-

摘要:

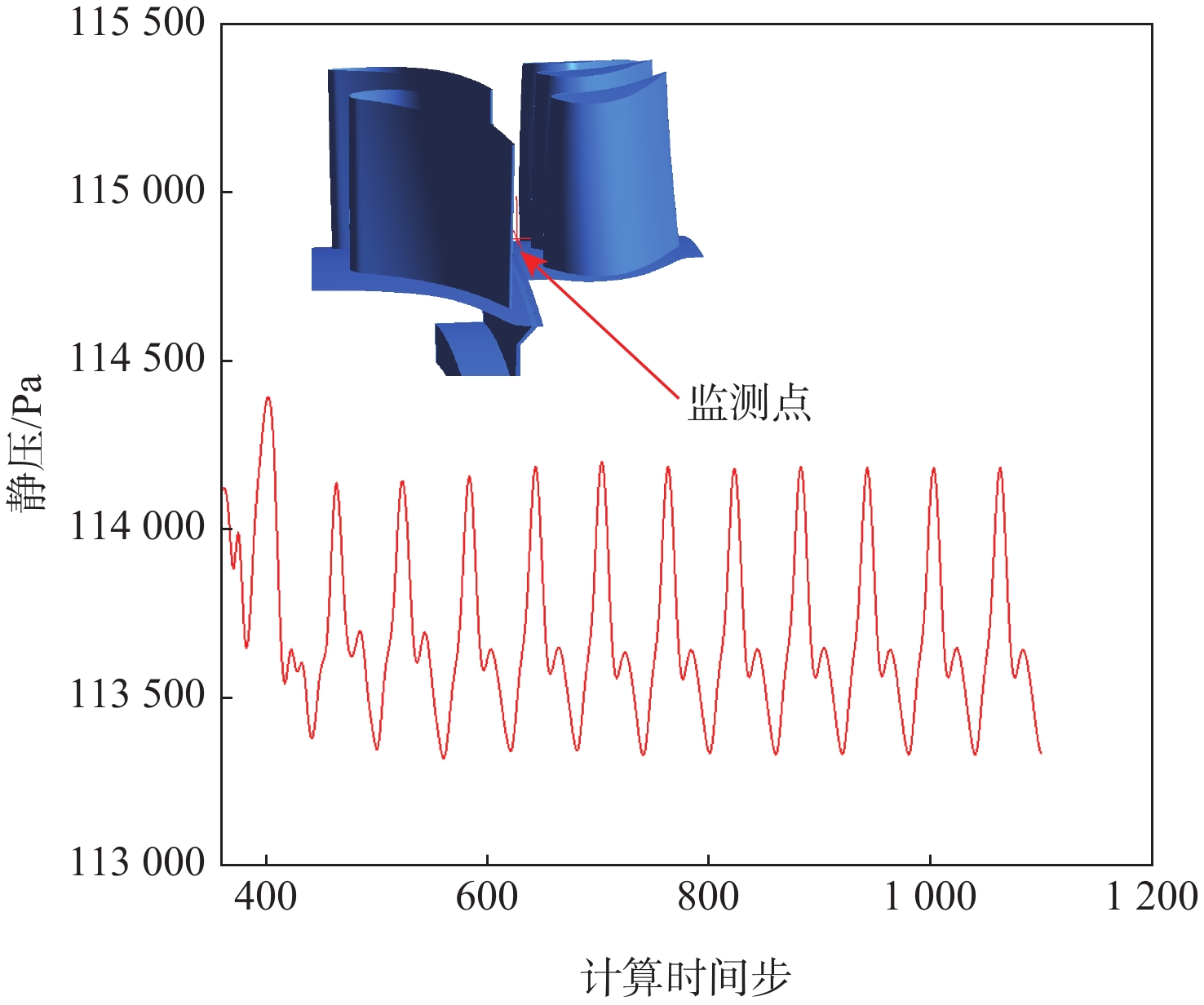

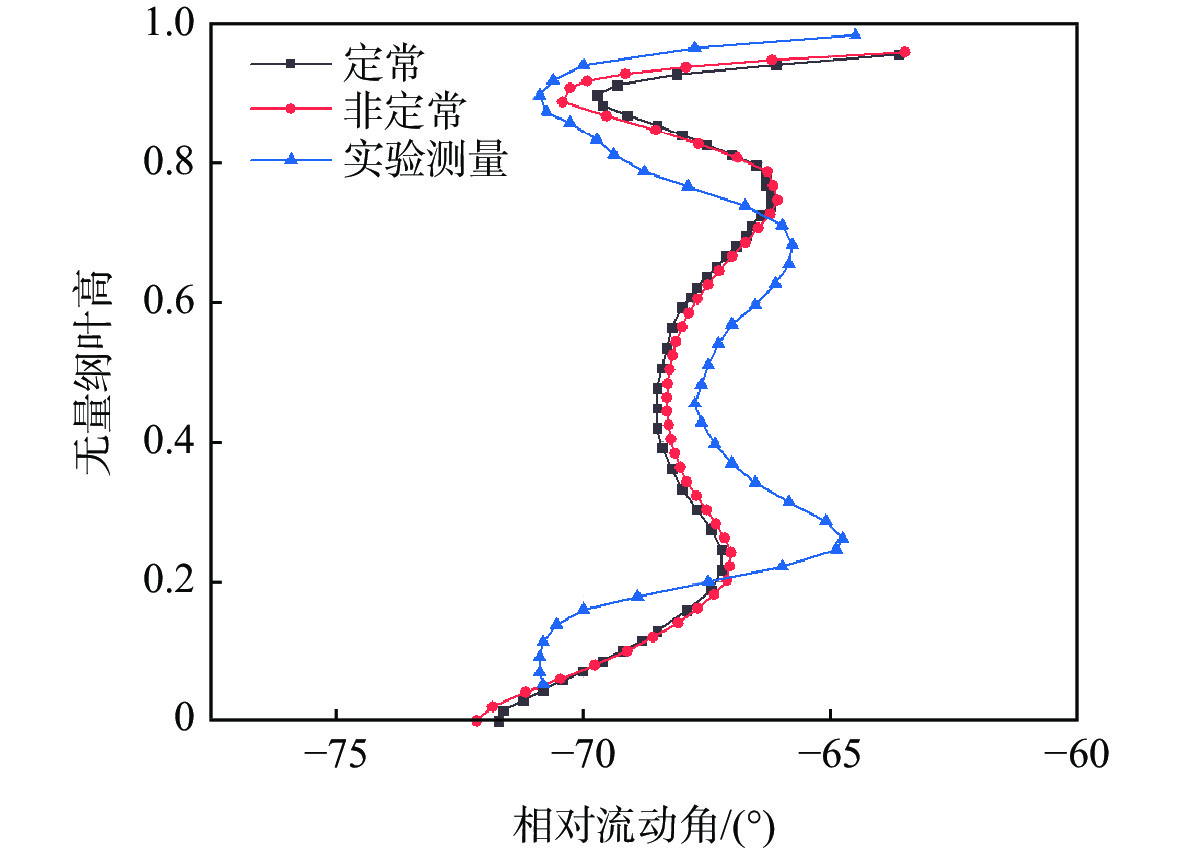

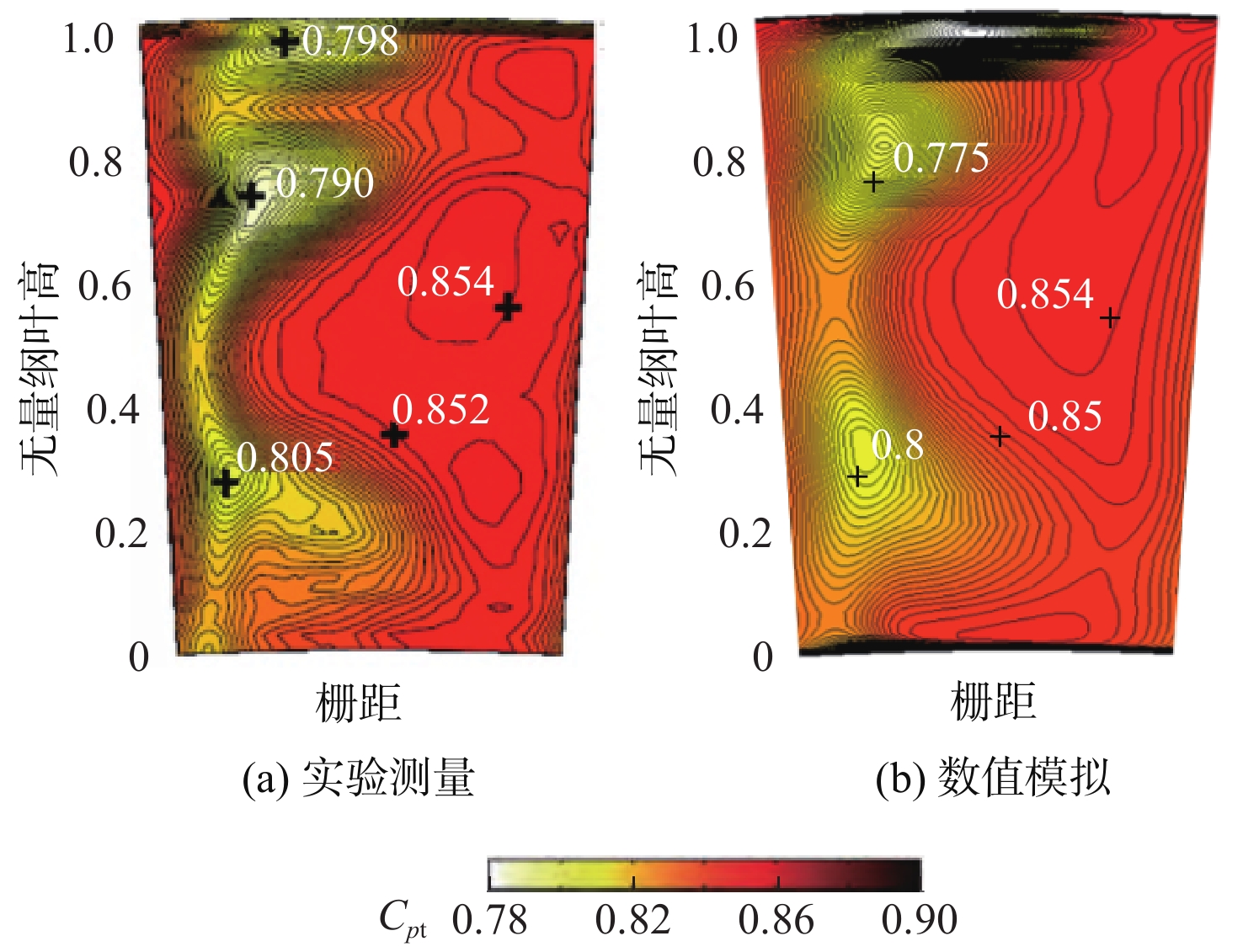

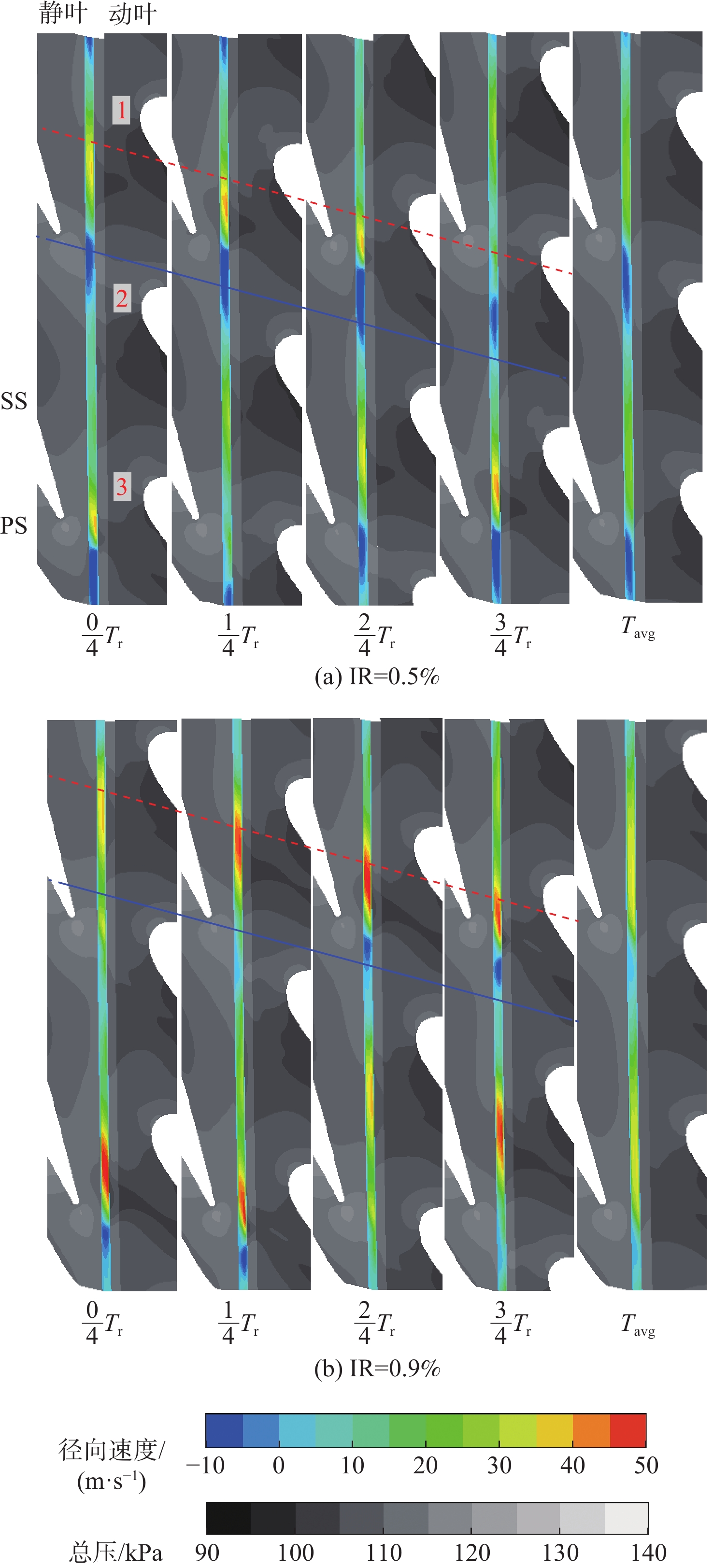

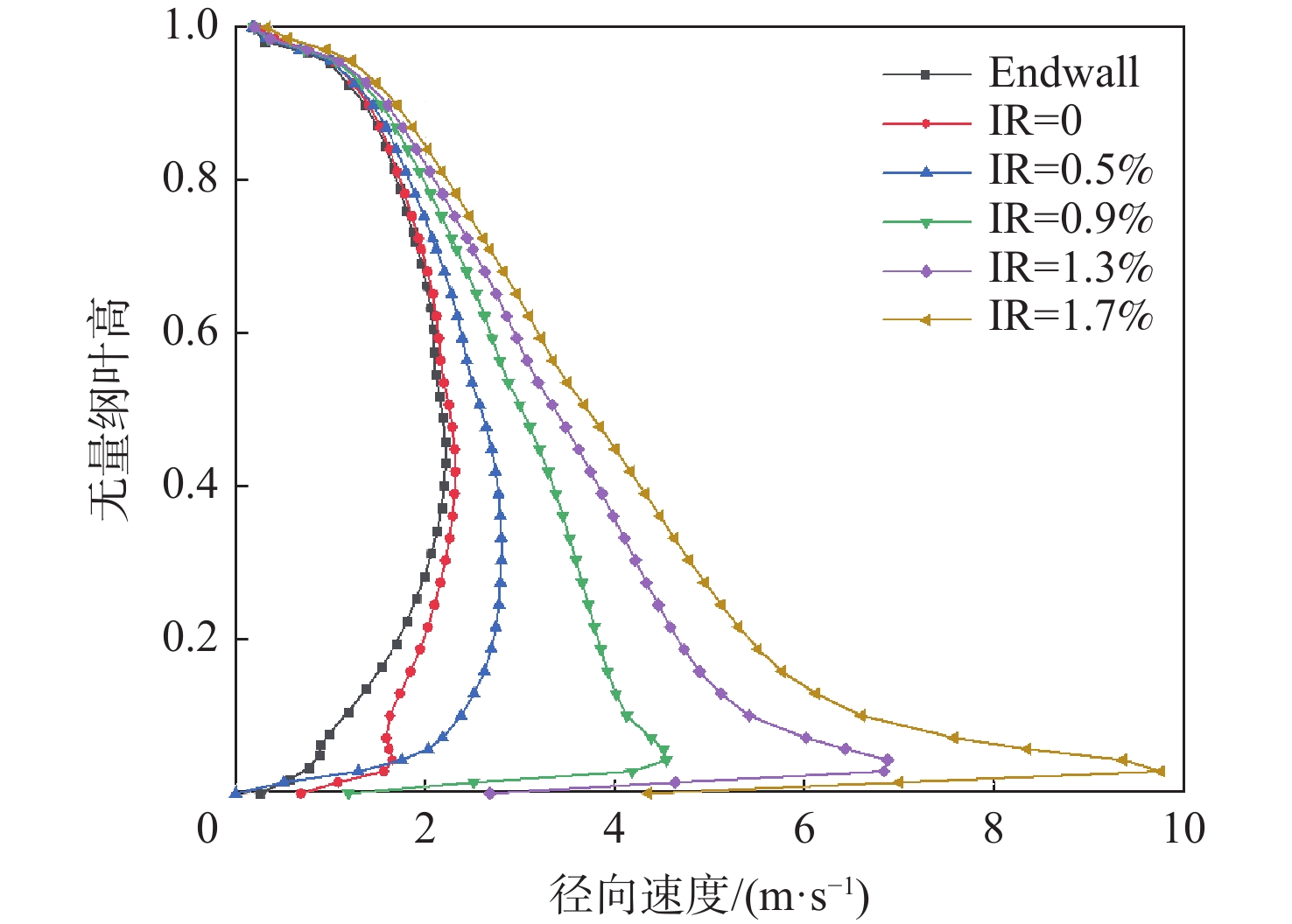

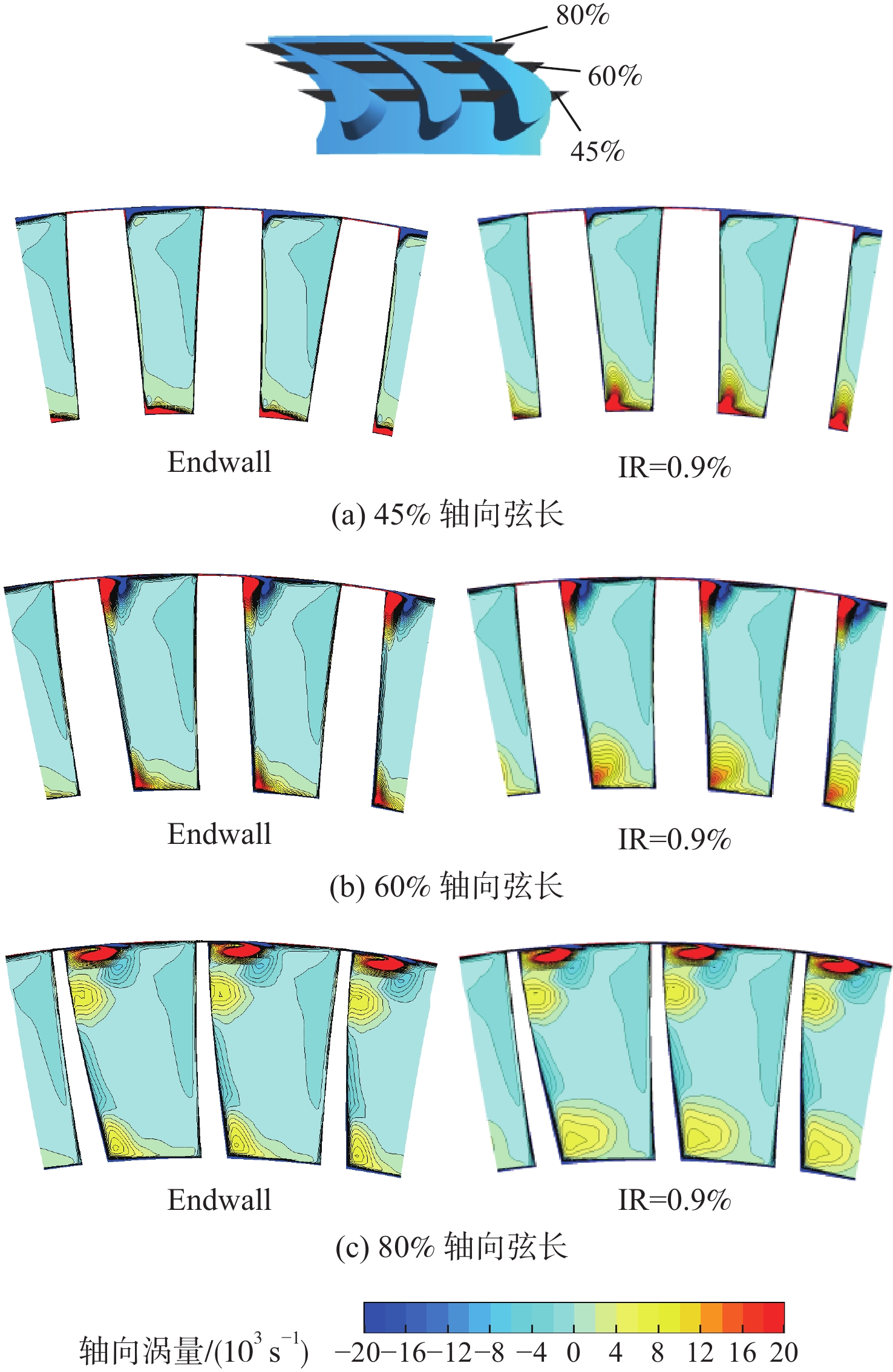

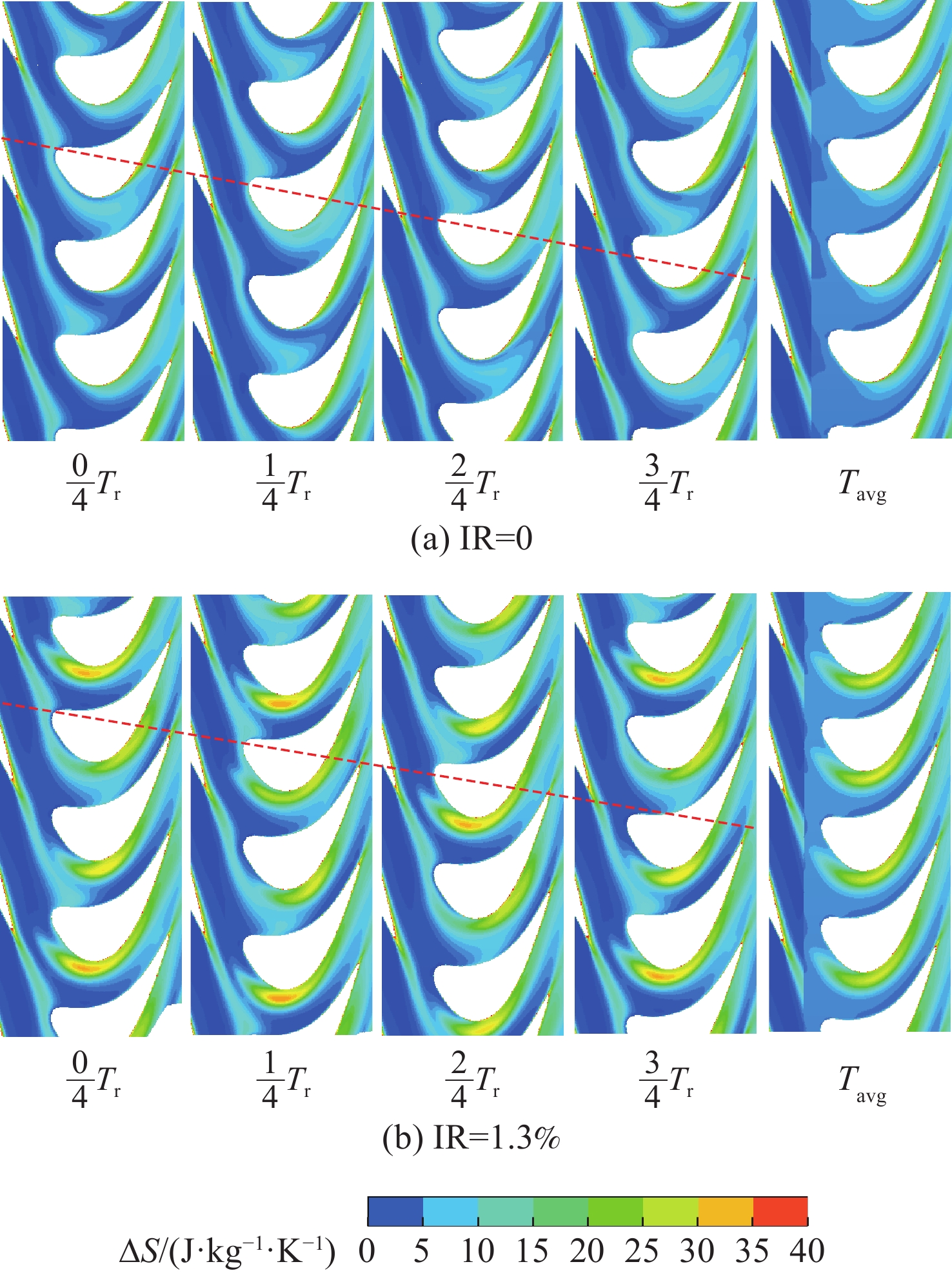

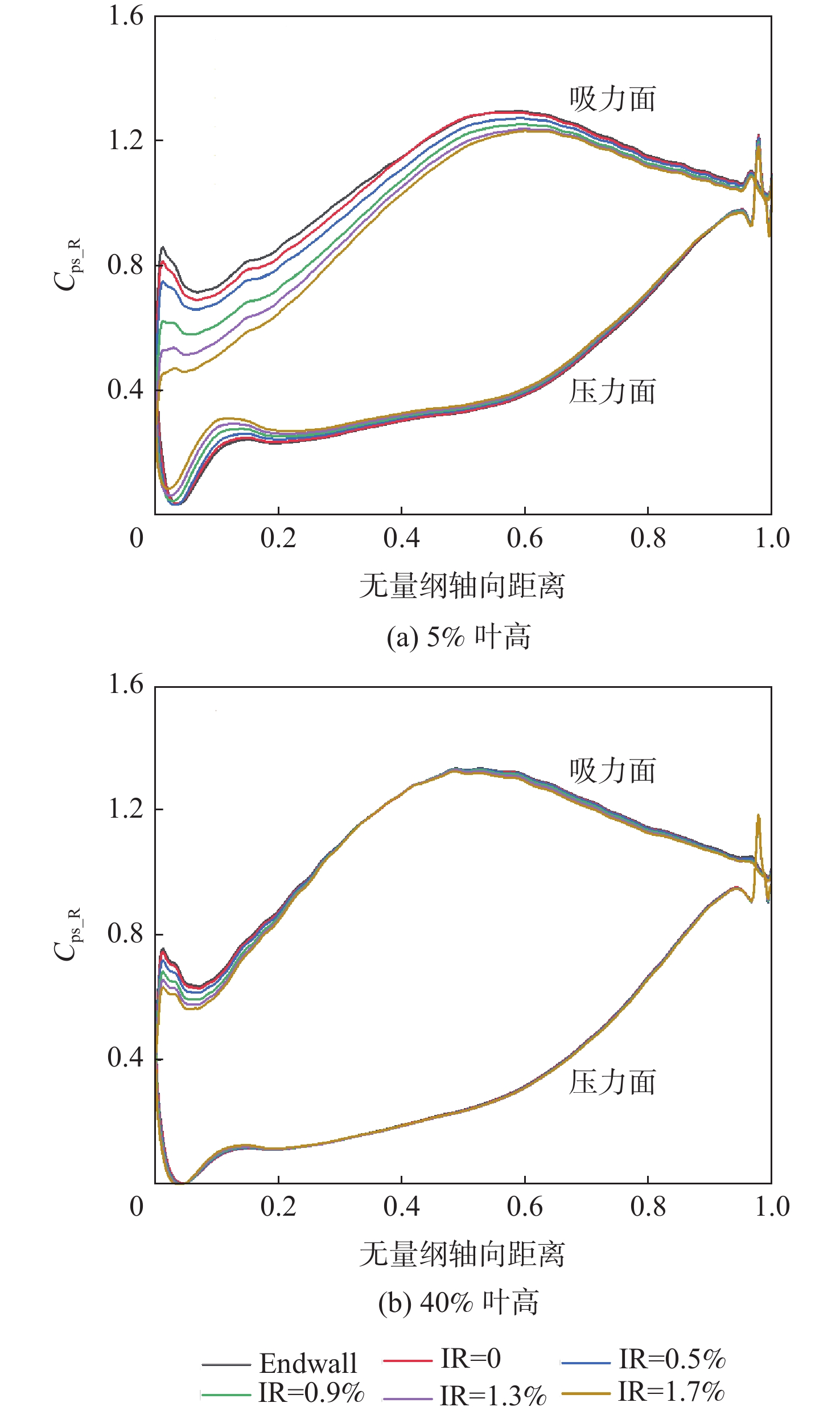

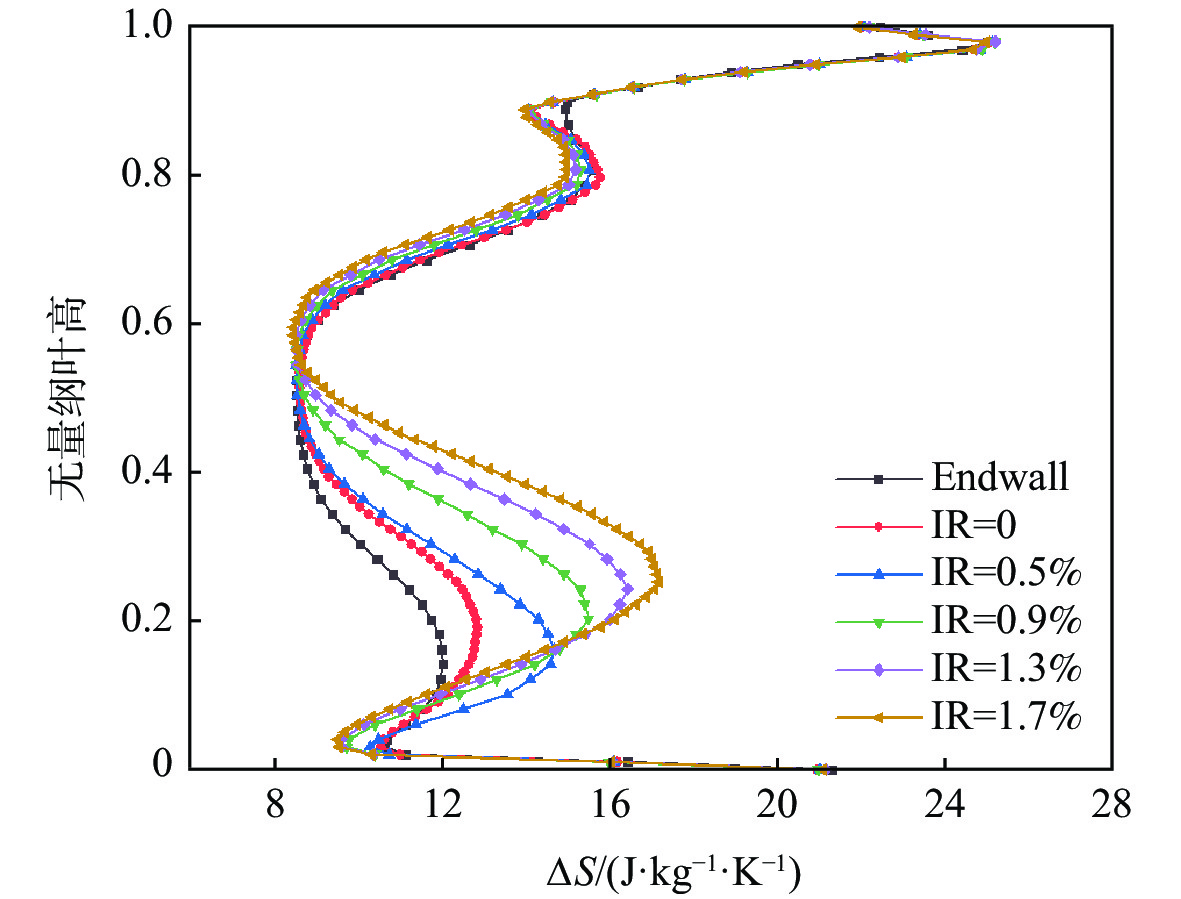

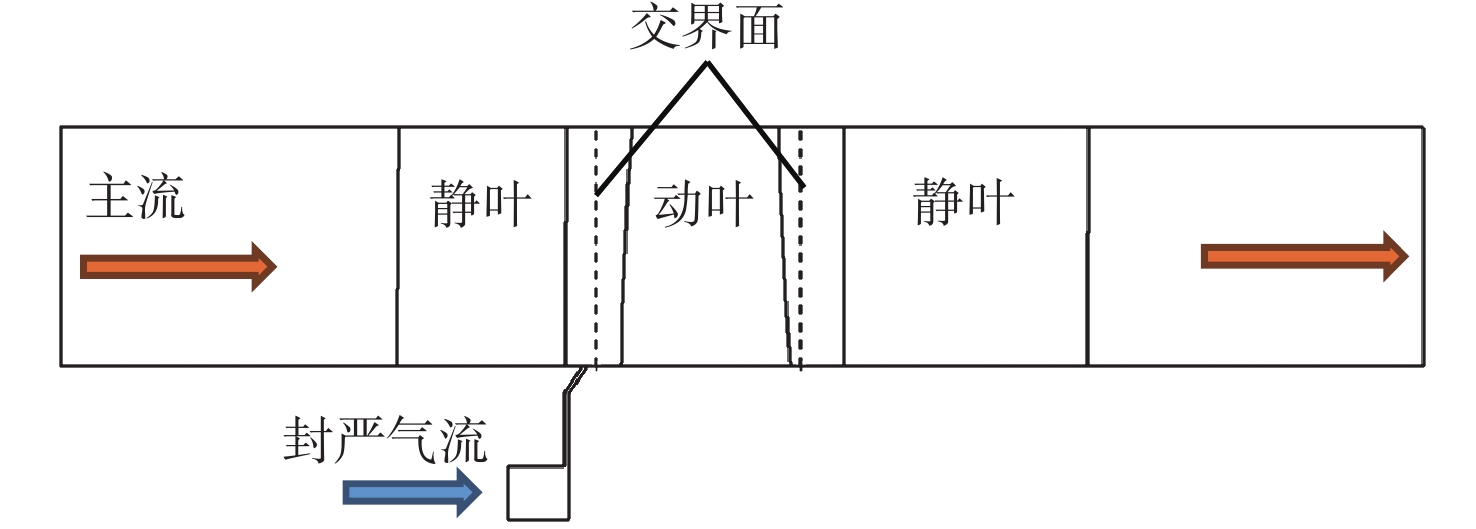

为了研究涡轮转静盘腔间轮缘封严结构对下游动叶通道内流动的影响,对无封严结构、无封严气流及采用不同封严流量时涡轮动叶通道内流场分布和气动损失进行了数值模拟。结果表明:封严腔出口位置气流受静叶与动叶相对位置变化的影响呈现较强的非定常特性,变化与动叶运动周期保持一致。动叶入口位置非定常波动受到封严气流与前缘势场共同作用,封严气流引起周向、径向速度变化的同时也造成了强烈的非定常效应。动叶通道内封严气流引起的端区气流偏转改变了前缘马蹄涡滞止点位置,增强了马蹄涡压力面分支,动叶吸力面一侧剪切诱导涡改变了轮毂通道涡的形成机制和吸力面侧相对低压区的位置。

Abstract:In order to study the influence of the rim seal between the turbine wheelspace on the downstream rotor passage, numerical simulations were performed on the flow field distribution and aerodynamic loss in the turbine rotor passage when unsealed cavity, unsealed air flow and different purge flow rates were employed. The research results show that the airflow at the exit of the sealed cavity is affected by the relative position change of the stator and the rotor, showing a strong unsteady characteristic, and the change is consistent with the motion period of the rotor. The unsteady fluctuation of the inlet position of the rotor is affected by the purge flow and the leading edge potential field. The purge flow causes circumferential and radial velocity changes as well as a strong unsteady effect. The deflection of the main flow in the end wall caused by the purge flow in the rotor passage changes the stagnation point of the horseshoe vortex on the leading edge and strengthens the pressure side leg of the horseshoe vortex. The shear induced vortex on the suction side of the blade changes the formation mechanism of the hub passage vortex, and the position of the suction side relative to the low pressure area.

-

Key words:

- turbine /

- rim seal /

- gas ingestion /

- purge flow injection /

- numerical simulation

-

-

[1] REGINA K, KALFAS A I, ABHARI R S. Experimental investigation of purge flow effects on a high pressure turbine stage[J]. Journal of Turbomachinery, 2015, 137(4): 0410061-0410069. [2] ZLATINOV M B, TAN V S, MONTGOMERY M, et al. Turbine hub and shroud sealing flow loss mechanisms[J]. Journal of Turboimachinery, 2012, 134(11): 061027. [3] SCHREWE S, WERSCHNIK H, SCHIFFER H. Experimental analysis of the interaction between rim seal and main annulus flow in a low pressure two stage axial turbine[J]. Journal of Turbomachinery, 2013, 135(5): 0510031-0510039. [4] POPOVIC I, HODSON H P. Improving turbine stage efficiency and sealing effectiveness through modifications of the rim seal geometry[J]. Journal of Turbomachinery, 2013, 135(6): 061016. [5] POPOVIC I, HODSON H P, JANKE E, et al. The effects of unsteadiness and compressibility on the interaction between hub leakage and mainstream flows in high-pressure turbines[J]. Journal of Turbomachinery, 2013, 135(6): 061015. [6] POPOVIC I, HODSON H P. The effects of a parametric variation of the rim seal geometry on the interaction between hub leakage and mainstream flows in high pressure Turbines[J]. Journal of Engineering for Gas Turbines and Power, 2013, 135(11): 112501. [7] POPOVIC I, HODSON H P. Aerothermal impact of the interaction between hub leakage and mainstream flows in highly-loaded high pressure turbine blades[J]. Journal of Turbomachinery, 2013, 135(6): 061014. [8] MONGE-CONCEPCION I, BERDANIER R A, BARRINGER M D, et al. Evaluating the effect of vane trailing edge flow on turbine rim sealing[J]. Journal of Turbomachinery, 2020, 142(8): 081001. [9] SCHREINER B D J, WILSON M, LI Y S, et al. Effect of purge on the secondary flow-field of a gas turbine blade-row[J]. Journal of Turbomachinery, 2020, 142(10): 101006. [10] 周杨, 牛为民, 邹正平, 等. 轮毂封严气体对高压涡轮二次流动的影响[J]. 推进技术, 2006, 27(6): 515-520. doi: 10.3321/j.issn:1001-4055.2006.06.009ZHOU Y, NIU W M, ZOU Z P, et al. Effects of coolant injection from rim seals on secondary flow in a high-pressure turbine[J]. Journal of Propulsion Technology, 2006, 27(6): 515-520(in Chinese). doi: 10.3321/j.issn:1001-4055.2006.06.009 [11] 贾惟. 轮毂封严与高负荷涡轮端区流动的非定常相互作用[J]. 推进技术, 2017, 38(12): 2674-2685. doi: 10.13675/j.cnki.tjjs.2017.12.005JIA W. Unsteady interaction between purge flow and endwall flow in highly-loaded turbines[J]. Journal of Propulsion Technology, 2017, 38(12): 2674-2685(in Chinese). doi: 10.13675/j.cnki.tjjs.2017.12.005 [12] 贾惟. 轮毂封严对涡轮端区流动影响的数值研究[J]. 热能动力工程, 2018, 33(8): 20-29. doi: 10.16146/j.cnki.rndlgc.2018.08.004JIA W. Numerical Investigation of influence of rim seal purge flow on turbine endwall flows[J]. Journal of Engineering for Thermal Energy and Power, 2018, 33(8): 20-29(in Chinese). doi: 10.16146/j.cnki.rndlgc.2018.08.004 [13] JIA W, LIU H X. Numerical investigation of the effect of rim seal on turbine aerodynamic design parameters and end wall flows in low-aspect ratio turbine[J]. Computers & Fluids, 2013, 74: 114-125. [14] 吴康, 任静, 蒋洪德, 等. 整级透平中转静轮缘封严问题研究. Part Ⅰ: 封严与入侵[J]. 工程热物理学报, 2014, 35(5): 873-877.WU K, REN J, JIANG H D, et al. Rotor-stator rim seal analysis in one stage gas turbine. Part Ⅰ: Ingestion and seal[J]. Journal of Engineering Thermophysics, 2014, 35(5): 873-877(in Chinese). [15] 吴康, 任静, 蒋洪德. 整级透平中转静轮缘封严问题研究. Part Ⅱ: 不同封严结构的特性[J]. 工程热物理学报, 2015, 36(3): 496-500.WU K, REN J, JIANG H D. Rotor-stator rim seal analysis in one stage gas turbine. Part Ⅱ: Characteristic of different seal structure[J]. Journal of Engineering Thermophysics, 2015, 36(3): 496-500(in Chinese). [16] 程舒娴, 李军, 李志刚, 等. 轮缘密封整周模型流动与封严特性数值研究[J]. 工程热物理学报, 2021, 42(2): 370-376.CHENG S X, LI J, LI Z G, et al. Numerical investigations on the flow and sealing effectiveness of a turbine rim seal model with whole cavity[J]. Journal of Engineering Thermophysics, 2021, 42(2): 370-376(in Chinese). [17] BEHR T. Control of rotor tip leakage and secondary flow by casing air injection in unshrouded axial turbines[D]. Dresden: Dresden University of Technology, 2007: 73-87. [18] SCHUEPBACH P. Influence of rim seal purge flow on performance of an endwall profiled axial turbine[D]. Swiss: Swiss Federal Institute of Technology, 2009: 50-54. [19] 张晶辉, 马宏伟. 轮缘封严气体对涡轮转子性能影响的非定常数值研究[J]. 推进技术, 2014, 35(4): 470-478. doi: 10.13675/j.cnki.tjjs.2014.03.007ZHANG J H, MA H W. Unsteady numerical investigation for effects of rim sealing flow on performance of a turbine rotor[J]. Journal of Propulsion Technology, 2014, 35(4): 470-478(in Chinese). doi: 10.13675/j.cnki.tjjs.2014.03.007 -

下载:

下载: