Total focusing imaging in anisotropic additive manufacturing components using ultrasonic array

-

摘要:

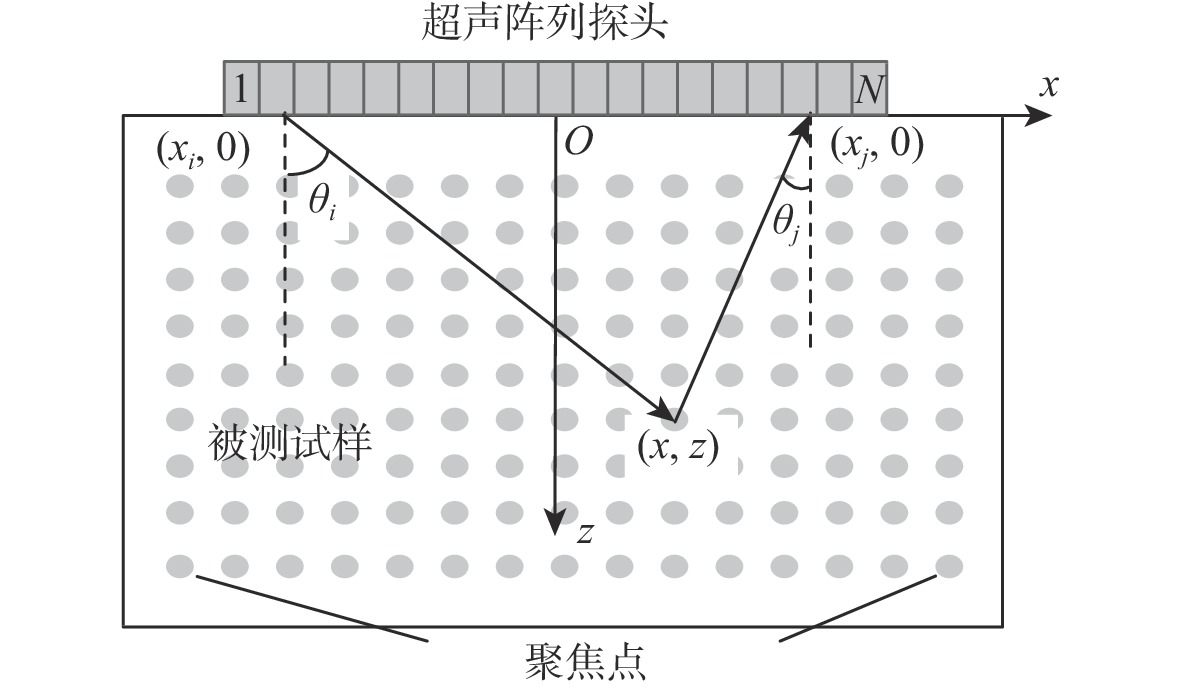

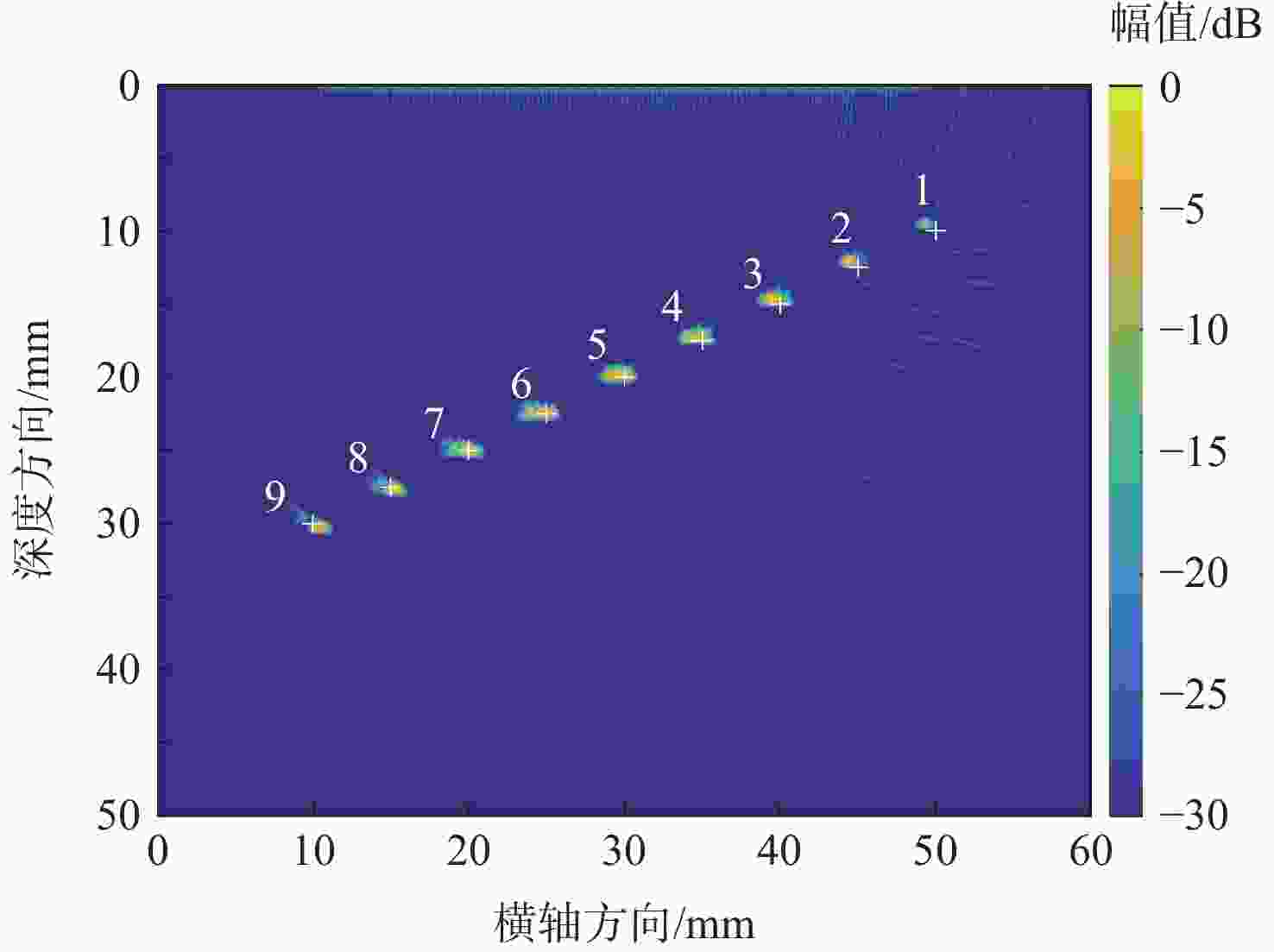

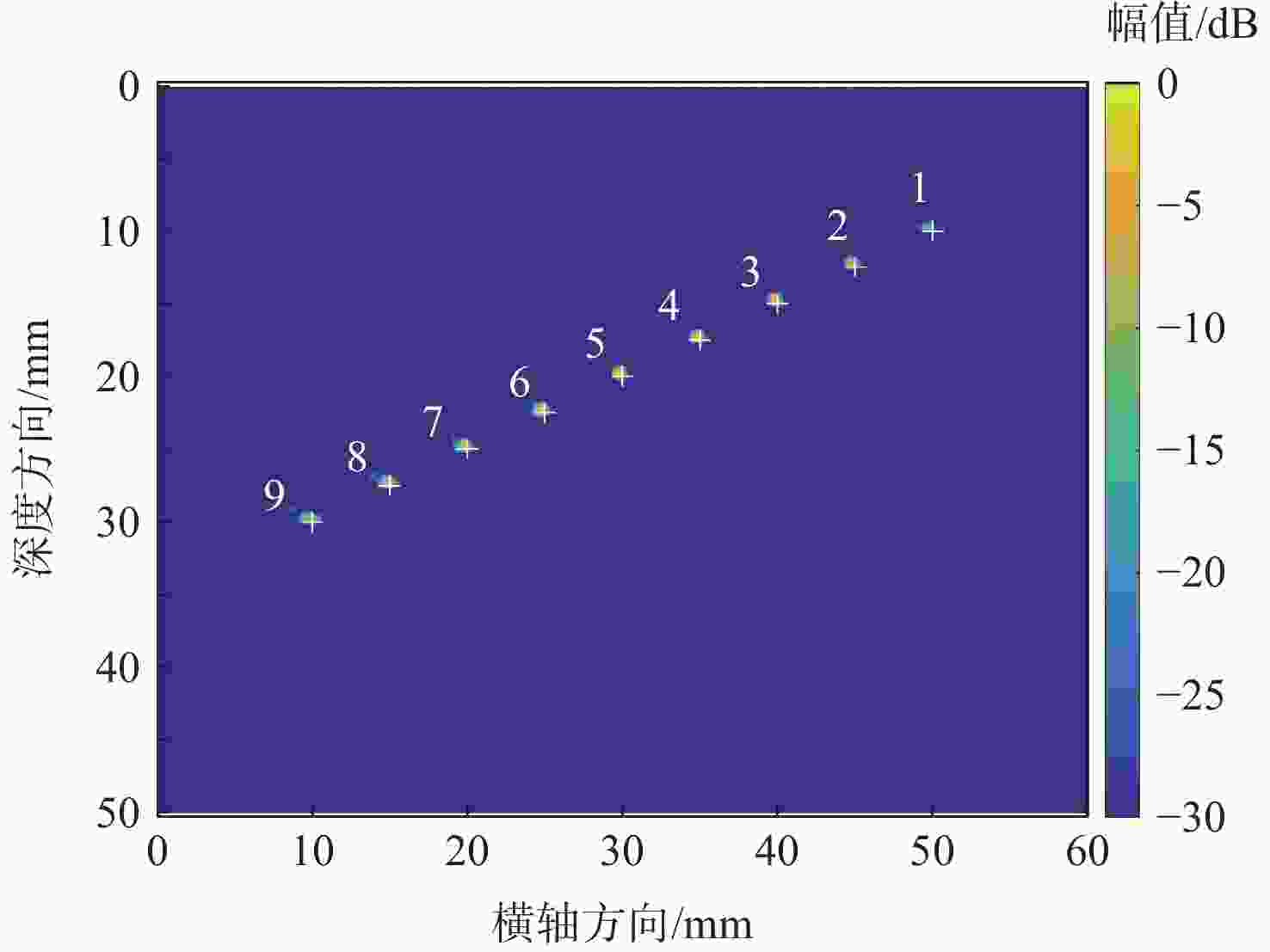

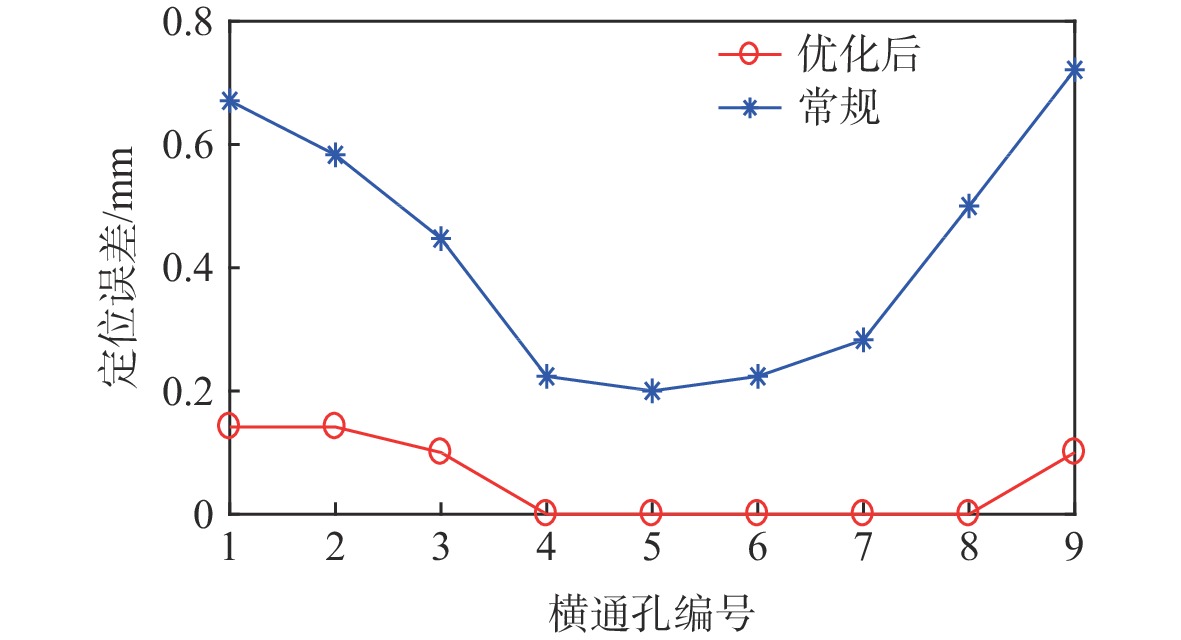

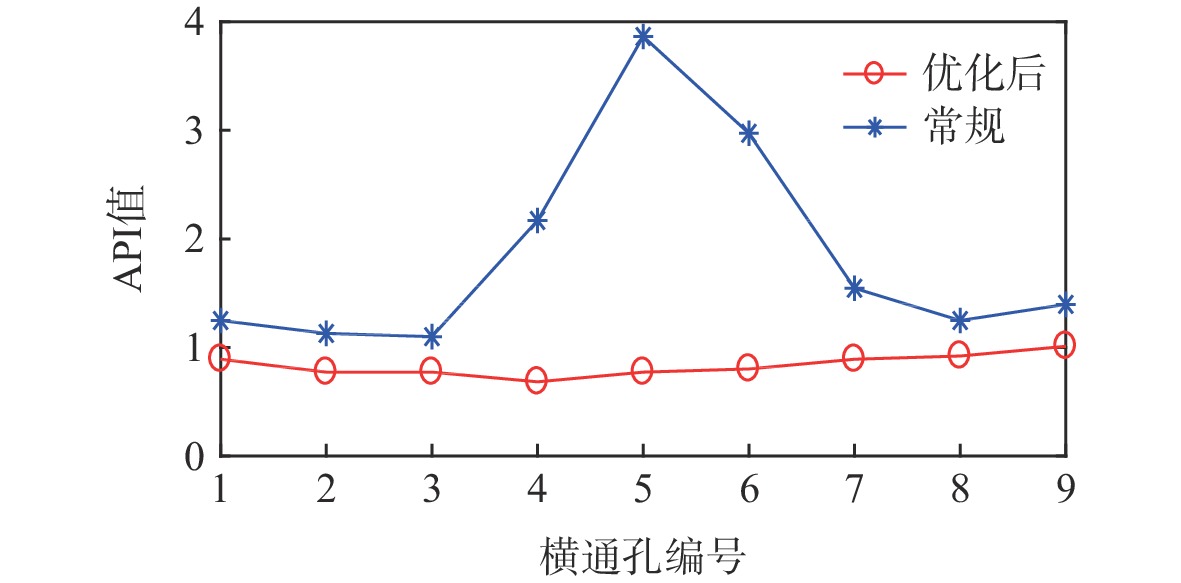

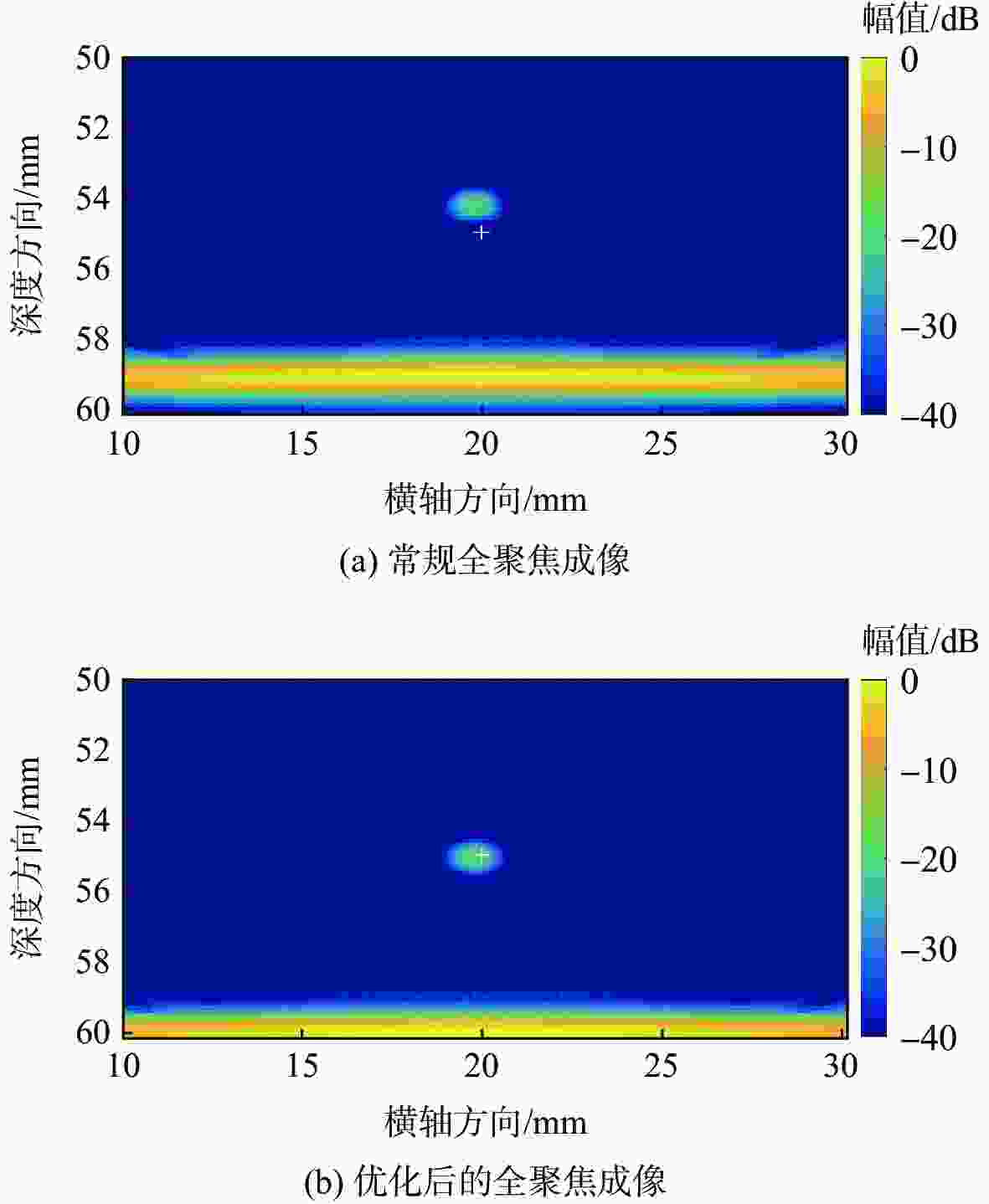

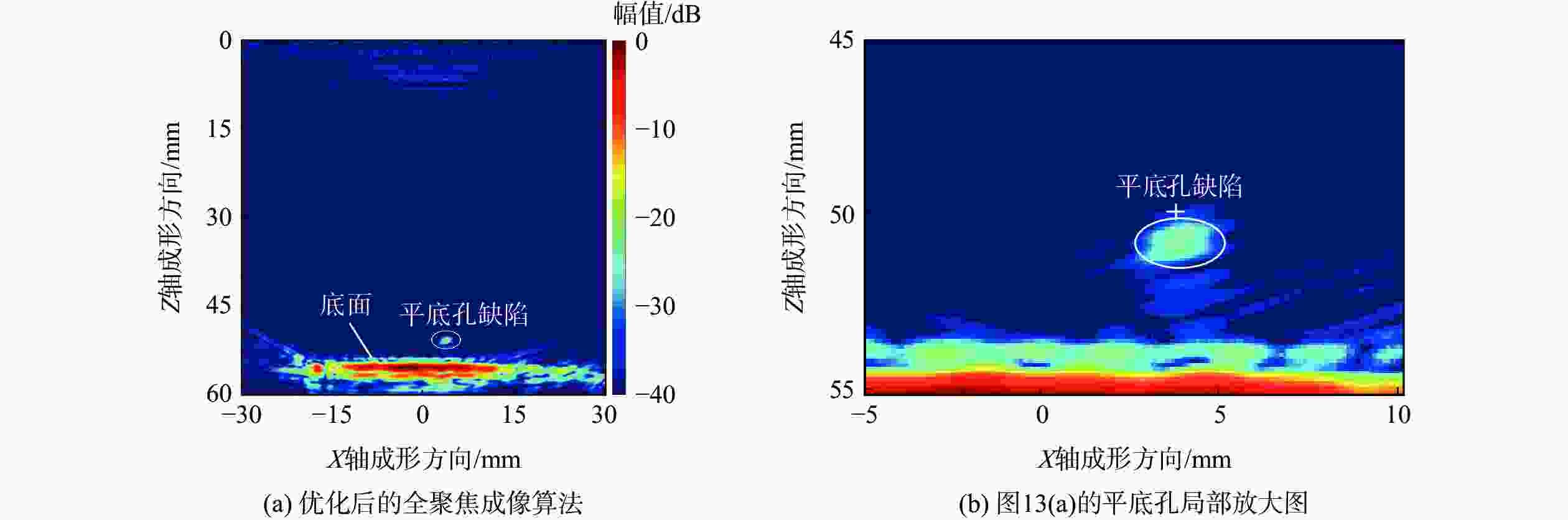

针对激光增材制造构件的各向异性特征,开展超声波传播特性研究,并基于群速度测量结果对常规超声阵列全聚焦成像算法进行优化。采用CIVA超声仿真软件对含有横通孔和平底孔缺陷的试样开展全聚焦仿真研究,结果表明,材料的各向异性对超声阵列全聚焦检测的成像质量、缺陷定位精度和缺陷分布范围均具有明显影响;开展全聚焦成像检测实验,结果表明,优化后的全聚焦成像算法能够实现激光增材制造钛合金试样中直径0.8 mm平底孔缺陷的准确检测,成像阵列性能指标(API)值减小至0.43,缺陷定位误差缩小至0.54 mm,检测能力和定位精度显著提高。

Abstract:To solve the anisotropic problem of laser additive manufacturing components, the propagation characteristics of ultrasonic wave in the anisotropic material have been researched and the total focusing method using an ultrasonic array has been optimized based on group velocity of anisotropic material. Then, the CIVA software was used to carry out a simulation study on total focusing imaging of samples with horizontal through holes and flat-bottom holes. Next, a simulated investigation of complete focusing imaging of samples with horizontal through holes and flat-bottomed holes was conducted using the CIVA program. The simulation results show that the anisotropy of material has a significant impact on the imaging quality, defect location accuracy and defect distribution range of total focusing imaging using an ultrasonic array. The inspection experiments using the conventional and optimized total focusing imaging method were carried out. The findings demonstrate that the flat-bottomed holes with a diameter of 0.8 mm in the titanium alloy specimen produced by laser additive manufacturing can be detected with accuracy, and that the array performance indicator (API) value is decreased to 0.43 and the defect positioning error is decreased to 0.54 mm. Both the detection capability and defect location accuracy are improved significantly.

-

Key words:

- laser additive manufacturing /

- anisotropy /

- ultrasonic array /

- total focusing /

- CIVA simulation

-

表 1 平底孔缺陷优化前后成像结果

Table 1. Imaging results before and after optimization for flat-bottom holes

算法 定位误差值/mm API值 常规全聚焦成像 0.8 1.63 优化后的全聚焦成像 0.14 1.66 -

[1] 王华明, 张述泉, 汤海波, 等. 大型钛合金结构激光快速成形技术研究进展[J]. 航空精密制造技术, 2008, 44(6): 28-30. doi: 10.3969/j.issn.1003-5451.2008.06.023WANG H M, ZHANG S Q, TANG H B, et al. Research progress of laser rapid prototyping technology for large titanium alloy structure[J]. Aviation Precision Manufacturing Technology, 2008, 44(6): 28-30(in Chinese). doi: 10.3969/j.issn.1003-5451.2008.06.023 [2] 王华明, 张述泉, 王向明. 大型钛合金结构件激光直接制造的进展与挑战(邀请论文)[J]. 中国激光, 2009, 36(12): 3204-3209. doi: 10.3788/CJL20093612.3204WANG H M, ZHANG S Q, WANG X M. Progress and challenges of laser direct manufacturing of large titanium structural components(invited paper)[J]. Chinese Journal of Lasers, 2009, 36(12): 3204-3209(in Chinese). doi: 10.3788/CJL20093612.3204 [3] 王华明. 航空高性能金属结构件激光快速成形研究进展[J]. 航空制造技术, 2005, 48(12): 26-28. doi: 10.3969/j.issn.1671-833X.2005.12.024WANG H M. Research progress of laser rapid prototyping of aviation high performance metal structures[J]. Aeronautical Manufacturing Technology, 2005, 48(12): 26-28(in Chinese). doi: 10.3969/j.issn.1671-833X.2005.12.024 [4] 张凤英, 陈静, 谭华, 等. 钛合金激光快速成形过程中缺陷形成机理研究[J]. 稀有金属材料与工程, 2007, 36(2): 211-215. doi: 10.3321/j.issn:1002-185x.2007.02.006ZHANG F Y, CHEN J, TAN H, et al. Research on forming mechanism of defects in laser rapid formed titanium alloy[J]. Rare Metal Materials and Engineering, 2007, 36(2): 211-215(in Chinese). doi: 10.3321/j.issn:1002-185x.2007.02.006 [5] 阮雪茜, 林鑫, 黄春平, 等. TC4合金激光立体成形孔洞类缺陷的超声检测[J]. 中国激光, 2015, 42(12): 72-79.RUAN X Q, LIN X, HUANG C P, et al. Ultrasonic nondestructive testing of hole type defects in laser solid forming TC4 alloy[J]. Chinese Journal of Lasers, 2015, 42(12): 72-79(in Chinese). [6] ROMETSCH P A, PELLICCIA D, TOMUS D. Evaluation of polychromatic X-ray radiography defect detection limits in a sample fabricated from Hastelloy X by selective laser melting[J]. NDT & E International, 2014, 62: 184-192. [7] SONG Y F, ZI X H, FU Y D, et al. Nondestructive testing of additively manufactured material based on ultrasonic scattering measurement[J]. Measurement, 2018, 118: 105-112. doi: 10.1016/j.measurement.2018.01.020 [8] ZIOLKOWSKI G, CHLEBUS E, SZYMCZYK P, et al. Application of X-ray CT method for discontinuity and porosity detection in 316L stainless steel parts produced with SLM technology[J]. Archives of Civil and Mechanical Engineering, 2014, 14(4): 608-614. doi: 10.1016/j.acme.2014.02.003 [9] 杨平华, 史丽军, 梁菁, 等. TC18钛合金增材制造材料超声检测特征的试验研究[J]. 航空制造技术, 2017, 60(5): 38-42. doi: 10.16080/j.issn1671-833x.2017.05.038YANG P H, SHI L J, LIANG J, et al. Experimental research on ultrasonic characteristics of TC18 additive manufacturing titanium alloy[J]. Aeronautical Manufacturing Technology, 2017, 60(5): 38-42(in Chinese). doi: 10.16080/j.issn1671-833x.2017.05.038 [10] 罗斯 J L. 固体中的超声波[M]. 何存富, 吴斌, 王秀彦, 译. 北京: 科学出版社, 2004: 21-23.ROSE J L. Ultrasonic waves in solid media[M]. HE C F, WU B, WANG X Y, translated. Beijing: Science Press, 2004: 21-23(in Chinese). [11] HOLMES C, DRINKWATER B, WILCOX P. The post-processing of ultrasonic array data using the total focusing method[J]. Insight-Non-Destructive Testing and Condition Monitoring, 2004, 46(11): 677-680. doi: 10.1784/insi.46.11.677.52285 [12] DRINKWATER B W, WILCOX P D. Ultrasonic arrays for non-destructive evaluation: A review[J]. NDT & E International, 2006, 39(7): 525-541. [13] HOLMES C, DRINKWATER B W, WILCOX P D. Post-processing of the full matrix of ultrasonic transmit-receive array data for non-destructive evaluation[J]. NDT & E International, 2005, 38(8): 701-711. [14] 杨敬, 吴斌, 焦敬品, 等. 各向异性焊缝缺陷超声阵列全聚焦成像方法[J]. 声学学报, 2019, 44(1): 125-135. doi: 10.15949/j.cnki.0371-0025.2019.01.014YANG J, WU B, JIAO J P, et al. Total focus imaging of defects in anisotropic welds using ultrasonic array[J]. Acta Acustica, 2019, 44(1): 125-135(in Chinese). doi: 10.15949/j.cnki.0371-0025.2019.01.014 [15] LI C, PAIN D, WILCOX P D, et al. Imaging composite material using ultrasonic arrays[J]. AIP Conference Proceedings, 2012, 1430(1): 897-904. [16] XU N, LI Y, ZHOU Z G. Ultrasonic nondestructive evaluation of composite components using advanced total focusing method[J]. Advanced Materials Research, 2013, 652-654: 1353-1356. doi: 10.4028/www.scientific.net/AMR.652-654.1353 [17] ZHOU H P, HAN Z D, DU D, et al. A combined marching and minimizing ray-tracing algorithm developed for ultrasonic array imaging of austenitic welds[J]. NDT & E International, 2018, 95: 45-56. -

下载:

下载: