/j.strusafe.2004.09.001 [15] 洪林雄, 李华聪, 彭凯, 等. 基于改进学习策略的Kriging模型结构可靠度算法[J]. 西北工业大学学报, 2020, 38(2): 412-419. doi: 10.3969/j.issn.1000-2758.2020.02.023HONG L X, LI H C, PENG K, et al. Structural reliability algorithms of Kriging model based on improved learning strategy[J]. Journal of Northwestern Polytechnical University, 2020, 38(2): 412-419(in Chinese). doi: 10.3969/j.issn.1000-2758.2020.02.023 [16] 吕震宙, 宋述芳, 李璐祎. 结构/机构可靠性设计基础[M]. 西安: 西北工业大学出版社, 2019: 216-236.LYU Z Z, SONG S F, LI L Y. Reliability design basis of structural mechanism[M]. Xi'an: Northwestern Polytechnical University Press, 2019: 216-236(in Chinese). [17] ECHARD B, GAYTON N, LEMAIRE M, et al. A combined importance sampling and Kriging reliability method for small failure probabilities with time-demanding numerical models[J]. Reliability Engineering & System Safety, 2013, 111: 232-240. [18] ZHOU H, DU R L, XIE A H, et al. Investigations of the micro surface shape for the gear-shaft/journal-bearing interface in water hydraulic internal gear pumps[J]. Advances in Mechanical Engineering, 2017, 9(11): 168781401774257. [19] 孙志礼, 陈良玉. 实用机械可靠性设计理论与方法[M]. 北京: 科学出版社, 2003: 55-60.SUN Z L, CHEN L Y. Practical mechanical reliability theory and method[M]. Beijing: Science Press, 2003: 55-60(in Chinese). -

下载:

下载: