-

摘要:

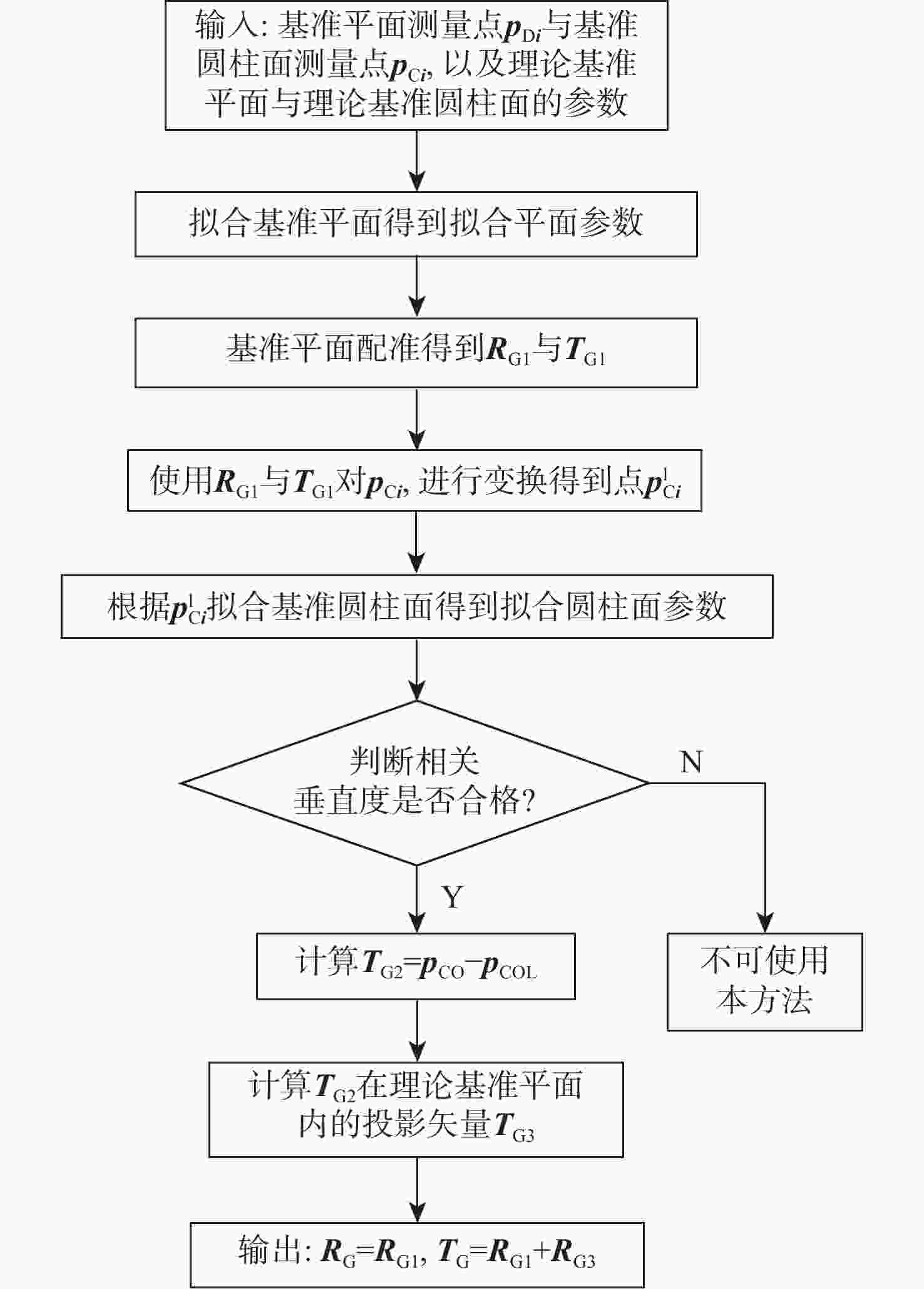

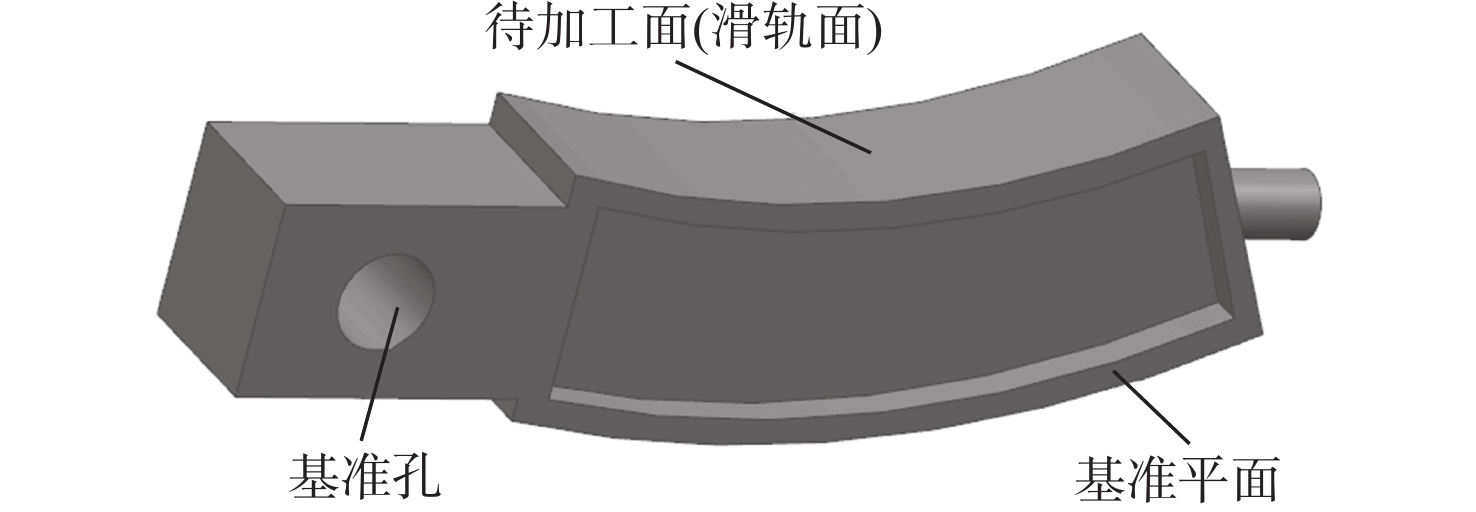

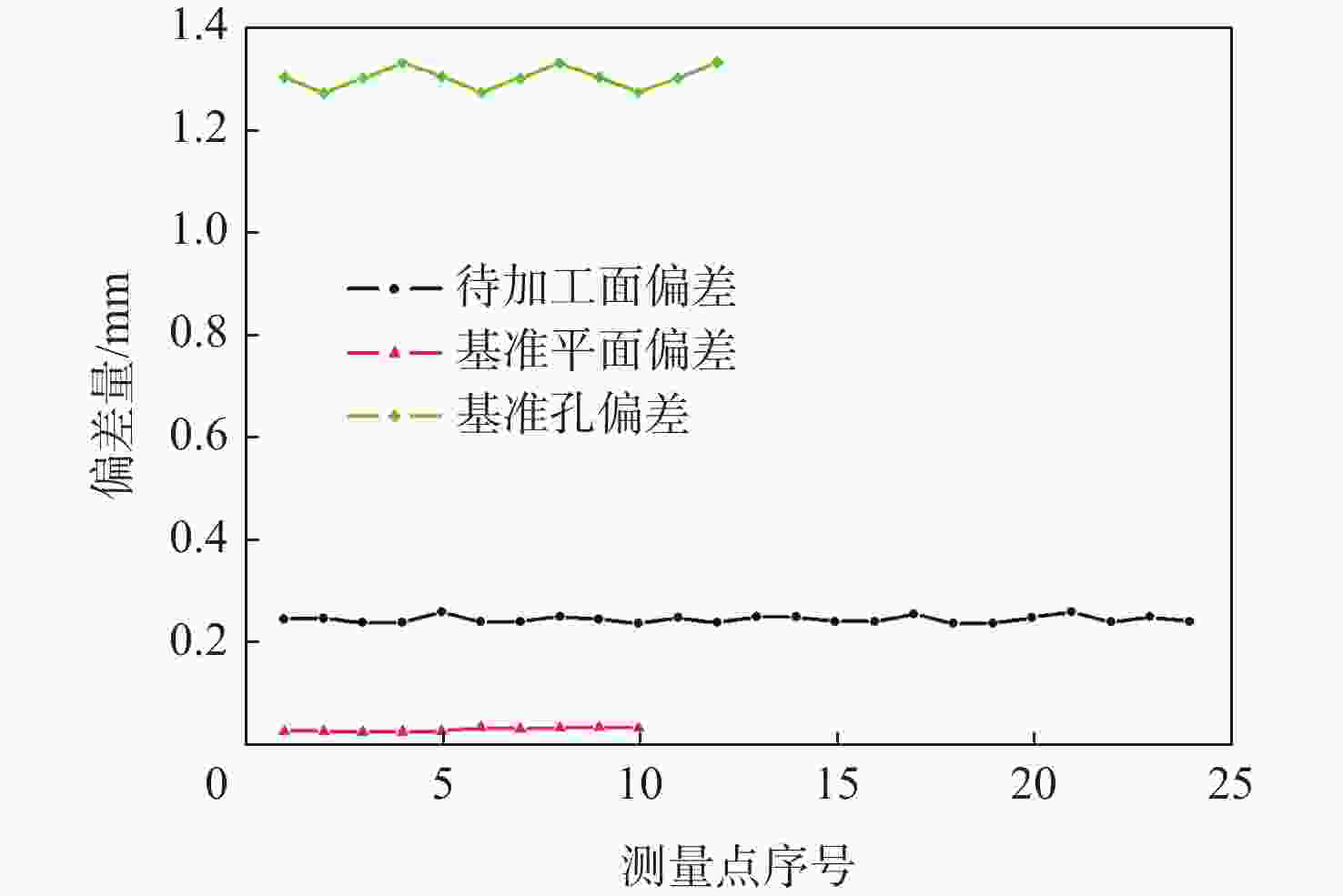

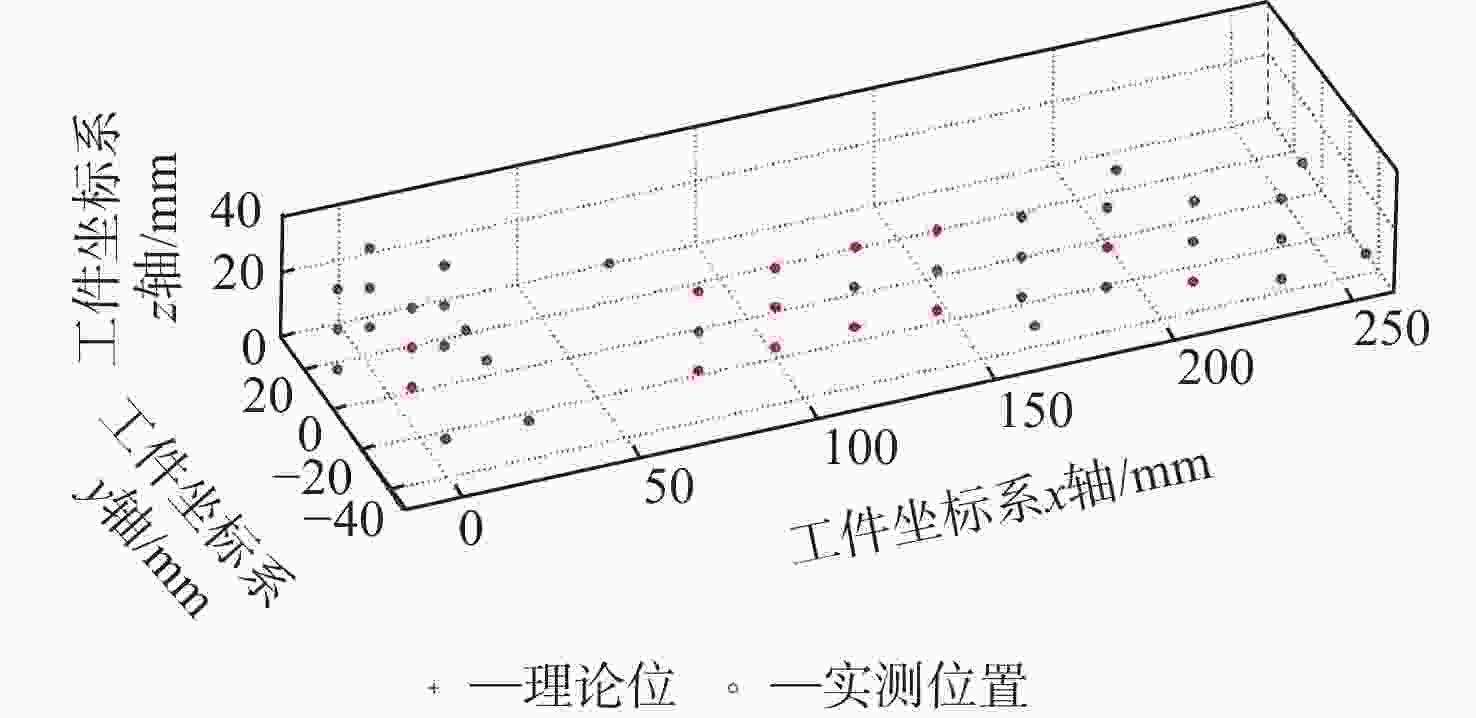

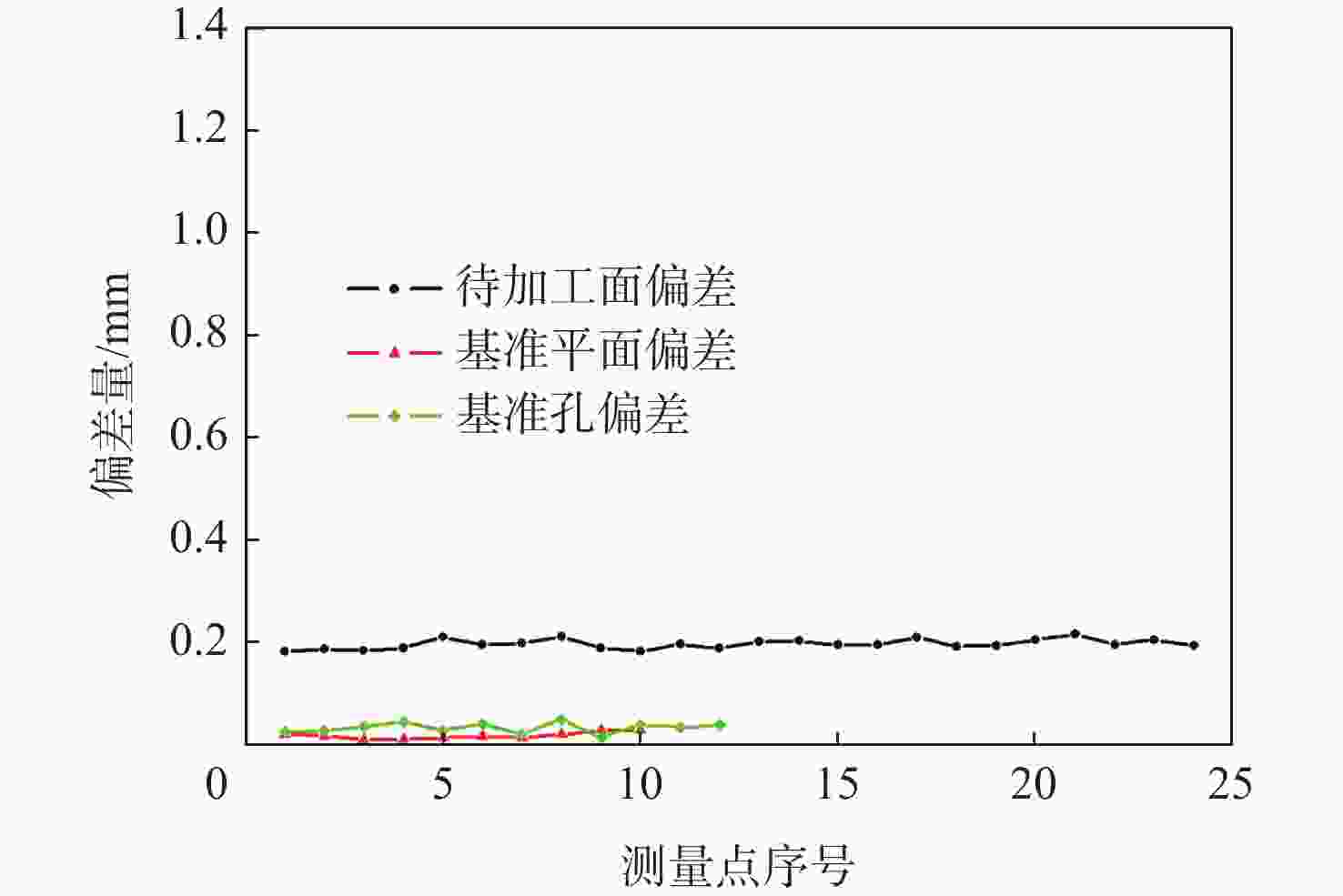

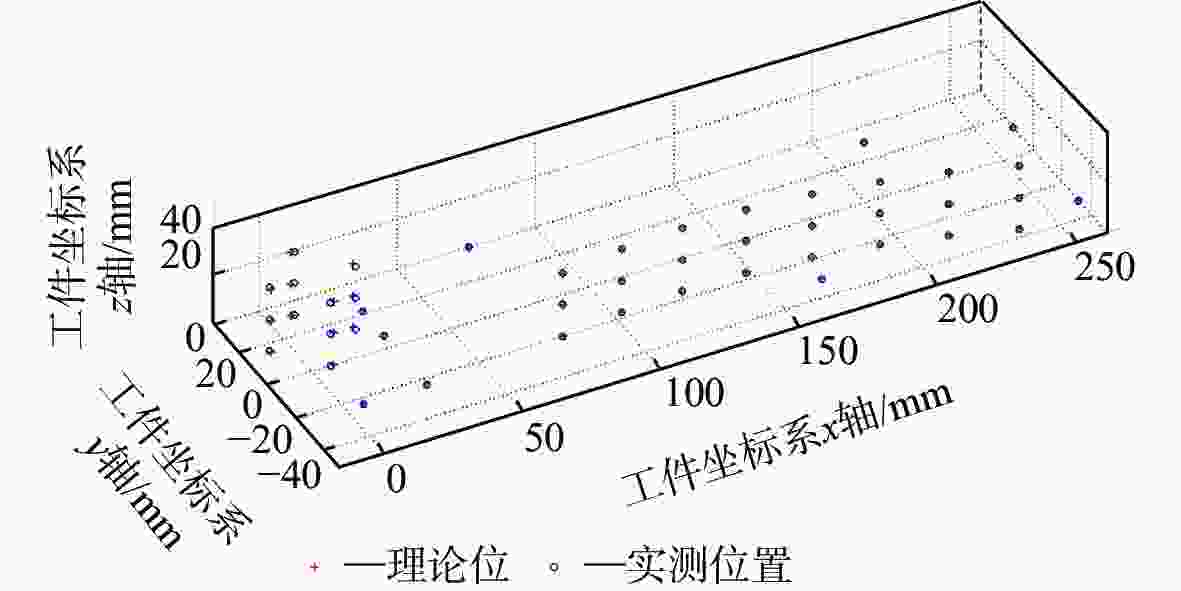

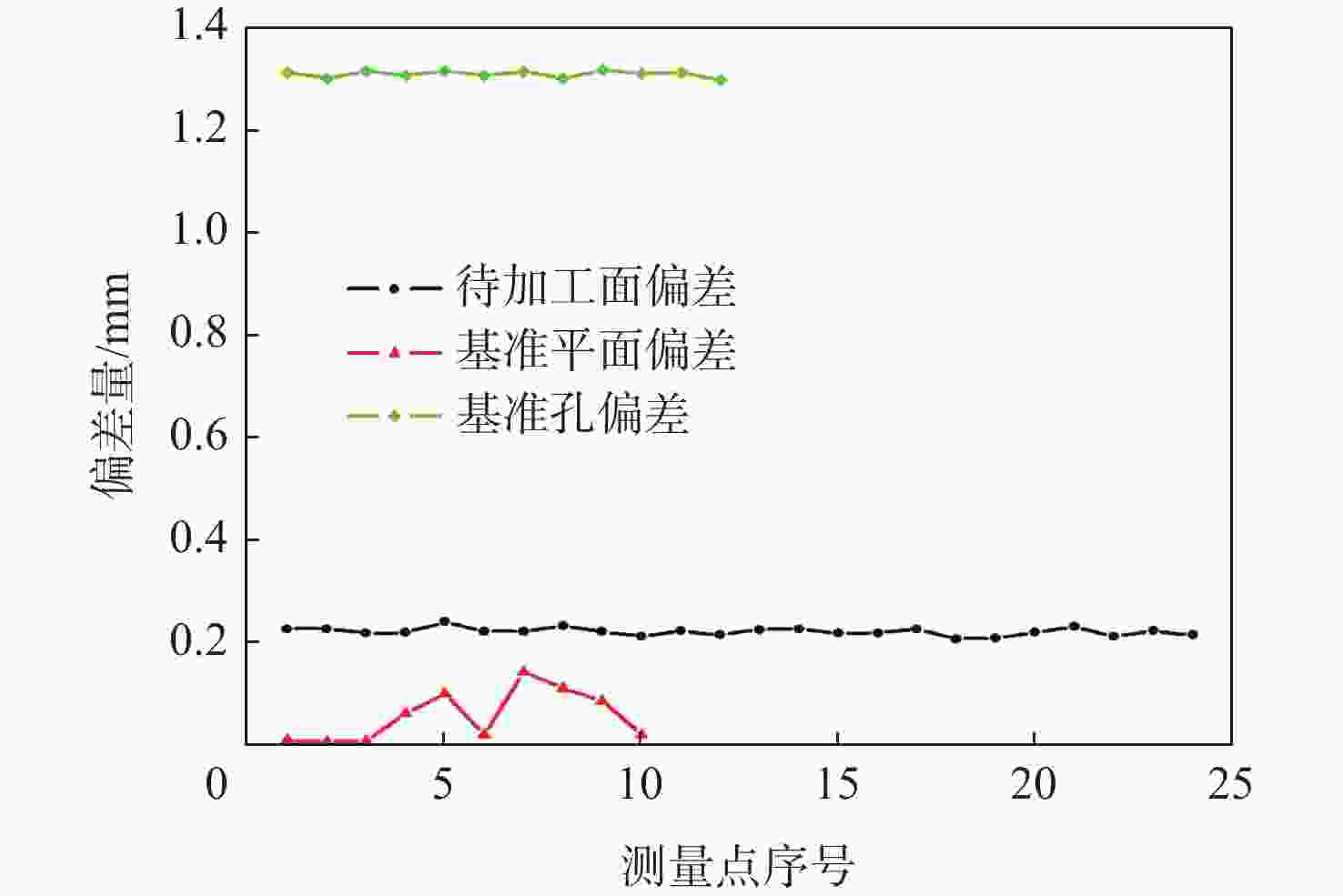

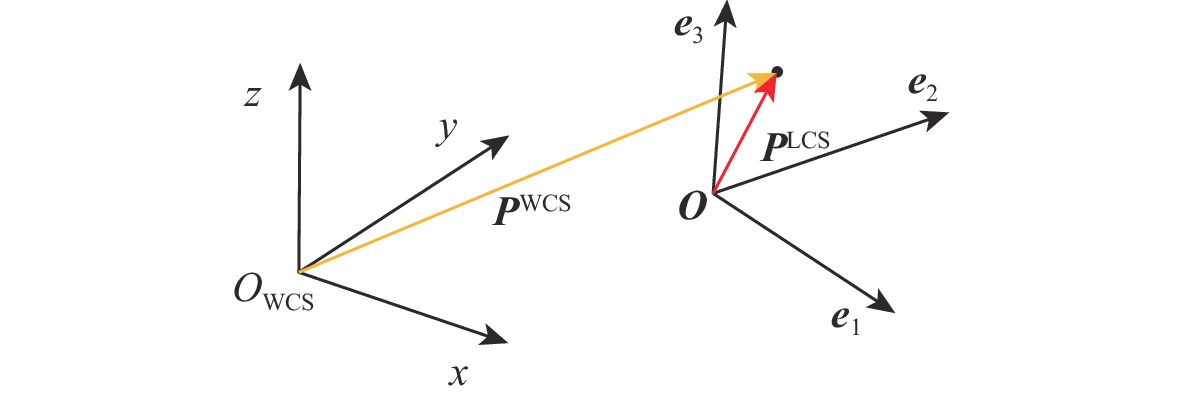

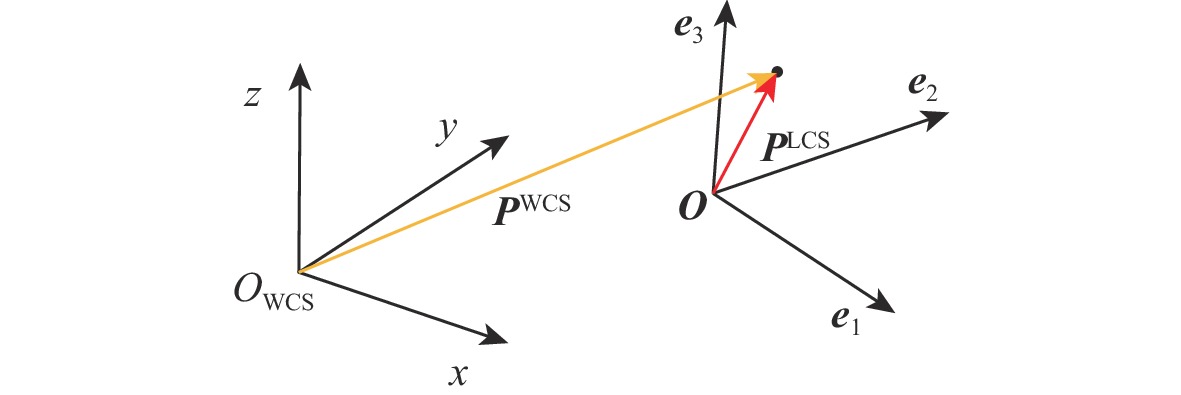

为了保证待加工型面加工余量的均匀性及其相对于基准之间的位置关系,提出一种同时基于基准约束与余量约束的配准算法。所提算法在配准模型中增加基准约束与余量约束,建立在基准约束与余量约束下的配准模型,引入局部坐标系进行配准计算,并将计算结果反算至全局坐标系中。通过引入局部坐标系进行配准计算的算法,降低了测量点变换过程中测量点的运动自由度,从而降低了计算过程中变量的维度,提高了计算效率,保证了计算结果满足基准面约束与余量约束。所提算法在典型的飞机零件“襟翼滑轨”的简化模型上进行了应用验证,相关结果表明:在平面基准约束与余量约束下的配准算法,计算时间为仅在余量约束下配准算法计算时间的33.6%,配准后基准面上测量点的最大偏差小于0.04 mm,待加工面上余量的波动小于0.03 mm,适用于该类零件的自适应精加工过程。

Abstract:This paper presents a registration algorithm based on datum constraints and allowance constraints, which allows the surface to be machined with a uniform allowance and to maintain accurate position relations. First, a local coordinate system was introduced to compute the registration results. Then a conversion method would be employed to solve the corresponding results in the global coordinate system. The introduction of the local coordinate system reduced the degree of freedom of the point set during registration, thus decreasing the number of dimensions and improving the computational efficiency while the algorithm was solved. The results can satisfy both the datum constraints and the allowance constraints. The algorithm was applied on a simplified model of a typical aircraft part “flap track”. The computational results showed that the computing time used by this method was only 33.6 percent of that used by the registration method with the allowance constraints alone, the maximal error for measure points was less than 0.04 mm, and the fluctuating of the allowance was less than 0.03 mm. Therefore, the method is suitable for finishing the surface of similar aircraft parts adaptively.

-

表 1 不同方法配准结果比较

Table 1. Comparison of different registration method

方法 基准平面最大偏差/mm 基准孔最大偏差/mm 待加工面最小偏差/mm 待加工面最大偏差/mm 偏差值波动量/mm 计算时间/s 方法 1 0.038436 1.337247 0.241043 0.263811 0.022768 0.146 方法 2 0.033438 0.054354 0.186074 0.219661 0.033587 0.254 方法 3 0.149557 1.320907 0.213938 0.247241 0.033303 0.434 -

[1] 王文理, 袁士平. 自适应加工技术在数控加工领域的分类与应用[J]. 航空制造技术, 2013(6): 26-29. doi: 10.3969/j.issn.1671-833X.2013.06.001WAGN W L, YUAN S P. Category and application of adaptive machining technology in NC machining field[J]. Aeronautical Manufacturing Technology, 2013(6): 26-29(in Chinese). doi: 10.3969/j.issn.1671-833X.2013.06.001 [2] MAISELI B, GU Y, GAO H. Recent developments and trends in point set registration methods[J]. Journal of Visual Communication and Image Representation, 2017, 46: 95-106. doi: 10.1016/j.jvcir.2017.03.012 [3] ZHU L, BARHAK J, SRIVATSAN V, et al. Efficient registration for precision inspection of free-form surface[J]. International Journal of Advanced Manufacturing Technology, 2007, 32(5): 505-515. [4] BÉARÉE R, DIEULOT J Y, RABATÉ P. An innovative subdivision-ICP registration method for tool-path correction applied to deformed aircraft parts machining[J]. International Journal of Advanced Manufacturing Technology, 2011, 53(5): 463-471. [5] SHI X Y, PENG J J, LI J P, et al. The iterative closest point registration algorithm based on the normal distribution transformation[J]. Procedia Computer Science, 2019, 147: 181-190. doi: 10.1016/j.procs.2019.01.219 [6] BERGSTRÖM P, EDLUND O, SÖDERKVIST I. Repeated surface registration for on-line use[J]. International Journal of Advanced Manufacturing Technology, 2011, 54(5): 677-689. [7] ZHOU Y Q, XU S Y, JIN C C, et al. Multiple point sets registration based on expectation maximization algorithm[J]. Computers and Electrical Engineering, 2018, 70: 1-11. doi: 10.1016/j.compeleceng.2018.05.026 [8] DU S Y, XU G L, ZHANG S R, et al. Robust rigid registration algorithm based on pointwise correspondence and correntropy[J]. Pattern Recognition Letters, 2020, 132: 91-98. doi: 10.1016/j.patrec.2018.06.028 [9] 郑德华, 岳东杰, 岳建平. 基于几何特征约束的建筑物点云配准算法[J]. 测绘学报, 2018, 31(4): 464-468.ZHENG D H, YUE D J, YUE J P. Geometric feature constraint based algorithm for building scanning point cloud registration[J]. Acta Geodaetica et Cartog Raphica Sinica, 2018, 31(4): 464-468(in Chinese). [10] 俞慈君, 李江雄, 余锋杰, 等. 带工程约束的点匹配算法[J]. 机械工程学报, 2010, 46(5): 183-190. doi: 10.3901/JME.2010.05.183YU C J, LI J X, YU F J, et al. 3D points registration algorithm with engineering constraints[J]. Journal of Mechanical Engineering, 2010, 46(5): 183-190(in Chinese). doi: 10.3901/JME.2010.05.183 [11] 冯亚洲, 任军学, 梁永收, 等. 多目标约束的精锻叶片几何重构优化算法[J]. 航空学报, 2018, 39(7): 421844.FENG Y Z, REN J X, LIANG Y S, et al. Multi-objective optimization algorithm for geometric reconstruction of precision forged blade[J]. Acta Aeronautic et Astronautica Sinica, 2018, 39(7): 421844(in Chinese). [12] CHEN S Y, WU C C, XUE S, et al. Fast registration of 3D point clouds with offset surfaces in precision grinding of free-form surfaces[J]. The International Journal of Advanced Manufacturing Technology, 2018, 97(9): 3595-3606. [13] XIE S Q, CHENG D, WONG S. Three-dimensional object recognition system for enhancing the intelligence of a KUKA robot[J]. The International Journal of Advanced Manufacturing Technology, 2008, 38(7): 822-839. [14] HE W T, LI Z W, GUO Y Y, et al. A robust and accurate automated registration method for turbine blade precision metrology[J]. The International Journal of Advanced Manufacturing Technology, 2018, 97(9): 3711-3721. [15] FENG C, LIANG J, GONG C Y, et al. Repair volume extraction method for damaged parts in remanufacturing repair[J]. The International Journal of Advanced Manufacturing Technology, 2018, 98(5): 1523-1536. [16] 张定华, 张莹, 吴宝海, 等. 自适应加工技术在整体叶盘制造中的应用[J]. 航空制造技术, 2013(13): 51-55. doi: 10.16080/j.issn1671-833x.2008.13.007ZHANG D H, ZHANG Y, WU B H, et al. Application of adaptive machining technology in blisk manufacturing[J]. Aeronautical Manufacturing Technology, 2013(13): 51-55(in Chinese). doi: 10.16080/j.issn1671-833x.2008.13.007 [17] 陈志同, 朱燏, 张云, 等. 整体叶盘超硬磨料砂轮数控磨削加工技术[J]. 航空制造技术, 2018, 61(19): 64-72. doi: 10.16080/j.issn1671-833x.2018.19.064CHEN Z T, ZHU Y, ZHANG Y, et al. CNC grinding technology with super-abrasive grinding wheels for blisk[J]. Aeronautical Manufacturing Technology, 2018, 61(19): 64-72(in Chinese). doi: 10.16080/j.issn1671-833x.2018.19.064 [18] 王兴波. 空间任意方向圆柱面的参数方程[J]. 佛山科学技术学院院报(自然科学版), 2010, 28(6): 58-63.WANG X B. Parametric equation of cylinder in arbitrary direction[J]. Journal of Foshan University(Natural Science Edition), 2010, 28(6): 58-63(in Chinese). -

下载:

下载: