Thermal vacuum test study of mechanically pumped two-phase loop for space remote sensor

-

摘要:

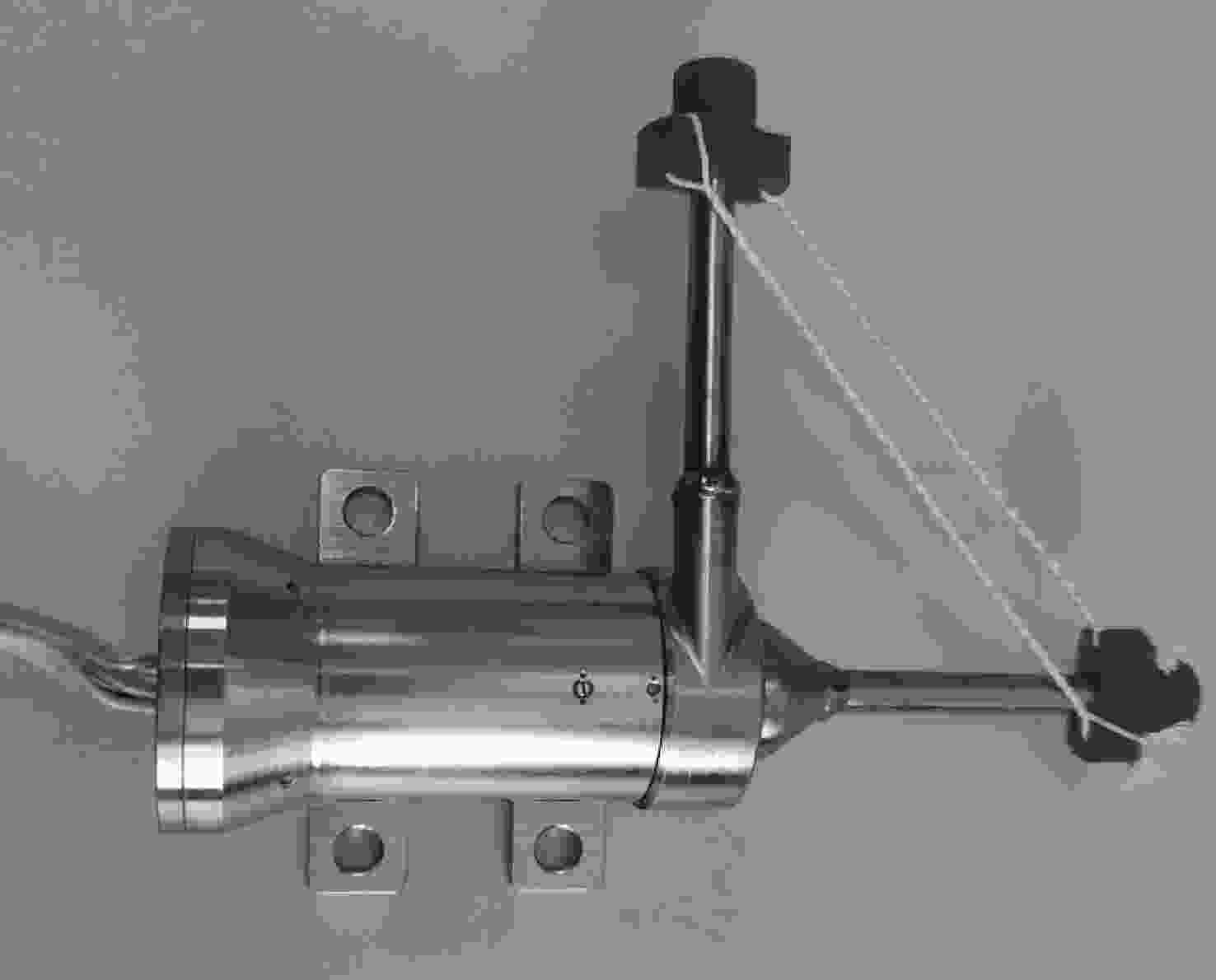

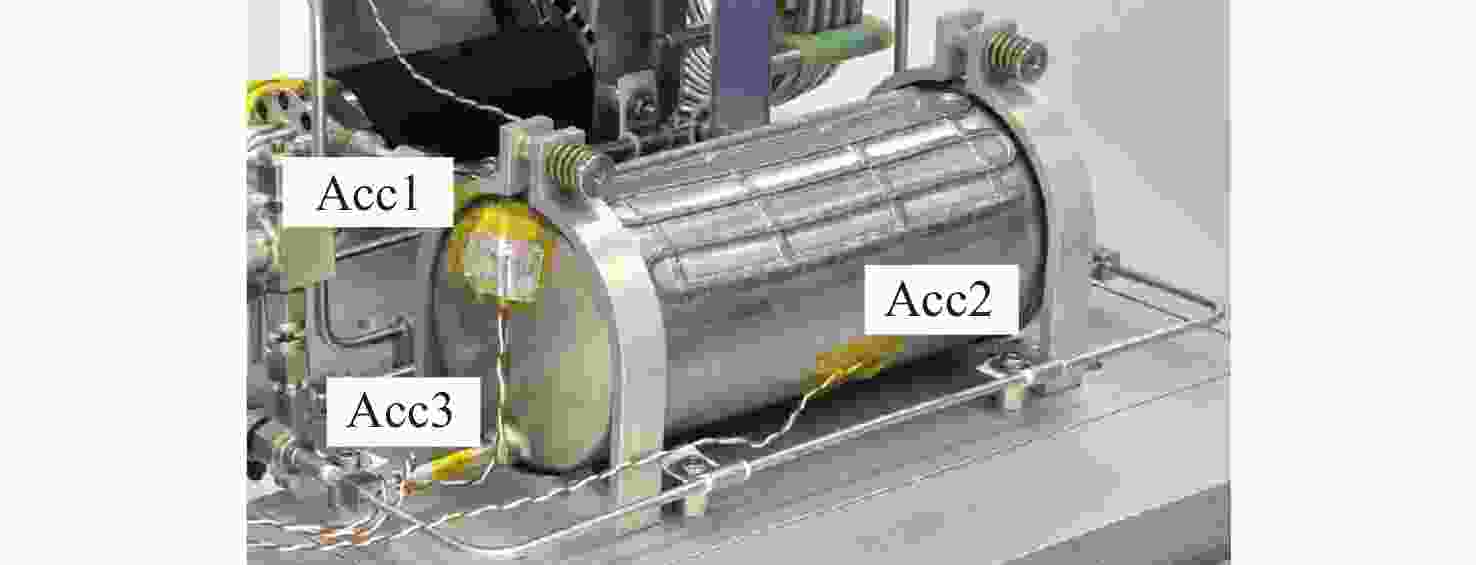

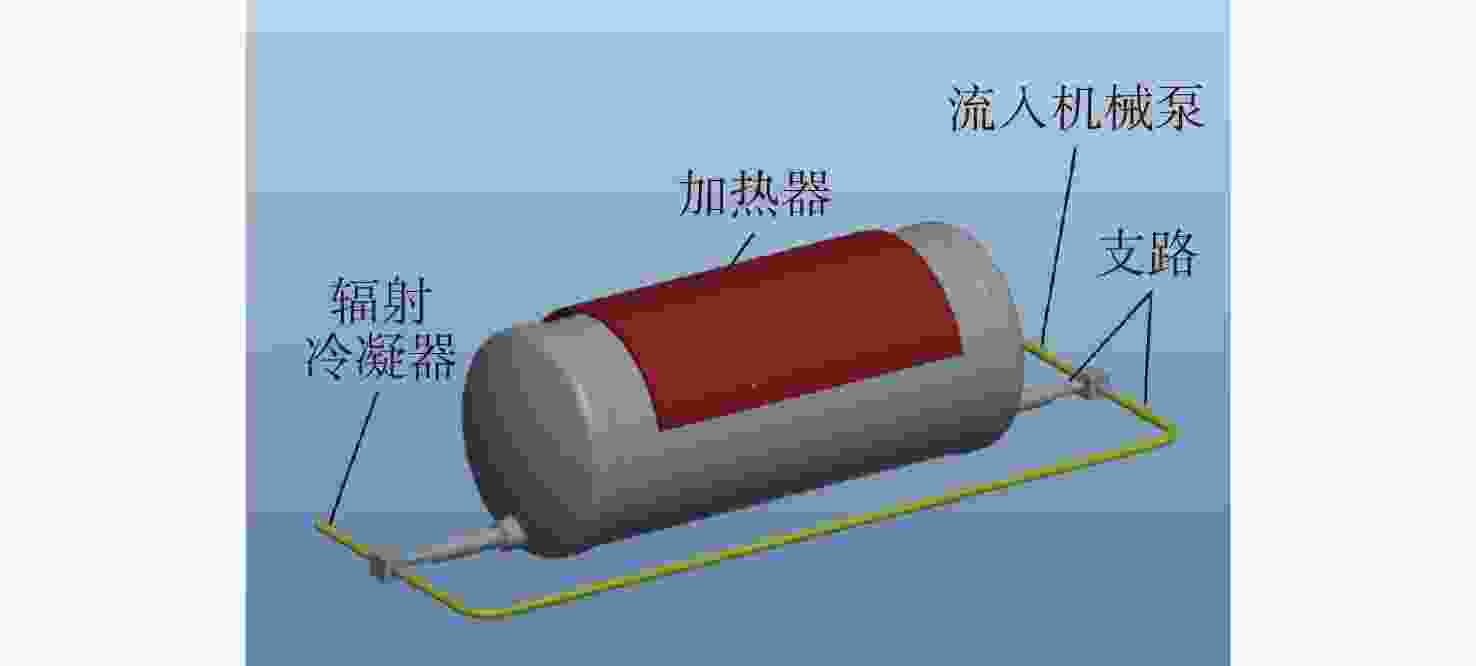

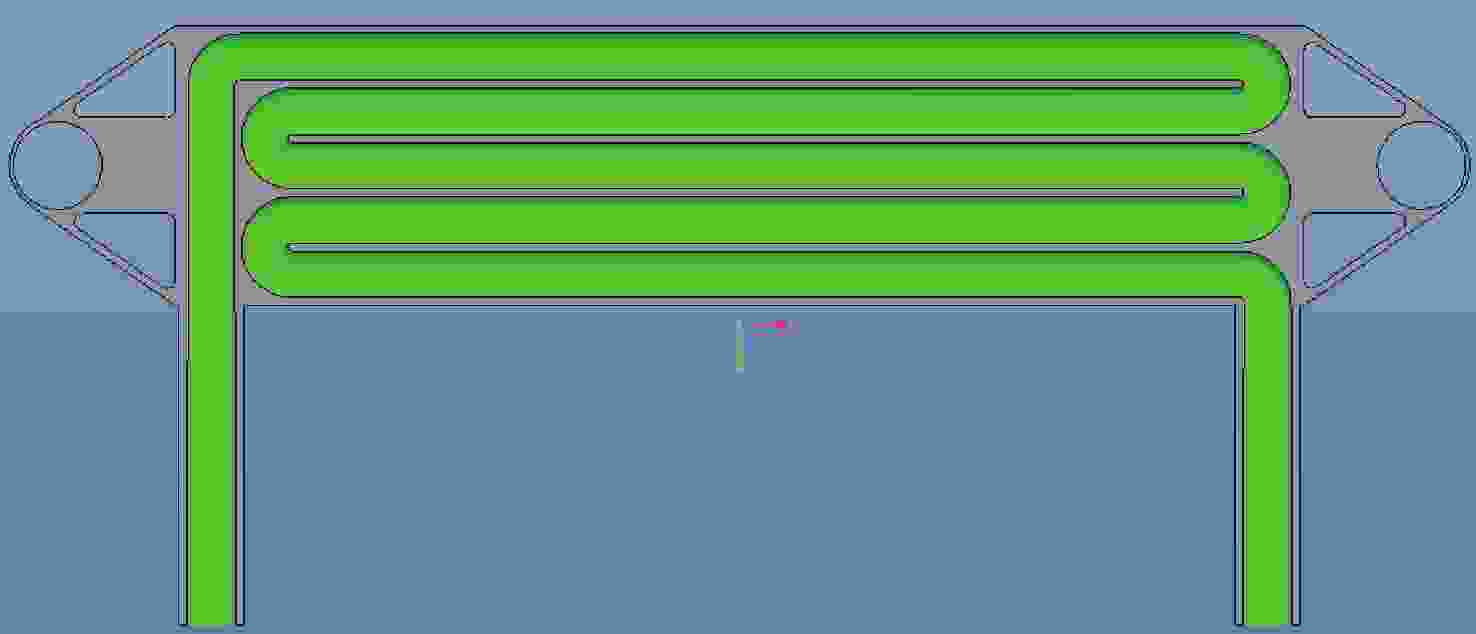

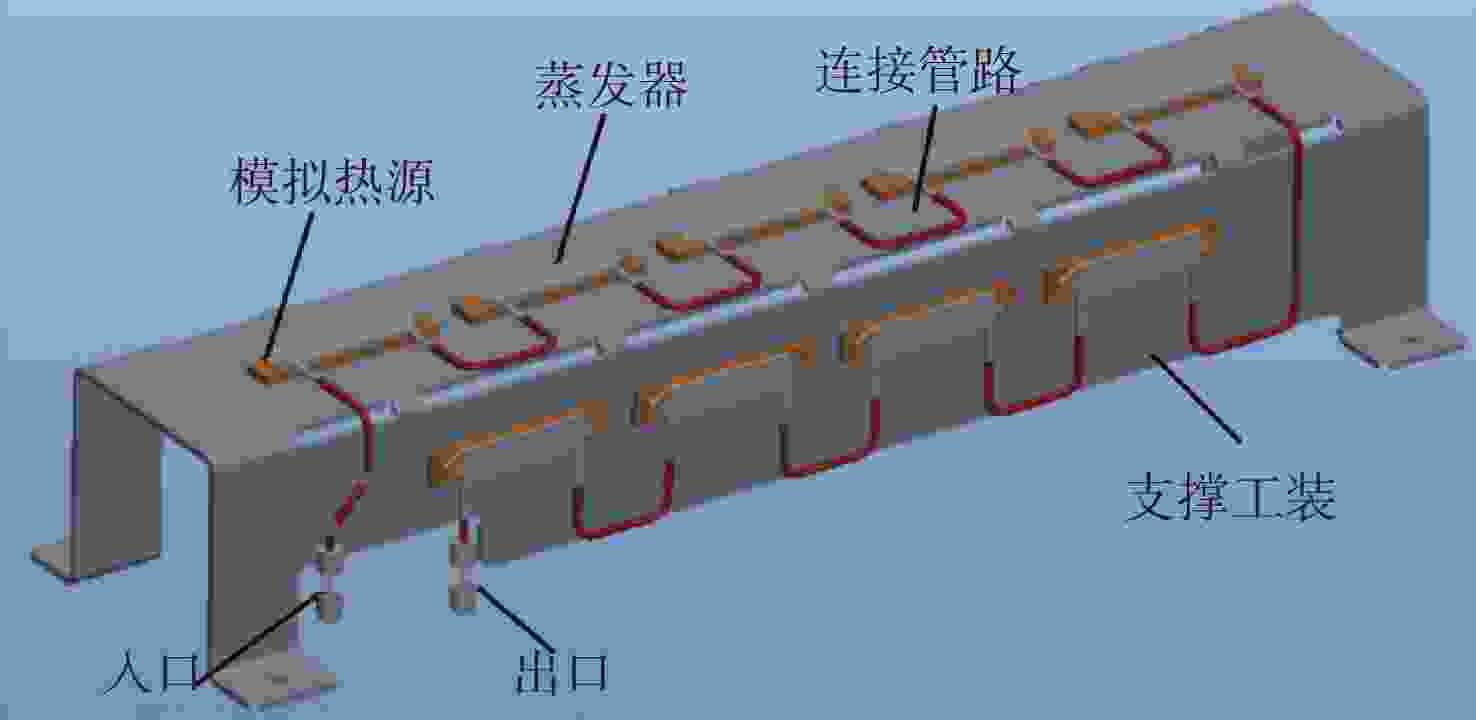

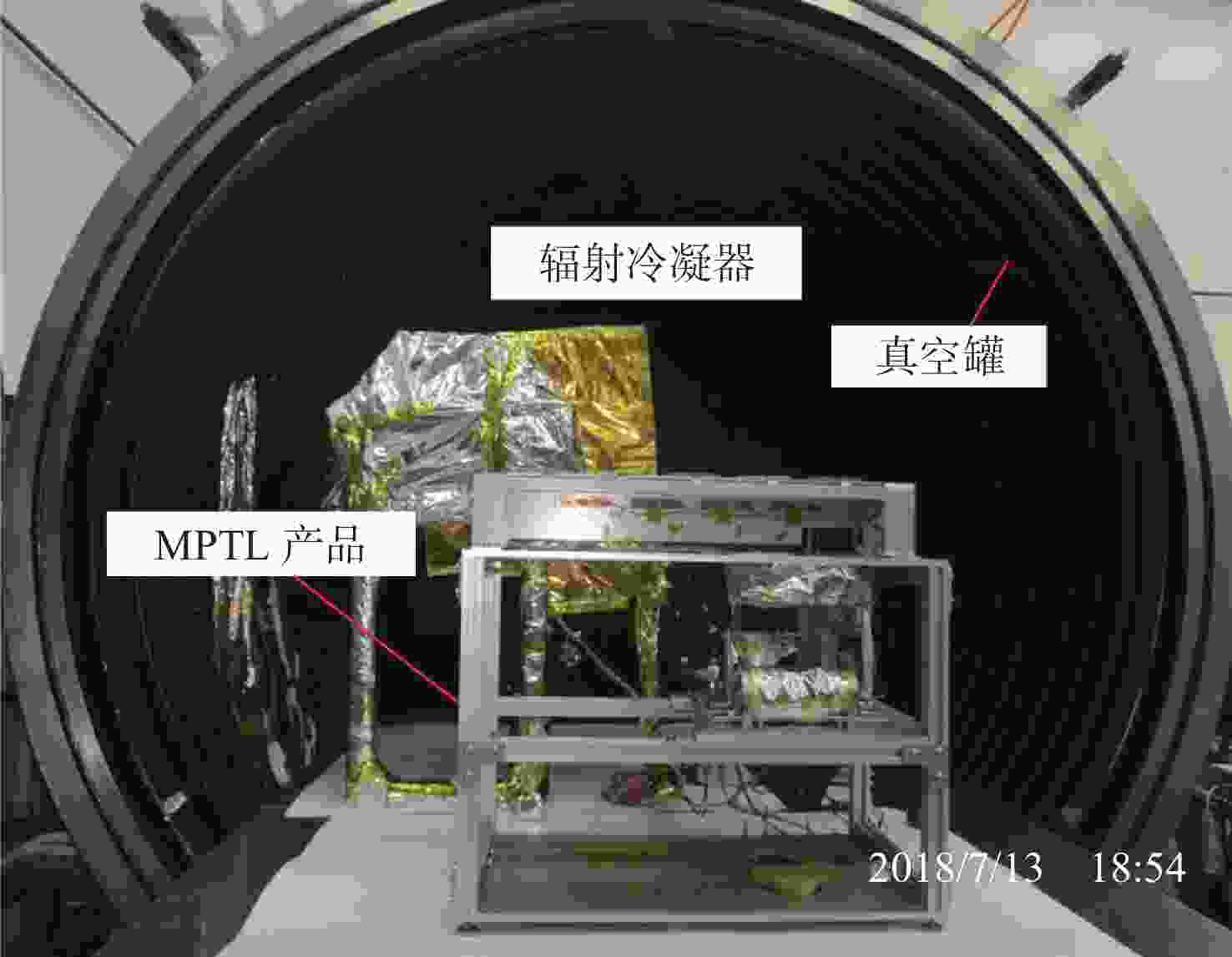

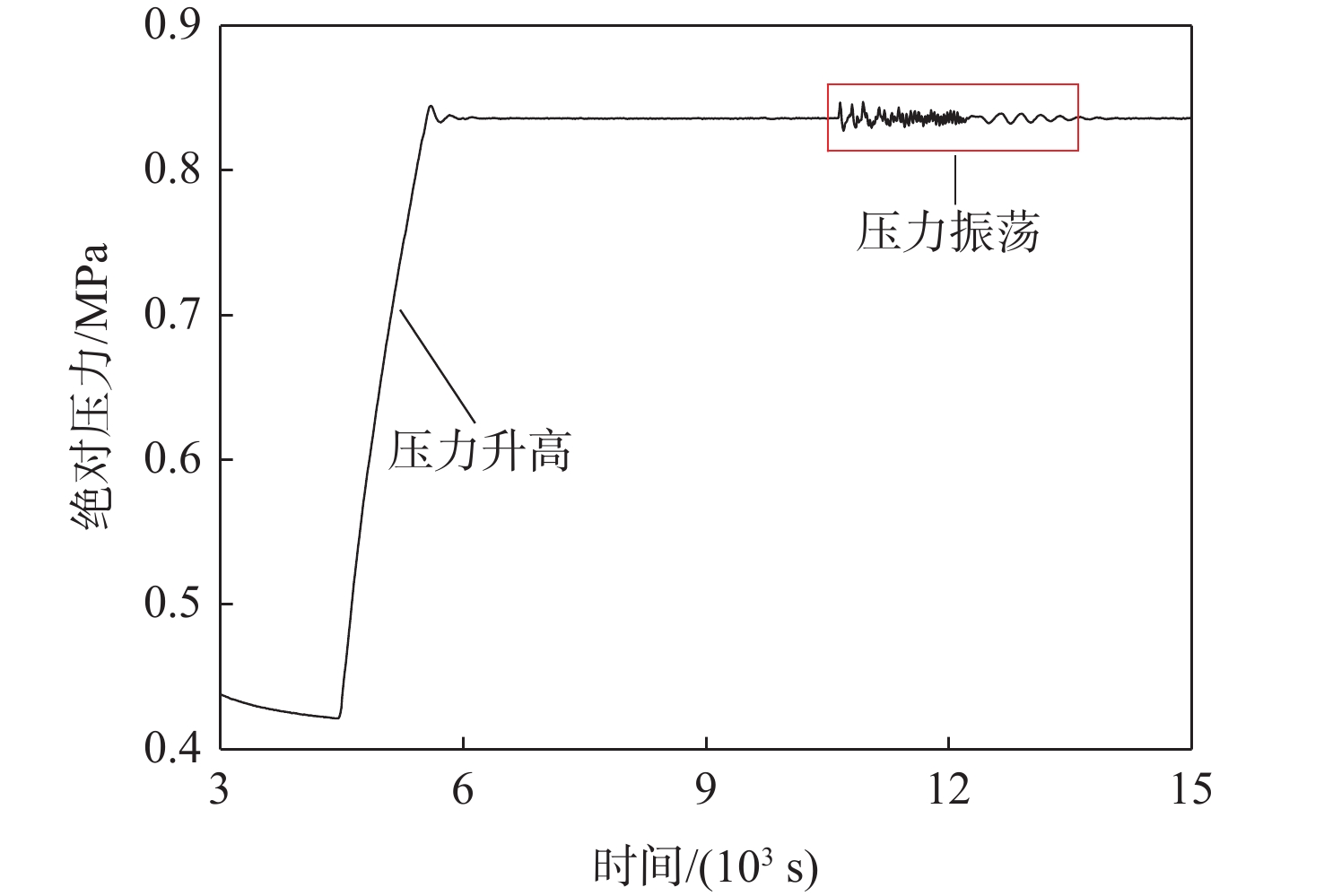

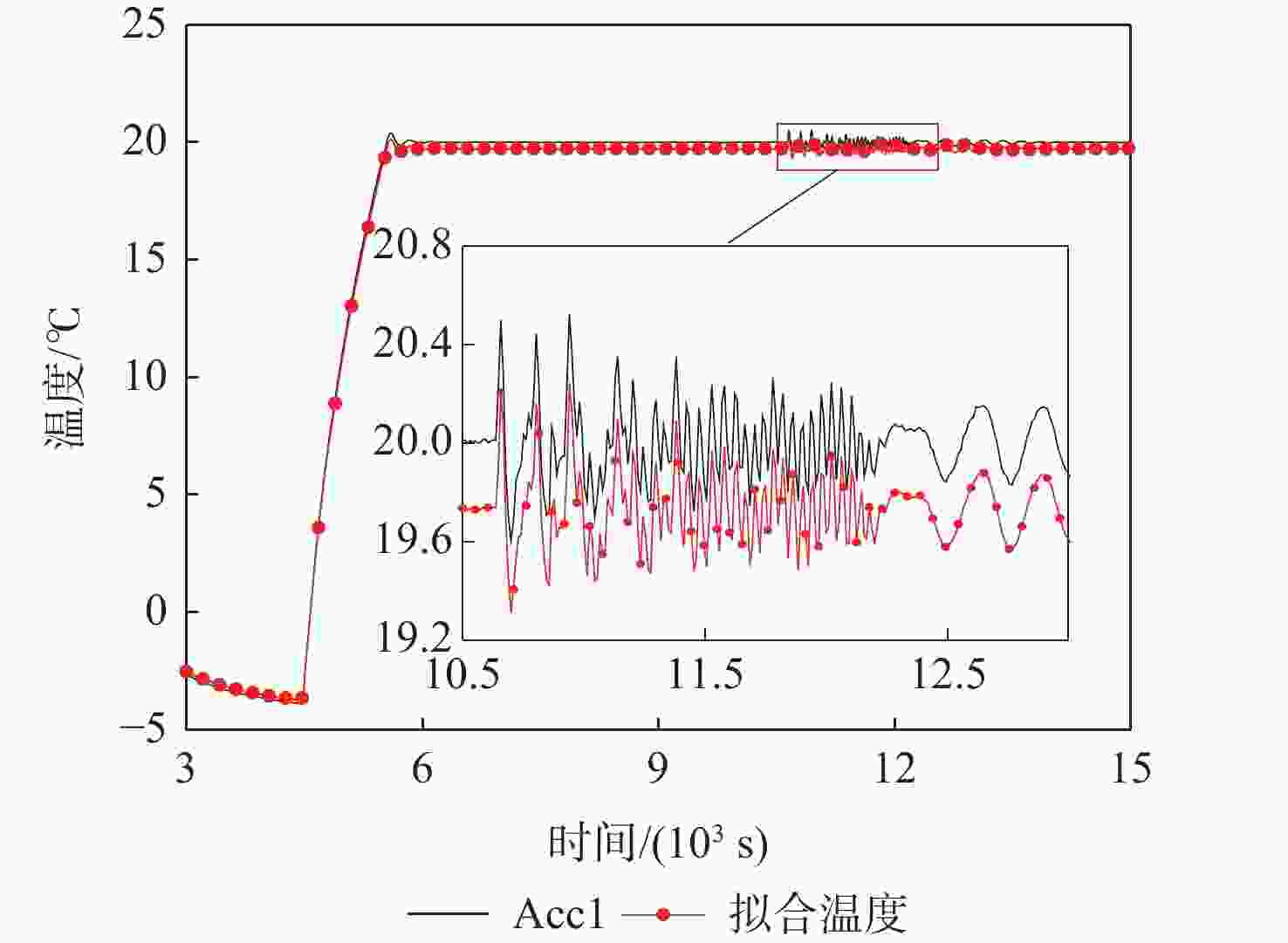

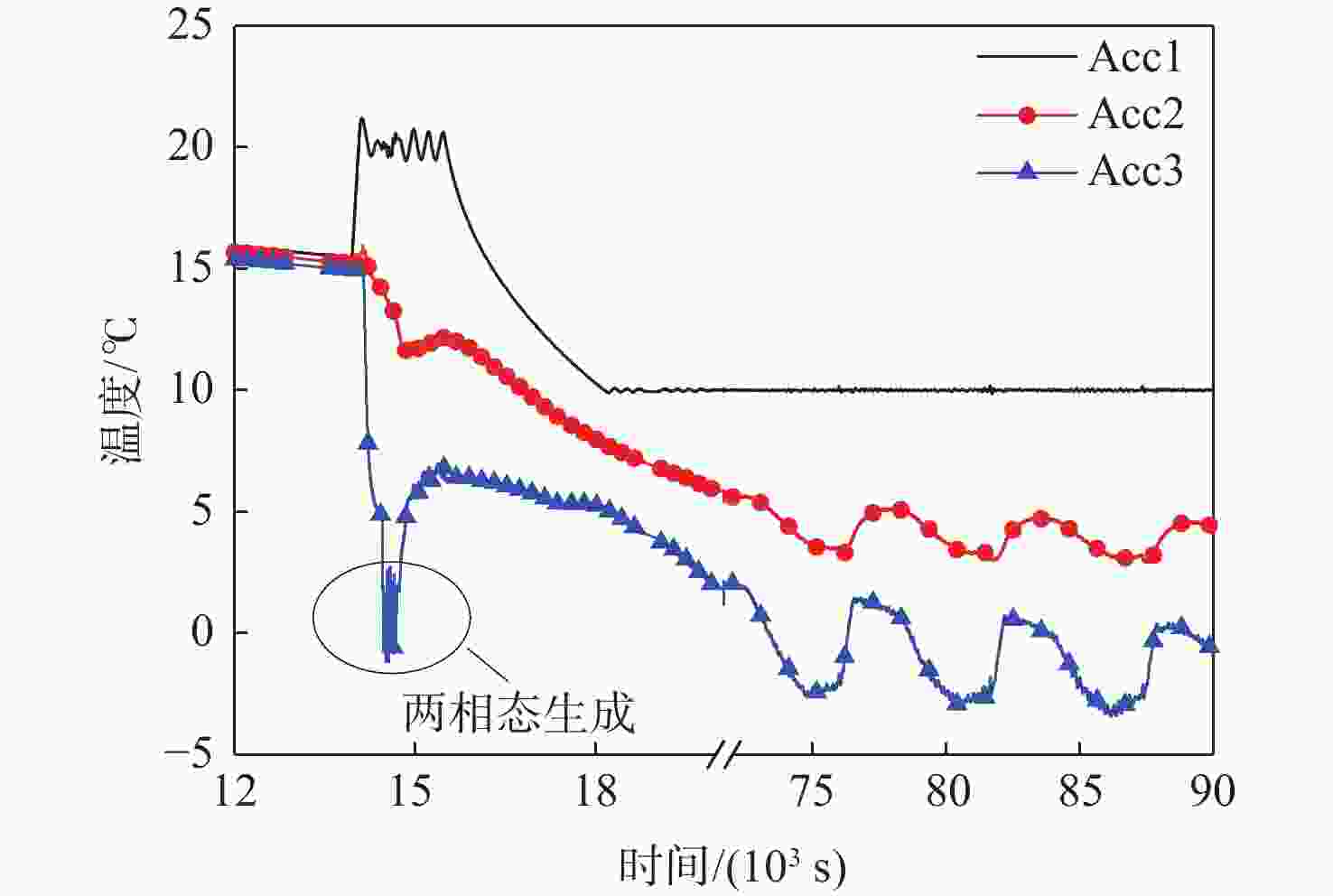

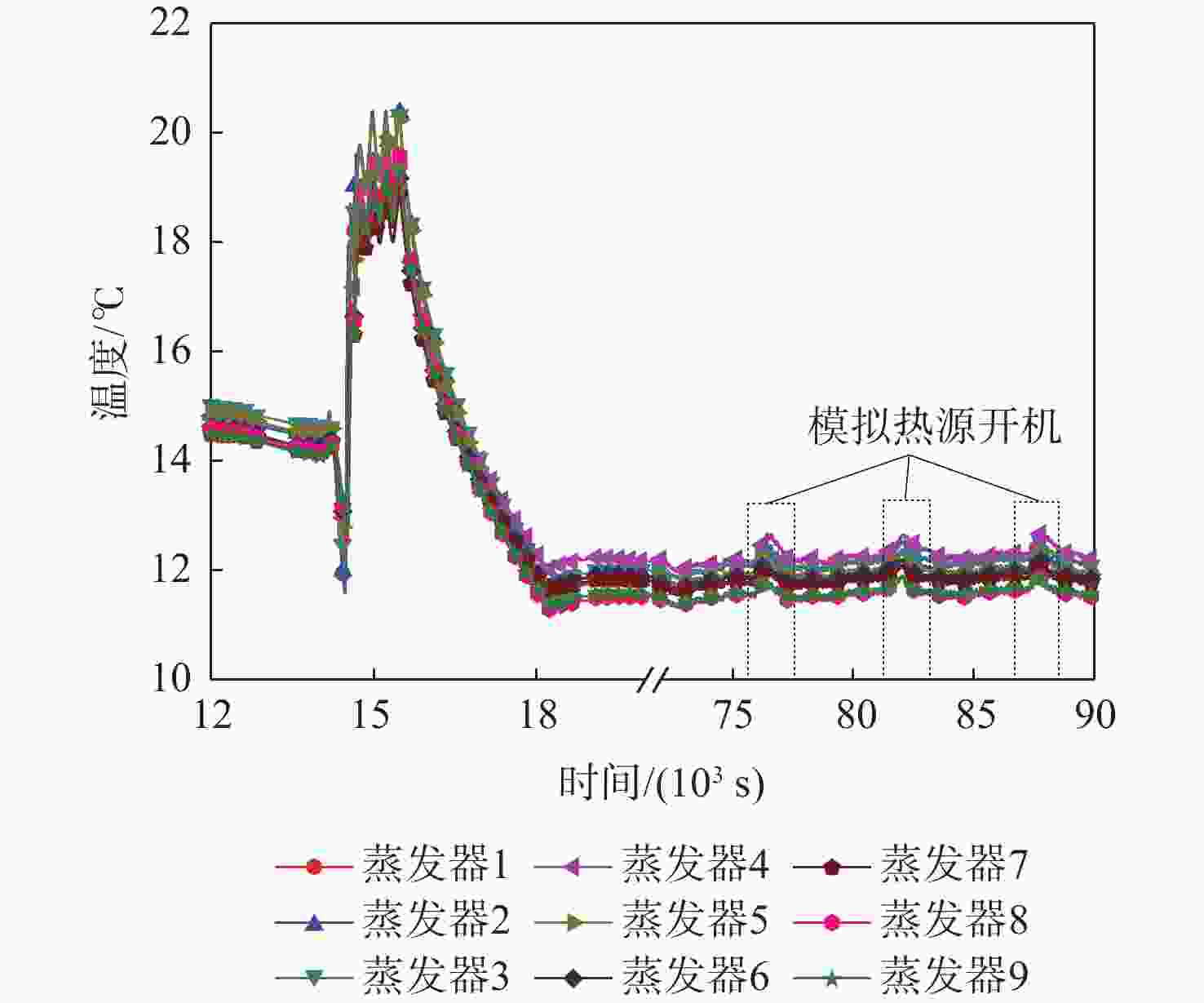

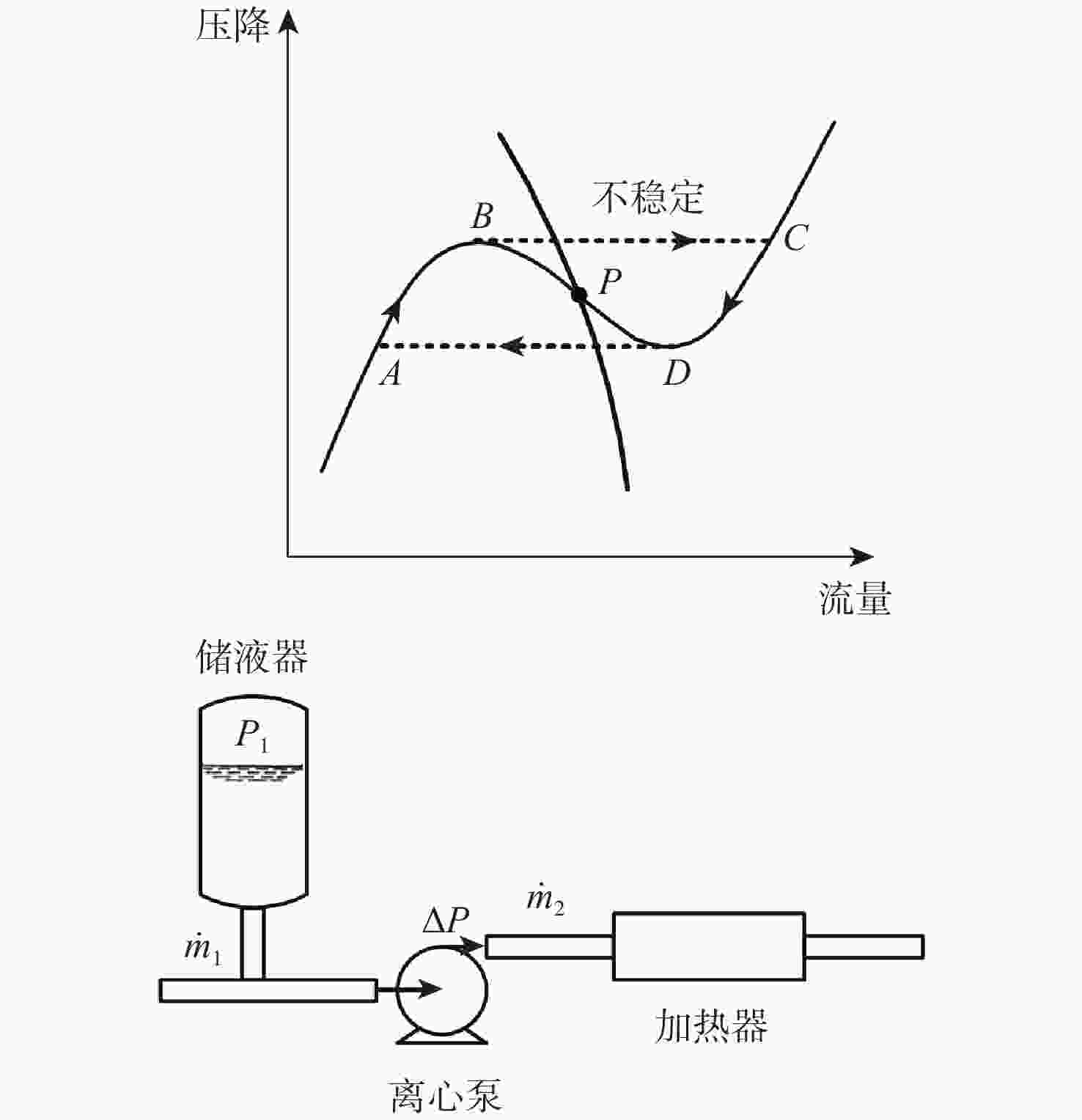

针对航天遥感器核心组件的高精度与高稳定度的控温需求,设计并搭建了一套泵驱两相流体回路(MPTL)试验装置,该装置使用了一套具有被动冷却能力的两相控温型储液器。为验证MPTL系统在高真空、极低温与变化外热流条件下的工作能力,在真空罐内对MPTL系统在不同工况点下的散热与控温能力进行了测试,并通过温度和压力等数据研究了主回路的运行特性、储液器内热力学变化特性及两者之间的传热传质过程。结果表明:MPTL系统的控温点可通过储液器进行快速调整,蒸发器温度的变化受外热流与热源开关影响较小;进入毛细管中的过冷液与储液器中的液相形成的温差保证了储液器冷量的供应;主回路发生相态转变时,储液器与主回路工质交换特性引起了系统压力降脉动。

Abstract:In this paper, a test setup of mechanically pumped two-phase loop (MPTL) was constructed in response to the demand for high precision and high stability temperature control of the core components in space remote sensors. In this setup, a two-phase thermal-controlled accumulator with passive cooling was adopted. For the purpose of verifying the working performance of the MPTL system under the conditions of high vacuum, ultra-low temperature and varied external heat flux, the heat dissipation and temperature control ability of the MPTL system under different test conditions were tested in the vacuum chamber. Then the obtained test data, including temperature and pressure, were used to analyze the operating characteristics of the main loop, the thermodynamic behaviors in the accumulator and the heat and mass transfer between the main loop and the accumulator. The test results showed that the temperature control points of the MPTL system could be quickly adjusted by the accumulator, and the external heat flux and the action of starting up and powering off of the heat source had little influence on the temperature of the evaporators. The cooling capacity was provided by the temperature difference between the subcooling liquid entering the capillary tube and the liquid phase in the accumulator. During the phase transition in the main loop, the mass transfer behaviors between accumulator and the main loop gave rise to the pressure-drop oscillations.

-

表 1 MPTL系统主要参数

Table 1. Main parameters of MPTL system

参数 数值 两相管路直径/mm 外径4.0,内径3.0 单相管路直径/mm 外径3.175,内径2.06 管路总长度/m 20.0 辐射冷凝器 面积0.32 m2;发射率0.86 储液器体积/L 0.53 冷凝器控温功率/W 20.0 预热器功率/W 40.0 蒸发器功率/W 45.0 表 2 外热流随时间周期变化值

Table 2. Temporal variation of external heat flux

加载时间/s 功率/W 0~634 10.8 635~2079 24.1 2080~2646 50.7 2647~4218 29.8 4219~5671 10.8 表 3 试验工况

Table 3. Test items

工况 系统工作点 试验内容 1 20 ℃ 测试流体回路启动特性,储液器控温稳定性及

蒸发器温度稳定性2 10 ℃ 测试储液器升降温速率,系统运行的稳定性 -

[1] GREGORY T H, ABEL J, MANDI J. Thermal design considerations of the hubble space telescope (HST) science instrument control and data handler (SI C&DH-2) : AIAA 2010-6055[R]. Reston: AIAA, 2010. [2] 李春林. 空间光学遥感器热控技术研究[J]. 宇航学报, 2014, 35(8): 863-870.LI C L. Research on space optical remote sensor thermal control technique[J]. Journal of Astronautics, 2014, 35(8): 863-870(in Chinese). [3] VAN ES J, VAN GERNER H J, VAN BENTHEM R C. Component developments in Europe for mechanically pumped loop systems (MPLs) for cooling applications in space[C]//46th International Conference on Environmental Systems, 2016: ICES-2016-196. [4] VAN ES J, PAUW A, VAN DONK G, et al. AMS02 tracker thermal control cooling system test results of the AMS02 thermal vacuum test in the ISS at ESA ESTEC : AIAA-2012-3577[R]. Reston: AIAA, 2012. [5] VAN ES J, PAUW A, VAN GERNER H J, et al. AMS02 tracker thermal control cooling system commissioning and operational results: AIAA-2013-3389[R]. Reston: AIAA, 2013. [6] 于新刚, 徐侃, 苗建印, 等. 高热流散热泵驱两相流体回路设计及飞行验证[J]. 宇航学报, 2017, 38(2): 192-197.YU X G, XU K, MIAO J Y, et al. Design and on-board validation of pumped two-phase fluid loop for high heat flux removal[J]. Journal of Astronautics, 2017, 38(2): 192-197(in Chinese). [7] 王镇锐, 张兴斌, 温世喆, 等. 结合TEC的泵驱两相温控系统的空间应用[J]. 宇航学报, 2018, 39(10): 1176-1184. doi: 10.3873/j.issn.1000-1328.2018.10.014WANG Z R, ZHANG X B, WEN S Z, et al. Space applications of pumped two-phase temperature control system combined with TEC[J]. Journal of Astronautics, 2018, 39(10): 1176-1184(in Chinese). doi: 10.3873/j.issn.1000-1328.2018.10.014 [8] 刘杰. 航天机械泵驱动两相流冷却环路循环特性的研究[D]. 上海: 上海交通大学, 2008.LIU J. Investigations on running characteristics of the mechanically pumped cooling loop for space applications[D]. Shanghai: Shanghai Jiaotong University, 2008(in Chinese). [9] 孙西辉. 机械泵驱动CO2两相流体回路稳定性研究[D]. 广州: 中山大学, 2010.SUN X H. Stabilities research of the mechanically pumped two-phase CO2 loop[D]. Guangzhou: Sun Yat-sen University, 2010(in Chinese). [10] 刘长鑫, 张济民, 徐涛, 等. 泵驱动两相流体回路流量漂移现象的试验研究 [J]. 上海航天, 2017, 34(4): 125-132.LIU C X, ZHANG J M, XU T, et al. Experimental research on flow excursion of mechanically pumped two-phase loop[J]. Aerospace Shanghai, 2017, 34(4): 125-132(in Chinese). [11] 赵振明, 孟庆亮, 张焕冬, 等. CCD器件用机械泵驱动两相流体回路仿真与试验[J]. 北京航空航天大学学报, 2019, 45(5): 893-901. doi: 10.13700/j.bh.1001-5965.2018.0519ZHAO Z M, MENG Q L, ZHANG H D, et al. Simulation and experimental study of mechanically pumped two-phase loop for CCD[J]. Journal of Beijing University of Aeronautics and Astronautics, 2019, 45(5): 893-901(in Chinese). doi: 10.13700/j.bh.1001-5965.2018.0519 [12] 黄臻成. 航天热控用机械驱动两相系统的数值模拟及控温特性分析[D]. 广州: 中山大学, 2008.HUANG Z C. Numerical simulation and thermal control characteristic of the space mechanically pumped two-phase CO2 loop[D]. Guangzhou: Sun Yat-sen University, 2008(in Chinese). [13] 袁俊飞, 唐大伟, 曹宏章. 泵驱动相变冷却系统中储液器压力响应特性[J]. 航空动力学报, 2015, 30(10): 2384-2390. doi: 10.13224/j.cnki.jasp.2015.10.012YUAN J F, TANG D W, CAO H Z. Response characteristics of accumulator pressure in pumped phase-change cooling system[J]. Journal of Aerospace Power, 2015, 30(10): 2384-2390(in Chinese). doi: 10.13224/j.cnki.jasp.2015.10.012 [14] VAN GERNER H J, BRAAKSMA N. Transient modelling of pumped two-phase cooling systems: comparison between experiment and simulation[C]//46th International Conference on Environmental Systems, 2016: ICES-2016-004. [15] VAN GERNER H J, BOLDER R, VAN ES J. Transient modelling of pumped two-phase cooling systems: comparison between experiment and simulation with R134a[C]//47th International Conference on Environmental Systems, 2017: ICES-2017-037. [16] 孟庆亮, 张焕冬, 赵振明. 两相控温型储液器进出流量的瞬态数值模拟[J]. 北京航空航天大学学报, 2019, 45(11): 2160-2169.MENG Q L, ZHANG H D, ZHAO Z M. Transient numerical simulations of flow rate into and out of two-phase temperature control accumulator[J]. Journal of Beijing University of Aeronautics and Astronautics, 2019, 45(11): 2160-2169(in Chinese). [17] 孟庆亮, 周振华, 赵振明. 用于微重力下两相控温型储液器性能研究[J]. 工程热物理学报, 2021, 42(7): 1770-1776.MENG Q L, ZHOU Z H, ZHAO Z M. Performance study of two-phase thermal-controlled accumulator for microgravity environment[J]. Journal of. Engineering Thermophysics, 2021, 42(7): 1770-1776(in Chinese). [18] 杜王芳, 乐述文, 赵建福, 等. 多相热流体系统中的重力无关性准则[J]. 河北水利电力学院学报, 2019, 29(2): 1-7.DU W F, YUE S W, ZHAO J F, et al. Criteria of gravity independence in multiphase thermal fluid system[J]. Journal of Hebei University of Water Resources and Electric Engineering, 2019, 29(2): 1-7(in Chinese). [19] LEMMON E W, HUBER M L, MCLINDEN M O. NIST standard reference database 23. NIST reference fluid thermodynamic and transport properties database (REFPROP). version 8.0. Standard reference data[Z]. Gaithersburg: NIST, 2007. -

下载:

下载: