-

摘要:

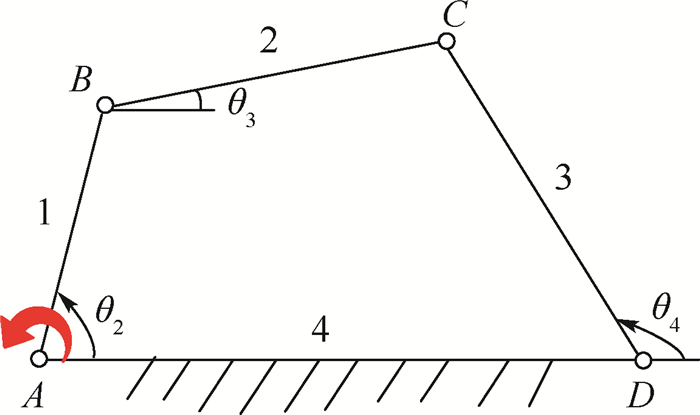

曲柄是连杆机构运动学分析的一个重要环节,其决定着机构的运动状态。现有的Grashof定理、N杆旋转定理可以很好地解决只含有转动副单闭环连杆机构的曲柄判定问题,但对于广泛应用于航空航天的复杂多环路连杆机构的曲柄判定,至今没有通用有效的解决手段。基于此,提出了复杂多环路连杆机构曲柄判定的分支图识别法。通过复杂多环路连杆机构内各个环路的杆件关系不等式,确定了其曲柄存在的第一个充分条件;结合连杆机构的运动分支识别图活动关节旋转范围确定了曲柄存在的第二个充分条件。在归纳了曲柄存在充分条件基础上,利用所提方法在平面4R、5R连杆机构做了实例分析,并与现有公认结果进行对比,验证了方法的有效性。在仅含转动副复杂多环路Stephenson六杆机构上进行了曲柄判定,证明了方法的可行性。

Abstract:Crank judgement is an important link in kinematic analysis of mechanisms, which determines the motion state of the mechanism. The existing Grashof theorem and N-bar rotation theorem can well solve the problem of crank judgement of single closed-loop linkage with only R joints, but there is no general and effective solution for crank judgement of complex multi-loop linkage widely used in aerospace. A branch graph identification method for determining the crank of complex multi-loop linkage is proposed. This method first determines the first sufficient condition for the existence of the crank through the inequality of the link relationship of each loop in the complex multi-loop linkage, and then determines the second sufficient condition for the existence of the crank by combining the branch graph of the linkage with the rotation range of the movable joint. On the basis of summing up the sufficient conditions, this method is used to analyze the planar 4R and 5R linkages, and the outcomes are compared with the existing recognized results, verifing the effectiveness of this method. Finally, the crank judgment is carried out on a complex multi-loop Stephenson six-bar linkage with only rotating pairs, which proves the feasibility of the method.

-

Key words:

- crank judgement /

- branch identification /

- Grashof theorem /

- N-bar rotation theorem /

- multi-loop linkage

-

杆号 杆1 杆2 杆3 杆4 杆长/dm 26.5 14.7 26.7 26 杆号 杆1 杆2 杆3 杆4 杆长/cm 13.2 62.2 35.6 56.7 杆号 杆1 杆2 杆3 杆4 杆长/cm 15.2 22.1 25.6 10.6 杆号 杆1 杆2 杆3 杆4 杆5 杆长/cm 8 10 19 21 24 杆号 杆1 杆2 杆3 杆4 杆5 杆长/cm 10 13 19 21 24 杆号 杆1 杆2 杆3 杆4 杆5 杆长/cm 12 14 16 20 45 杆号 杆1 杆2 杆3 杆4 杆5 杆长/cm 20 25 30 42 45 参数 数值 a1/dm 2.67 a2/dm 3.6 a3/dm 2.71 a4/dm 1 a5/dm 4.2 a6/dm 5 a7/dm 3.4 a9/dm 4.2 α/(°) 25 β/(°) 5 表 9 图 13 Stephenson六杆机构输入θ2曲柄对应参数

Table 9. Parameters of Stephenson six-bar linkage with input joint θ2 in Fig. 13

参数 数值 a1/dm 1 a2/dm 3.6 a3/dm 2.71 a4/dm 2.67 a5/dm 5.6 a6/dm 5.6 a7/dm 5.7 a9/dm 2 α/(°) 25 β/(°) 5 参数 数值 a2/dm 5.6 a4/dm 1 a5/dm 4.2 a6/dm 5 a7/dm 3.4 a8/dm 2.67 a9/dm 5.6 a10/dm 2.2 η/(°) 5 λ/(°) 25 -

[1] GRASHOF F. Theroetische maschinenlehre[M]. Leipzig: Engineering Press, 1983: 382. [2] 张全明, 梁文贤, 常勇. 关于2-DOF平面五杆机构的双曲柄存在条件的再研究[J]. 机械科学与技术, 2008, 27(1): 78-82. https://www.cnki.com.cn/Article/CJFDTOTAL-JXKX200801019.htmZHANG Q M, LIANG W X, CHANG Y. Further study of conditions for double-crank of 2-DOF planar five-link linkage[J]. Mechanical Science and Technology for Aerospace Engineering, 2008, 27(1): 78-82(in Chinese). https://www.cnki.com.cn/Article/CJFDTOTAL-JXKX200801019.htm [3] 田汉民, 张策, 张新华. 二自由度平面五杆机构的双曲柄存在条件[J]. 机械设计, 2001(3): 23-25. https://www.cnki.com.cn/Article/CJFDTOTAL-JXSJ200103008.htmTIAN H M, ZHANG C, ZHANG X H. Existence conditions for double crank of planar five-bar linkage with two free degrees[J]. Journal of Machine Design, 2001(3): 23-25(in Chinese). https://www.cnki.com.cn/Article/CJFDTOTAL-JXSJ200103008.htm [4] 廖汉元, 孔建益, 李佳, 等. 平面两自由度铰链五杆机构的类型及判别[J]. 湖北工业大学学报, 2006, 21(3): 4-6. https://www.cnki.com.cn/Article/CJFDTOTAL-HBGX200603001.htmLIAO H Y, KONG J Y, LI J, et al. The types of 5-bra linkage with two-degree of freedom and their differentiation[J]. Journal of Hubei University of Technology, 2006, 21(3): 4-6(in Chinese). https://www.cnki.com.cn/Article/CJFDTOTAL-HBGX200603001.htm [5] TING K L, TSAI G H. Mobility and synthesis of five-bar-programmable-linkages[C]//Proceedings of the 9th OSU Applied Mechanisms Conference, 1985: 1-8. [6] TING K L. Five-bar Grashof criteria[J]. Journal of Mechanisms, Transmissions, and Automation in Design, 1986, 108(4): 533-537. doi: 10.1115/1.3258765 [7] TING K, WANG J, XUE C, et al. Full rotatability of Stephenson six-bar and geared five-bar linkages[C]//Proceedings of the ASME 2008 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference. New York: ASME, 2008: 581-590. [8] WANG J, TING K L, ZHAO D, et al. Full rotatability of Watt six-bar linkages[C]//Proceedings of the ASME 2014 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference. New York: ASME, 2014, 46360: V05AT08A049. [9] 郭晓宁, 褚金奎. Stephenson Ⅱ型六杆机构曲柄存在条件及判断方法[J]. 农业机械学报, 2004, 35(3): 120-123. doi: 10.3969/j.issn.1000-1298.2004.03.033GUO X N, CHU J K. Identification of a crank for Stephenson Ⅱ six-bar linkage[J]. Transactions of the Chinese Society for Agricultural Machinery, 2004, 35(3): 120-123(in Chinese). doi: 10.3969/j.issn.1000-1298.2004.03.033 [10] 宋杰, 梅瑛, 李瑞琴. 平面3-DOF PRR-RRP型六杆机构的曲柄存在条件[J]. 机械传动, 2013, 37(11): 32-34. https://www.cnki.com.cn/Article/CJFDTOTAL-JXCD201311008.htmSONG J, MEI Y, LI R Q. Crank existence condition of planar 3-DOF PRR-RRP type six-bar mechanism[J]. Journal of Mechanical Transmission, 2013, 37(11): 32-34(in Chinese). https://www.cnki.com.cn/Article/CJFDTOTAL-JXCD201311008.htm [11] DAI J S, SHAH P. Orientation capability of planar serial mani-pulators using rotatability analysis based on workspace decomposition[J]. Proceedings of the Institution of Mechanical Engineers, Part C: Journal of Mechanical Engineering Science, 2002, 216(3): 275-288. [12] TING K. Joint rotation space and mobility of linkages[C]//Proceedings of the ASME 2007 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference. New York: ASME, 2007: 427-437. [13] WANG J. Mobility identification and rectification of planar multiloop mechanisms[D]. Cookeville: Tennessee Technological University, 2010: 152-153. [14] NIE L, WANG J, TING K L, et al. Branch identification of spherical six-bar linkages[C]//Proceedings of the ASME 2016 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference. New York: ASME, 2016, 50169: V05BT07A072. [15] NIE L, DING H, KECSKEMÉTHY A, et al. Singularity and branch identification of a 2 degree-of-freedom (DOF) seven-bar spherical parallel manipulator[J]. Mechanical Sciences, 2020, 11(2): 381-393. [16] TING K, LIU Y. Rotatability laws for N-bar kinematic chains and their proof[J]. ASME Journal of Mechanical Design, 1991, 113(1): 32-39. -

下载:

下载: