-

摘要:

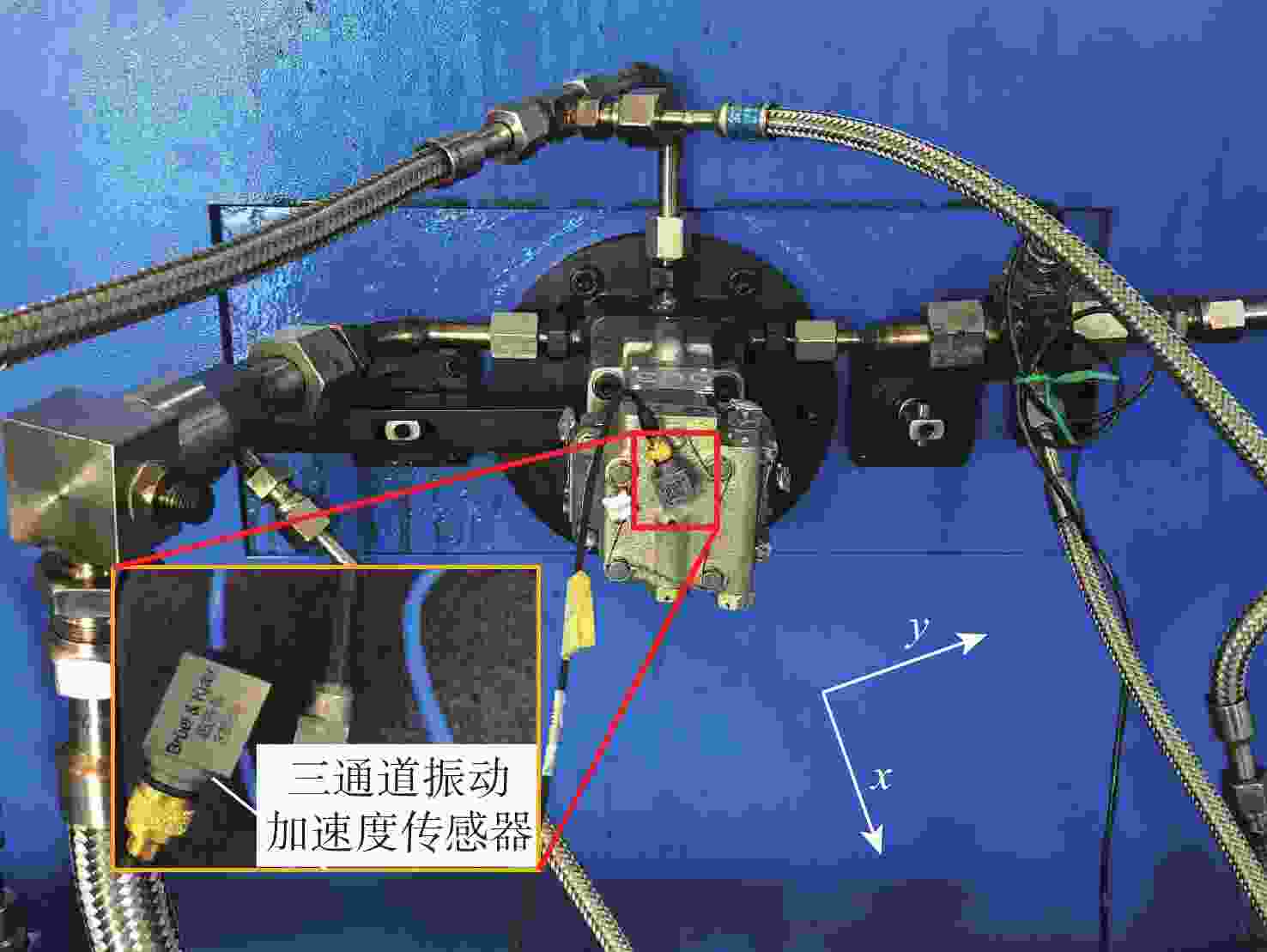

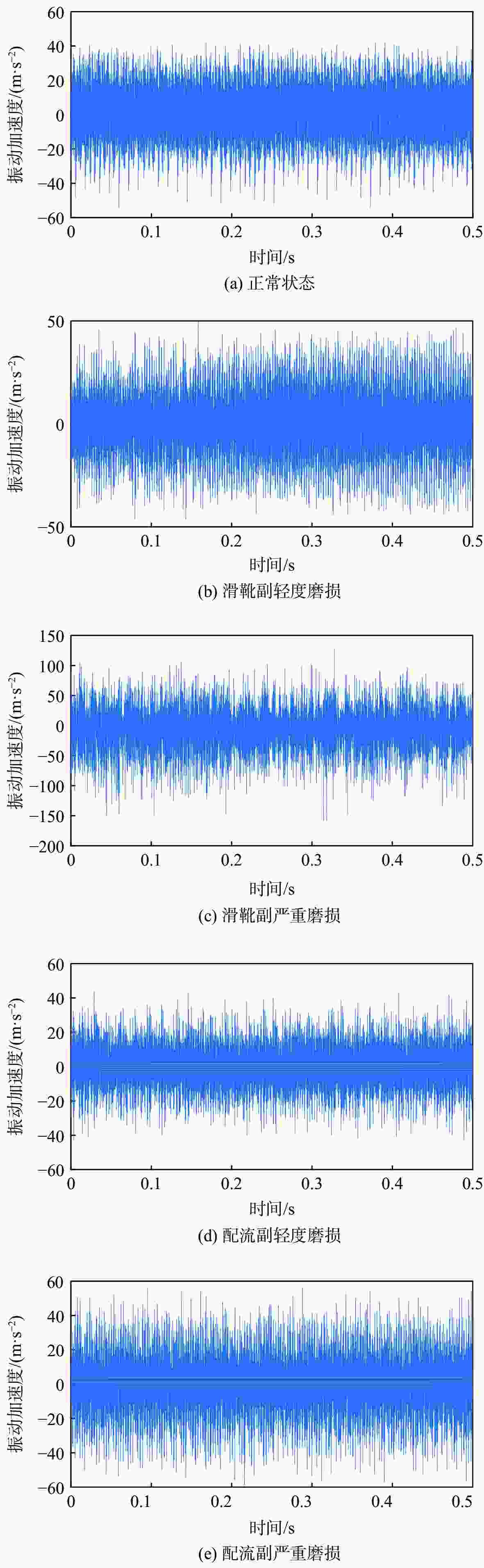

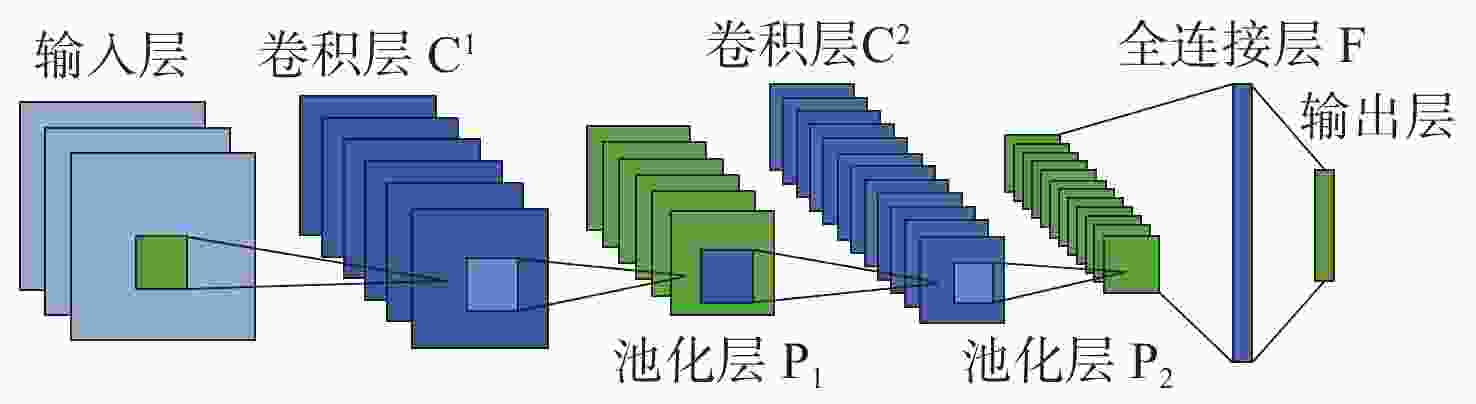

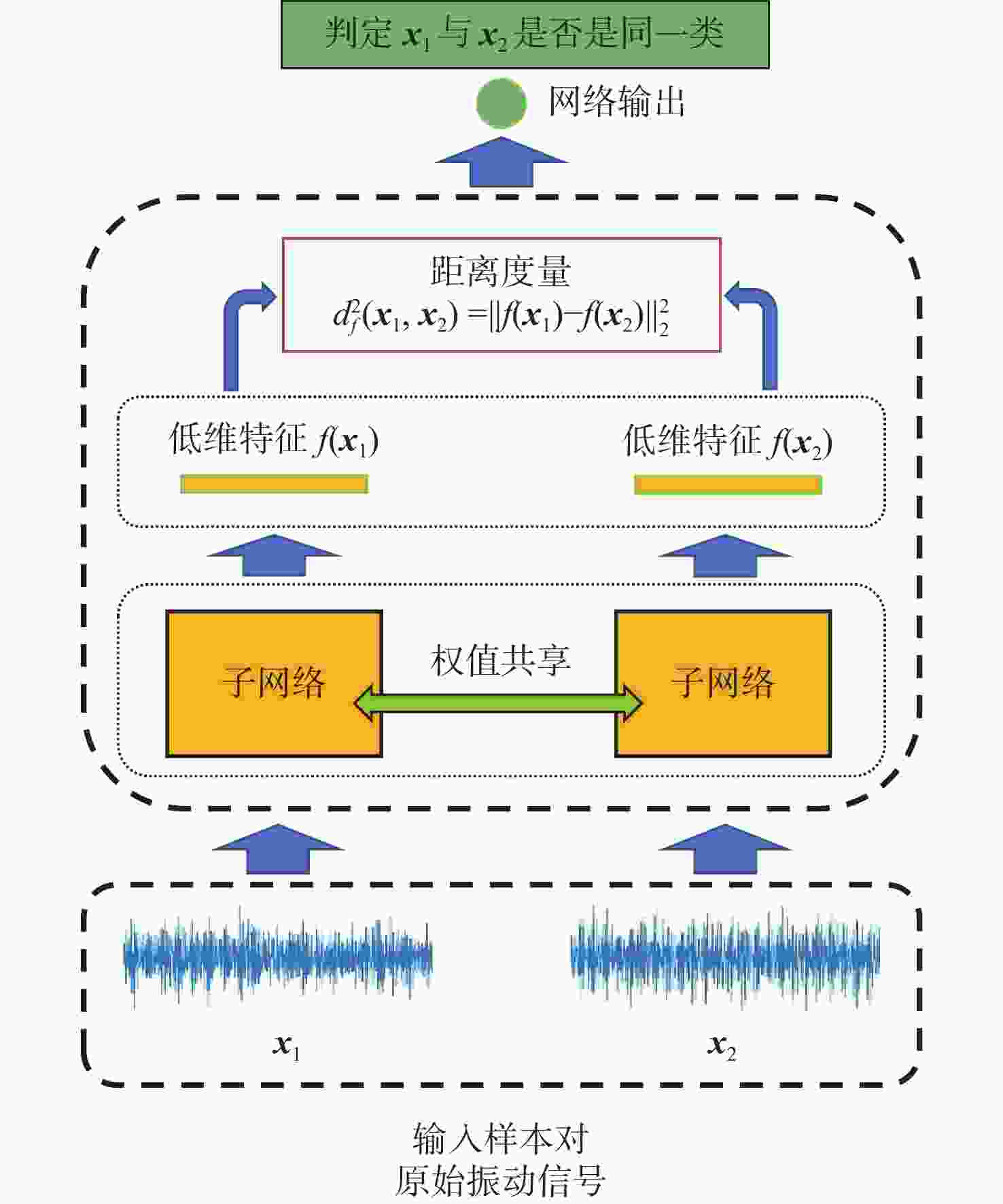

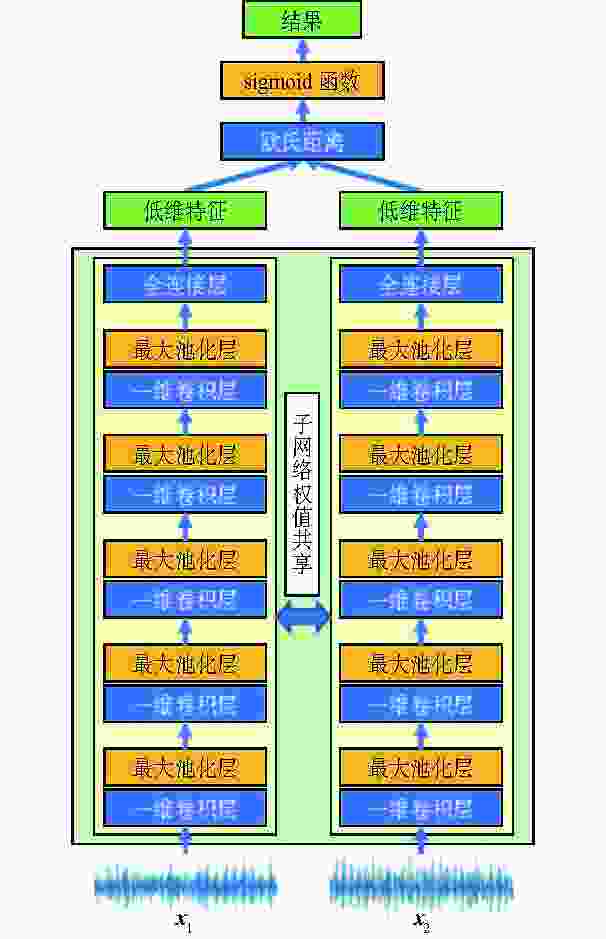

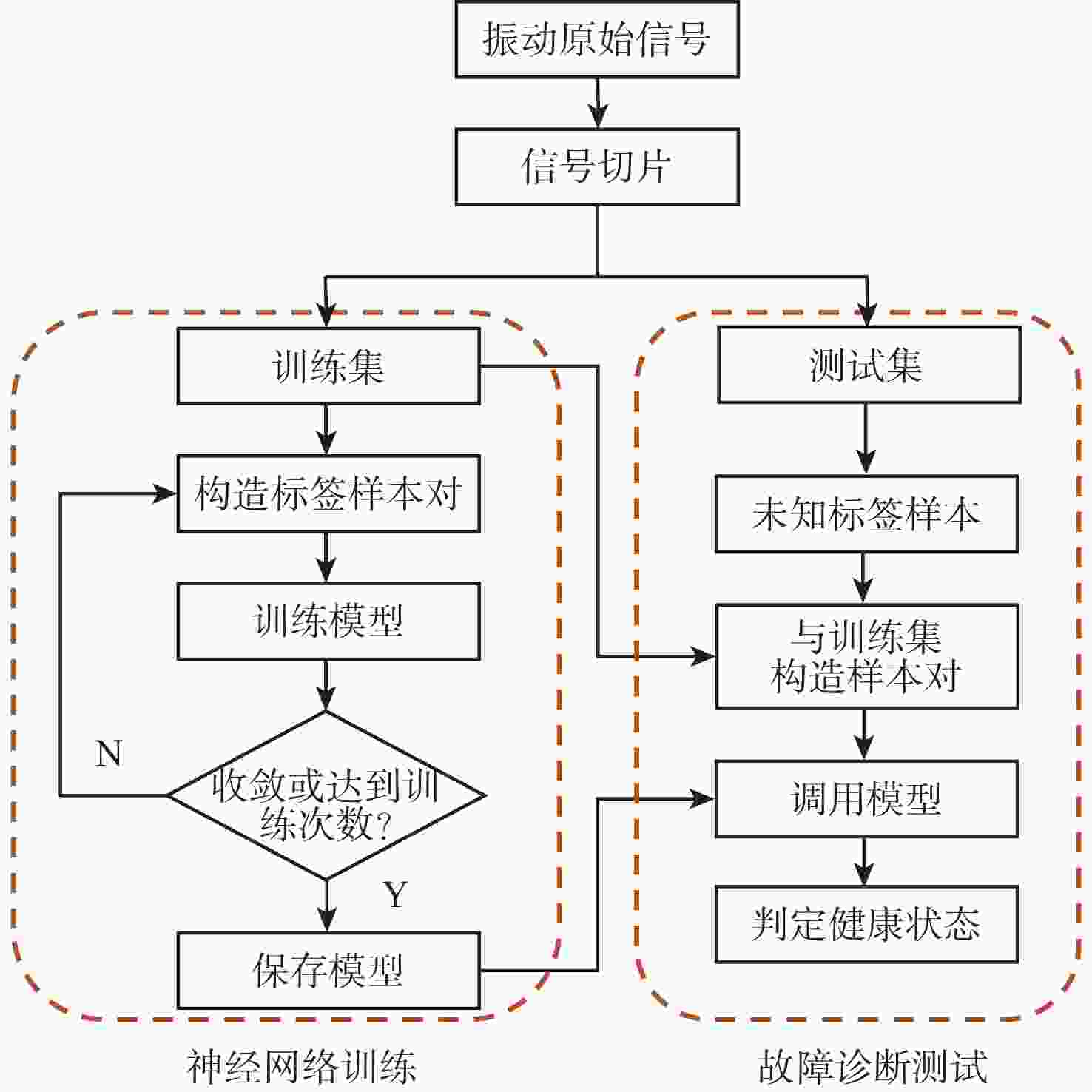

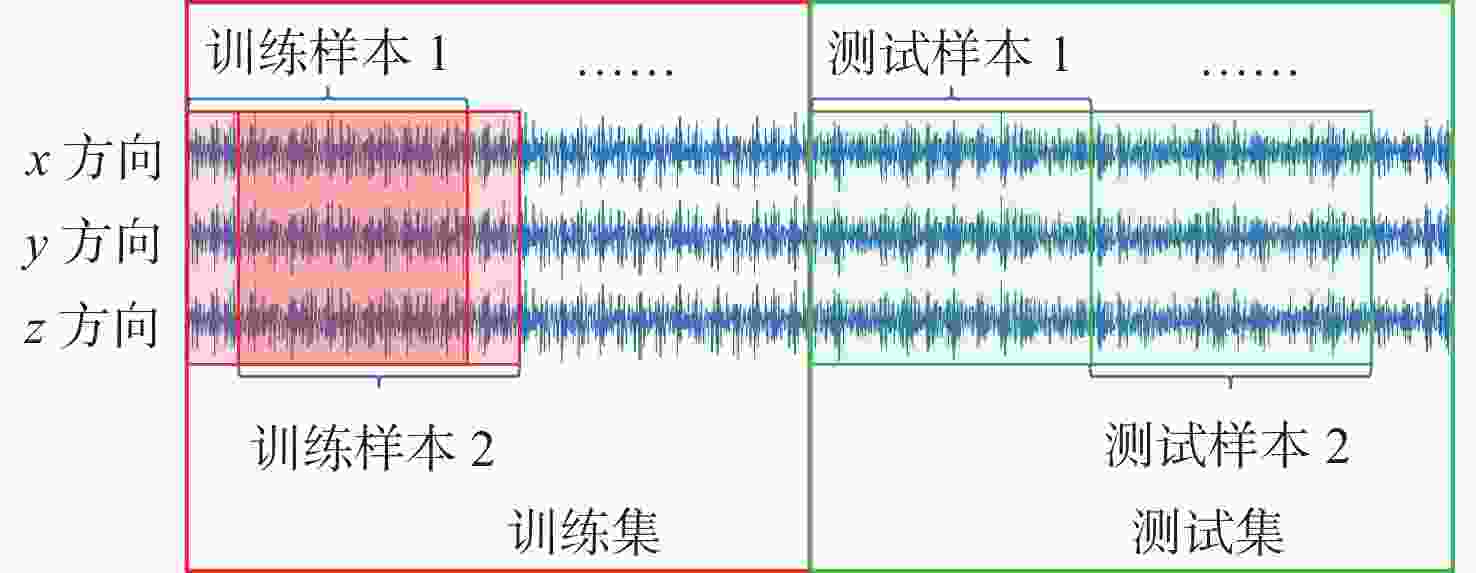

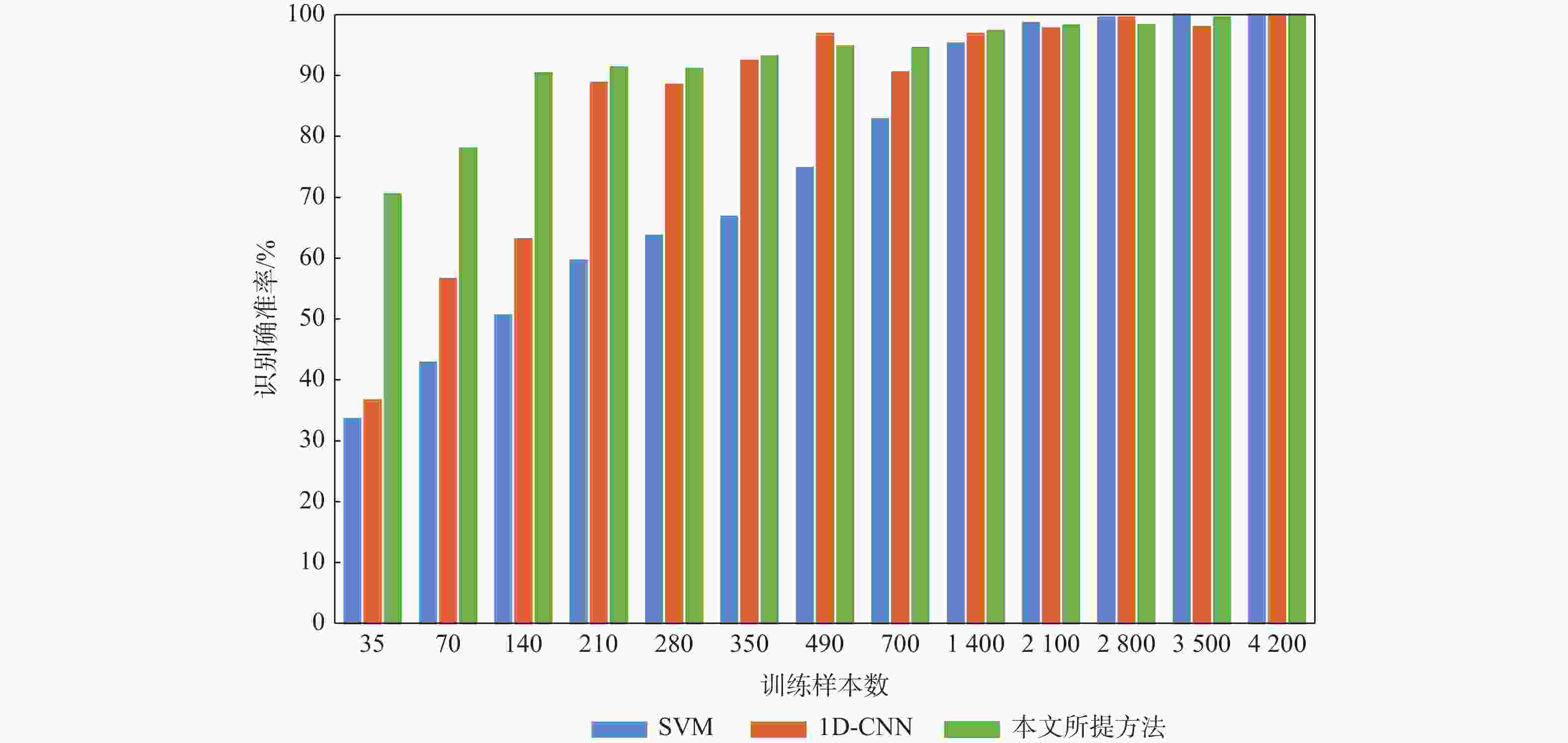

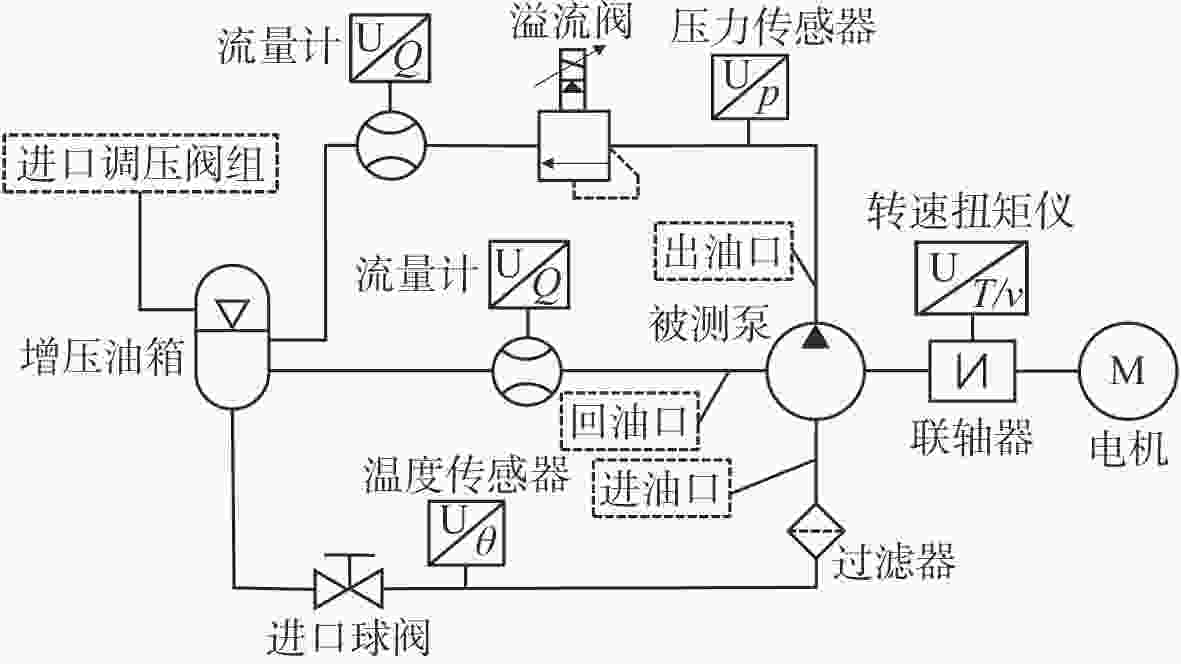

针对目前基于深度神经网络的柱塞泵故障诊断方法在小样本条件下精度低、模型欠拟合问题,提出一种小样本条件下基于孪生神经网络的柱塞泵故障诊断方法。搭建了柱塞泵故障实验台,采集柱塞泵在不同健康状态下的壳体振动信号;使用由卷积层和池化层组成孪生子网络自适应地从原始振动信号中提取低维特征,使用欧式距离判定输入样本对的特征相似度;通过相似度对比的方法扩大训练样本数量并训练孪生神经网络模型;最后,对测试样本进行健康状态识别。实验结果表明:与传统深度神经相比,所提方法在小样本情况下具有更高的准确率。同时,多通道数据融合实验表明:所提方法能够从不同通道的信号中学习到有关故障信息,多通道数据融合可以进一步提高诊断准确率。

Abstract:Aiming at the problems of low accuracy and under-fitting in current fault diagnosis methods for piston pumps based on deep neural networks with small samples, a new fault diagnosis method for piston pumps based on Siamese neural networks was proposed. A test bench for piston pumps was built to collect the vibration signals of the pump housing under different health states. The convolution layers and pooling layers were used to construct the Siamese sub network and adaptively extract low-dimensional features from the raw vibration signals. The similarity of the input sample pairs was determined by Euclidean distance to expand training samples, train the Siamese neural network model. And finally identify the health states on the testing dataset. Experimental results demonstrate that compared with traditional deep neural networks, the proposed method has higher diagnosis accuracy with small samples. In addition, data fusion experiments show that the proposed method can learn relevant fault information from signals in different channels, which can improve the accuracy of the fault diagnosis.

-

Key words:

- piston pump /

- convolution neural network /

- Siamese neural network /

- small sample /

- fault diagnosis /

- data fusion

-

表 1 被测泵的额定参数

Table 1. Rated parameters of tested pump

参数 数值 柱塞数 9 排量/(mL·r−1) 1.2 额定转速/(r·min−1) 1 000 出口压力/MPa 21 进口压力/MPa 0.25 表 2 被测泵的健康状态、故障注入方式与状态标签

Table 2. Health states, fault injection modes and labels of tested pump

健康状态 注入方式/ mm 标签 正常 0 滑靴副轻度磨损 摩擦副间隙0.05 1 滑靴副中度磨损 摩擦副间隙0.15 2 滑靴副严重磨损 摩擦副间隙0.20 3 配流副轻度磨损 转子弹簧剪短1.0 4 配流副中度磨损 转子弹簧剪短3.6 5 配流副严重磨损 转子弹簧剪短5.6 6 表 3 孪生神经网络主要结构参数

Table 3. Main structural parameters of Siamese neural network

网络层 关键参数 激活函数 卷积层1 卷积核为32,数目为16,步长为8 ReLU 池化层1 池化核为2 卷积层2 卷积核为3,数目为16,步长为1 ReLU 池化层2 池化核为2 卷积层3 卷积核为2,数目为32,步长为1 ReLU 池化层3 池化核为2 卷积层4 卷积核为3,数目为32,步长为1 ReLU 池化层4 池化核为2 卷积层5 卷积核为3,数目为64,步长为1 ReLU 池化层5 池化核为2 全连接层 神经元数量为100 sigmoid 输出层 神经元数量为1 sigmoid 表 4 数据集划分

Table 4. Data set division

健康状态 状态标签 训练集数量 测试集数量 正常 0 600 30 滑靴副轻度磨损 1 600 30 滑靴副中度磨损 2 600 30 滑靴副严重磨损 3 600 30 配流副轻度磨损 4 600 30 配流副中度磨损 5 600 30 配流副严重磨损 6 600 30 表 5 不同训练样本数量下对各模型的诊断结果

Table 5. Diagnosis results of models under different number of training samples

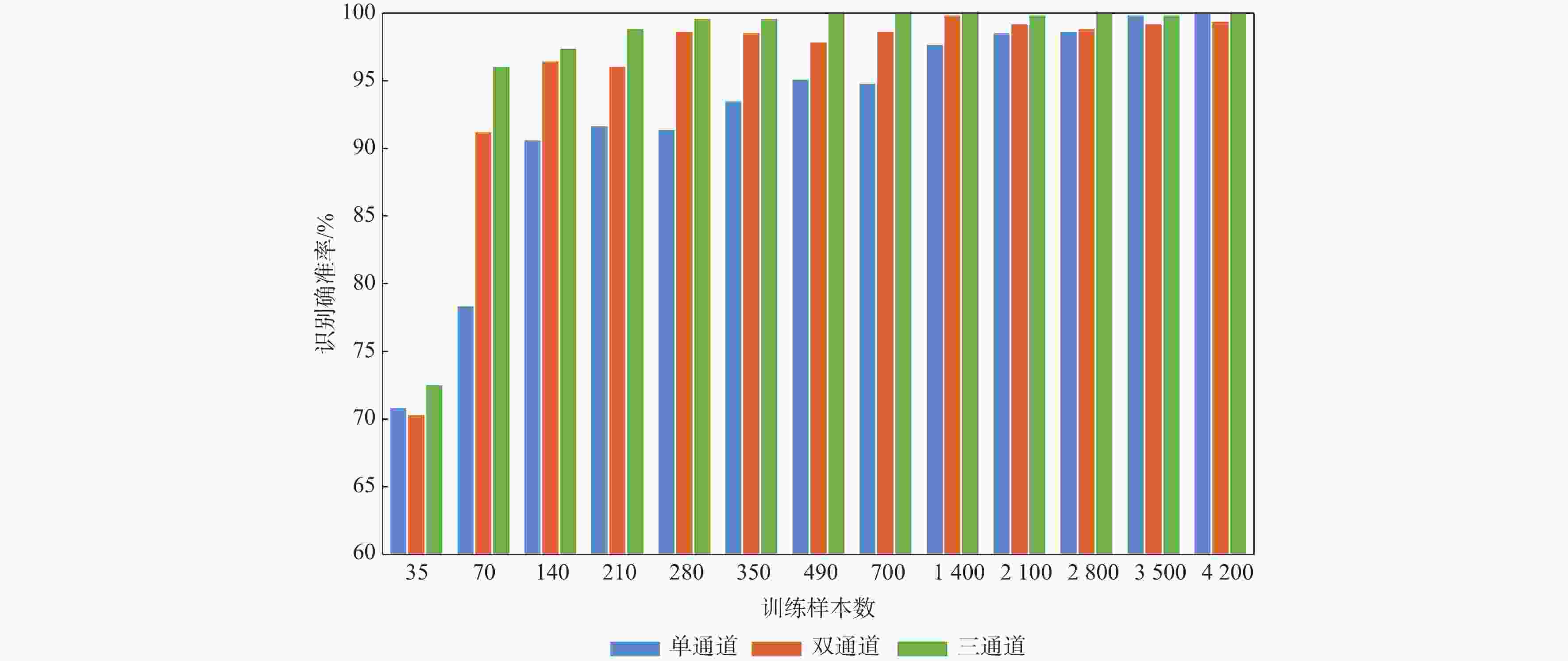

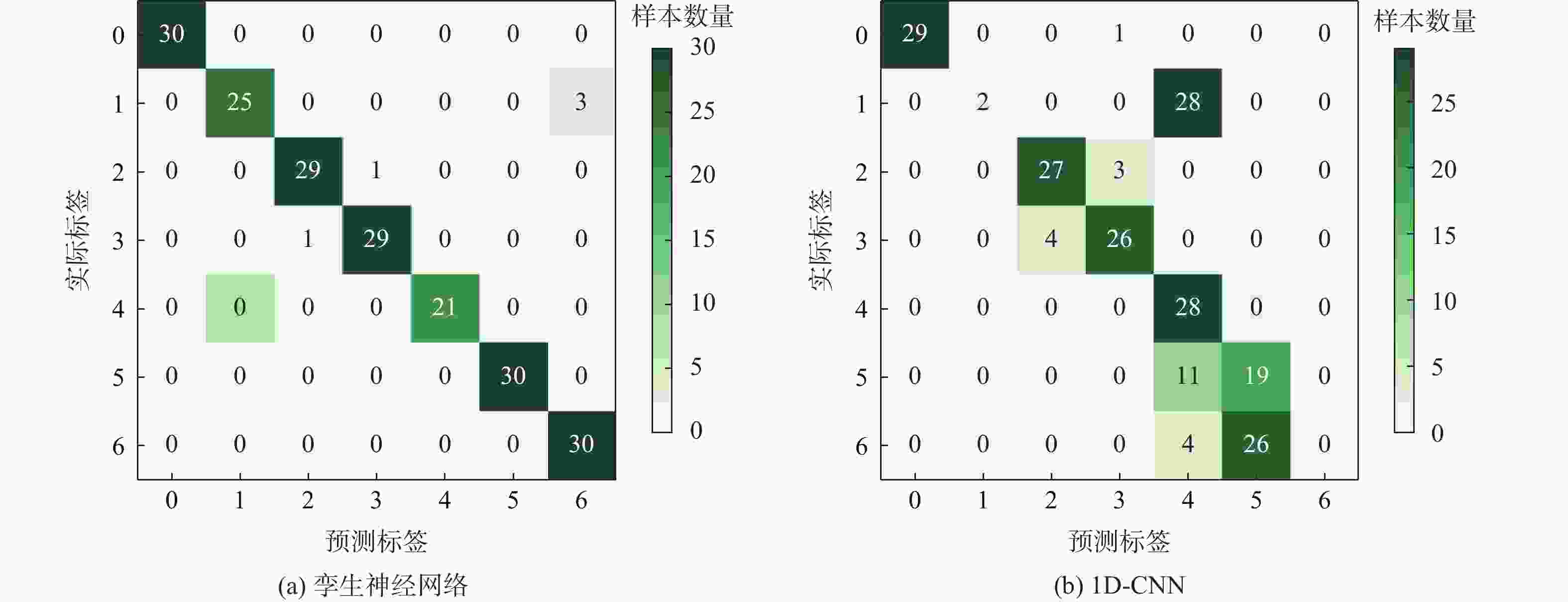

诊断模型 不同训练样本数量下的识别准确率/% 35 70 140 210 280 350 490 700 1 400 2 100 2 800 3 500 4 200 SVM 34.00 43.14 50.59 60.00 64.10 67.14 75.14 83.24 95.62 98.95 99.80 99.90 100 1D-CNN 36.95 56.95 63.43 89.14 88.86 92.76 97.14 90.86 97.14 98.10 99.90 98.29 100 本文所提方法 70.86 78.38 90.67 91.71 91.43 93.52 95.14 94.68 97.71 98.57 98.67 99.90 100 表 6 不同通道数量下的诊断结果

Table 6. Diagnosis results under different number of channels

诊断模型 不同训练样本数量下的识别准确率/% 35 70 140 210 280 350 490 700 1 400 2 100 2 800 3 500 4 200 单通道 70.86 78.38 90.67 91.71 91.43 93.52 95.14 94.86 97.71 98.57 98.67 99.90 100 双通道 70.34 91.24 96.48 96.10 98.67 98.57 97.90 98.67 99.90 99.24 98.86 99.24 99.43 三通道 72.57 96.10 97.43 98.86 99.62 99.62 100 100 100 99.90 100 99.90 100 -

[1] 彭熙伟, 陈建萍. 液压技术的发展动向[J]. 液压与气动, 2007(3): 1-5. doi: 10.3969/j.issn.1000-4858.2007.03.001PENG X W, CHEN J P. The future trends of hydraulics[J]. Chinese Hydraulics & Pneumatics, 2007(3): 1-5(in Chinese). doi: 10.3969/j.issn.1000-4858.2007.03.001 [2] TANG S N, ZHU Y, YUAN S Q, et al. Intelligent diagnosis towards hydraulic axial piston pump using a novel integrated CNN model[J]. Sensors, 2020, 20(24): 7152. doi: 10.3390/s20247152 [3] KUMAR S, BERGADA J M, WATTON J. Axial piston pump grooved slipper analysis by CFD simulation of three-dimensional NVS equation in cylindrical coordinates[J]. Computers & Fluids, 2009, 38(3): 648-663. [4] 雷亚国, 贾峰, 孔德同, 等. 大数据下机械智能故障诊断的机遇与挑战[J]. 机械工程学报, 2018, 54(5): 94-104. doi: 10.3901/JME.2018.05.094LEI Y G, JIA F, KONG D T, et al. Opportunities and challenges of machinery intelligent fault diagnosis in big data era[J]. Journal of Mechanical Engineering, 2018, 54(5): 94-104(in Chinese). doi: 10.3901/JME.2018.05.094 [5] WANG S H, XIANG J W, ZHONG Y T, et al. A data indicator-based deep belief networks to detect multiple faults in axial piston pumps[J]. Mechanical Systems and Signal Processing, 2018, 112: 154-170. doi: 10.1016/j.ymssp.2018.04.038 [6] LIU R N, YANG B Y, ZIO E, et al. Artificial intelligence for fault diagnosis of rotating machinery: A review[J]. Mechanical Systems and Signal Processing, 2018, 108: 33-47. doi: 10.1016/j.ymssp.2018.02.016 [7] LAN Y, HU J W, HUANG J H, et al. Fault diagnosis on slipper abrasion of axial piston pump based on Extreme Learning Machine[J]. Measurement, 2018, 124: 378-385. doi: 10.1016/j.measurement.2018.03.050 [8] LU C Q, WANG S P, MAKIS V. Fault severity recognition of aviation piston pump based on feature extraction of EEMD paving and optimized support vector regression model[J]. Aerospace Science and Technology, 2017, 67: 105-117. doi: 10.1016/j.ast.2017.03.039 [9] 杜振东, 赵建民, 李海平, 等. 基于SA-EMD-PNN的柱塞泵故障诊断方法研究[J]. 振动与冲击, 2019, 38(8): 145-152. doi: 10.13465/j.cnki.jvs.2019.08.022DU Z D, ZHAO J M, LI H P, et al. A fault diagnosis method of a plunger pump based on SA-EMD-PNN[J]. Journal of Vibration and Shock, 2019, 38(8): 145-152(in Chinese). doi: 10.13465/j.cnki.jvs.2019.08.022 [10] 王鹏飞, 王新晴, 高天宇, 等. 基于包络谱和SVM的柱塞泵负荷状态识别[J]. 机械设计与制造, 2015(12): 237-239. doi: 10.3969/j.issn.1001-3997.2015.12.066WANG P F, WANG X Q, GAO T Y, et al. The recognition of piston pump’s load condition based on envelop spectrum and SVM[J]. Machinery Design & Manufacture, 2015(12): 237-239(in Chinese). doi: 10.3969/j.issn.1001-3997.2015.12.066 [11] 汪海晋, 尹宗宇, 柯臻铮, 等. 基于一维卷积神经网络的螺旋铣刀具磨损监测[J]. 浙江大学学报(工学版), 2020, 54(5): 931-939. doi: 10.3785/j.issn.1008-973X.2020.05.010WANG H J, YIN Z Y, KE Z Z, et al. Wear monitoring of helical milling tool based on one-dimensional convolutional neural network[J]. Journal of Zhejiang University (Engineering Science), 2020, 54(5): 931-939(in Chinese). doi: 10.3785/j.issn.1008-973X.2020.05.010 [12] HINTON G E, OSINDERO S, TEH Y W. A fast learning algorithm for deep belief nets[J]. Neural Computation, 2006, 18(7): 1527-1554. doi: 10.1162/neco.2006.18.7.1527 [13] VOULODIMOS A, DOULAMIS N, DOULAMIS A, et al. Deep learning for computer vision: A brief review[J]. Computational Intelligence and Neuroscience, 2018, 2018: 7068349. [14] YOUNG T, HAZARIKA D, PORIA S, et al. Recent trends in deep learning based natural language processing[J]. IEEE Computational Intelligence Magazine, 2018, 13(3): 55-75. doi: 10.1109/MCI.2018.2840738 [15] TIAN C W, FEI L K, ZHENG W X, et al. Deep learning on image denoising: an overview[J]. Neural Networks, 2020, 131: 251-275. doi: 10.1016/j.neunet.2020.07.025 [16] HOANG D T, KANG H J. A survey on deep learning based bearing fault diagnosis[J]. Neurocomputing, 2019, 335: 327-335. doi: 10.1016/j.neucom.2018.06.078 [17] 任浩, 屈剑锋, 柴毅, 等. 深度学习在故障诊断领域中的研究现状与挑战[J]. 控制与决策, 2017, 32(8): 1345-1358. doi: 10.13195/j.kzyjc.2016.1625REN H, QU J F, CHAI Y, et al. Deep learning for fault diagnosis: The state of the art and challenge[J]. Control and Decision, 2017, 32(8): 1345-1358(in Chinese). doi: 10.13195/j.kzyjc.2016.1625 [18] 魏晓良, 潮群, 陶建峰, 等. 基于LSTM和CNN的高速柱塞泵故障诊断[J]. 航空学报, 2021, 42(3): 423876.WEI X L, CHAO Q, TAO J F, et al. Cavitation fault diagnosis method for high-speed plunger pumps based on LSTM and CNN[J]. Acta Aeronautica et Astronautica Sinica, 2021, 42(3): 423876(in Chinese). [19] SUN S W, ZHANG S, JIANG W L, et al. Study on the health condition monitoring method of hydraulic pump based on convolutional neural network[C]//2020 12th International Conference on Measuring Technology and Mechatronics Automation. Piscataway: IEEE Press, 2020: 149-153. [20] XU G W, LIU M, JIANG Z F, et al. Online fault diagnosis method based on transfer convolutional neural networks[J]. IEEE Transactions on Instrumentation and Measurement, 2020, 69(2): 509-520. doi: 10.1109/TIM.2019.2902003 [21] WANG S H, XIANG J W. A minimum entropy deconvolution-enhanced convolutional neural networks for fault diagnosis of axial piston pumps[J]. Soft Computing, 2020, 24(4): 2983-2997. doi: 10.1007/s00500-019-04076-2 [22] CHICCO D. Siamese neural networks: An overview[J]. Methods in Molecular Biology, 2021, 2190: 73-94. [23] 贾智涵. 基于深度神经网络的机械故障诊断技术研究[D]. 北京: 北京邮电大学, 2019: 32-34.JIA Z H. A study of mechanical fault diagnosis technology based on deep neural network[D]. Beijing: Beijing University of Posts and Telecommunications, 2019: 32-34 (in Chinese). [24] 樊琳, 张惊雷. 联合损失优化孪生网络的行人重识别[J]. 计算机工程与科学, 2020, 42(2): 273-280. doi: 10.3969/j.issn.1007-130X.2020.02.012FAN L, ZHANG J L. Person re-identification based on joint loss and Siamese network[J]. Computer Engineering & Science, 2020, 42(2): 273-280(in Chinese). doi: 10.3969/j.issn.1007-130X.2020.02.012 [25] ZHANG Y C, PARDO B, DUAN Z Y. Siamese style convolutional neural networks for sound search by vocal imitation[J]. IEEE/ACM Transactions on Audio, Speech, and Language Processing, 2019, 27(2): 429-441. doi: 10.1109/TASLP.2018.2868428 [26] AHRABIAN K, BABAALI B. Usage of autoencoders and Siamese networks for online handwritten signature verification[J]. Neural Computing and Applications, 2019, 31(12): 9321-9334. doi: 10.1007/s00521-018-3844-z [27] 汤何胜, 李晶, 訚耀保. 轴向柱塞泵滑靴副功率损失特性[J]. 中南大学学报(自然科学版), 2017, 48(2): 361-369.TANG H S, LI J, YIN Y B. Power loss characteristics of slipper/swash plate pair in axial piston pump[J]. Journal of Central South University (Science and Technology), 2017, 48(2): 361-369(in Chinese). [28] 金列俊, 詹建明, 陈俊华, 等. 基于一维卷积神经网络的钻杆故障诊断[J]. 浙江大学学报(工学版), 2020, 54(3): 467-474. doi: 10.3785/j.issn.1008-973X.2020.03.006JIN L J, ZHAN J M, CHEN J H, et al. Drill pipe fault diagnosis method based on one-dimensional convolutional neural network[J]. Journal of Zhejiang University (Engineering Science), 2020, 54(3): 467-474(in Chinese). doi: 10.3785/j.issn.1008-973X.2020.03.006 -

下载:

下载: