Infrared radiation characteristics of carbon/glass hybrid composites under low-velocity impact

-

摘要:

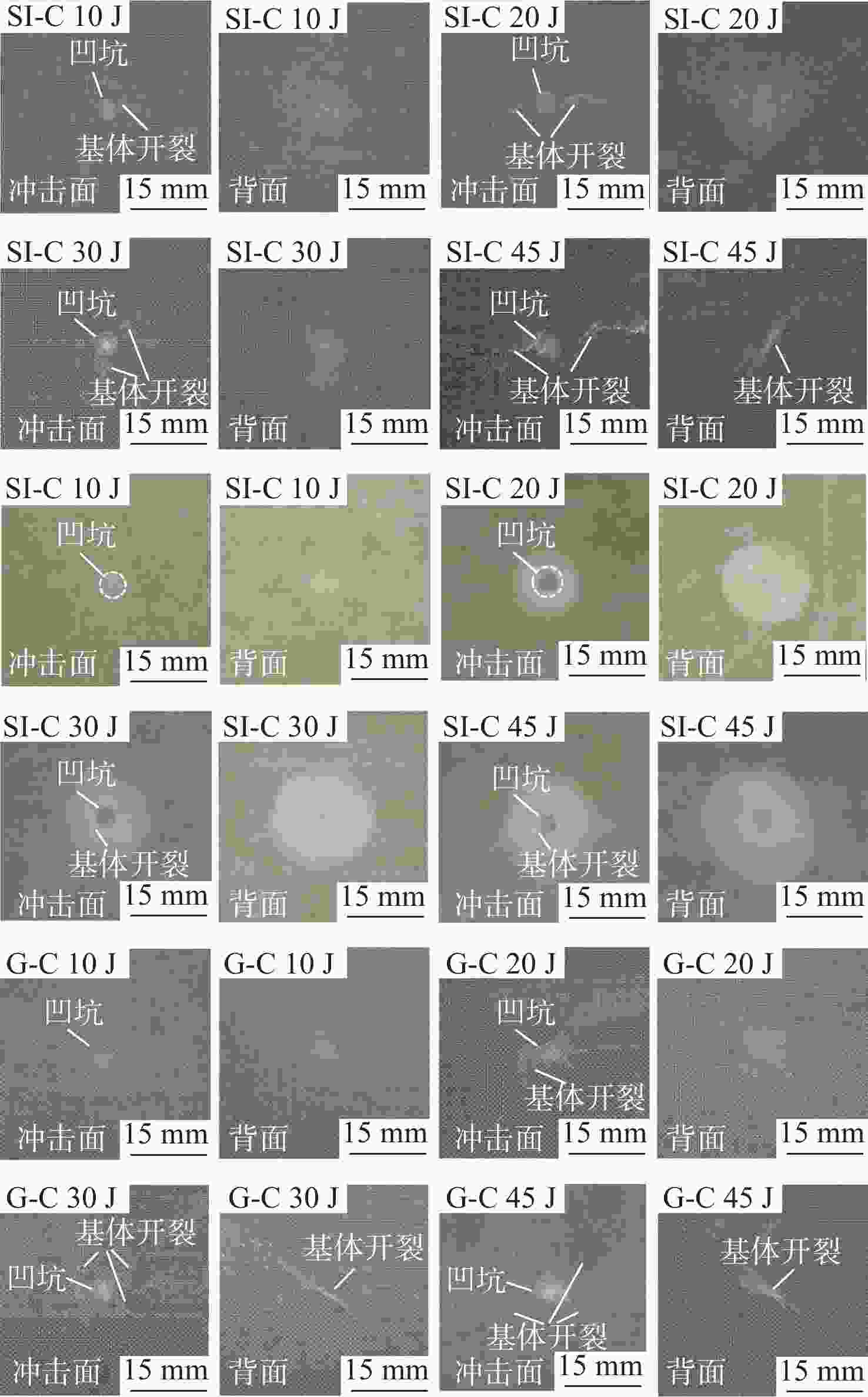

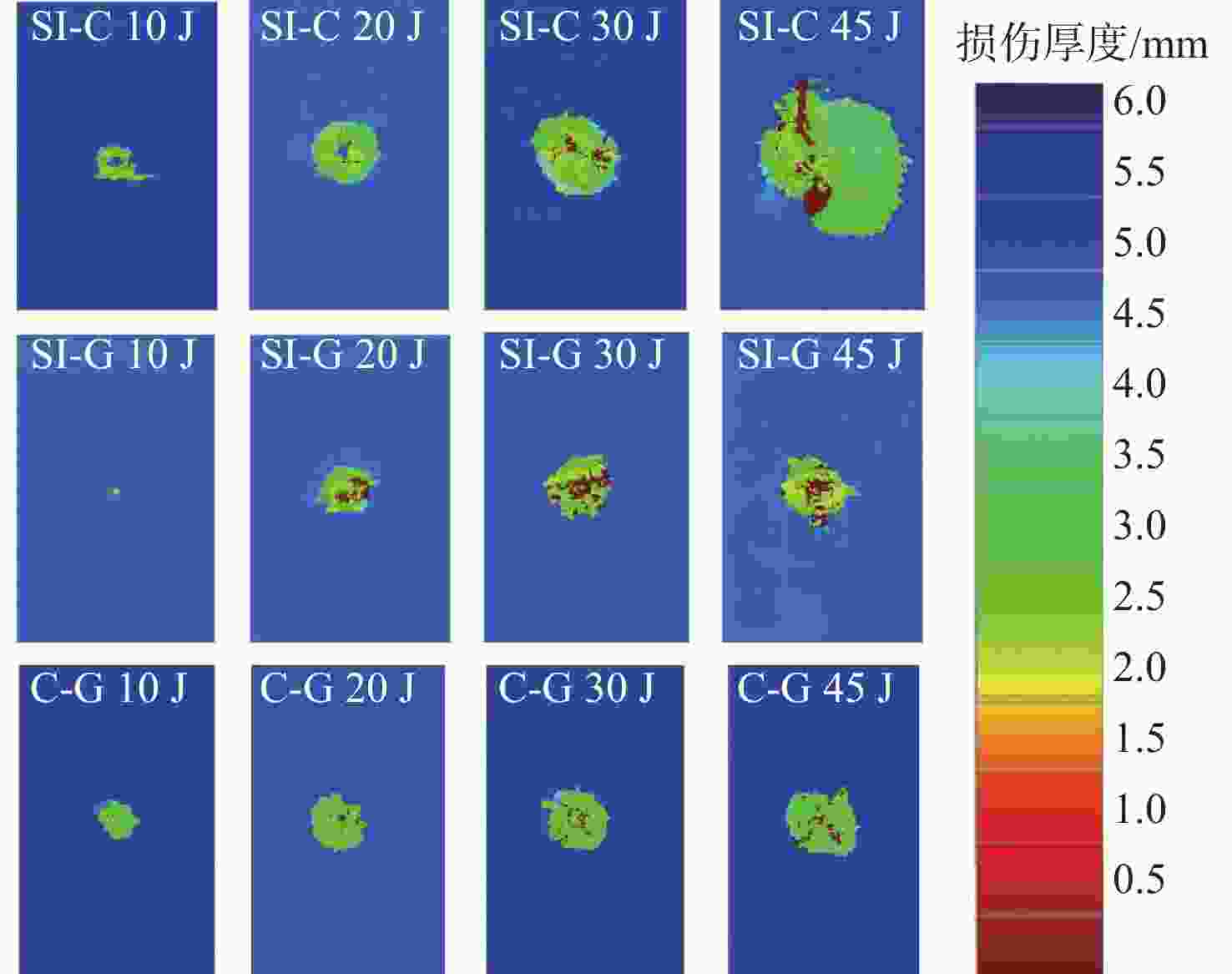

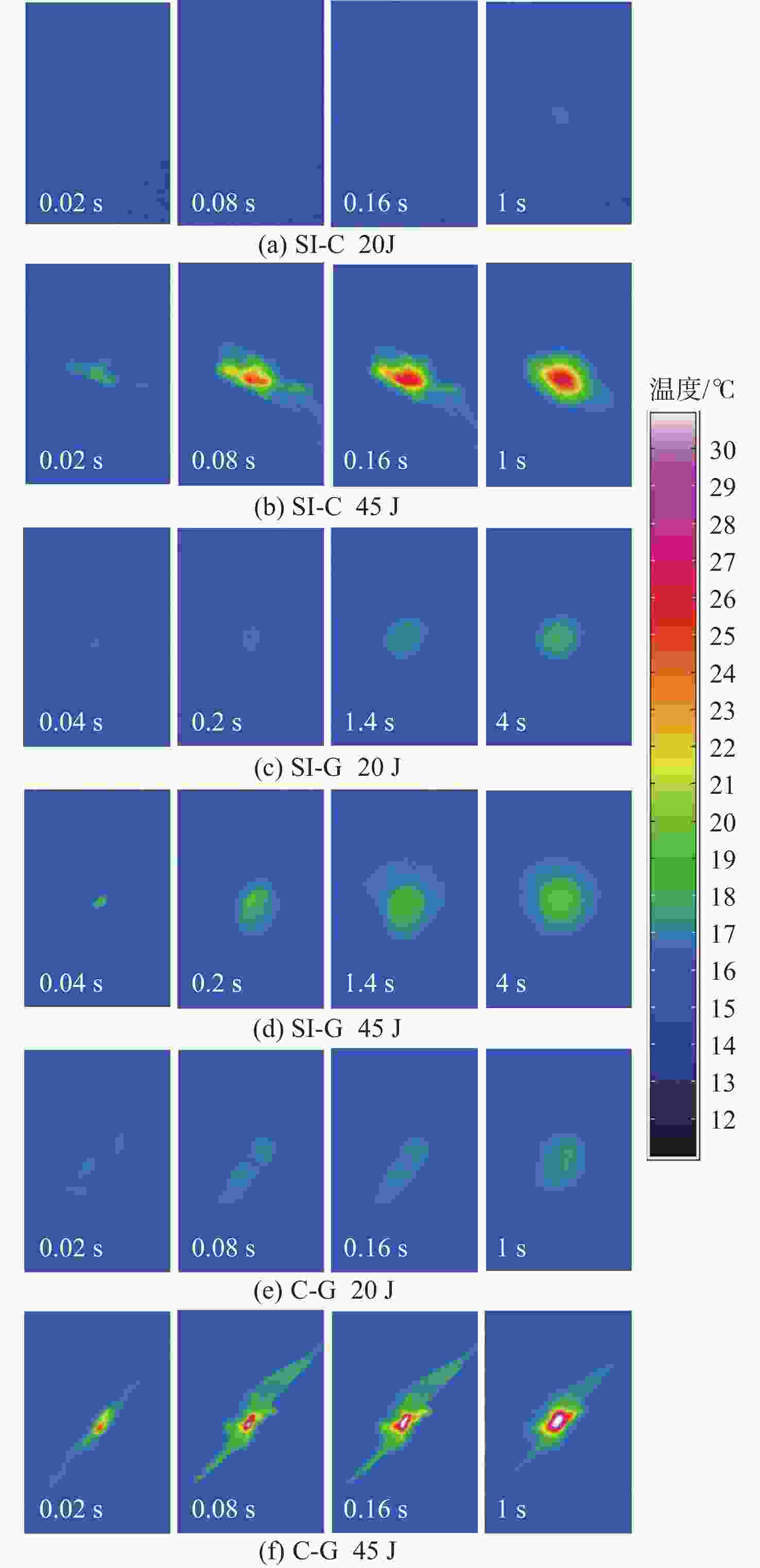

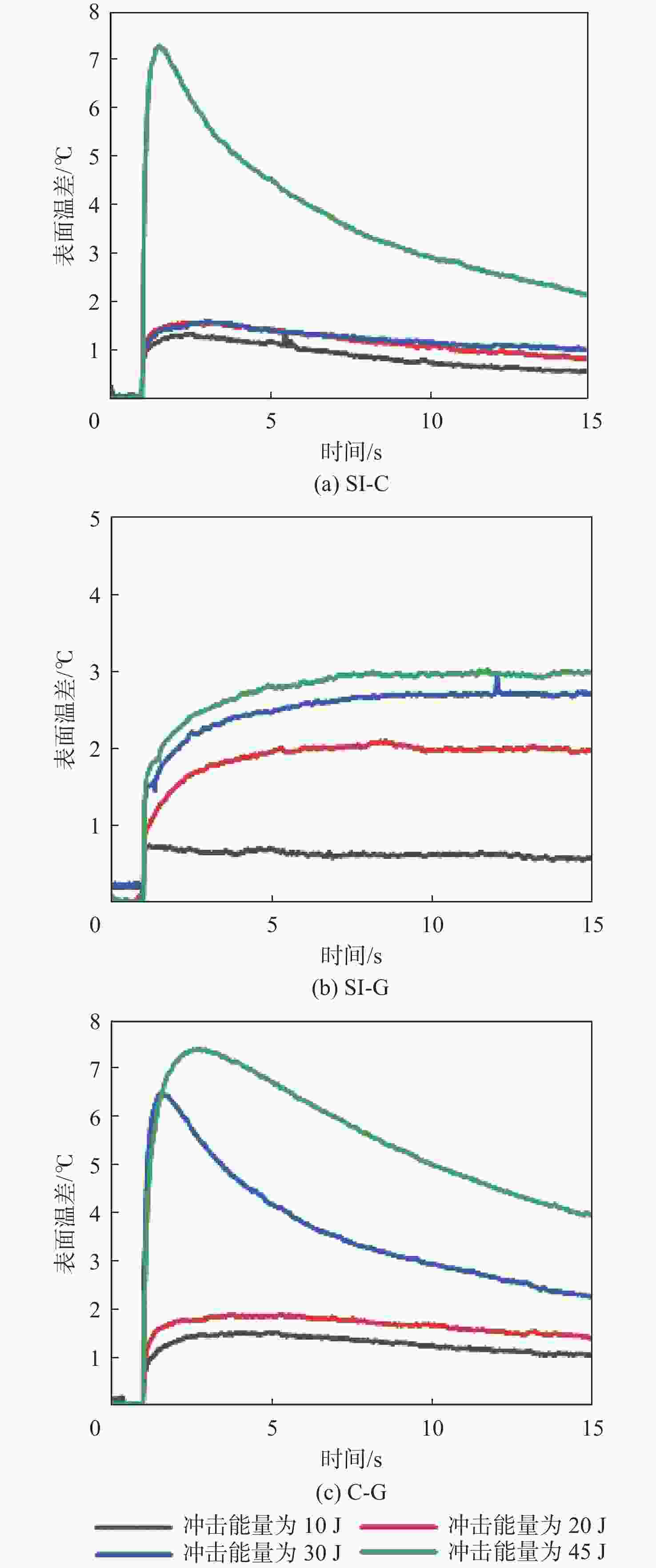

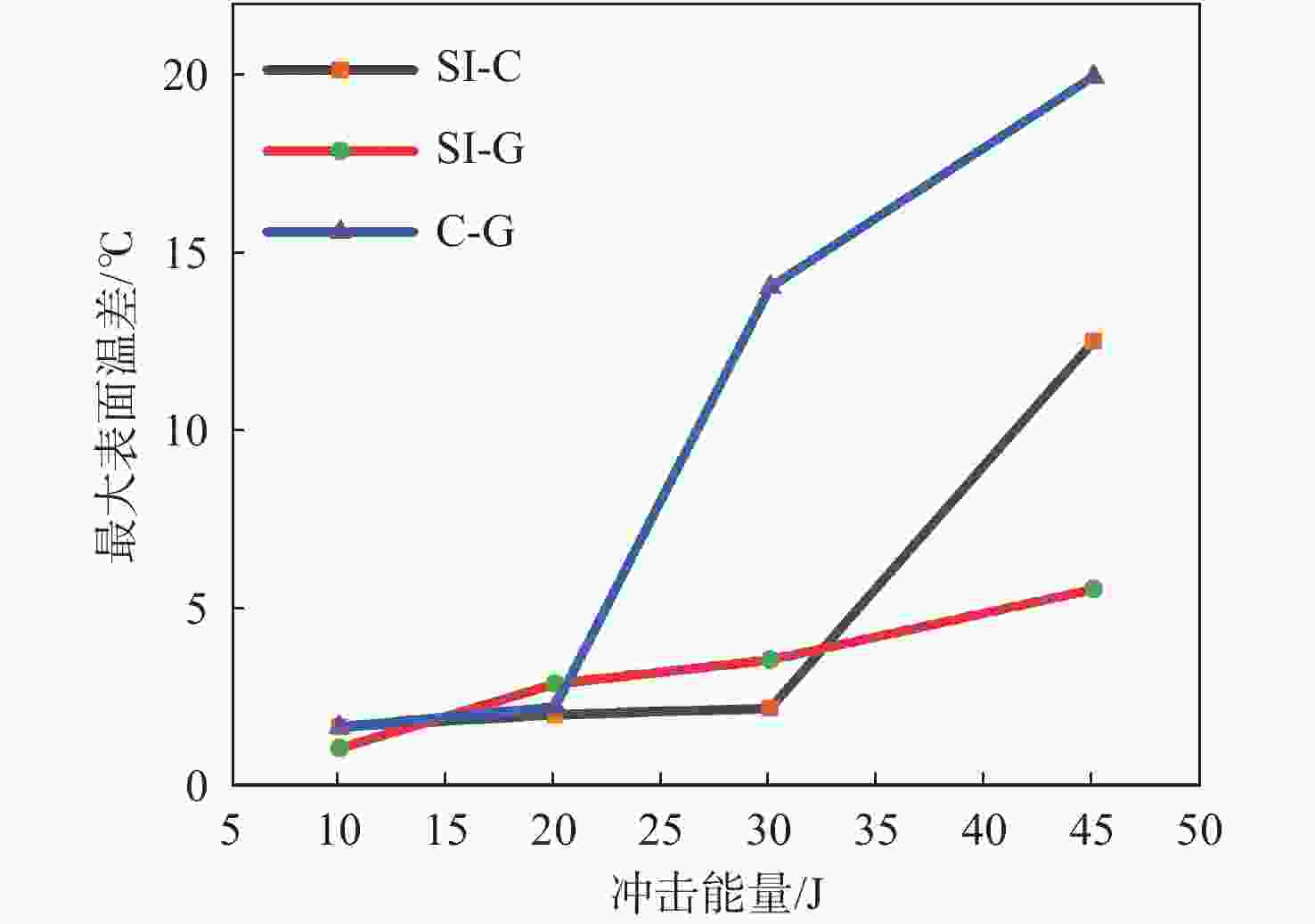

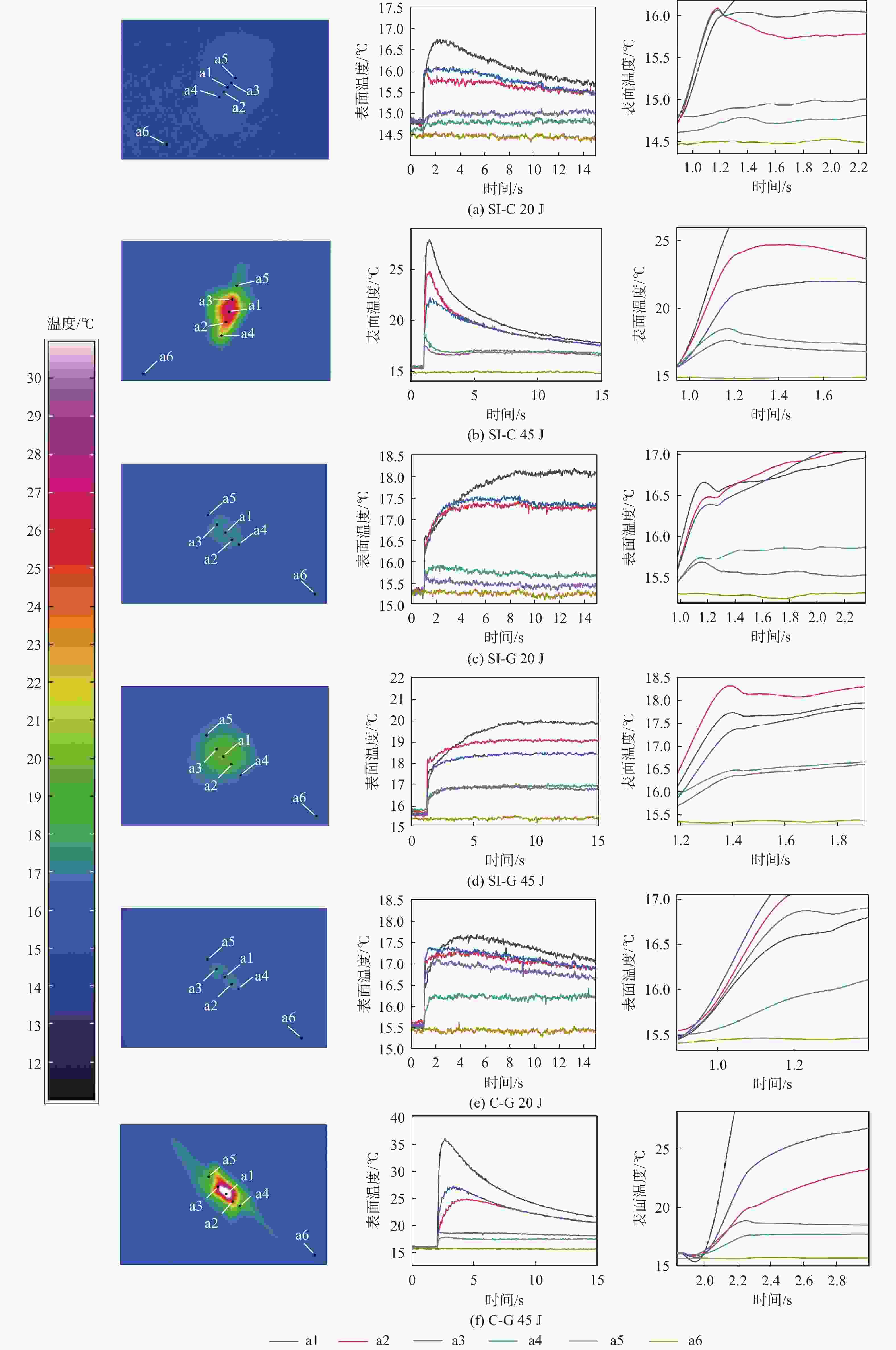

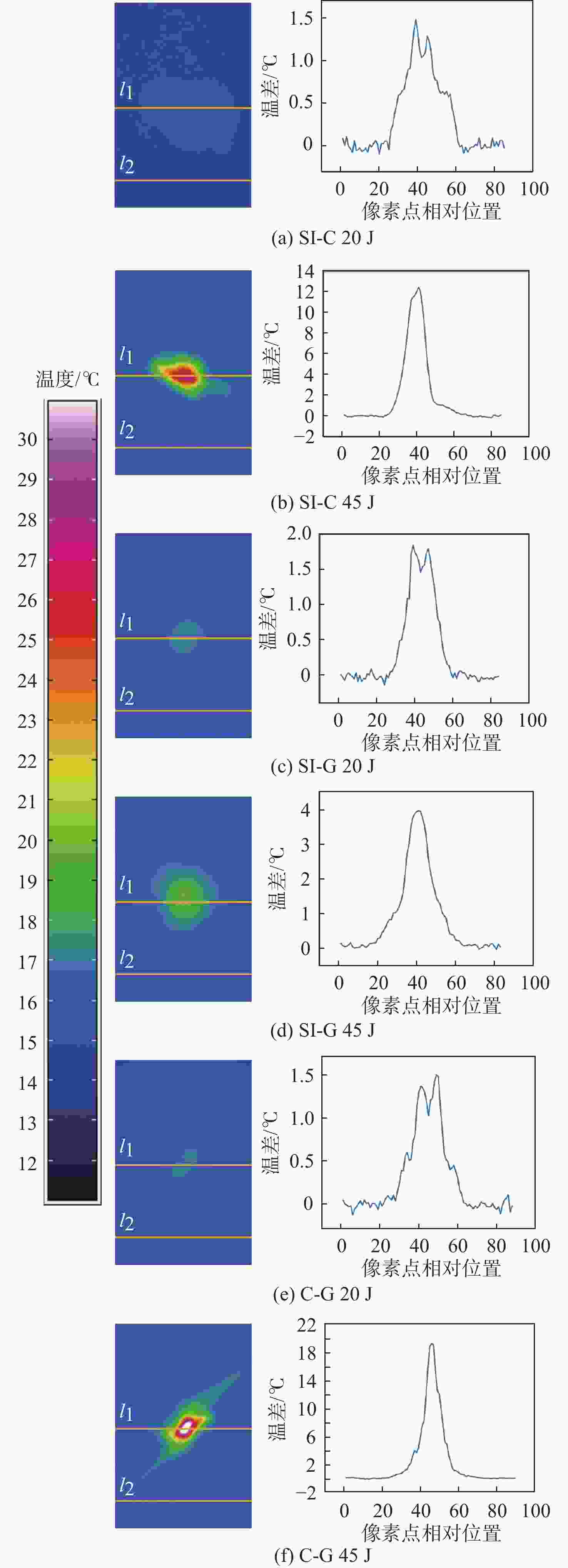

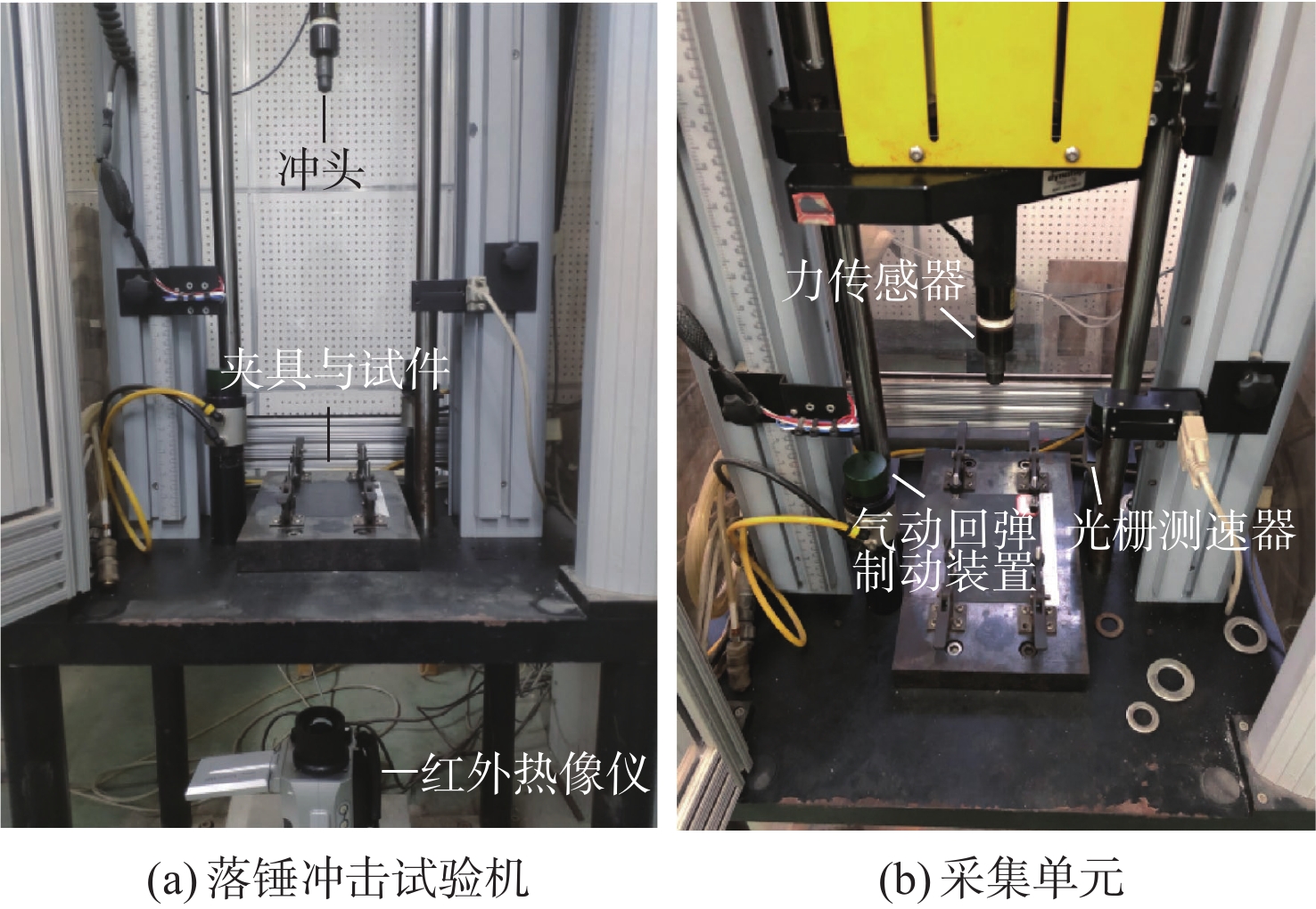

碳/玻混杂复合材料在工业应用中表现出巨大的应用潜力。基于红外热像法试验研究了碳/玻混杂复合材料层压板与2种非混杂材料低速冲击下的红外辐射特征。通过目视、超声C扫描和光学显微镜等方法确定冲击后层压板的损伤模式,分析热图序列的时序变化特征和温度分布特征,从而表征冲击过程中的热耗散效应。结果表明:红外热成像技术非常适合监测低速冲击下纤维增强复合材料的损伤过程,通过热图序列可以建立起监测特征与各损伤模式之间的联系;同时发现碳/玻纤维的层间混杂可有效提升碳纤维强基复合材料(CFRP)的抗分层能力,随着冲击能量增加其抗分层能力愈加明显,冲击后的碳/玻混杂复合材料兼具较大的表面损伤和较小的分层损伤,拥有较好的损伤容限。

Abstract:Carbon/glass hybrid composites have shown great potential in industrial applications. The infrared radiation characteristics of carbon/glass hybrid composite laminates and two types of non-hybrid composites under low velocity impact were studied experimentally by infrared thermography. The damage mode of the laminates was determined after impact by visual, ultrasonic C-scan and optical microscopy, and then the time series variation and temperature distribution characteristics of the thermal map sequence were analyzed to characterize the heat dissipation effect during the impact. Results show that the infrared thermography is highly suitable for monitoring the damage process of fiber reinforced composites under low velocity impact, and that the relationship between the monitoring characteristics and the damage modes can be established through the thermal map sequence. It is also found that the interlaminar hybrid of carbon glass fibers can effectively improve the anti-delamination ability of carbon fiber reinforced polymer (CFRP) composites. With the increase of impact energy, the anti-delamination ability becomes more obvious. After impact, carbon glass hybrid composites show both larger surface damage and smaller delamination damage with better damage tolerance.

-

表 1 两类预浸料纤维物理和力学性能参数

Table 1. Physical and mechanical properties of two prepreg fibers

纤维类型 丝直

径/μm纤维密

度/(g·cm−3)拉伸强

度/MPa拉伸模

量/GPa伸长

率/%线密

度/tex碳纤 7 1.8 4 300 240 2.1 223 玻纤 19.2 2.55 2 300 81 2.9 410 注:1tex=1g/km。 表 2 层压板试件结构参数

Table 2. Structural parameters of laminate specimens

试件 杂交结构 层配置 面密度/(kg·m−2) 厚度/mm 树脂 SI-C 单碳纤维 [45c/0c/−45c/90c]4S 0.59 4.8 环氧YH69 SI-G 单玻璃纤维 [45g/0g/−45g/90g]4S 0.82 4.6 环氧YH69 C-G 碳/玻纤

维混杂[45c/0g/−45c/90g]4S 0.70 4.7 环氧YH69 注:下标c为铺层角度,g为单层纤维类型。 -

[1] GHORI S W, SIAKENG R, RASHEED M, et al. The role of advanced polymer materials in aerospace[C]//Sustainable Composites for Aerospace Applications. Amsterdam: Elsevier, 2018: 19-34. [2] ZHOU J, LIAO B, SHI Y, et al. Low-velocity impact behavior and residual tensile strength of CFRP laminates[J]. Composites Part B:Engineering, 2019, 161: 300-313. doi: 10.1016/j.compositesb.2018.10.090 [3] JAGANNATHA T D, HARISH G. Mechanical properties of carbon/glass fiber reinforced epoxy hybrid polymer composites[J]. International Journal of Mechanical Engineering and Robotics Research, 2015, 4(2): 131-137. [4] CHEN D D, LUO Q T, MENG M Z, et al. Low velocity impact behavior of interlayer hybrid composite laminates with carbon/glass/basalt fibres[J]. Composites Part B:Engineering, 2019, 176: 107191. doi: 10.1016/j.compositesb.2019.107191 [5] PAPA I, BOCCARUSSO L, LANGELLA A, et al. Carbon/glass hybrid composite laminates in vinylester resin: Bending and low velocity impact tests[J]. Composite Structures, 2020, 232: 111571. doi: 10.1016/j.compstruct.2019.111571 [6] SAFRI S N A, SULTAN M T H, JAWAID M, et al. Impact behaviour of hybrid composites for structural applications: A review[J]. Composites Part B:Engineering, 2018, 133: 112-121. doi: 10.1016/j.compositesb.2017.09.008 [7] NAIK N K, RAMASIMHA R, ARYA H, et al. Impact response and damage tolerance characteristics of glass-carbon/epoxy hybrid composite plates[J]. Composites Part B:Engineering, 2001, 32(7): 565-574. doi: 10.1016/S1359-8368(01)00036-1 [8] 管清宇, 冯剑飞, 夏品奇, 等. 复合材料层压板低速冲击行为及剩余拉伸强度[J]. 北京航空航天大学学报, 2021, 47(6): 1220-1232. doi: 10.13700/j.bh.1001-5965.2020.0132GUAN Q Y, FENG J F, XIA P Q, et al. Low-velocity impact behavior and residual tensile strength of composite laminates[J]. Journal of Beijing University of Aeronautics and Astronautics, 2021, 47(6): 1220-1232(in Chinese). doi: 10.13700/j.bh.1001-5965.2020.0132 [9] ZHOU J, LIAO B, SHI Y, et al. Experimental investigation of the double impact position effect on the mechanical behavior of lowvelocity impact in CFRP laminates[J]. Composites Part B:Engineering, 2020, 193: 108020. doi: 10.1016/j.compositesb.2020.108020 [10] 张超, 方鑫, 刘建春. 复合材料层板冰雹高速冲击损伤预测及失效分析[J]. 北京航空航天大学学报, 2022, 48(4): 698-707.ZHANG C, FANG X, LIU J C. Damage prediction and failure mechanism of composite laminates under high-velocity hailstone impact[J]. Journal of Beijing University of Aeronautics and Astronautics, 2022, 48(4): 698-707(in Chinese). [11] LOGANATHAN T M, SULTAN M T H, MUHAMMAD AMIR S M, et al. Infrared thermographic and ultrasonic inspection of randomly-oriented short-natural fiber-reinforced polymeric composites[J]. Frontiers in Materials, 2021, 7: 604459. doi: 10.3389/fmats.2020.604459 [12] DOSHVARPASSAND S, WU C Z, WANG X Y. An overview of corrosion defect characterization using active infrared thermography[J]. Infrared Physics & Technology, 2019, 96: 366-389. [13] ALFREDO OSORNIO-RIOS R, ANTONINO-DAVIU J A, DE JESUS ROMERO-TRONCOSO R. Recent industrial applications of infrared thermography: A review[J]. IEEE Transactions on Industrial Informatics, 2019, 15(2): 615-625. doi: 10.1109/TII.2018.2884738 [14] VAVILOV V, BURLEIGH D. Infrared thermography and thermal nondestructive testing[M]. Cham: Springer International Publishing, 2020: 7-11. [15] BAGAVATHIAPPAN S, LAHIRI B B, SARAVANAN T, et al. Infrared thermography for condition monitoring: A review[J]. Infrared Physics & Technology, 2013, 60: 35-55. [16] KRSTULOVIC-OPARA L, KLARIN B, NEVES P, et al. Thermal imaging and thermoelastic stress analysis of impact damage of composite materials[J]. Engineering Failure Analysis, 2011, 18(2): 713-719. doi: 10.1016/j.engfailanal.2010.11.010 [17] JAKUBCZAK P, BIENIAŚ J, SUROWSKA B. Impact damage live-time analysis of modern composite materials using thermography[J]. Composites Theory and Practice, 2014, 14: 219-223. [18] MEOLA C, CARLOMAGNO G M. Impact damage in GFRP: New insights with infrared thermography[J]. Composites Part A:Applied Science and Manufacturing, 2010, 41(12): 1839-1847. doi: 10.1016/j.compositesa.2010.09.002 [19] MEOLA C, BOCCARDI S, CARLOMAGNO G M, et al. Nondestructive evaluation of carbon fibre reinforced composites with infrared thermography and ultrasonics[J]. Composite Structures, 2015, 134: 845-853. doi: 10.1016/j.compstruct.2015.08.119 [20] MEOLA C, BOCCARDI S, BOFFA N D, et al. New perspectives on impact damaging of thermoset-and thermoplastic-matrix composites from thermographic images[J]. Composite Structures, 2016, 152: 746-754. doi: 10.1016/j.compstruct.2016.05.083 [21] MEOLA C, BOCCARDI S, CARLOMAGNO G M, et al. Impact damaging of composites through online monitoring and non-destructive evaluation with infrared thermography[J]. NDT & E International, 2017, 85: 34-42. [22] MEOLA C, BOCCARDI S, CARLOMAGNO G M. Infrared thermography for inline monitoring of glass/epoxy under impact and quasi-static bending[J]. Applied Sciences, 2018, 8(2): 301. doi: 10.3390/app8020301 [23] BOCCARDI S, CARLOMAGNO G M, SIMEOLI G, et al. Evaluation of impact-affected areas of glass fibre thermoplastic composites from thermographic images[J]. Measurement Science and Technology, 2016, 27(7): 075602. doi: 10.1088/0957-0233/27/7/075602 [24] BOCCARDI S, BOFFA N D, CARLOMAGNO G M, et al. Inline monitoring of basalt-based composites under impact tests[J]. Composite Structures, 2019, 210: 152-158. doi: 10.1016/j.compstruct.2018.11.038 [25] BOCCARDI S, CARLOMAGNO G M, BOFFA N D, et al. Infrared thermography to locate impact damage in thin and thicker carbon/epoxy panels[J]. Polymer Engineering & Science, 2017, 57(7): 657-664. [26] MAIERHOFER C, KRANKENHAGEN R, RÖLLIG M. Application of thermographic testing for the characterization of impact damage during and after impact load[J]. Composites Part B:Engineering, 2019, 173: 106899. doi: 10.1016/j.compositesb.2019.106899 [27] ASTM Committee. Standard test method for measuring the damage resistance of a fiber-reinforced polymer matrix composite to a drop-weight impact event: ASTM D7136/D7136M-12[S]. West Conshohocken: [s.n.], 2015: 1-16. [28] RICHARDSON M O W, WISHEART M J. Review of low-velocity impact properties of composite materials[J]. Composites Part A:Applied Science and Manufacturing, 1996, 27(12): 1123-1131. doi: 10.1016/1359-835X(96)00074-7 [29] KANG T J, KIM C. Impact energy absorption mechanism of largely deformable composites with different reinforcing structures[J]. Fibers and Polymers, 2000, 1(1): 45-54. doi: 10.1007/BF02874876 [30] BIOT M A. Thermoelasticity and irreversible thermodynamics[J]. Journal of Applied Physics, 1956, 27(3): 240-253. doi: 10.1063/1.1722351 [31] MEOLA C, CARLOMAGNO G M. Infrared thermography to evaluate impact damage in glass/epoxy with manufacturing defects[J]. International Journal of Impact Engineering, 2014, 67: 1-11. doi: 10.1016/j.ijimpeng.2013.12.010 -

下载:

下载: