-

摘要:

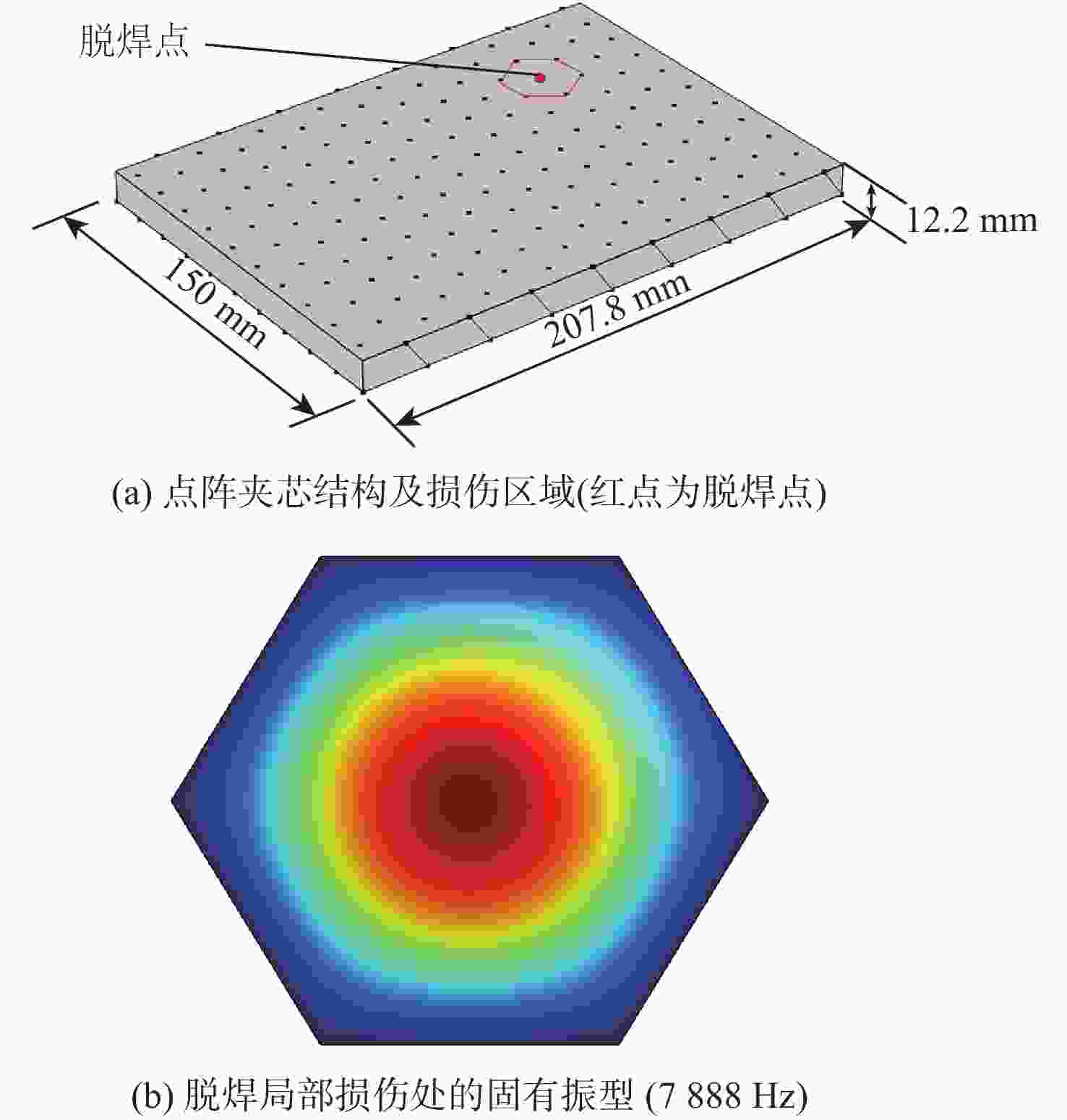

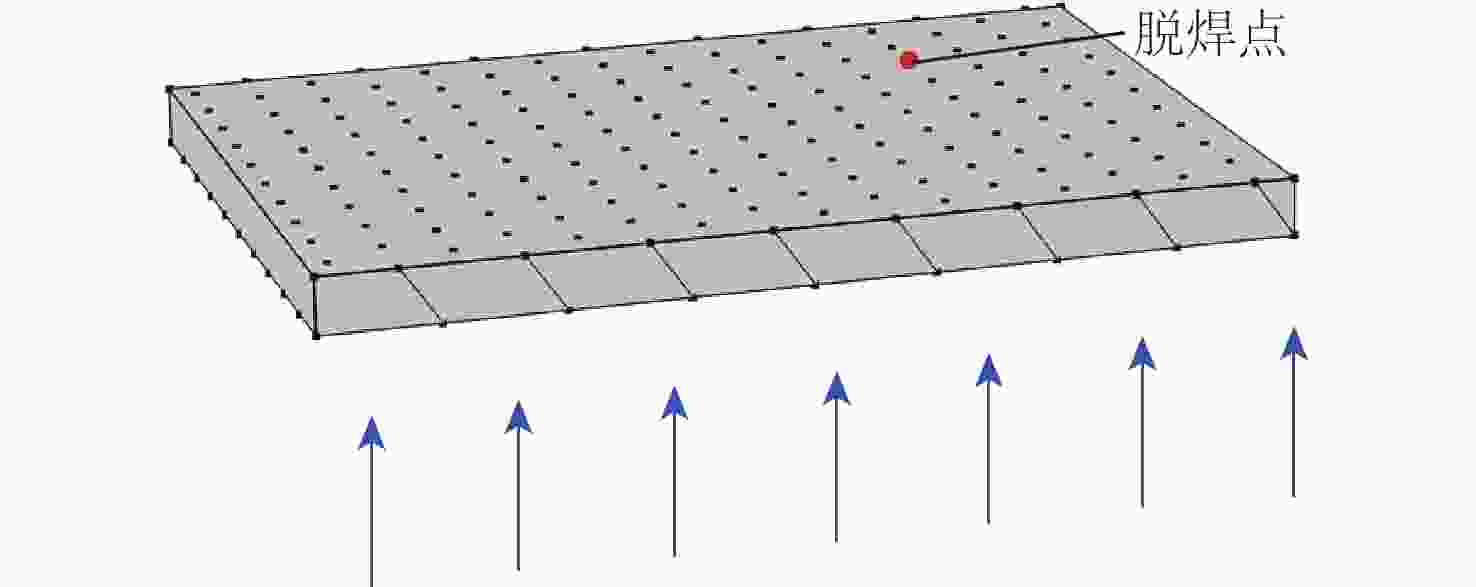

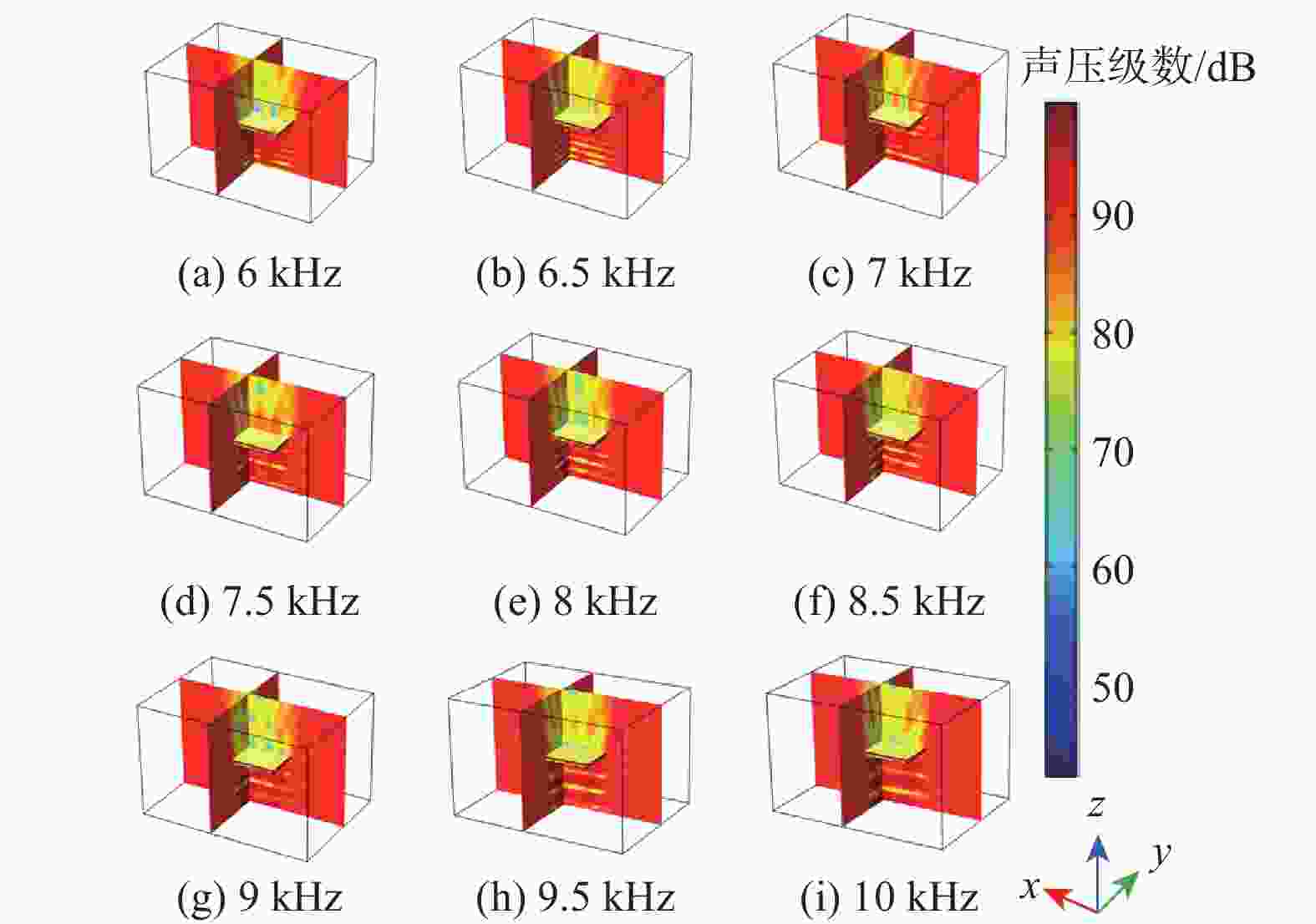

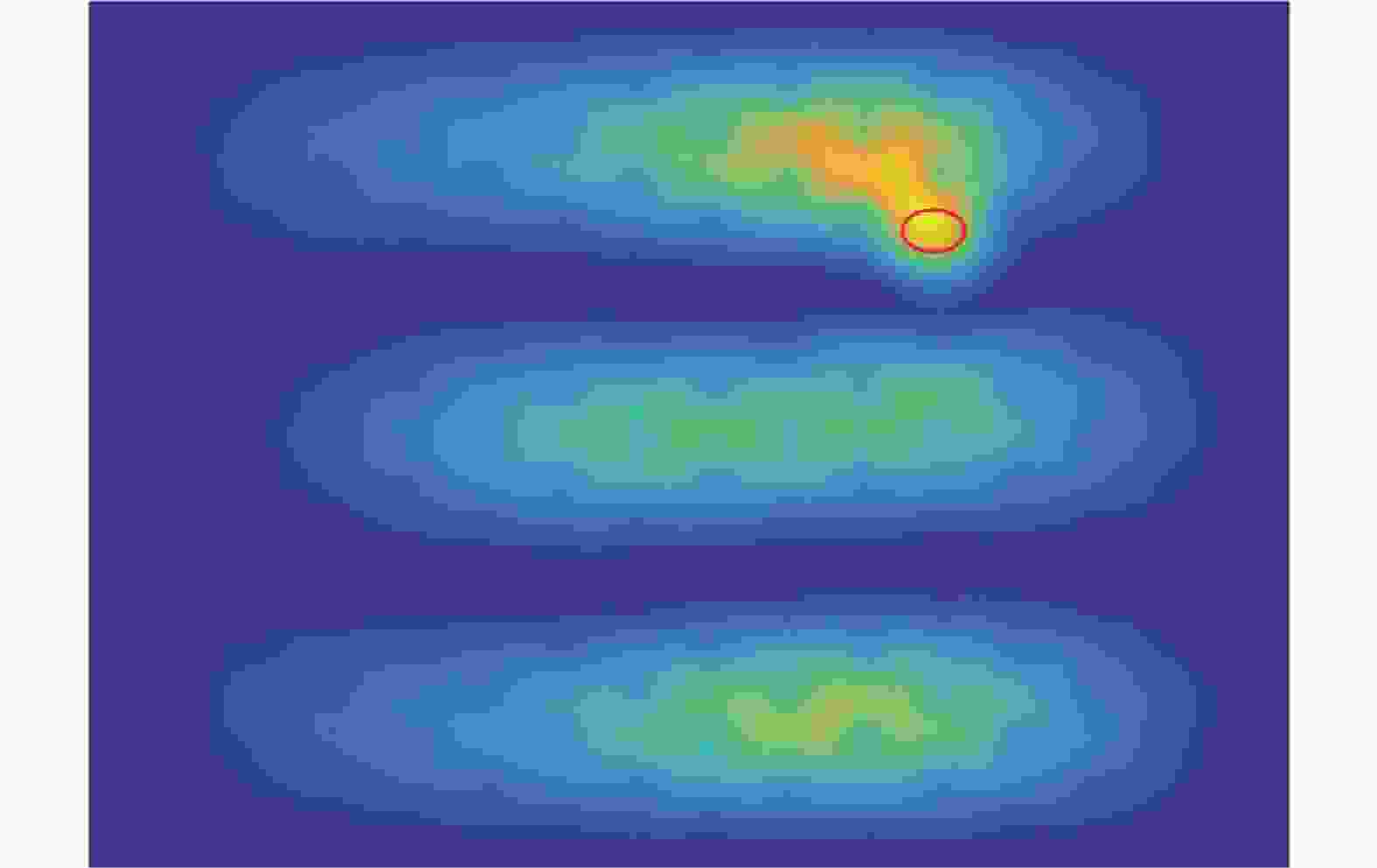

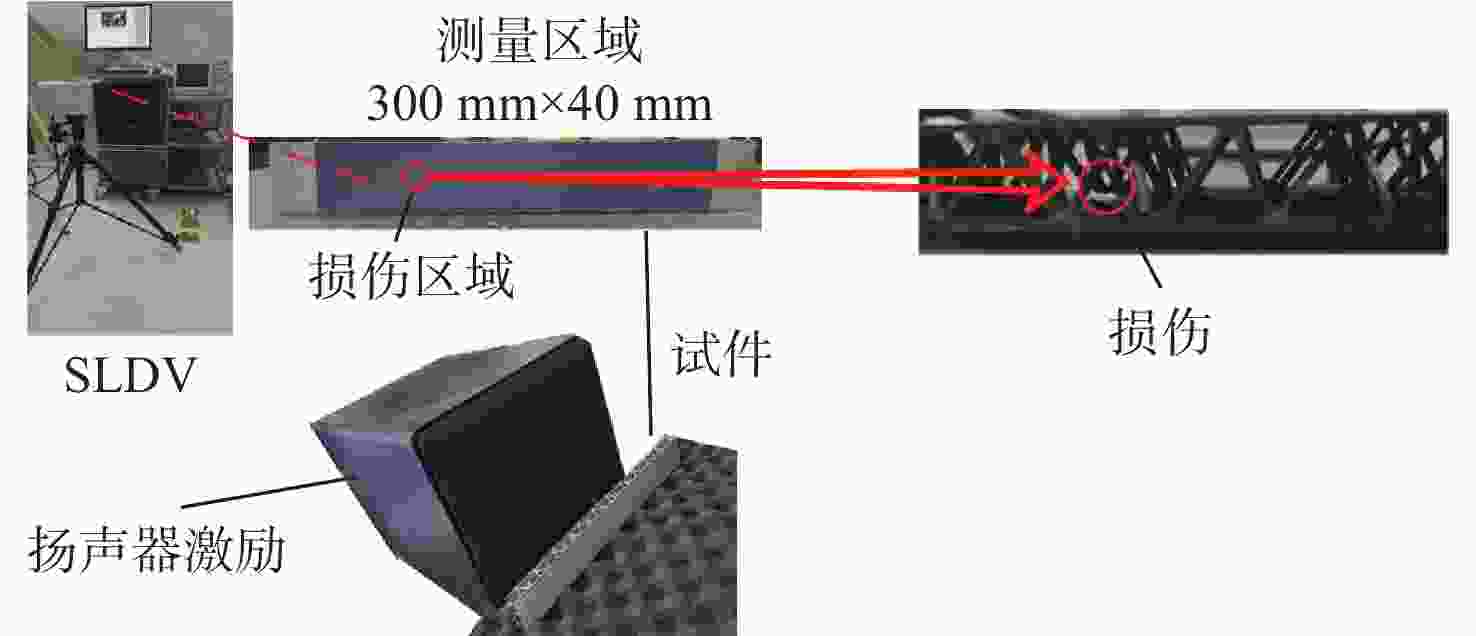

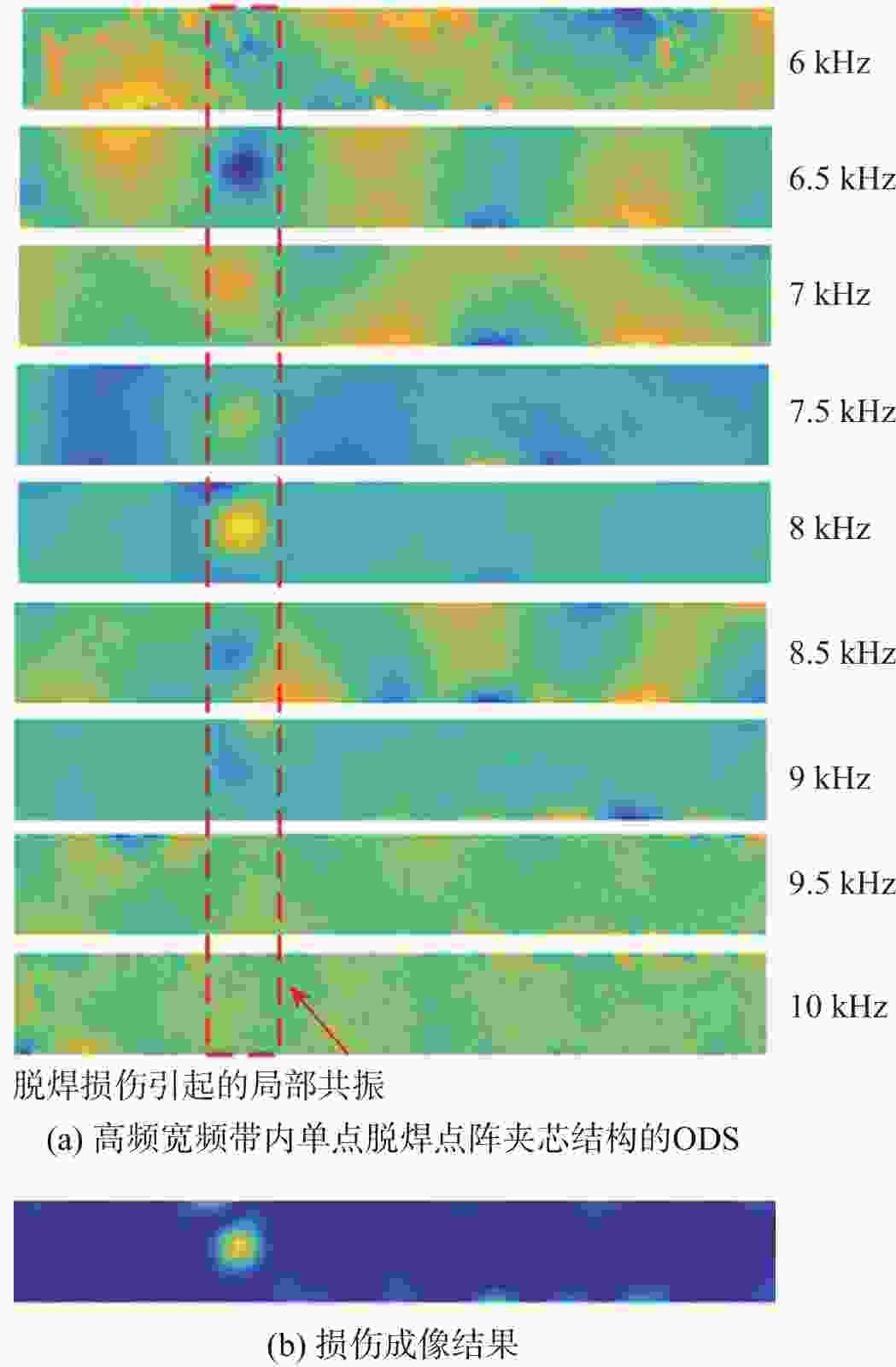

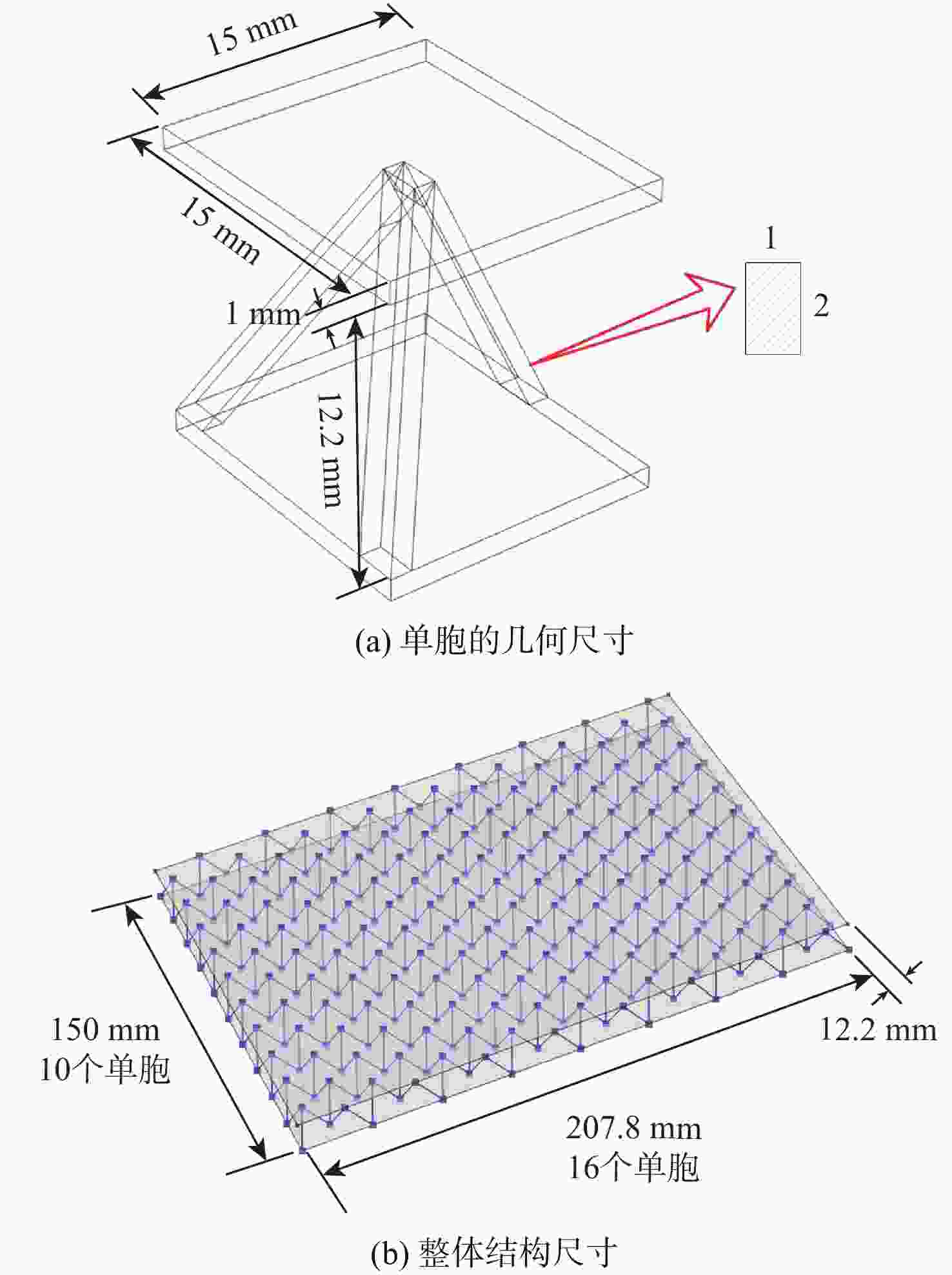

针对点阵夹芯结构的脱焊等损伤问题,提出了基于高频动态响应的非接触式损伤成像技术,根据无基线损伤指标分析结构高频响应,实现脱焊损伤成像。数值仿真中,依据局部共振理论,以损伤区域低阶固有频率作为中心频率计算结构在声场激振下宽频段内振动响应,采用无基线损伤指标实现损伤成像,由损伤成像结果准确识别脱焊损伤位置;试验中,采用扬声器激振,扫描时激光测振系统进行全场振型拾取的非接触式试验测量方案,成功识别脱焊损伤的位置。验证了非接触式成像技术对点阵夹芯结构脱焊损伤检测的适用性与可行性,实现了无附加结构质量、无健康基准信号下的损伤识别。

Abstract:Aiming at the damage problems such as debonding of lattice sandwich structure, a non-contact damage imaging technology based on high-frequency dynamic response is proposed. The high-frequency response of the structure is analysed according to the non-baseline damage index to realize debonding damage imaging. In the numerical simulation, based on the local resonance theory, the low-order natural frequency of the damage area is used as the centre frequency to calculate the response of the structure in a wide frequency range under sound field excitation, and the damage imaging is realized by using no baseline damage index. The damage imaging results can accurately identify the damage location; In the test, the non-contact test measurement scheme of using the loudspeaker to excite, and the laser vibration measurement system to pick up the full-field mode shape during scanning successfully identified the location of the debonding damage. The applicability and feasibility of the non-contact imaging technology for the damage detection of the dot matrix sandwich structure debonding is verified, and the damage identification without additional structural quality and without health reference signals is realized.

-

-

[1] 陈东, 吴永鹏, 李忠盛, 等. 轻质高强多功能点阵夹层结构研究进展[J]. 装备环境工程, 2020, 17(4): 87-94.CHEN D, WU Y P, LI Z S, et al. Research progress of light weight, high strength and multifunctional lattice sandwich structure[J]. Equipment Environmental Engineering, 2020, 17(4): 87-94(in Chinese). [2] 曾卫. 超轻多孔金属材料的多功能特性及应用[J]. 科技传播, 2016(14): 218-219. doi: 10.16607/j.cnki.1674-6708.2016.14.134ZENG W. Multifunctional properties and applications of ultra-light porous metal materials[J]. Science and Technology Communication, 2016(14): 218-219(in Chinese). doi: 10.16607/j.cnki.1674-6708.2016.14.134 [3] HAN Y, JIANG W, WANG J, et al. Multi-functional sandwich structure with metamaterial antenna lattice cores: Protection, radiation and absorption[J]. IET Microwaves Antennas & Propagation, 2020, 14(7): 593-599. [4] 王向明, 苏亚东, 吴斌, 等. 微桁架点阵结构在飞机结构/功能一体化中的应用[J]. 航空制造技术, 2018, 61(10): 16-25. doi: 10.16080/j.issn1671-833x.2018.10.016WANG X M, SU Y D, WU B, et al. Application for additive manufacturing of lattice materials on integrated aircraft structures and functions[J]. Aviation Manufacturing Technology, 2018, 61(10): 16-25(in Chinese). doi: 10.16080/j.issn1671-833x.2018.10.016 [5] 郑云. 中空夹芯复合材料在轨道交通内装上的应用[J]. 玻璃纤维, 2013(4): 19-23. doi: 10.3969/j.issn.1005-6262.2013.04.006ZHENG Y. Application of 3D sandwich composite in interiors of rail vehicles[J]. Fiber Glass, 2013(4): 19-23(in Chinese). doi: 10.3969/j.issn.1005-6262.2013.04.006 [6] WANG B, ZHANG G Q, WANG S X, et al. High velocity impact response of composite lattice core sandwich structures[J]. Applied Composite Materials, 2014, 21(2): 377-389. doi: 10.1007/s10443-013-9345-4 [7] 励争, 周洁, 李冰, 等. 轻质点阵夹芯板热屈曲的实验研究[J]. 实验力学, 2018, 33(2): 167-174. doi: 10.7520/1001-4888-17-078LI Z, ZHOU J, LI B, et al. Experimental study of thermal buckling of lightweight lattice sandwich panel[J]. Journal of Experimental Mechanics, 2018, 33(2): 167-174(in Chinese). doi: 10.7520/1001-4888-17-078 [8] LOU J, WU L, MA L, et al. Effects of local damage on vibration characteristics of composite pyramidal truss core sandwich structure [J]. Composites Part B: Engineering, 2014, 62: 73-87. [9] MCELROY M, LEONE F, RATCLIFFE J, et al. Simulation of delamination-migration and core crushing in a CFRP sandwich structure [J]. Composites, Part A: Applied Science and Manufacturing, 2015, 79: 192-202. [10] YUAN W, SONG H, LU L, et al. Effect of local damages on the buckling behaviour of pyramidal truss core sandwich panels[J]. Composite Structures, 2016, 149: 271-278. [11] 袁梅, 商富凯, 董韶鹏. 基于经验小波变换的复合材料板声发射源定位[J]. 北京航空航天大学学报, 2018, 44(7): 1395-1401. doi: 10.13700/j.bh.1001-5965.2017.0527YUAN M, SHANG F K, DONG S P. Acoustic emission source location for composite plate based on empirical wavelet transform[J]. Journal of Beijing University of Aeronautics and Astronautics, 2018, 44(7): 1395-1401(in Chinese). doi: 10.13700/j.bh.1001-5965.2017.0527 [12] 曾康洋. 浅谈射线检测技术在无损检测中的应用[J]. 城市建设理论研究(电子版), 2015, 5(26): 2377.ZENG K Y. On the application of ray detection technology in nondestructive testing[J]. Theoretical Research on Urban Construction (Electronic Version), 2015, 5(26): 2377(in Chinese). [13] 王树志, 刘广华, 贾玉军, 等. 表面状态对铝合金铸件荧光渗透检测的影响[J]. 无损检测, 2016, 38(2): 48-51. doi: 10.11973/wsjc201602012WANG S Z, LIU G H, JIA Y J, et al. Influence of surface state on fluorescent penetrant inspection of aluminium alloy casting[J]. Nondestructive Testing, 2016, 38(2): 48-51(in Chinese). doi: 10.11973/wsjc201602012 [14] BALASUBRAMANIAM K, SIKDAR S, FIBOREK P, et al. Ultrasonic guided wave signal based nondestructive testing of a bonded composite structure using piezoelectric transducers[J]. Signals, 2021, 2(1): 13-24. doi: 10.3390/signals2010002 [15] PARK S M, KWAK Y, LEE J, et al. Nondestructive spot weld quality evaluation by measurement of structural vibration transfer through joined panels[J]. Journal of Nondestructive Evaluation, 2019, 38: 71. doi: 10.1007/s10921-019-0610-9 [16] SOKOLINSKY V S, BREMEN H, LESKO J, et al. Higher-order free vibrations of sandwich beams with a locally damaged core[J]. International Journal of Solids & Structures, 2004, 41(22-23): 6529-6547. [17] LU L L, SONG H W, YUAN W, et al. Baseline-free damage identification of metallic sandwich panels with truss core based on vibration characteristics[J]. Structural Health Monitoring, 2017, 16(1): 24-38. doi: 10.1177/1475921716660055 [18] LI B, LI Z, ZHOU J, et al. Damage localization in composite lattice truss core sandwich structures based on vibration characteristics[J]. Composite Structures, 2015, 126: 34-51. doi: 10.1016/j.compstruct.2015.02.046 [19] LU L L, LE J, SONG H, et al. Damage detection of sandwich panels with truss core based on time domain dynamic responses[J]. Composite Structures, 2019, 211: 443-454. [20] 孙建刚, 赵晓宇, 吴有生, 等. 针对一型深水结构物的水下声场计算与试验研究[J]. 船舶力学, 2018, 22(8): 1011-1019.SUN J G, ZHAO X Y, WU Y S, et al. Numerical analysis and acoustic test of sound field characteristics for some type of deepwater structure[J]. Journal of Ship Mechanics, 2018, 22(8): 1011-1019(in Chinese). -

下载:

下载: