Design and optimization of large-stroke decoupled three-translational micro-positioning platform

-

摘要:

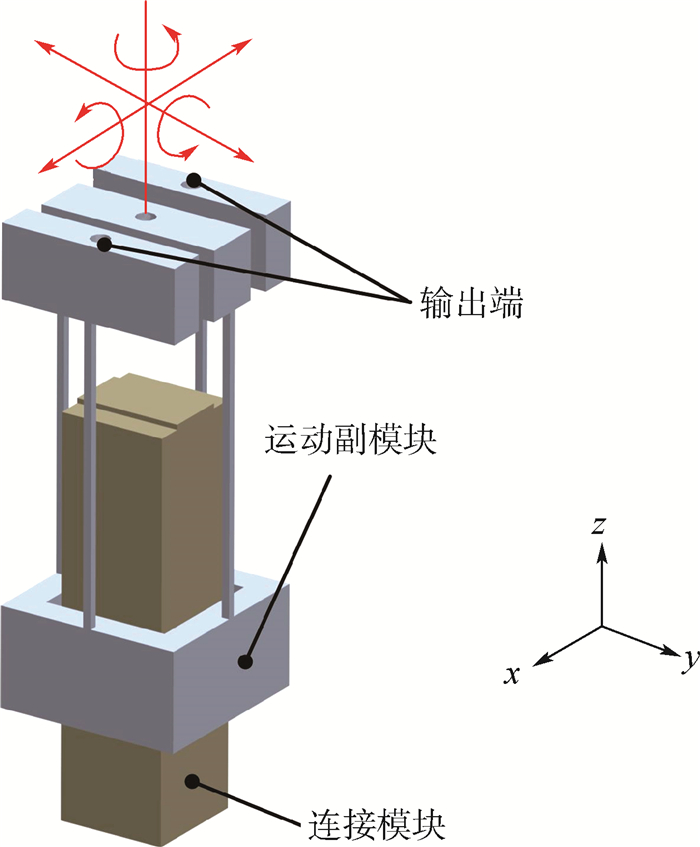

为设计具有大行程与良好解耦特性的三平动微定位平台,提出了一种新型2T3R型运动副。基于2T3R型运动副,设计了三平动微定位平台的结构;采用非线性模型法建立了平台力-位移关系与丢失运动的理论模型,并采用拉格朗日方程建立了平台固有频率的理论模型;采用目标规划法对三平动微定位平台进行了参数优化;通过有限元仿真验证了理论模型的正确性。理论计算与仿真研究结果表明:平台一阶固有频率为51.27 Hz,在1 mm运动行程内,

x 、z 轴方向的丢失运动分别小于0.67%、0.20%,输入与输出完全解耦。研究结果证明了运动副、平台结构设计的有效性及优化模型的可行性。Abstract:To design large-stroke three-translational micro-positioning platforms with excellent decoupling characteristics, a new 2T3R type motion pair was proposed. The structure of three-translational micro-positioning platform was designed based on the 2T3R type motion pair. The theoretical models of force-displacement relationship and lost motion were established by nonlinear model method, the theoretical models of platform natural frequency were established by Lagrange equation. The goal programming method was used to optimize parameters of the micro-positioning platform. The correctness of the above theoretical model was verified by finite element simulation. According to the theoretical calculation and simulation results, the first-order natural frequency of the platform is 51.27 Hz. the lost motions in

x andz directions are less than 0.67% and 0.20% in 1 mm motion stroke, and the input and output motions are completely decoupled. Results show that the structure design of motion pair and platform is effective, and the optimization model is feasible. -

表 1 微定位平台的结构参数

Table 1. Structural parameters of micro-positioning platform

mm 参数 数值 l1 55.00 w1 18.00 t1 0.51 l2 49.96 w2 19.75 t2 0.83 lw 31.62 tw 1.00 表 2 优化前后微定位平台的静、动态性能参数

Table 2. Static and dynamic performance parameters of micro-positioning platform before and after optimization

优化前/后 δxlost/μm δzlost/μm fz/Hz fx-fz/Hz 优化前 9.31 2.62 34.59 23.53 优化后 6.97 2.01 49.74 0.63 优化率/% -25.1 -23.3 43.8 -97.3 表 3 微定位平台输入耦合位移仿真值

Table 3. Simulation value of input coupling displacement for micro-positioning platforms

表 4 微定位平台固有频率的理论值、仿真值及相对误差

Table 4. Theoretical value, simulation value and relative error of natural frequency for micro-positioning platform

阶数 固有频率/Hz 相对误差/% 理论值 仿真值 1 49.74 51.27 3.1 2 50.37 52.44 4.1 3 50.37 53.11 5.4 4 208.57 5 220.31 6 221.65 -

[1] 于靖军, 郝广波, 陈贵敏, 等. 柔性机构及其应用研究进展[J]. 机械工程学报, 2015, 51(13): 53-68. https://www.cnki.com.cn/Article/CJFDTOTAL-JXXB201513006.htmYU J J, HAO G B, CHEN G M, et al. State-of-art of compliant mechanisms and their applications[J]. Journal of Mechanical Engineering, 2015, 51(13): 53-68(in Chinese). https://www.cnki.com.cn/Article/CJFDTOTAL-JXXB201513006.htm [2] 周睿, 周辉, 桂和利, 等. 基于柔性铰链的二自由度微动平台分析及优化[J]. 北京航空航天大学学报, 2018, 44(9): 199-207. doi: 10.13700/j.bh.1001-5965.2017.0706ZHOU R, ZHOU H, GUI H L, et al. Analysis and optimization of 2-DoF micro-positioning stage based on flexible hinges[J]. Journal of Beijing University of Aeronautics and Astronautics, 2018, 44(9): 199-207(in Chinese) doi: 10.13700/j.bh.1001-5965.2017.0706 [3] 李杨民, 汤晖, 徐青松, 等. 面向生物医学应用的微操作机器人技术发展态势[J]. 机械工程学报, 2011, 47(23): 1-13. https://www.cnki.com.cn/Article/CJFDTOTAL-JXXB201123002.htmLI Y M, TANG H, XU Q S, et al. Development status of micromanipulator technology for biomedical applications[J]. Journal of Mechanical Engineering, 2011, 47(23): 1-13(in Chinese). https://www.cnki.com.cn/Article/CJFDTOTAL-JXXB201123002.htm [4] ÖZKALE B, PARREIRA R, BEKDEMIR A, et al. Modular soft robotic micro-devices for dexterous biomanipulation[J]. Lab on a Chip, 2019, 19(5): 778-788. doi: 10.1039/C8LC01200H [5] 王保兴, 孟刚, 林苗, 等. 3-PPP型柔性并联微定位平台的设计与分析[J]. 北京航空航天大学学报, 2020, 46(4): 798-807. doi: 10.13700/j.bh.1001-5965.2019.0286WANG B X, MENG G, LIN M, et al. Design and analysis of a 3-PPP compliant parallel micro-positioning stage[J]. Journal of Beijing University of Aeronautics and Astronautics, 2020, 46(4): 798-807(in Chinese). doi: 10.13700/j.bh.1001-5965.2019.0286 [6] ZHU Z, TO S, ZHU W L, et al. Optimum design of a piezo-actuated triaxial compliant mechanism for nanocutting[J]. IEEE Transactions on Industrial Electronics, 2018, 65(8): 6362-6371. doi: 10.1109/TIE.2017.2787592 [7] WATANABE S, ANDO T. High-speed XYZ nano-positioner for scanning ion conductance microscopy[J]. Applied Physics Letters, 2017, 111(11): 113106. doi: 10.1063/1.4993296 [8] AWTAR S, USTICK J, SEN S. An XYZ parallel kinematic flexure mechanism with geometrically decoupled degrees of freedom[C]//Proceedings of the ASME International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, 2011: 119-126. [9] LI H Y, HAO G B, KAVANAGH R C. A new XYZ compliant parallel mechanism for micro-/nano-manipulation: Design and analysis[J]. Micromachines, 2016, 7(2): 23. doi: 10.3390/mi7020023 [10] HAO G B, LI H Y. Design of 3-legged XYZ compliant parallel manipulators with minimized parasitic rotations[J]. Robotica, 2015, 33(4): 787-806. doi: 10.1017/S0263574714000575 [11] HOPKINS J B, CULPEPPER M L. Synthesis of multi-degree of freedom, parallel flexure system concepts via freedom and constraint topology (FACT). Part I: Principles[J]. Precision Engineering, 2010, 34(2): 259-270. doi: 10.1016/j.precisioneng.2009.06.008 [12] HOPKINS J B, CULPEPPER M L. Synthesis of multi-degree of freedom, parallel flexure system concepts via freedom and constraint topology (FACT). Part Ⅱ: Principles[J]. Precision Engineering, 2010, 34(2): 271-278. doi: 10.1016/j.precisioneng.2009.06.007 [13] XU Q S. A totally decoupled piezo-driven XYZ flexure parallel micropositioning stage for micro/nanomanipulation[J]. IEEE Transactions on Automation Science and Engineering, 2011, 8(2): 265-279. [14] 李海洋, 郝广波, 于靖军, 等. 空间平动柔性并联机构的系统设计方法研究[J]. 机械工程学报, 2018, 54(13): 57-65. https://www.cnki.com.cn/Article/CJFDTOTAL-JXXB201813006.htmLI H Y, HAO G B, YU J J. et al. Systematic approach to the design of spatial translational compliant parallel mechanisms[J]. Journal of Mechanical Engineering, 2018, 54(13): 57-65(in Chinese). https://www.cnki.com.cn/Article/CJFDTOTAL-JXXB201813006.htm [15] ZHANG X Z, XU Q S. Design, fabrication and testing of a novel symmetrical 3-DOF large-stroke parallel micro/nano-positioning stage[J]. Robotics and Computer-Integrated Manufacturing, 2018, 54: 162-172. doi: 10.1016/j.rcim.2017.11.006 [16] HAO G B, KONG X W, MENG Q L. Design and modelling of spatial compliant parallel mechanisms for large range of translation[C]//Proceedings of the ASME International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, 2010, 2: 329-340. [17] 曹毅, 王保兴, 孟刚, 等. 大行程三平动柔性微定位平台的设计分析及优化[J]. 机械工程学报, 2020, 56(17): 71-81. https://www.cnki.com.cn/Article/CJFDTOTAL-JXXB202017008.htmCAO Y, WANG B X, MENG G, et al. Design analysis and optimization of large range spatial translational compliant micro-positioning stage[J]. Journal of Mechanical Engineering, 2020, 56(17): 71-81(in Chinese). https://www.cnki.com.cn/Article/CJFDTOTAL-JXXB202017008.htm [18] 曹毅, 孟刚, 居勇健, 等. 基于2T3R型柔性运动副的微定位平台: CN111785318A[P]. 2020-10-16.CAO Y, MENG G, JU Y J, et al. Micro-positioning stage based on 2T3R compliant kinematic pair: CN111785318A[P]. 2020-10-16(in Chinese). [19] 杨志军, 白有盾, 陈新, 等. 基于应力刚化效应的动态特性可调微动平台设计新方法[J]. 机械工程学报, 2015, 51(23): 153-159. https://www.cnki.com.cn/Article/CJFDTOTAL-JXXB201523019.htmYANG Z J, BAI Y D, CHEN X, et al. A new design method of dynamic characteristics adjustable micro motion stage based on tension stiffening[J]. Journal of Mechanical Engineering, 2015, 51(23): 153-159(in Chinese). https://www.cnki.com.cn/Article/CJFDTOTAL-JXXB201523019.htm [20] YU J J, LI S Z, SU H J, et al. Screw theory based methodology for the deterministic type synthesis of flexure mechanisms[J]. Journal of Mechanisms and Robotics, 2011, 3(3): 1194-1204. [21] MA F L, CHEN G M. Bi-BCM: A closed-form solution for fixed-guided beams in compliant mechanisms[J]. Journal of Mechanisms and Robotics, 2017, 9(1): 014501. [22] HERPE X, WALKER R, DUNNIGAN M, et al. On a simplified nonlinear analytical model for the characterization and design optimization of a compliant XY micro-motion stage[J]. Robotics and Computer-Integrated Manufacturing, 2018, 49: 66-76. [23] HOWELL L L. Compliant mechanisms[M]. New York: John Wiley and Sons, 2001: 302. -

下载:

下载: