-

摘要:

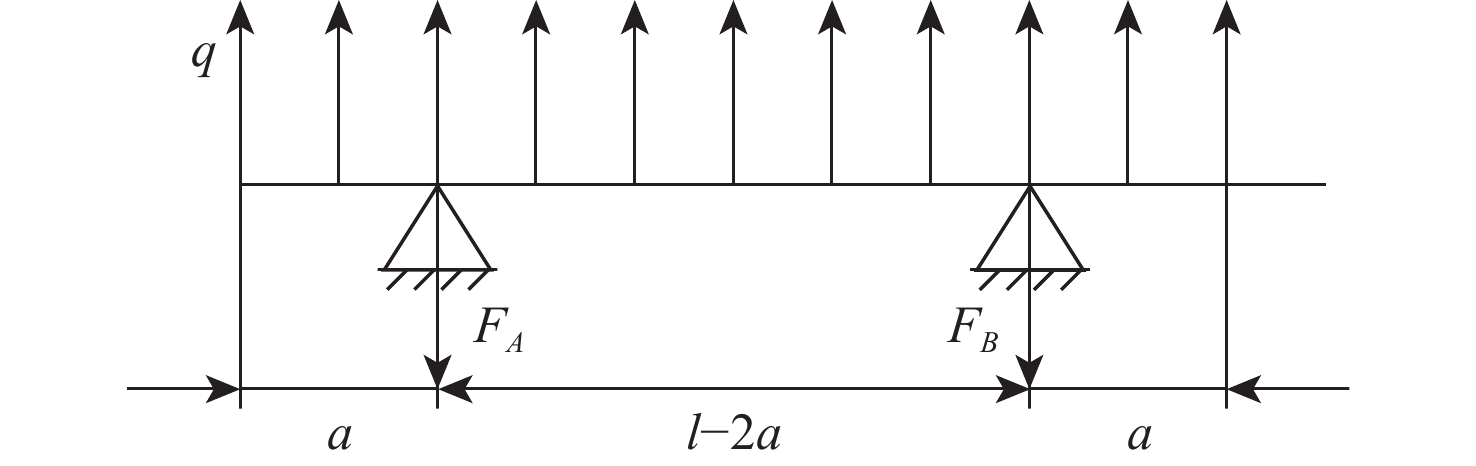

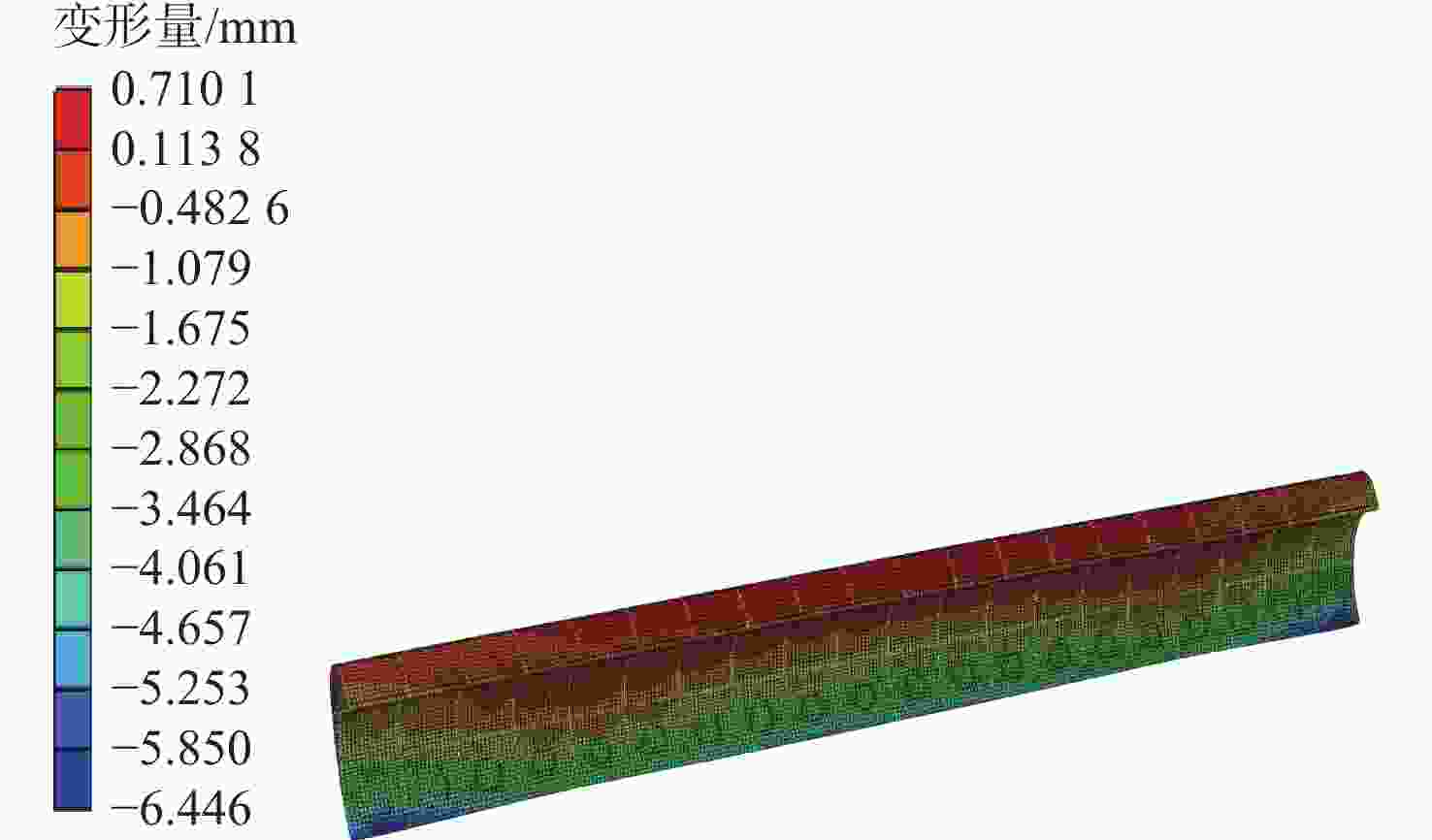

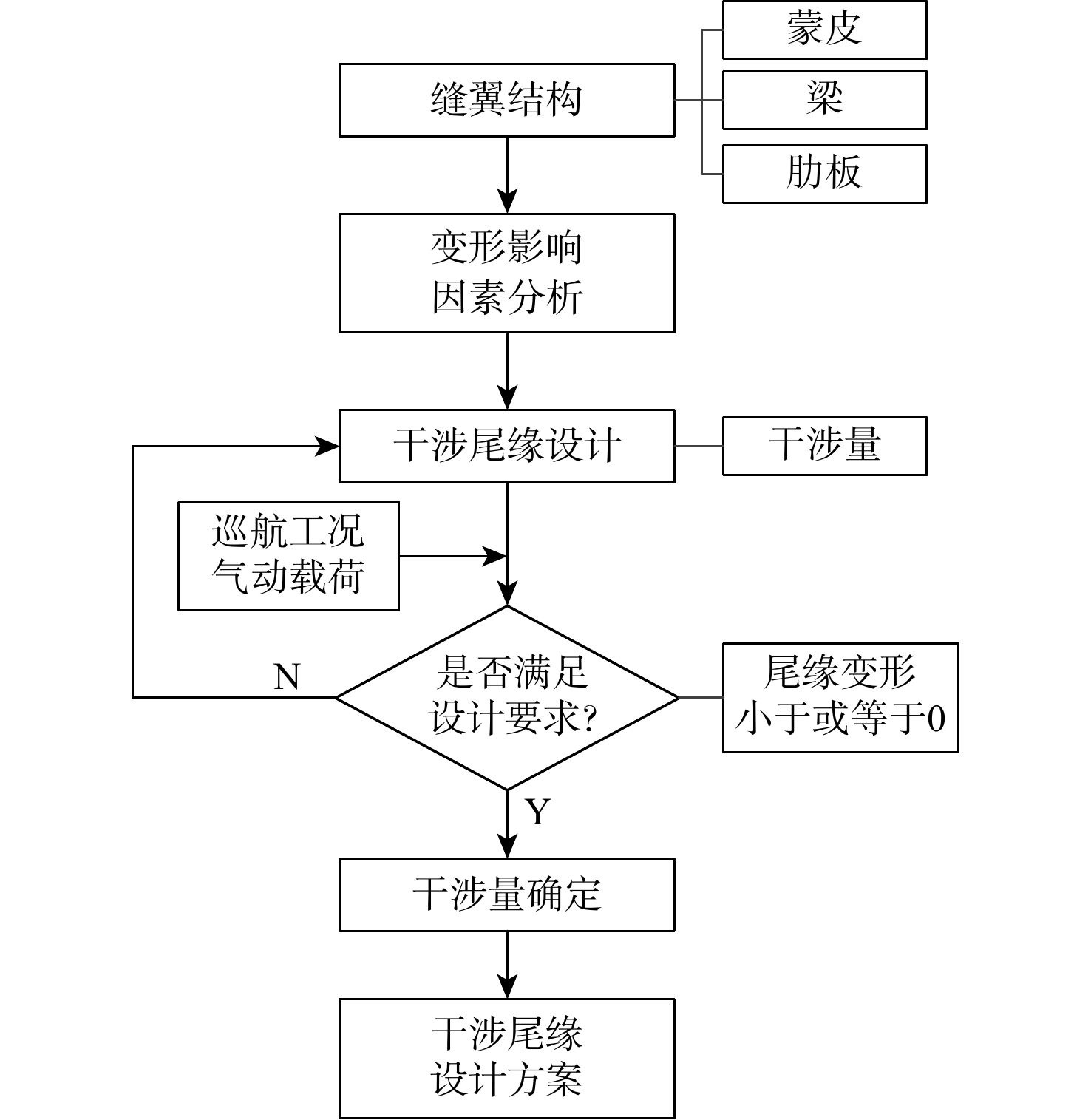

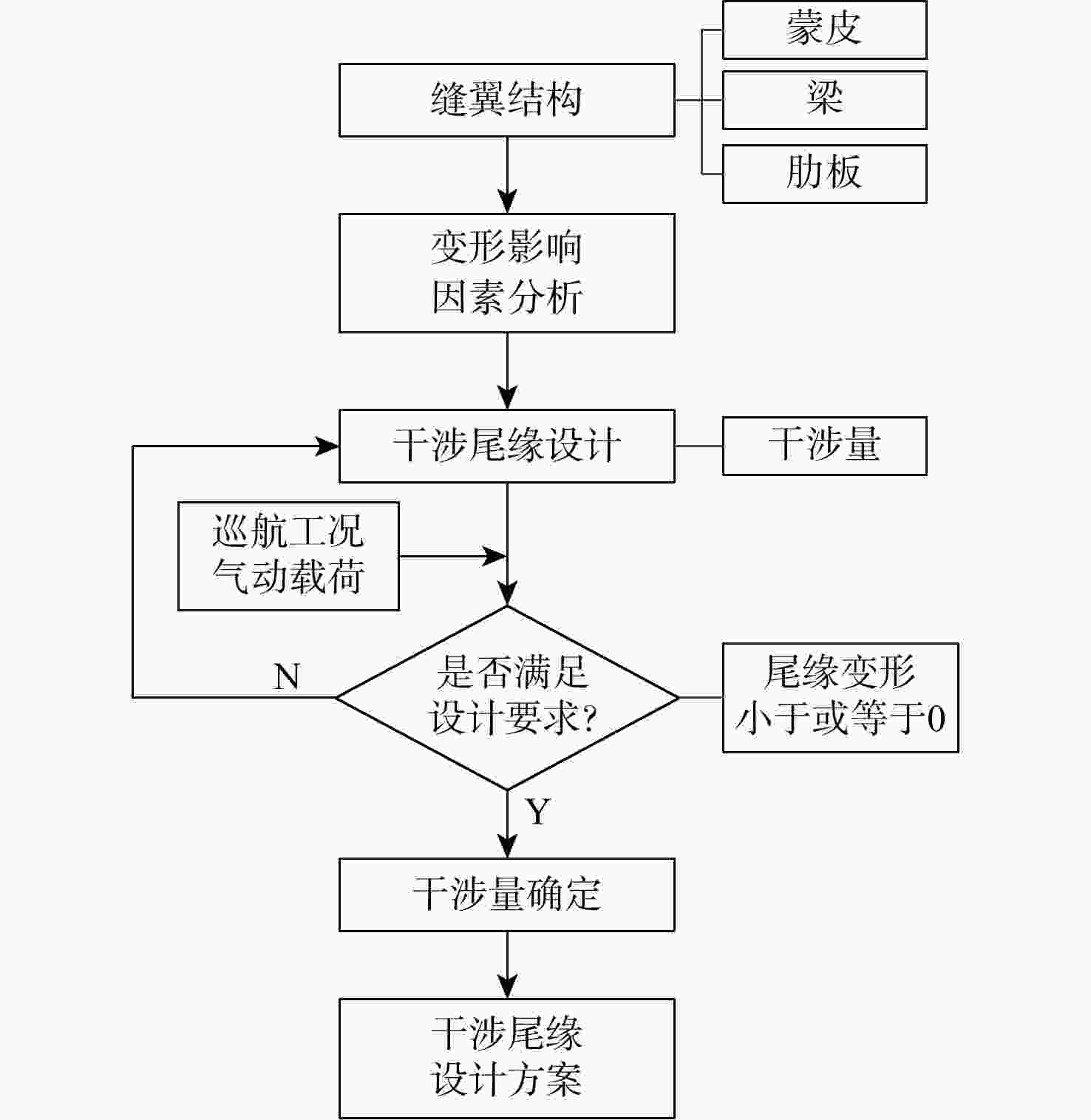

前缘缝翼是大型飞机起飞与降落阶段重要的增升装置,但受自身结构刚度及其支持刚度影响,承受气动载荷时缝翼易发生翘曲变形,与翼盒产生缝隙,影响到机翼的气动效率。为消除巡航状态缝翼的变形,提高机翼气动效率,提出前缘缝翼干涉尾缘结构设计技术。对影响前缘缝翼结构法向和弦向变形的主要因素进行理论分析。以国内某大型飞机前缘缝翼为研究对象,针对蒙皮等各结构尺寸对前缘缝翼本体刚度的影响,从质量和变形两方面进行详细论述。在保持原有前缘缝翼结构尺寸、质量的前提下,进行前缘缝翼干涉尾缘结构的设计。结果表明:所提的前缘缝翼干涉尾缘结构在巡航工况气动载荷下,可以保持与机翼不分离的状态,提高气动性能,且有效避免了质量的增加。

Abstract:The leading edge slat is an important lift increasing device in the take-off and landing stages of large aircraft. But affected by its own body stiffness and support stiffness, the slat is prone to warpage and deformation under aerodynamic load, resulting in gaps with the wing box, which affects the aerodynamic efficiency of the wing. To eliminate the deformation of slat in cruise and improve the aerodynamic efficiency of the wing, the leading edge slat interference trailing edge structural design technology is proposed in this paper. Firstly, the main factors affecting the normal and chord deformation of slat structure are theoretically analyzed. Then, taking the leading edge slat of a large domestic aircraft as the research object, the influence of skin and other structural dimensions on the stiffness of slat body is discussed in detail from two aspects of weight and deformation. Finally, on the premise of maintaining the size and weight of the original slat structure, the leading edge slat interference trailing edge structure is designed. The results show that the proposed interference trailing edge structure can maintain the state of non separation from the wing under the aerodynamic load of cruise condition, improve the aerodynamic performance, and effectively avoid the increase of weight.

-

Key words:

- interference trailing edge /

- leading edge slat /

- deformation factor /

- body stiffness /

- structural design

-

表 1 不同前缘缝翼本体刚度相关结构尺寸

Table 1. Structural dimensions of different leading edge slat body stiffness

mm 方案 蒙皮

厚度梁 普通肋 端肋 加强肋 腹板厚度 缘条宽度 缘条厚度 腹板厚度 缘条宽度 缘条厚度 腹板厚度 缘条宽度 缘条厚度 腹板厚度 缘条宽度 缘条厚度 1 1.6 1.6 20 1.6 2 12 2 2 30 2 8 45 2 2 3.2 1.6 20 1.6 2 12 2 2 30 2 8 45 2 3 1.6 3.2 40 3.2 2 12 2 2 30 2 8 45 2 4 1.6 1.6 20 1.6 4 24 4 2 30 2 8 45 2 5 1.6 1.6 20 1.6 2 12 2 4 60 4 8 45 2 6 1.6 1.6 20 1.6 2 12 2 2 30 2 16 90 4 7 1.6 1.6 20 1.6 2 12 2 2 30 2 16 45 2 表 2 不同方案结果对比分析

Table 2. Comparative analysis of results of different schemes

方案 最大应

力/MPa应力相对

变化/%最大变

形/mm变形相对

变化/%质量/kg 质量相对

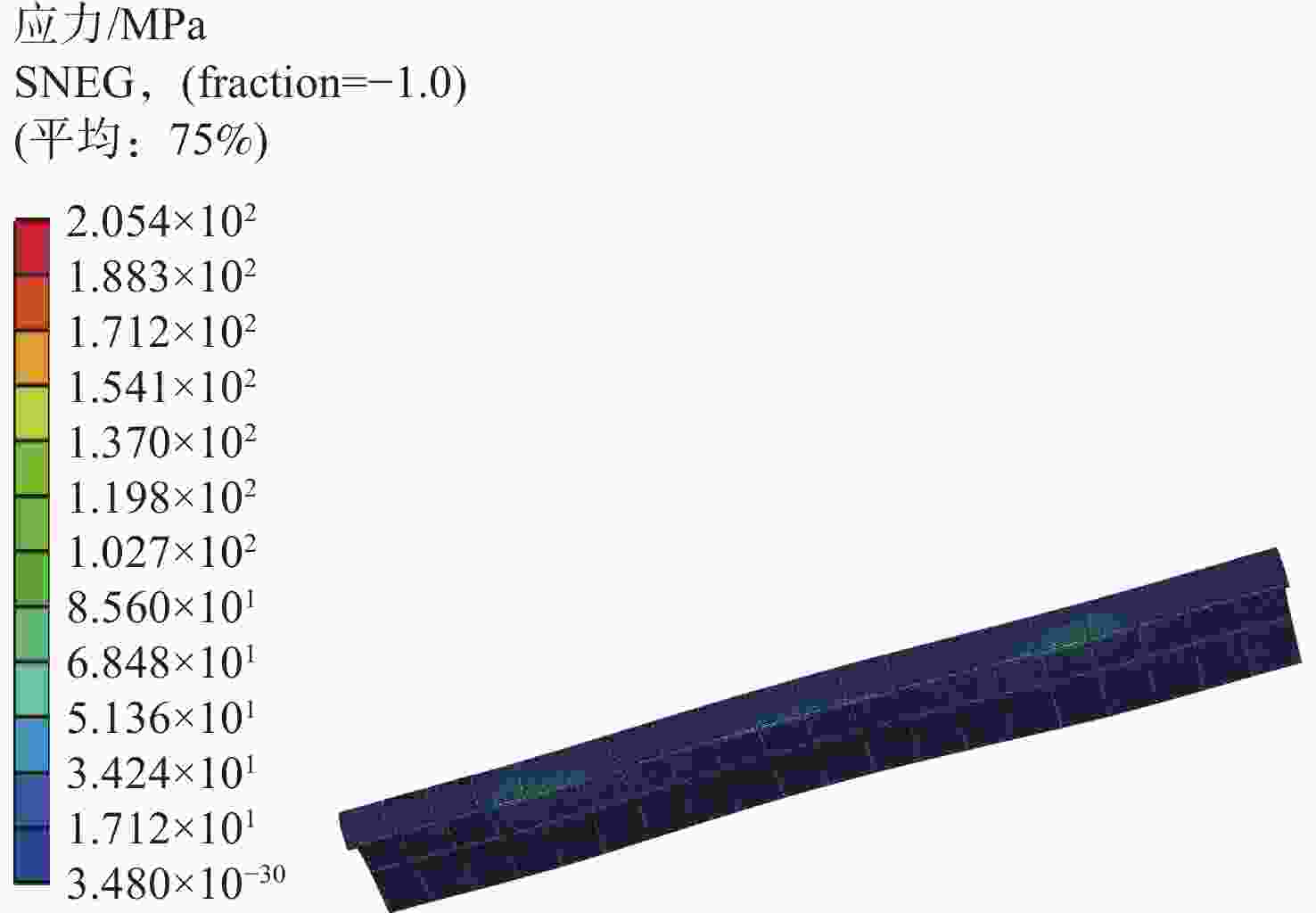

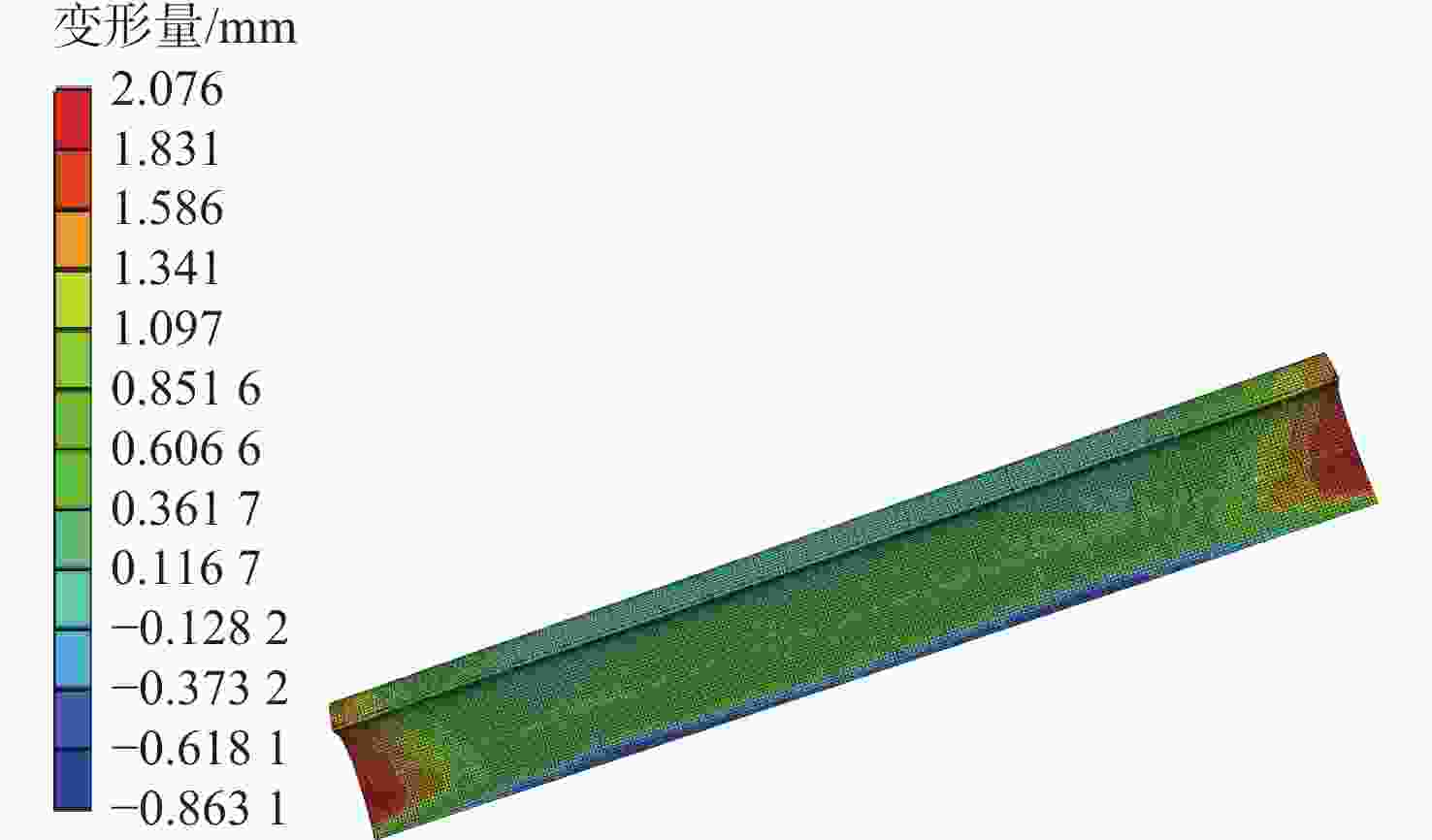

变化/%1 250.0 5.733 19.18 2 180.2 −27.9 3.065 −46.5 32.32 68.5 3 233.5 −6.6 5.302 −7.5 23.35 21.7 4 249.7 −0.1 5.274 −8.0 23.40 22.0 5 250.3 0.1 5.667 −1.2 19.78 3.1 6 199.2 −20.3 5.245 −8.5 19.79 3.2 7 205.4 −17.8 5.368 −6.4 19.78 3.1 表 3 四种仿真结果分析

Table 3. Analysis of four simulation results

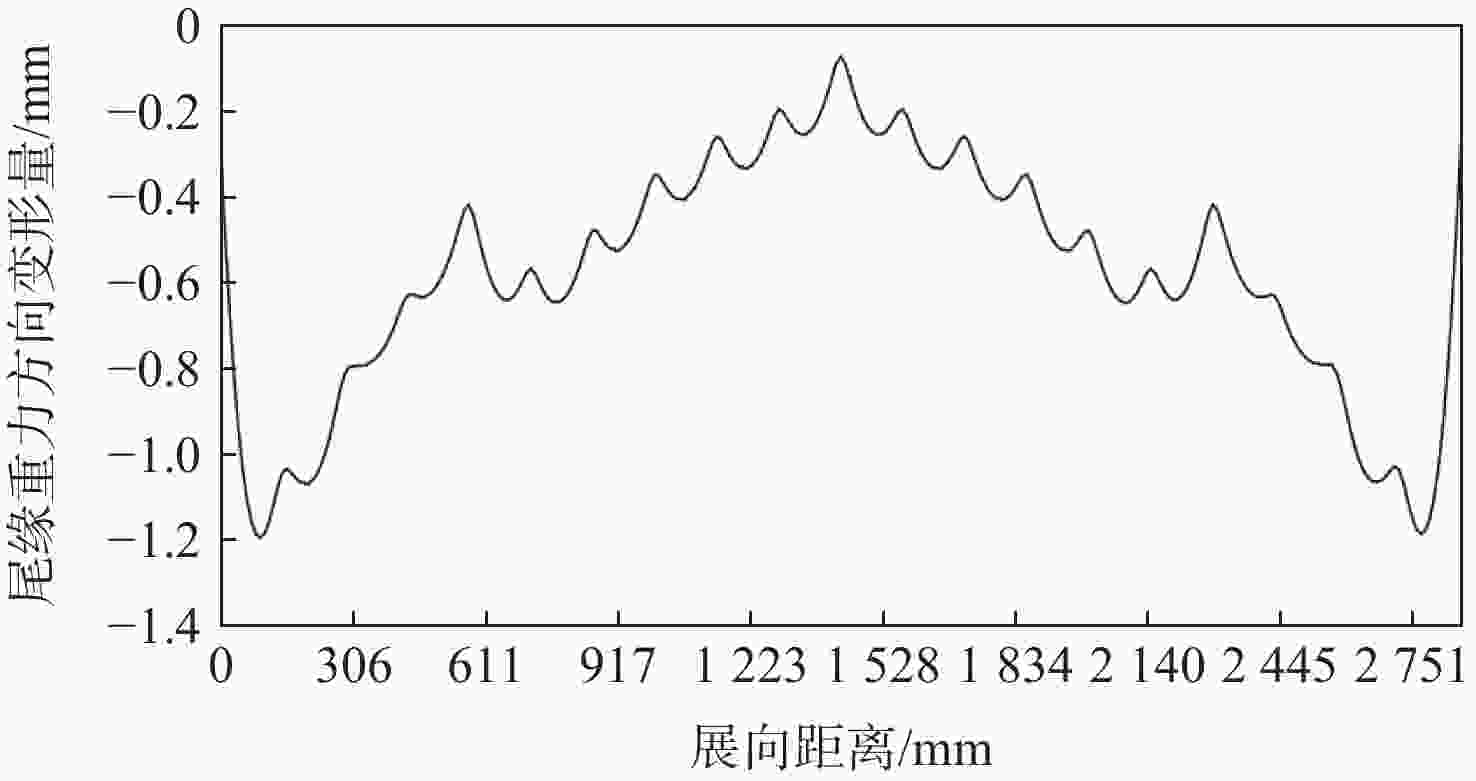

回复力/N 尾缘重力方向

最大变形/mm尾缘重力方向

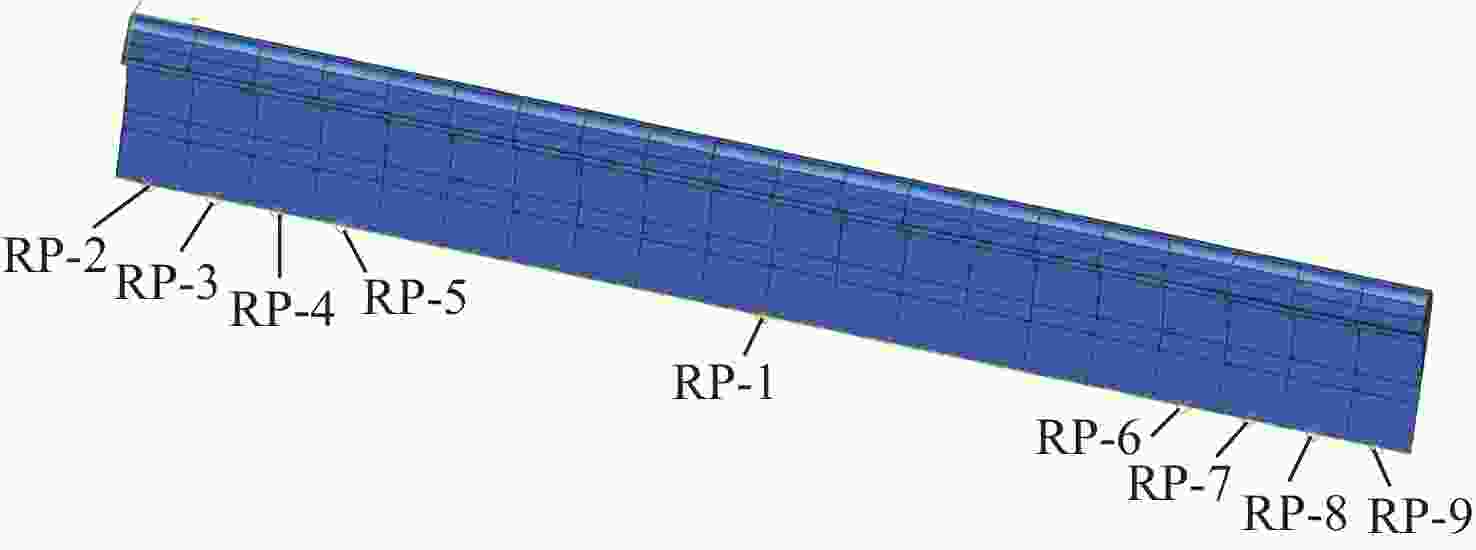

最小变形/mm6000 2.372 0.863 7000 1.867 0.198 8000 1.365 –0.466 8500 0.959 –1.139 表 4 尾缘各段回复力结果

Table 4. Recovery force of each segment of trailing edge

N 施加点 回复力 方案a 方案b 方案c 方案d RP2 400 450 450 650 RP3 400 400 400 500 RP4 375 375 375 400 RP5 375 375 375 375 RP1 4200 4200 4500 4500 RP6 375 375 375 375 RP7 375 375 375 400 RP8 400 400 400 500 RP9 400 450 450 650 总计 7300 7400 7700 8350 表 5 八种仿真结果分析

Table 5. Analysis of eight simulation results

回复力/N 尾缘重力方向

最大变形/mm尾缘重力方向

最小变形/mm6000 2.372 0.863 7000 1.867 0.198 7300(方案a) 1.563 0.273 7400(方案b) 1.306 0.266 7700(方案c) 1.286 −0.025 8000 1.365 −0.455 8350(方案d) −1.194 −0.073 8500 0.959 −1.139 -

[1] 翟晨. 大型高抗浪水陆两栖飞机增升装置设计[D]. 南京: 南京航空航天大学, 2019: 3-5.ZHAI C. Aerodynamic design of high-lift devices for a large-scale amphibious aircraft[D]. Nanjing: Nanjing University of Aeronautics and Astronautics, 2019: 3-5(in Chinese). [2] 李正洲. 某型客机增升装置的气动/机构优化设计[D]. 南京: 南京航空航天大学, 2013: 1-5.LI Z Z. Aero-mechanical optimization design of a civil aircraft’s high-lift system[D]. Nanjing: Nanjing University of Aeronautics and Astronautics, 2013: 1-5(in Chinese). [3] 刘明. 支线客机增升装置气动分析与优化设计[D]. 南京: 南京航空航天大学, 2012: 3-5.LIU M. Aerodynamic analysis and optimization design of regional jet’s high-lift device[D]. Nanjing: Nanjing University of Aeronautics and Astronautics, 2012: 3-5(in Chinese). [4] 《飞机设计手册》总编委会. 飞机设计手册. 第9册[M]. 北京: 航空工业出版社, 2002: 428-428.General Editorial Board of Aircraft Design Manual. Aircraft design manual. Volume 9[M]. Beijing: Aviation Industry Press, 2002: 428-429(in Chinese). [5] RECKZEH D. Aerodynamic design of the high-lift-wing for a Megaliner aircraft[J]. Aerospace Science and Technology, 2003(2): 107-119. [6] DIMINO I, AMENDOLA G, AMOROSO F, et al. Morphing technologies: Adaptive ailerons[J/OL]. Recent Progress in Some Aircraft Technologies, 2016(2016-09-08)[2021-06-01]. https://www.intechopen.com/chapters/50748. [7] 仪志胜, 何景武. 民用飞机后缘襟翼机构设计仿真计算研究[J]. 飞机设计, 2010, 30(1): 43-46. doi: 10.3969/j.issn.1673-4599.2010.01.010YI Z S, HE J W. Mechanical design and research of trailing edge flap for civil aircraft[J]. Aircraft Design, 2010, 30(1): 43-46(in Chinese). doi: 10.3969/j.issn.1673-4599.2010.01.010 [8] FRANCOIS C, EDMUND K. Actuation system for deploying high-lift device on leading edge of aircraft wing: U. S. Patent WO2009056873-A1[P]. 2010-07-29. [9] POTT-POLLENSKE M, WILD J W, BERTSCH L. Aerodynamic and acoustic design of silent leading edge device: AIAA 2014-2076[R]. Reston: AIAA, 2014. [10] PAGANI C C, SOUZA D S, MEDEIROS M A F. Experimental investigation on the effect of slat geometrical configurations on aerodynamic noise[J]. Journal of Sound and Vibration, 2017, 394: 256-279. doi: 10.1016/j.jsv.2017.01.013 [11] 杨小权, 丁珏, 翁培奋, 等. 大型客机增升装置前缘缝翼噪声波纹控制技术[C]//中国航空学会声学分会2020年度学术交流会, 2020: 46.YANG X Q, DING Y, WONG P F, et al. Noise ripple control technology for leading edge slats of lift augmenter for large passenger aircraft[C]//Academic Exchange Meeting of Acoustics Branch of CAAC in 2020, 2020: 46(in Chinese). [12] 邓一菊, 廖振荣, 段卓毅. 前缘缝翼内型的气动设计研究[J]. 空气动力学学报, 2014, 32(3): 400-404.DENG Y J, LIAO Z R, DUAN Z Y. The aerodynamic design research on slat coves[J]. Acta Aerodynamica Sinica, 2014, 32(3): 400-404(in Chinese). [13] OLSON L E, MCGOWAN P R, GUEST C J, et al. Leading-edge slat optimization for maximum airfoil lift[R]. [S.l.]: NASA Technical Memorandum, 1979. [14] 王红建, 田峻源, 罗望. 缝翼结构参数对缝翼噪声影响的三维仿真分析[J]. 西北工业大学学报, 2019, 37(6): 1129-1137. doi: 10.3969/j.issn.1000-2758.2019.06.006WANG H J, TIAN J Y, LUO W. Three-dimensional simulation analysis of the influence of slat structural parameters on slat aerodynamic noise[J]. Journal of Northwestern Polytechnical University, 2019, 37(6): 1129-1137(in Chinese). doi: 10.3969/j.issn.1000-2758.2019.06.006 [15] 钟园, 陈勇, 陈真利, 等. 翼身融合布局低速验证机前缘缝翼设计[J]. 航空学报, 2019, 40(9): 623050.ZHONG Y, CHEN Y, CHEN Z L, et al. Design of slat of blended-wing-body low speed testing aircraft[J]. Acta Aeronautica et Astronautica Sinica, 2019, 40(9): 623050(in Chinese). [16] WANG C, KHODAPARAST H H, FRISWELL M I, et al. Conceptual-level evaluation of a variable stiffness skin for a morphing wing leading edge[J]. Proceedings of the Institution of Mechanical Engineers, Part G:Journal of Aerospace Engineering, 2019, 233(15): 5703-5716. doi: 10.1177/0954410019855576 [17] 何志全. 某型飞机前缘缝翼蒙皮厚度优化[J]. 江苏科技信息, 2015(21): 54-56. doi: 10.3969/j.issn.1004-7530.2015.21.019HE Z Q. Optimization on slat skin thickness of a certain type of aircraft[J]. Jiangsu Science & Technology Information, 2015(21): 54-56(in Chinese). doi: 10.3969/j.issn.1004-7530.2015.21.019 [18] 张振辉, 李栋, 杨茵. 基于前缘缝翼微型后缘装置的多段翼型被动流动控制[J]. 航空学报, 2017, 38(5): 120650.ZHANG Z H, LI D, YANG Y. Passive flow control of multi-element airfoils using slat mini-trailing edge device[J]. Acta Aeronautica et Astronautica Sinica, 2017, 38(5): 120650(in Chinese). [19] 许可, 章荣平, 张刘, 等. 大飞机缝翼滑轨影响研究[J]. 空气动力学学报, 2016, 34(3): 368-372.XU K, ZHANG R P, ZHANG L, et al. Research on influence of slat brackets of large airplane[J]. Acta Aeronautica Sinica, 2016, 34(3): 368-372(in Chinese). [20] NIU M C Y. Airframe structural design[M]. Hongkong: Conmilit Press Ltd., 2008: 417-420. [21] 刘鸿文. 材料力学[M]. 北京: 高等教育出版社, 2017: 183-202.LIU H W. Mechanics of materials[M]. Beijing: Higher Education Press, 2017: 183-202(in Chinese). -

下载:

下载: