Numerical simulation on internal flow performances of multi-stage pressure drop valve

-

摘要:

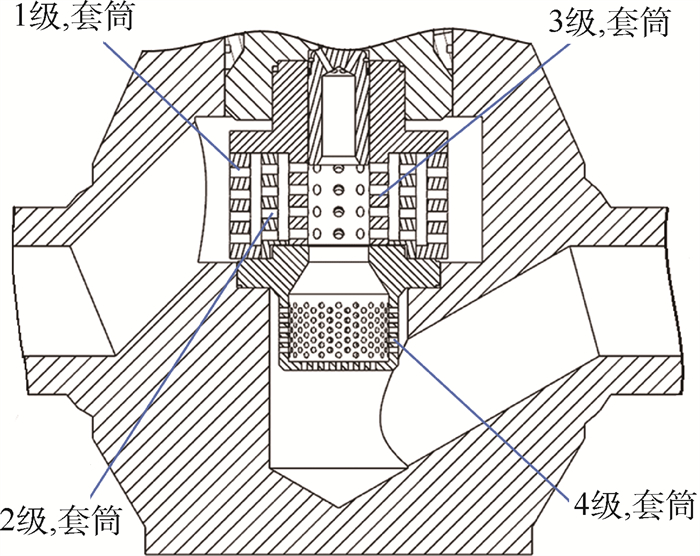

为研究多级降压调节阀内部流动过程和各降压级的压降影响因素及规律,基于Mixture两相流模型和Schnerr-Sauer空化模型的数值计算方法,建立了多级降压调节阀内部流场的计算模型。通过数值模拟计算,获得了调节阀内部的流动特性,分析和探讨不同压差和不同阀门开度下各降压级压降特性。数值计算结果表明:流体流经阀门节流元件时,由于多股流体的强烈掺混和剪切使得阀门内存在大量的漩涡;各降压级的压降存在一定的差异,第3级套筒处的空化程度最大,阀座处更易发生空化;阀门在同一开度下,工质沿各降压级的压降在不同压差下的变化趋势相同;第3降压级的压降随阀门开度的减小而增大,在25%开度下阀门第3降压级的平均压降最大,达到了8 MPa,相同流量下该降压级小孔中工质的速度也增加。研究结果为降压阀的合理设计提供了理论依据和参考价值。

-

关键词:

- 调节阀 /

- 多级套筒 /

- 高压降 /

- 计算流体动力学(CFD) /

- 空化

Abstract:To study the internal flow process of the multi-stage pressure drop valve and the influencing factors and influence laws of the pressure drop of pressure-drop-stage, based on the numerical calculation method of the Mixture two-phase flow model and the Schnerr-Sauer cavitation model, the calculation model of the flow field of a multi-stage inside the valve was established. The flow characteristics inside the pressure drop valve are obtained through numerical simulation calculation, and the impact of various pressure differences and various opening degrees of the valve on the pressure drop of each pressure-drop-stage is analyzed and discussed. Numerical calculation results show that there are a large number of vortices in the valve due to the vigorous mixing and shear of multiple fluids when the fluid flows through the throttle element of the valve. The pressure drop of each pressure-drop-stage is different, and the degree of cavitation of the third stage sleeve is the largest, cavitation is more likely to occur at the valve seat. The pressure drop of the working fluid along each pressure-drop-stage exhibits the same changing trend at the same opening degree of the valve under various pressure differences. The pressure drop of the third pressure-drop-stage rises when the opening degree of the valve is reduced. The average pressure drop of the 3rd pressure-drop-stage reaches 8 MPa at the opening degree of 25%. The velocity of working fluid in the small hole of the pressure-drop-stage also increases under the condition of the same mass flow rate. This paper provides the theoretical basis and reference value for the designs of the pressure reducing valve.

-

Key words:

- valve /

- multi-stage sleeve /

- high pressure-drop /

- computational fluid dynamics (CFD) /

- cavitation

-

表 1 不同工况条件实验组阀门的进出口压力及压差

Table 1. Inlet and outlet pressures and pressure differe under different conditions

工况 进口压力/ MPa 出口压力/ MPa 进出口压差/ MPa 实验组1 8.82 0.21 8.61 实验组2 9.4 0.15 9.25 实验组3 9.4 0.1 9.3 实验组4 9.4 0.05 9.35 表 2 关键数值计算方法

Table 2. Key numerical calculation methods

类别 数值方法 压力-速度耦合形式 PISO 湍流模型 IDDES 多相流模型 Mixture 空化模型 Schnerr & Sauer 表 3 网格类别

Table 3. Mesh specifications

网格类型 网格数量 质量流量/(kg·s-1) M1(粗糙) 7.326×106 15.982 3 M2(中等) 12.03×106 16.233 3 M3(精细) 17.58×106 16.517 8 -

[1] 陆培文. 实用阀门设计手册[M]. 3版. 北京: 机械工业出版社, 2012: 1315-1416.LU P W. Design manual of practical valve[M]. 3rd ed. Beijing: China Machine Press, 2012: 1315-1416(in Chinese). [2] 刘芳. 控制阀闪蒸和空化现象及阻塞流的计算[J]. 石油化工自动化, 2010, 46(2): 64-65. https://www.cnki.com.cn/Article/CJFDTOTAL-LYHG201002020.htmLIU F. Control valve flash and cavitation phenomenon and the calculation of blocking flow[J]. Automation in Petro-Chemical, 2010, 46(2): 64-65(in Chinese). https://www.cnki.com.cn/Article/CJFDTOTAL-LYHG201002020.htm [3] 王燕, 胡建华, 胡建, 等. 多级套筒调节阀消声减振元件设计研究[J]. 流体机械, 2013, 41(7): 19-22. https://www.cnki.com.cn/Article/CJFDTOTAL-LTJX201307006.htmWANG Y, HU J H, HU J, et al. Design and research of noise elimination and vibration reduction sleeve in control valve[J]. Fluid Machinery, 2013, 41(7): 19-22(in Chinese). https://www.cnki.com.cn/Article/CJFDTOTAL-LTJX201307006.htm [4] FRANZONI F, MILANI M, MONTORSI L. Cavitating flows in hydraulic multidimensional CFD analysis[J]. Journal of Sexual Medicine, 2008, 1(1): 424-436. [5] BERNAD S I, SUSAN-RESIGA R. Numerical model for cavitational flow in hydraulic poppet valves[J]. Modelling and Simulation in Engineering, 2012, 2012: 742162. [6] ZARYANKIN A E, ZROICHIKOV N A, PARAMONOV A N, et al. Pressure pulsations in the turbine steam-admission path and their influence on the vibration state of the turbine control valves[J]. Thermal Engineering, 2012, 59(2): 106-112. doi: 10.1134/S0040601512020176 [7] SHIN C H. A numerical study on the characteristics of transient flow in a pressure regulator resulting from closure of the pressure control valve[J]. Journal of Mechanical ence and Technology, 2013, 27(2): 443-449. doi: 10.1007/s12206-012-1257-y [8] 项美根, 孙晓霞. 用多级降压法消除电厂调节阀气蚀[J]. 流体工程, 1992(11): 58-61. https://www.cnki.com.cn/Article/CJFDTOTAL-LTJX199211009.htmXIANG M G, SUN X X. Eliminate cavitation in power plant regulating valve with multi-stage pressure reduction method[J]. Fluid Engineering, 1992(11): 58-61(in Chinese). https://www.cnki.com.cn/Article/CJFDTOTAL-LTJX199211009.htm [9] 蒋玲. 浅谈一种多级降压高压差结构在放空阀中的应用设计[J]. 仪器仪表用户, 2018, 25(8): 54-56. https://www.cnki.com.cn/Article/CJFDTOTAL-DZYQ201808024.htmJIANG L. Application design of a multi stage buck high pre-ssure differential structure in vent valve[J]. Instrumentation Customers, 2018, 25(8): 54-56(in Chinese). https://www.cnki.com.cn/Article/CJFDTOTAL-DZYQ201808024.htm [10] 顾成果. 套筒调节阀套筒结构的设计与分析[J]. 阀门, 2010(4): 8-10. https://www.cnki.com.cn/Article/CJFDTOTAL-FAME201004003.htmGU C G. Design & analysis for sleeve structure of the cage control valve[J]. Valve, 2010(4): 8-10(in Chinese). https://www.cnki.com.cn/Article/CJFDTOTAL-FAME201004003.htm [11] 徐晓刚, 王天龙, 李树勋, 等. 高温高压降多级套筒调节阀噪声抑制研究[J]. 自动化与仪器仪表, 2016(1): 4-6. https://www.cnki.com.cn/Article/CJFDTOTAL-ZDYY201601003.htmXU X G, WANG T L, LI S X, et al. Research on noise suppression of multi-stage sleeve control valve with high temperature and high pressure drop[J]. Automation and Instrumentation, 2016(1): 4-6(in Chinese). https://www.cnki.com.cn/Article/CJFDTOTAL-ZDYY201601003.htm [12] 彭健, 何世权. 高压调节阀结构改进与汽蚀仿真[J]. 液压与气动, 2019(3): 120-125. https://www.cnki.com.cn/Article/CJFDTOTAL-YYYQ201903022.htmPENG J, HE S Q. Structural improvement and cavitation simulation of high pressure regulating valve[J]. Chinese Hydraulics & Pneumatics, 2019(3): 120-125(in Chinese). https://www.cnki.com.cn/Article/CJFDTOTAL-YYYQ201903022.htm [13] 李树勋, 王天龙, 徐晓刚, 等. 高压降套筒式蒸汽疏水阀振动特性研究[J]. 振动与冲击, 2018, 37(4): 147-152. https://www.cnki.com.cn/Article/CJFDTOTAL-ZDCJ201804022.htmLI S X, WANG T L, XU X G, et al. A study on the vibration characteristics of high pressure drop sleeve trap[J]. Journal of Vibration and Shock, 2018, 37(4): 147-152(in Chinese). https://www.cnki.com.cn/Article/CJFDTOTAL-ZDCJ201804022.htm [14] 李树勋, 康云星, 孟令旗, 等. 多级降压疏水调节阀流致噪声数值模拟研究[J]. 振动与冲击, 2020, 39(14): 116-121. https://www.cnki.com.cn/Article/CJFDTOTAL-ZDCJ202014017.htmLI S X, KANG Y X, MENG L Q, et al. Flow-induced noise of a high pressure drop control valve[J]. Journal of Vibration and Shock, 2020, 39(14): 116-121(in Chinese). https://www.cnki.com.cn/Article/CJFDTOTAL-ZDCJ202014017.htm [15] 武世敏. 迷宫式调节阀流通能力的研究[D]. 银川: 宁夏大学, 2014: 20-37.WU S M. The research of flow characteristic and pressure reducing mechanism of labyrinth steam conditioning control valve[D]. Yinchuan: Ningxia University, 2014: 20-37(in Chinese). [16] SHUR M L, SPALART P R M K, STRELETS M K, et al. A hybrid RANS-LES approach with delayed-DES and wall-modelled LES capabilities[J]. International Journal of Heat and Fluid Flow, 2008, 29(6): 1638-1649. [17] GRITSKEVICH M S, GARBARUK A V, SCHUTZE J, et al. Development of DDES and IDDES formulations for the k-ω shear stress transport model[J]. Flow, Turbulence and Combustion, 2012, 88(3): 431-449. [18] MANNINEN M, TAIVASSALO V, KALLIO S. On the mixture model for multiphase flow[M]. Espoo: VTT Publications, 1996: 11-59. [19] SCHILLER L, NAUMANN A. A drag coefficient correlation[J]. Zeitschrift des Vereins Deutscher Ingenieure, 1935, 77: 318-320. [20] SHABIL S I. Physical and numerical modeling of unsteady cavitation dynamics[C]//4th International Conference on Multiphase Flow, 2001: 1-12. -

下载:

下载: