-

摘要:

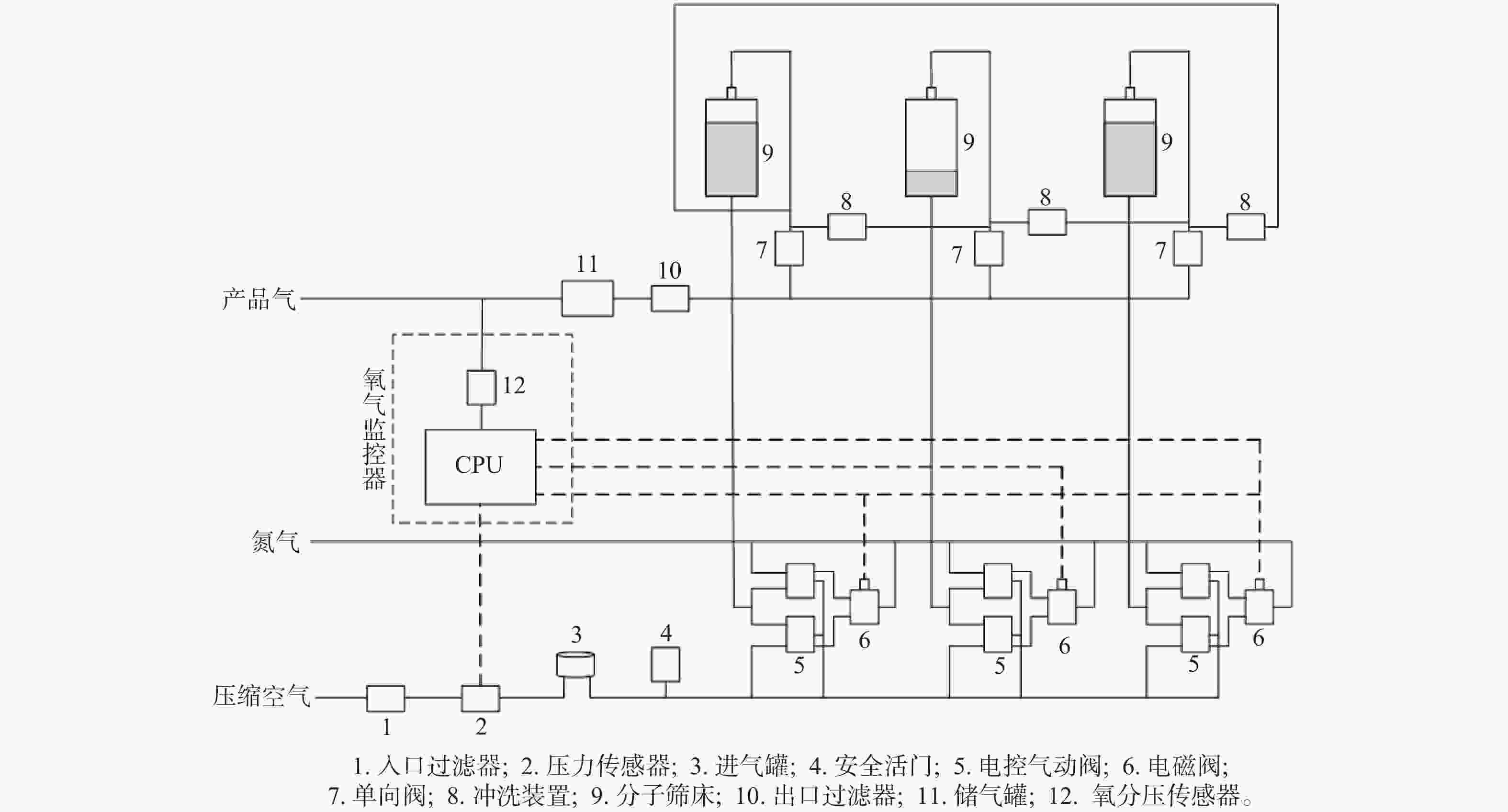

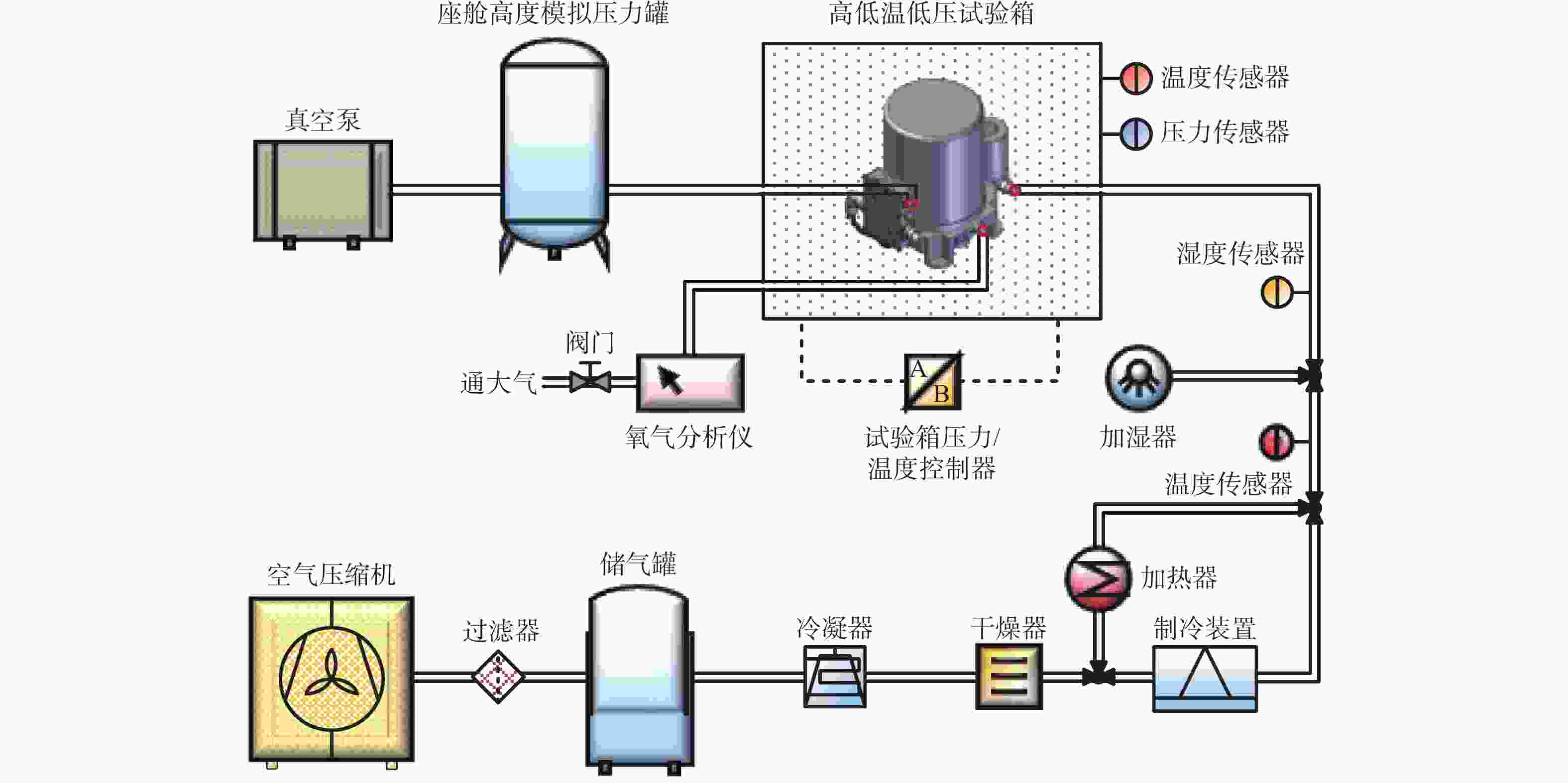

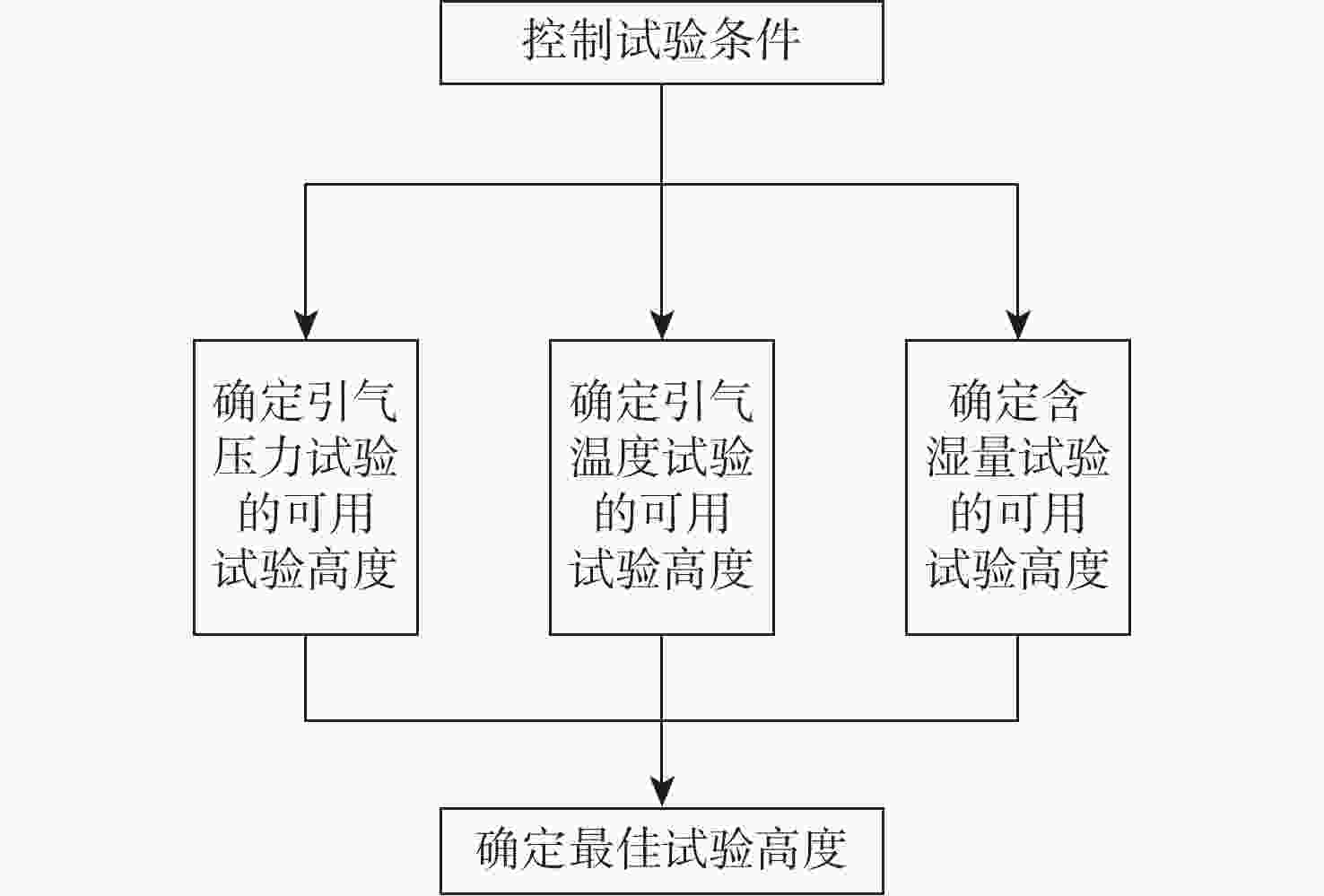

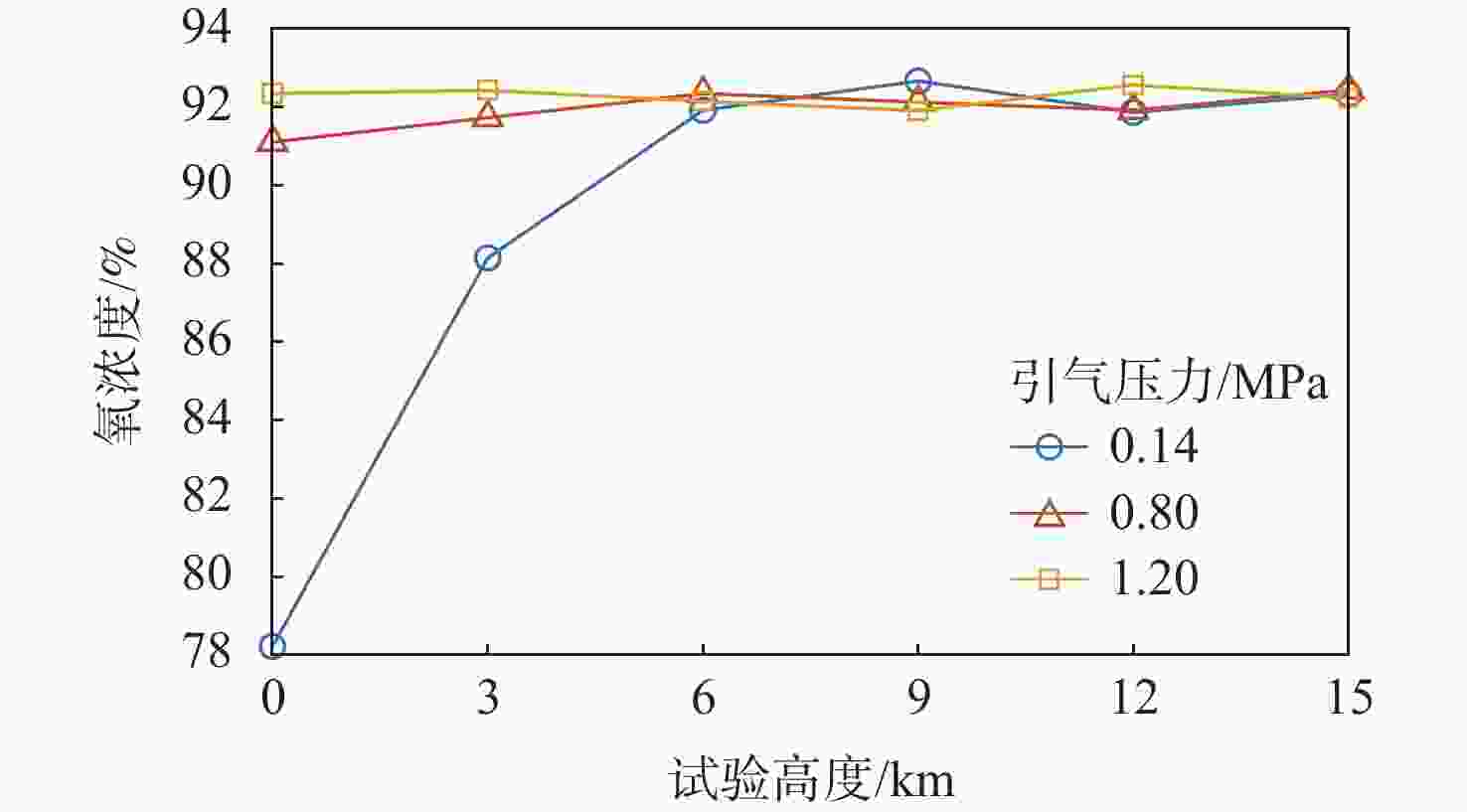

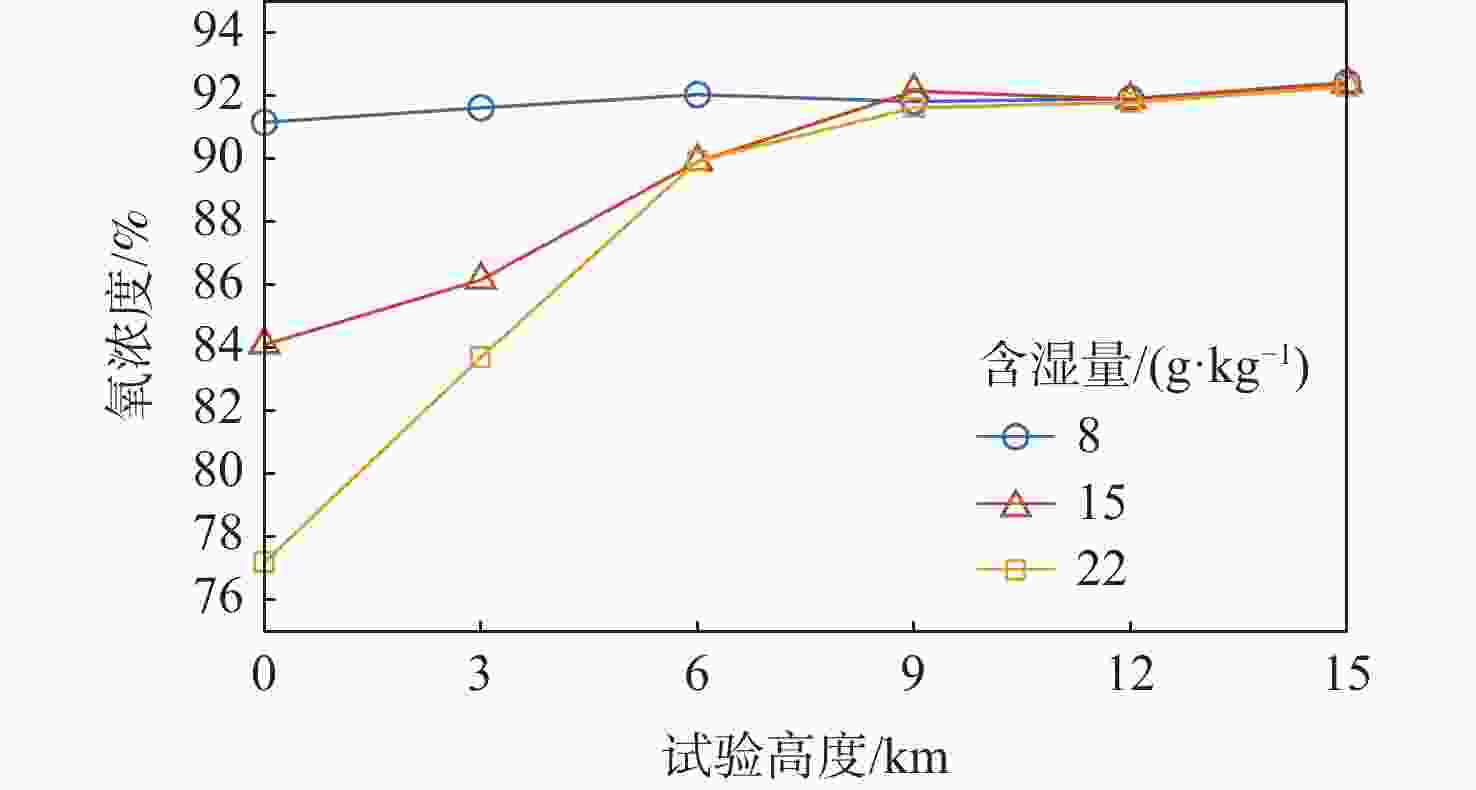

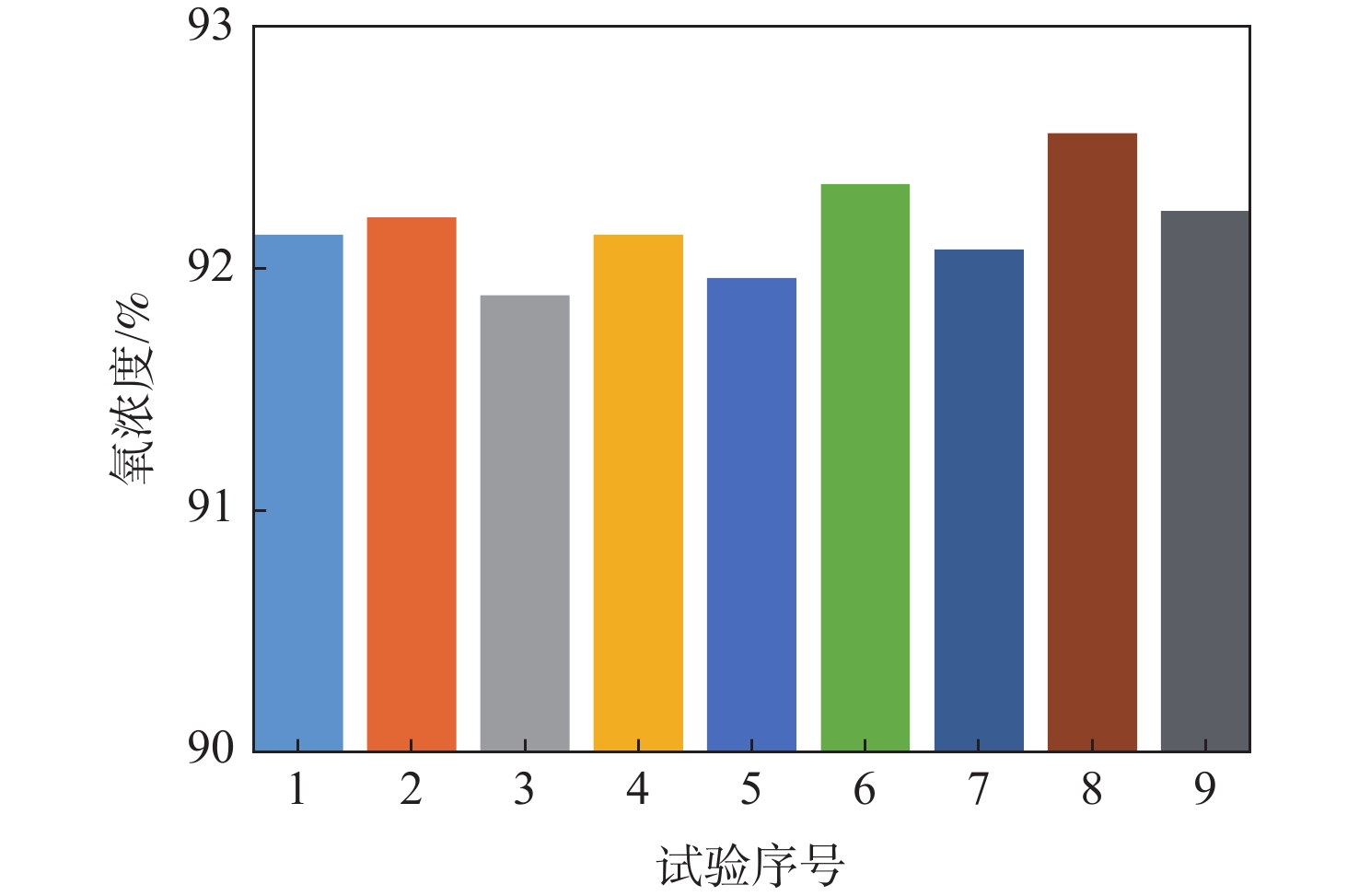

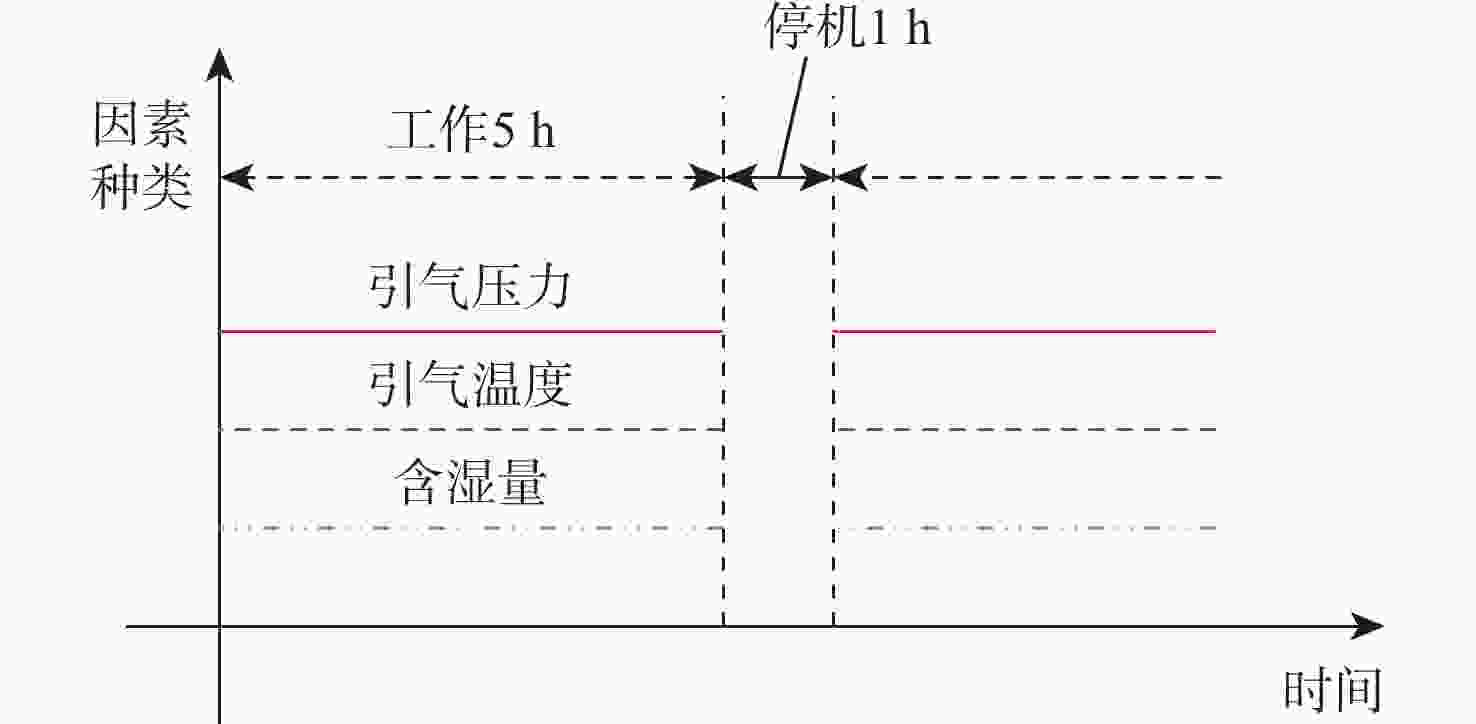

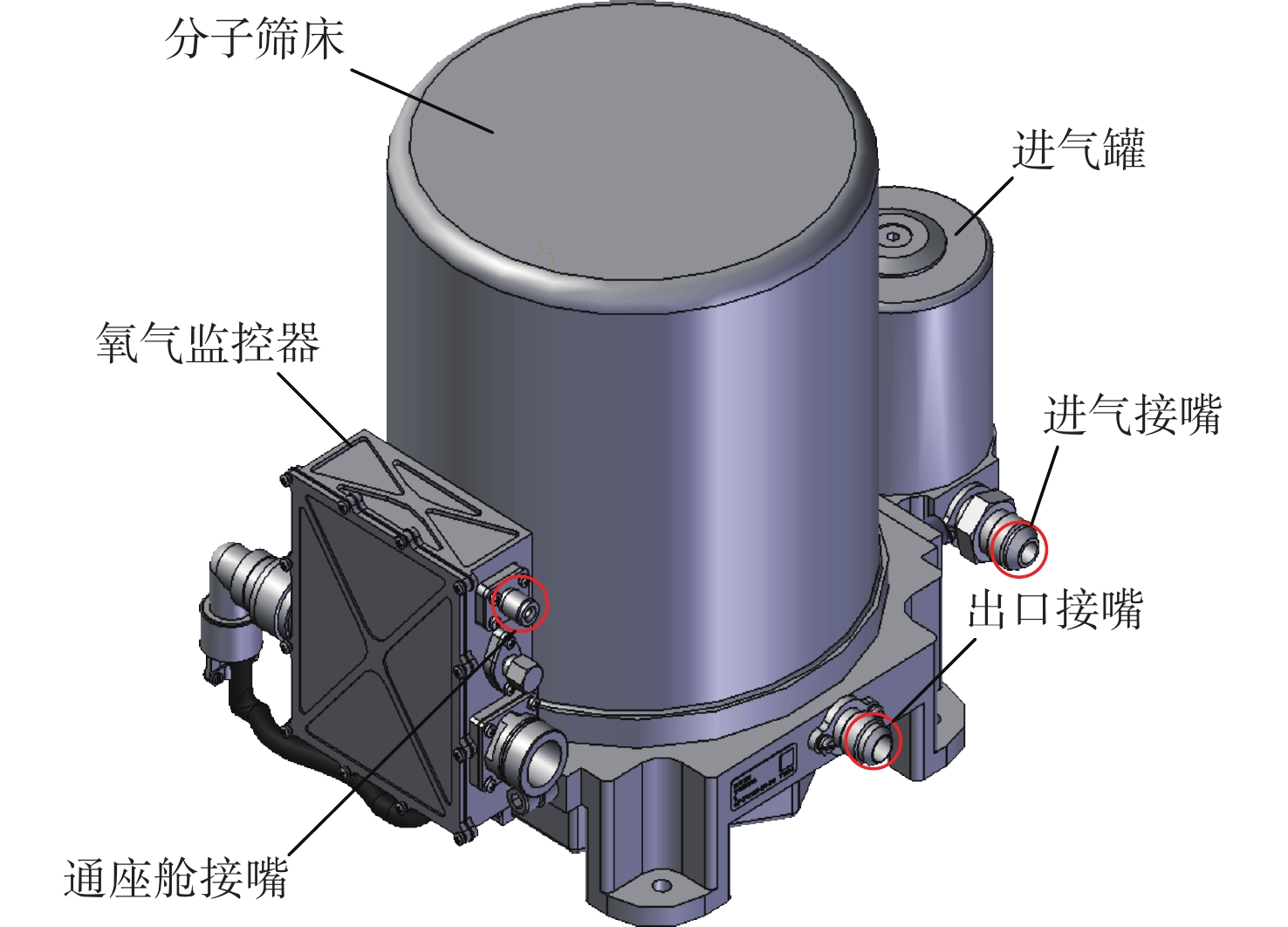

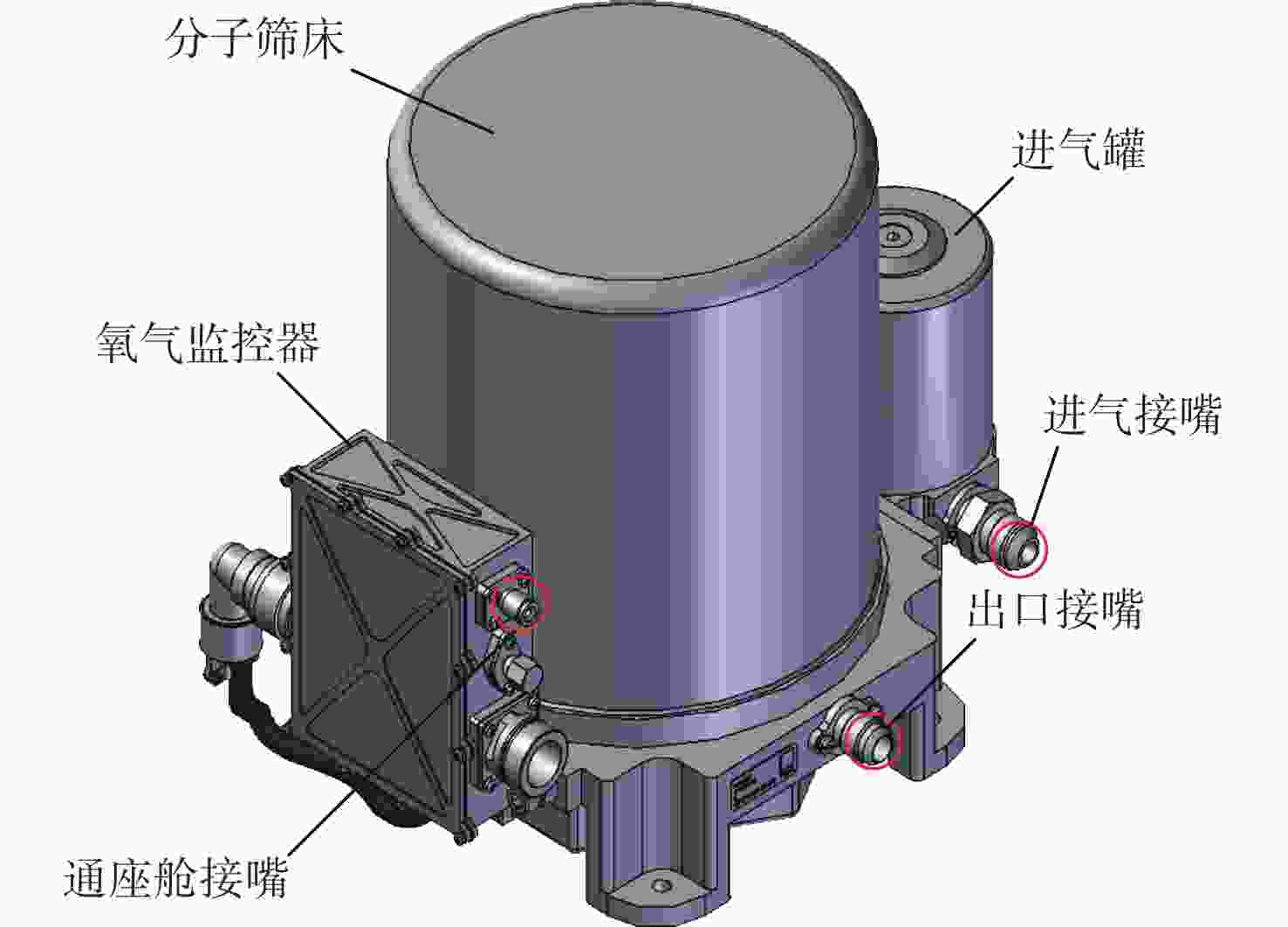

针对分子筛氧气浓缩器(MSOC)退化试验(DT)研究不足及分子筛床(MSB)退化失效影响因素不明确的情况,提出了一种基于正交试验的氧气浓缩器退化试验设计方法。在分析氧气浓缩器工作原理的基础上,确定了造成分子筛床退化失效的主要因素,并搭建了分子筛氧气浓缩器退化试验系统,通过多组对照试验确定并验证了退化试验的最佳试验高度为9 km;基于正交试验思想设计了分子筛氧气浓缩器退化试验方案,采用9组典型试验即可获得各因素的影响结果,减少了试验次数,降低了试验成本,提高了耦合试验的效率。该试验设计可以模拟受试设备的真实工作环境,并可有效降低试验因素变化对试验结果初值的影响。

Abstract:For lack of research on degradation test (DT) for molecular sieve oxygen concentrator (MSOC) and clear account of the factors causing degradation failure of molecular sieve bed (MSB), a DT design method of MSOC based on orthogonal test was proposed. Based on the working principle of MSOC, the main factors causing degradation failure of MSB were determined, and a DT system of the MSOC was built. The optimal test height for the DT was 9 km, as was determined and verified by several controlled tests. A DT scheme of MSOC was designed based on the orthogonal test idea. The influence of various factors could be obtained through 9 typical tests, which reduced the test times and costs, and improved the efficiency of coupling tests. The test design can simulate the real working environment, and can effectively reduce the impact of test factors on the initial value of the test results.

-

Key words:

- molecular sieve /

- oxygen concentrator /

- degradation test /

- orthogonal test /

- coupling test

-

表 1 各因素水平

Table 1. Factors of different levels

水平等级 引气压力/MPa 引气温度/℃ 含湿量/(g·kg−1) 低 0.14 15 8 中 0.8 30 15 高 1.2 50 22 表 2 正交试验方案

Table 2. Orthogonal test scheme

试验序号 引气压力/MPa 引气温度/℃ 含湿量/(g·kg−1) 1 0.14 15 8 2 0.14 30 15 3 0.14 50 22 4 0.8 15 15 5 0.8 30 22 6 0.8 50 8 7 1.2 15 22 8 1.2 30 8 9 1.2 50 15 -

[1] 孙兵, 肖华军, 袁修干, 等. 分子筛氧气浓缩器产氧性能实验分析[J]. 北京航空航天大学学报, 2003, 29(1): 46-49. doi: 10.3969/j.issn.1001-5965.2003.01.013SUN B, XIAO H J, YUAN X G, et al. Experiments on performance of a molecular sieve oxygen concentrator system[J]. Journal of Beijing University of Aeronautics and Astronautics, 2003, 29(1): 46-49(in Chinese). doi: 10.3969/j.issn.1001-5965.2003.01.013 [2] 杨锋, 林贵平, 袁修干. 分子筛氧浓缩器的串联混合池计算模型[J]. 北京航空航天大学学报, 2002, 28(6): 609-612. doi: 10.3969/j.issn.1001-5965.2002.06.002YANG F, LIN G P, YUAN X G. Series-mixed-cell computational model of molecular sieve oxygen concentrator[J]. Journal of Beijing University of Aeronautics and Astronautics, 2002, 28(6): 609-612(in Chinese). doi: 10.3969/j.issn.1001-5965.2002.06.002 [3] 杨锋, 林贵平, 赵竞全. 分子筛氧浓缩器非等温吸附模型[J]. 北京航空航天大学学报, 2002, 28(1): 8-11.YANG F, LIN G P, ZHAO J Q. Nonisothermal adsorption model for molecular sieve oxygen concentrator(MSOC)[J]. Journal of Beijing University of Aeronautics and Astronautics, 2002, 28(1): 8-11(in Chinese). [4] 刘忠宝. 分子筛氧气浓缩器性能模拟预测模型及分析[J]. 深冷技术, 2001(1): 14-16. doi: 10.3969/j.issn.978-7-807.2001.01.004LIU Z B. Modeling of predicting performance of a molecular sieve oxygen concentrator and analysis[J]. Cryogenic Technology, 2001(1): 14-16(in Chinese). doi: 10.3969/j.issn.978-7-807.2001.01.004 [5] SANTOS J C, MAGALHÃES F D, MENDES A. Contamination of zeolites used in oxygen production by PSA: Effects of water and carbon dioxide[J]. Industrial & Engineering Chemistry Research, 2008, 47(16): 6197-6203. [6] PAN M F, OMAR H M, ROHANI S. Application of nanosize zeolite molecular sieves for medical oxygen concentration[J]. Nanomaterials (Basel, Switzerland), 2017, 7(8): 195. doi: 10.3390/nano7080195 [7] ZHU X Q, LIU Y S, YANG R T. Effects of operating temperature on the performance of small scale rapid cycle pressure swing adsorption air separation process[J]. Adsorption, 2021, 27(2): 205-212. doi: 10.1007/s10450-020-00266-9 [8] 徐正红, 杜珍. 机载氧气浓缩器性能测试系统设计及校准技术研究[J]. 合肥工业大学学报(自然科学版), 2012, 35(8): 1068-1070.XU Z H, DU Z. Design of performance measurement system and development of calibration technology for molecular sieve oxygen generator[J]. Journal of Hefei University of Technology (Natural Science), 2012, 35(8): 1068-1070(in Chinese). [9] 周伟俊, 王妍, 张雷. 机载制氧分子筛污染加注模拟系统设计[J]. 工业控制计算机, 2018, 31(5): 110-111. doi: 10.3969/j.issn.1001-182X.2018.05.045ZHOU W J, WANG Y, ZHANG L. Design of pollution injection simulation system for airborne oxygen molecular sieve[J]. Industrial Control Computer, 2018, 31(5): 110-111(in Chinese). doi: 10.3969/j.issn.1001-182X.2018.05.045 [10] BULFIN B, BUTTSWORTH L, LIDOR A, et al. High-purity nitrogen production from air by pressure swing adsorption combined with SrFeO3 redox chemical looping[J]. Chemical Engineering Journal, 2021, 421: 127734. [11] 王慧丹, 林贵平, 王亮, 等. 三床机载制氧系统性能仿真及影响因素分析[J]. 北京航空航天大学学报, 2011, 37(6): 717-722.WANG H D, LIN G P, WANG L, et al. Simulation on performance and effects of parameters analysis on three-bed OBOGS[J]. Journal of Beijing University of Aeronautics and Astronautics, 2011, 37(6): 717-722(in Chinese). [12] 蒋东升, 卜雪琴, 林贵平, 等. 三床型机载制氧系统控制设计与实验验证[J]. 北京航空航天大学学报, 2018, 44(8): 1603-1608.JIANG D S, BU X Q, LIN G P, et al. Control design and experimental verification of three-bed onboard oxygen generation system[J]. Journal of Beijing University of Aeronautics and Astronautics, 2018, 44(8): 1603-1608(in Chinese). [13] 刘珊珊, 柴玉超, 关乃佳, 等. 分子筛材料在小分子吸附分离中的应用[J]. 高等学校化学学报, 2021, 42(1): 268-288.LIU S S, CHAI Y C, GUAN N J, et al. Small molecule adsorption and separation on zeolites[J]. Chemical Journal of Chinese Universities, 2021, 42(1): 268-288(in Chinese). [14] 杨东升, 刘猛, 庞丽萍, 等. H2O对空间站5A分子筛CO2去除性能影响[J]. 北京航空航天大学学报, 2015, 41(8): 1485-1491.YANG D S, LIU M, PANG L P, et al. H2O impact on CO2 removal performance of 5A molecular sieve in space station[J]. Journal of Beijing University of Aeronautics and Astronautics, 2015, 41(8): 1485-1491(in Chinese). [15] 曾宇, 林贵平. 分子筛氧浓缩器实验台集散控制系统的设计[J]. 计算机测量与控制, 2008, 16(9): 1220-1222. doi: 10.16526/j.cnki.11-4762/tp.2008.09.027ZENG Y, LIN G P. Distributed control system design in molecular sieve function experiment station[J]. Computer Measurement & Control, 2008, 16(9): 1220-1222(in Chinese). doi: 10.16526/j.cnki.11-4762/tp.2008.09.027 [16] 张燕平, 赵宏韬. 测控技术在分子筛机载制氧领域的应用研究[C]//2015航空试验测试技术学术交流会, 2015: 285-287.ZHANG Y P, ZHAO H T. Research application of measuring technology in on-board molecular sieve oxygen generation[C]//Proceedings of 2015 Symposium on Aviation Test Technology, 2015: 285-287 (in Chinese). [17] HAN S L, LI Z Y, GAO Y, et al. Numerical study on Die design parameters of self-pierce riveting process based on orthogonal test[J]. Journal of Shanghai Jiaotong University (Science), 2014, 19(3): 308-312. doi: 10.1007/s12204-014-1504-8 [18] 郑源, 孙奥冉, 杨春霞, 等. 轴流泵多目标优化正交试验[J]. 农业机械学报, 2017, 48(9): 129-136. doi: 10.6041/j.issn.1000-1298.2017.09.016ZHENG Y, SUN A R, YANG C X, et al. Multi-objective optimization design and test of axial-flow pump[J]. Transactions of the Chinese Society for Agricultural Machinery, 2017, 48(9): 129-136(in Chinese). doi: 10.6041/j.issn.1000-1298.2017.09.016 [19] 中华人民共和国国家质量监督检验检疫总局, 中国国家标准化管理委员会. 氧气浓缩器: GB/T 24714—2009[S]. 北京: 中国标准出版社, 2010.General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China, Standardization Administration of China. Oxygen concentrator: GB/T 24714—2009[S]. Beijing: China Standards Press, 2010 (in Chinese). -

下载:

下载: