EHA fault diagnosis and fault tolerant control based on adaptive neural network robust observer

-

摘要:

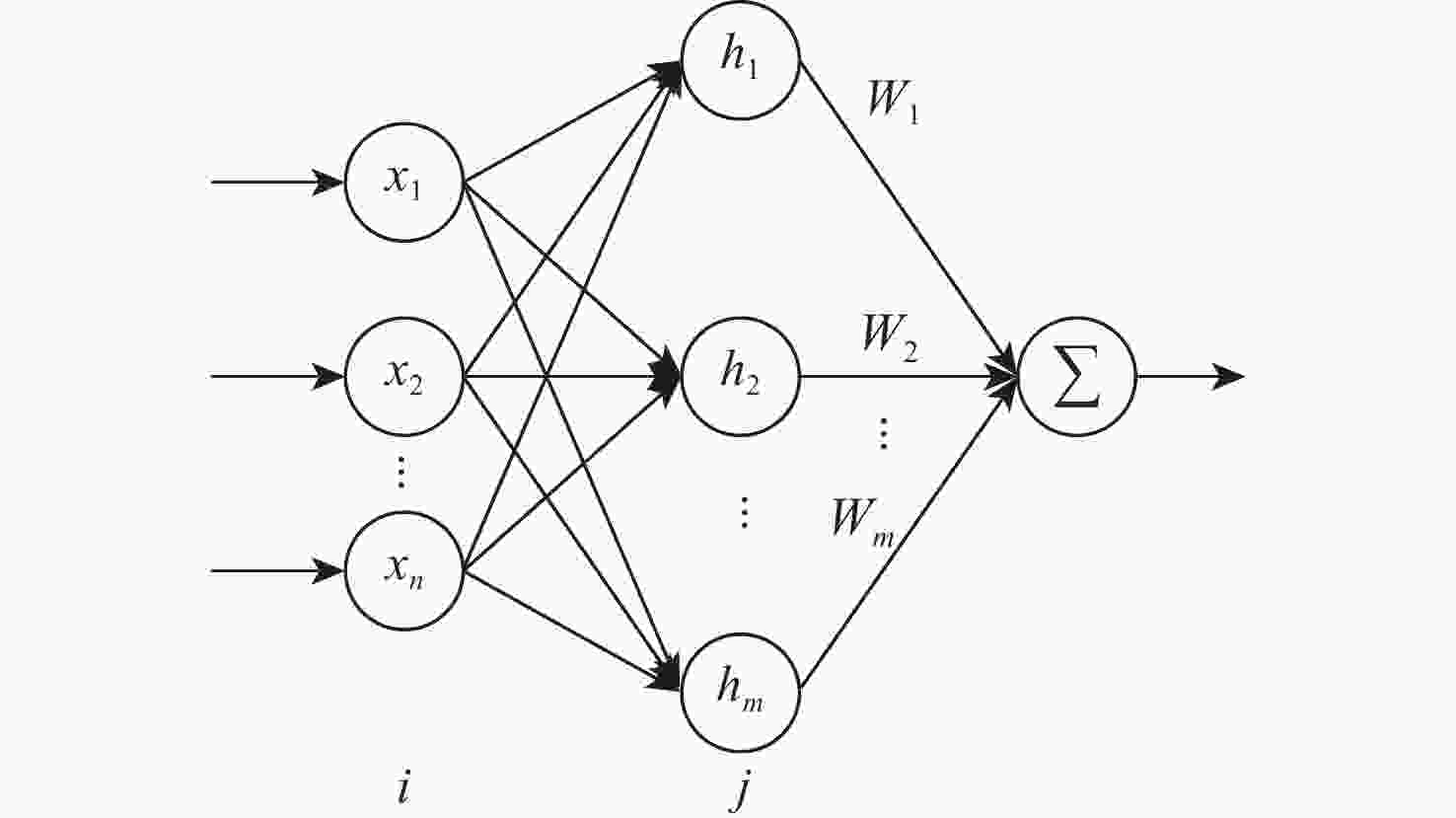

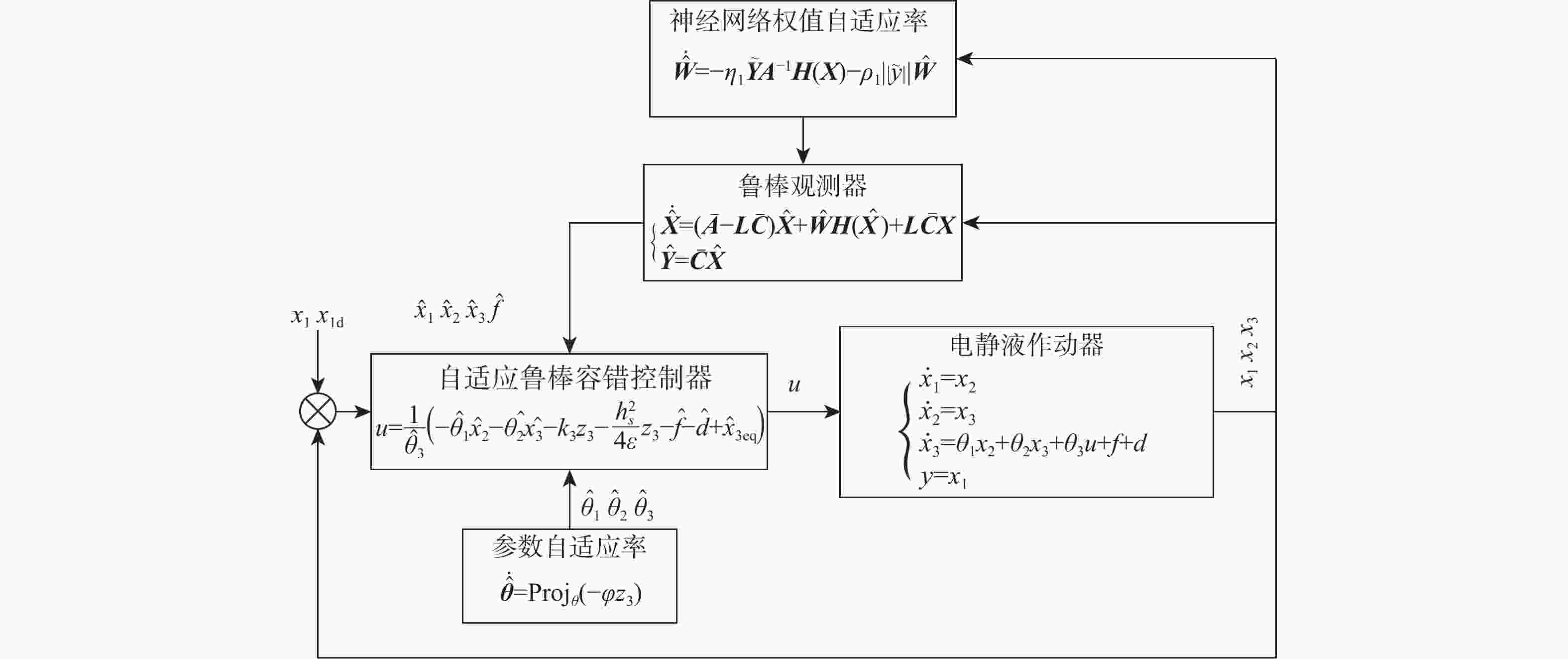

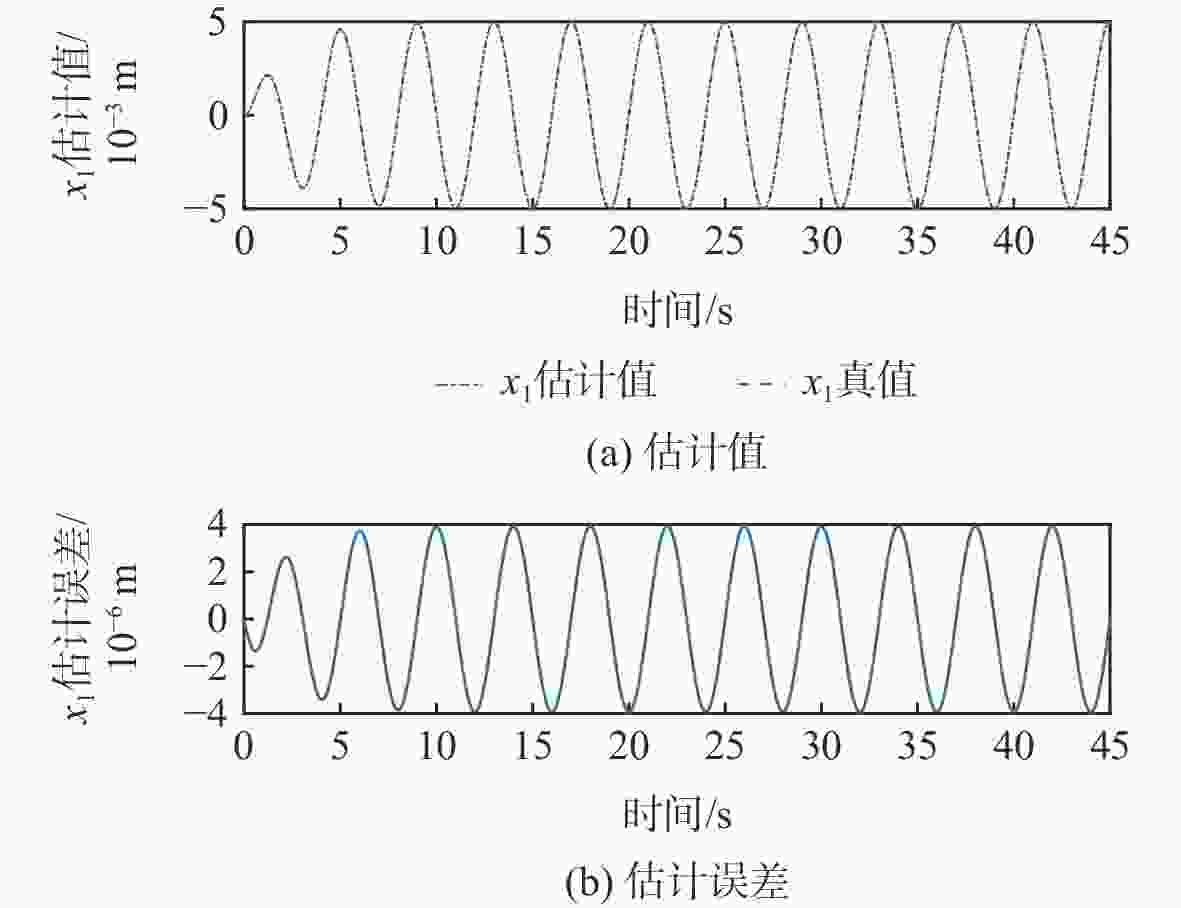

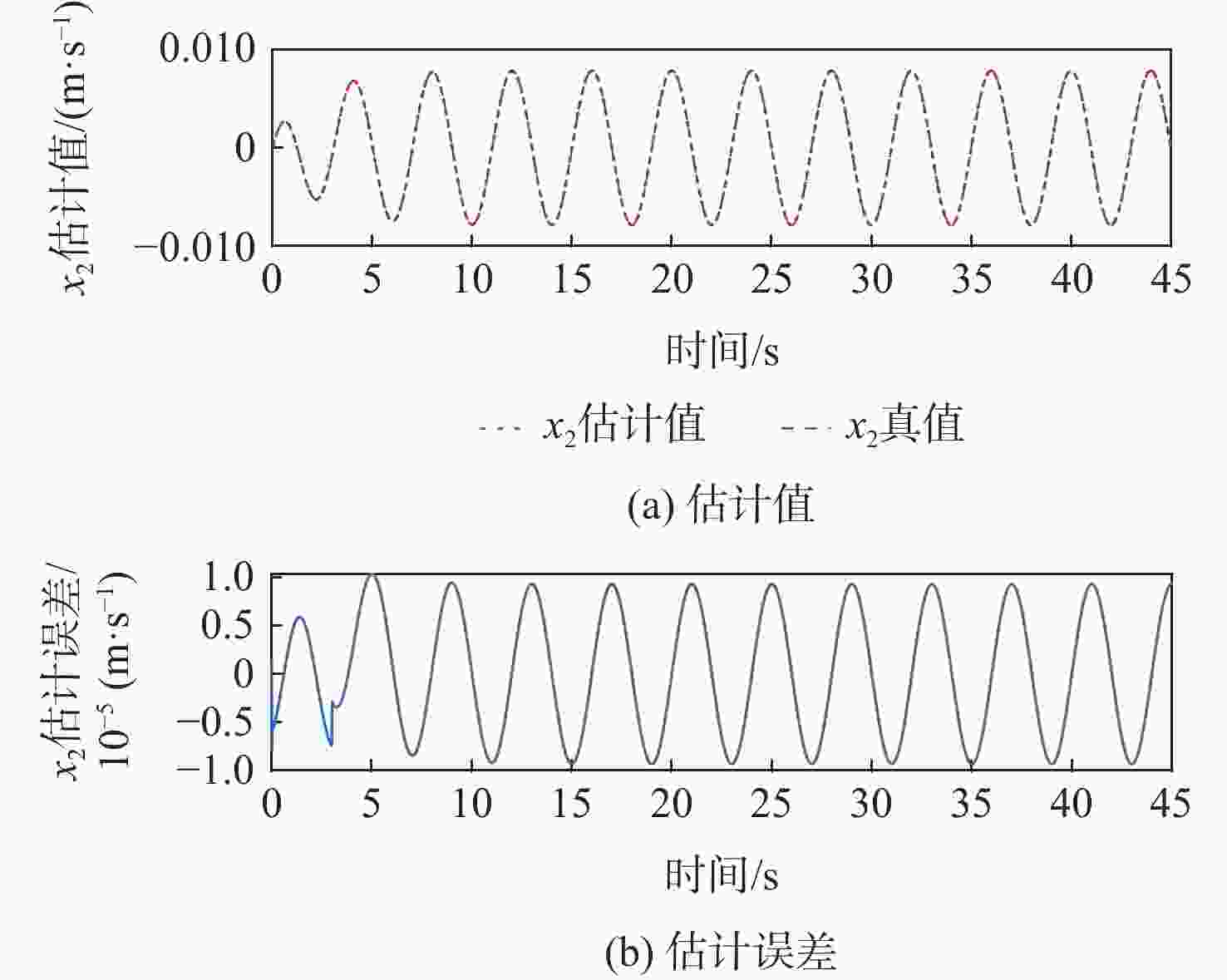

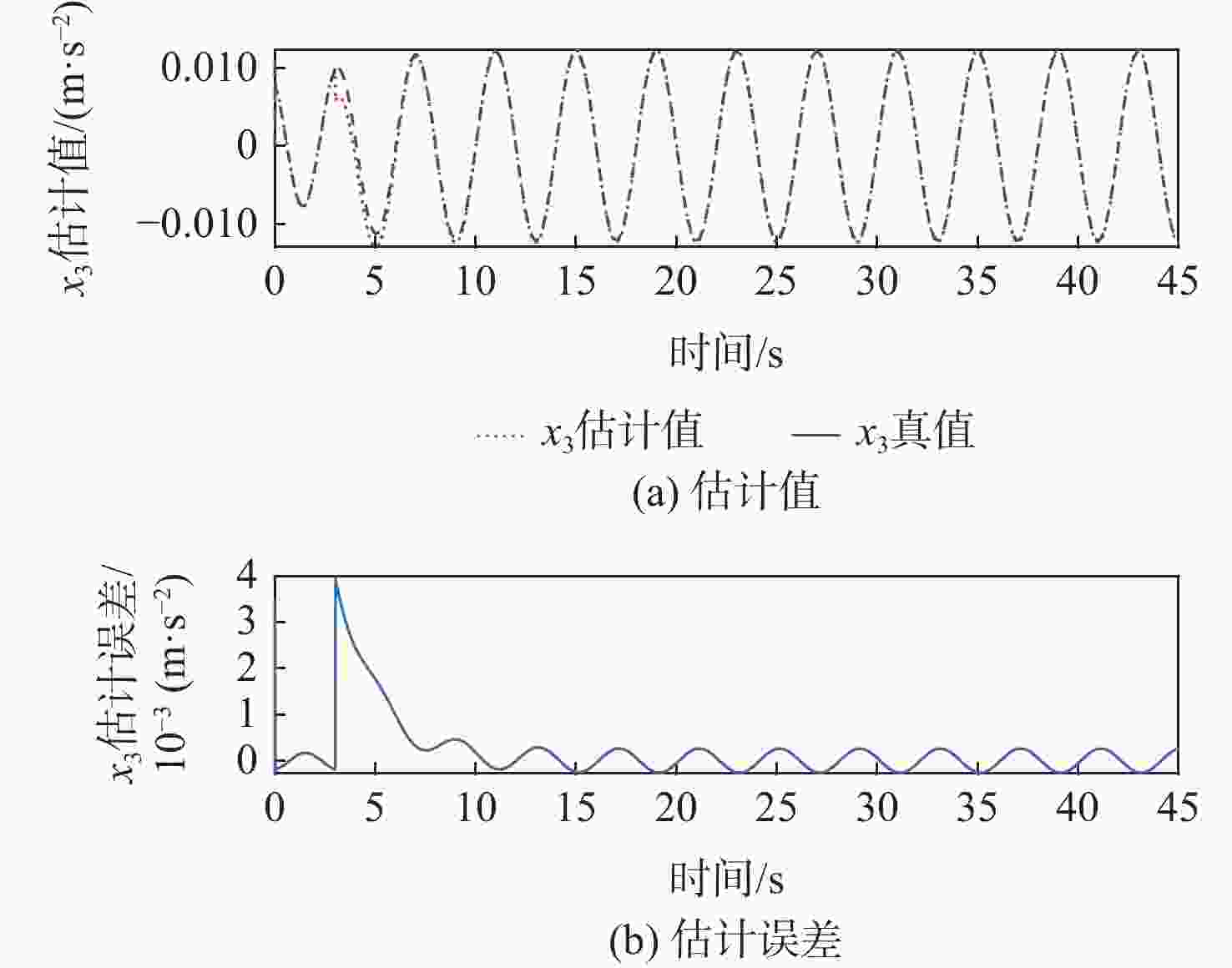

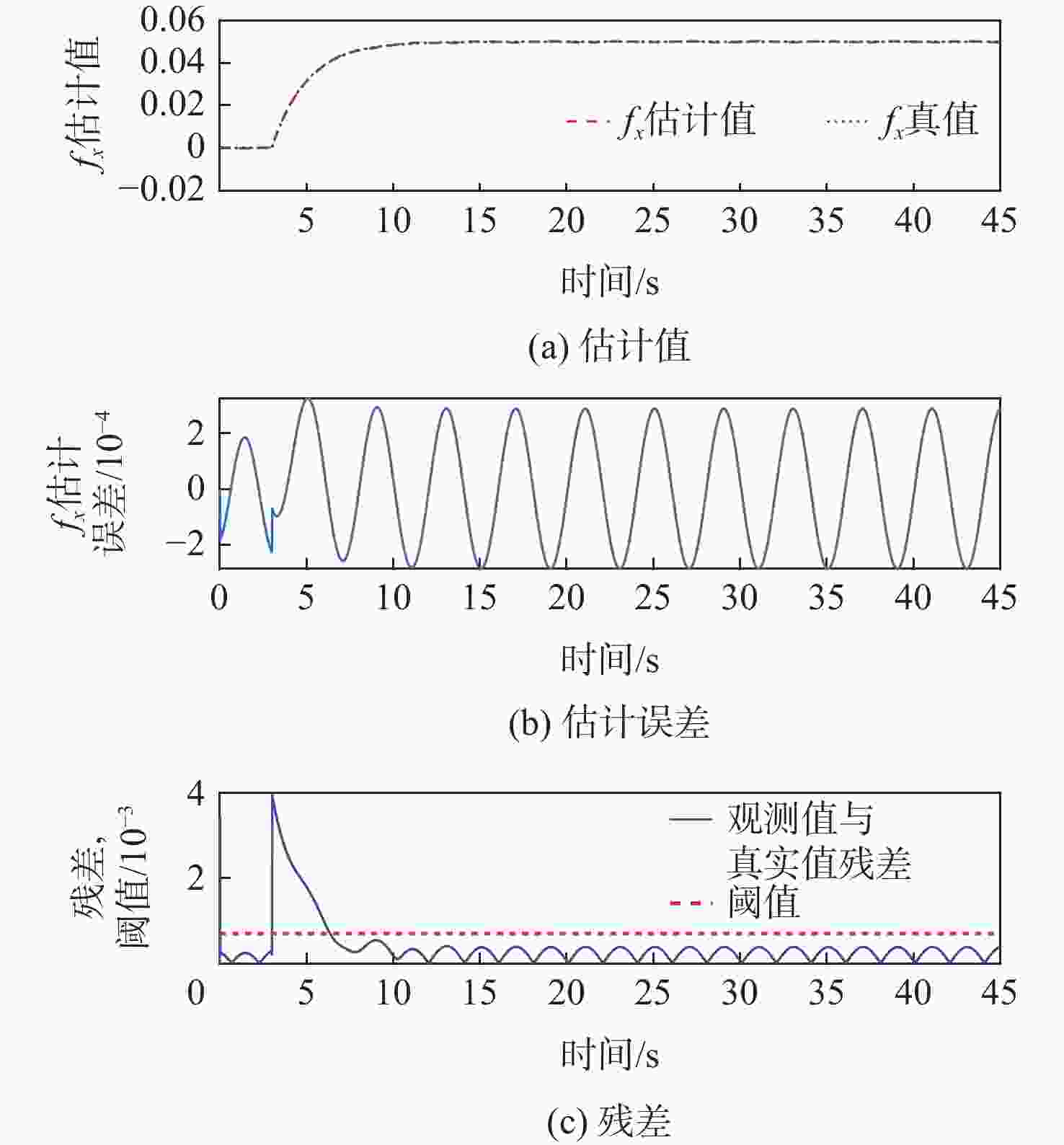

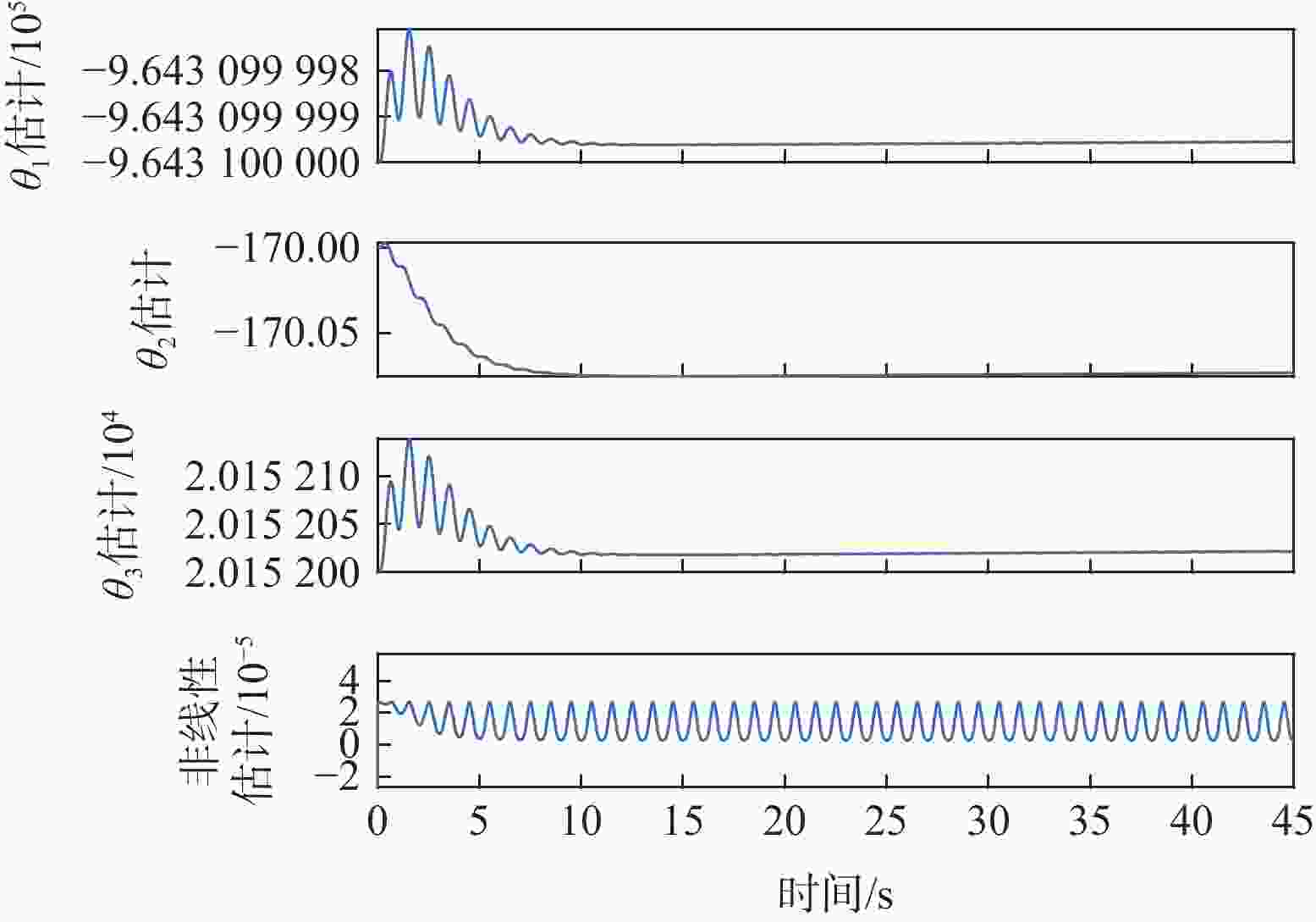

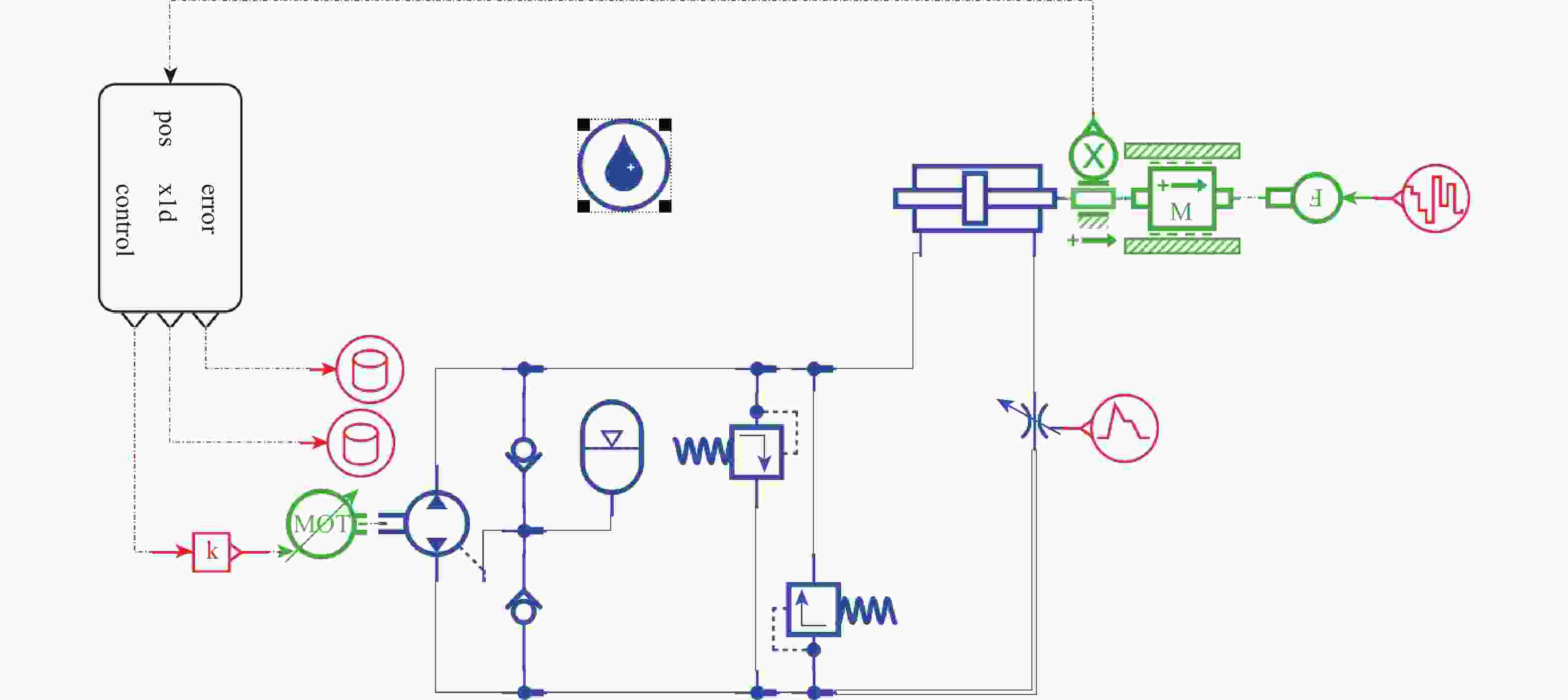

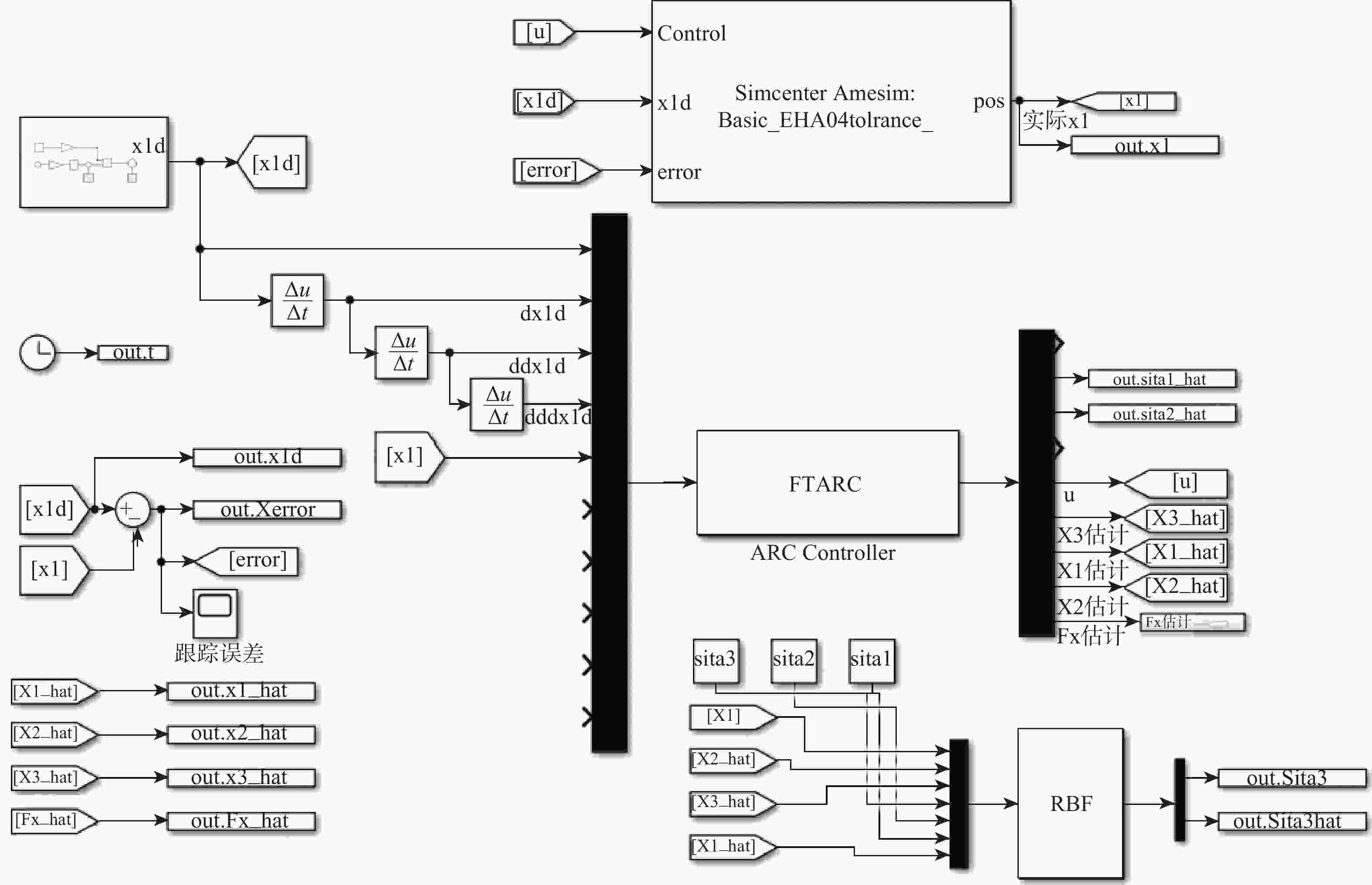

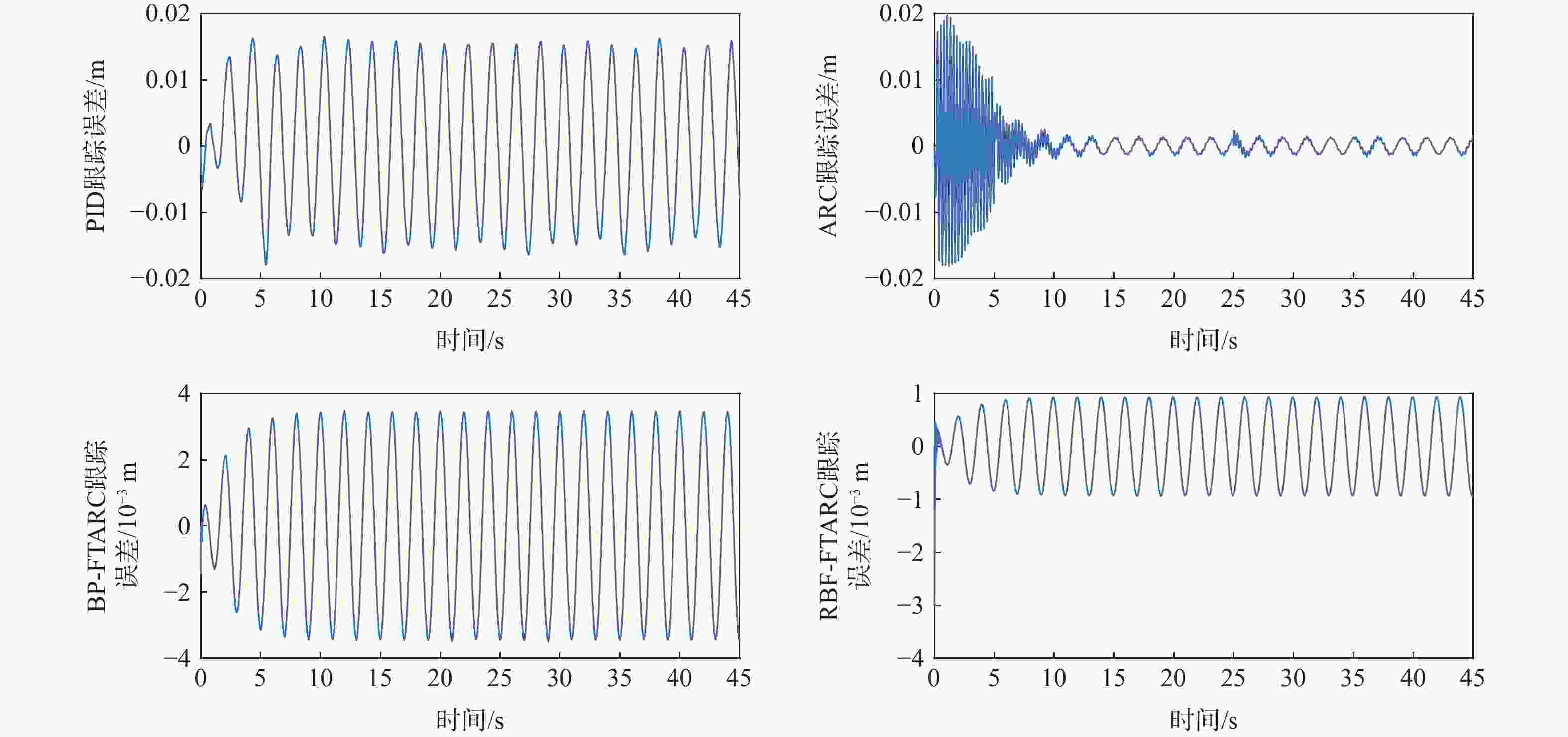

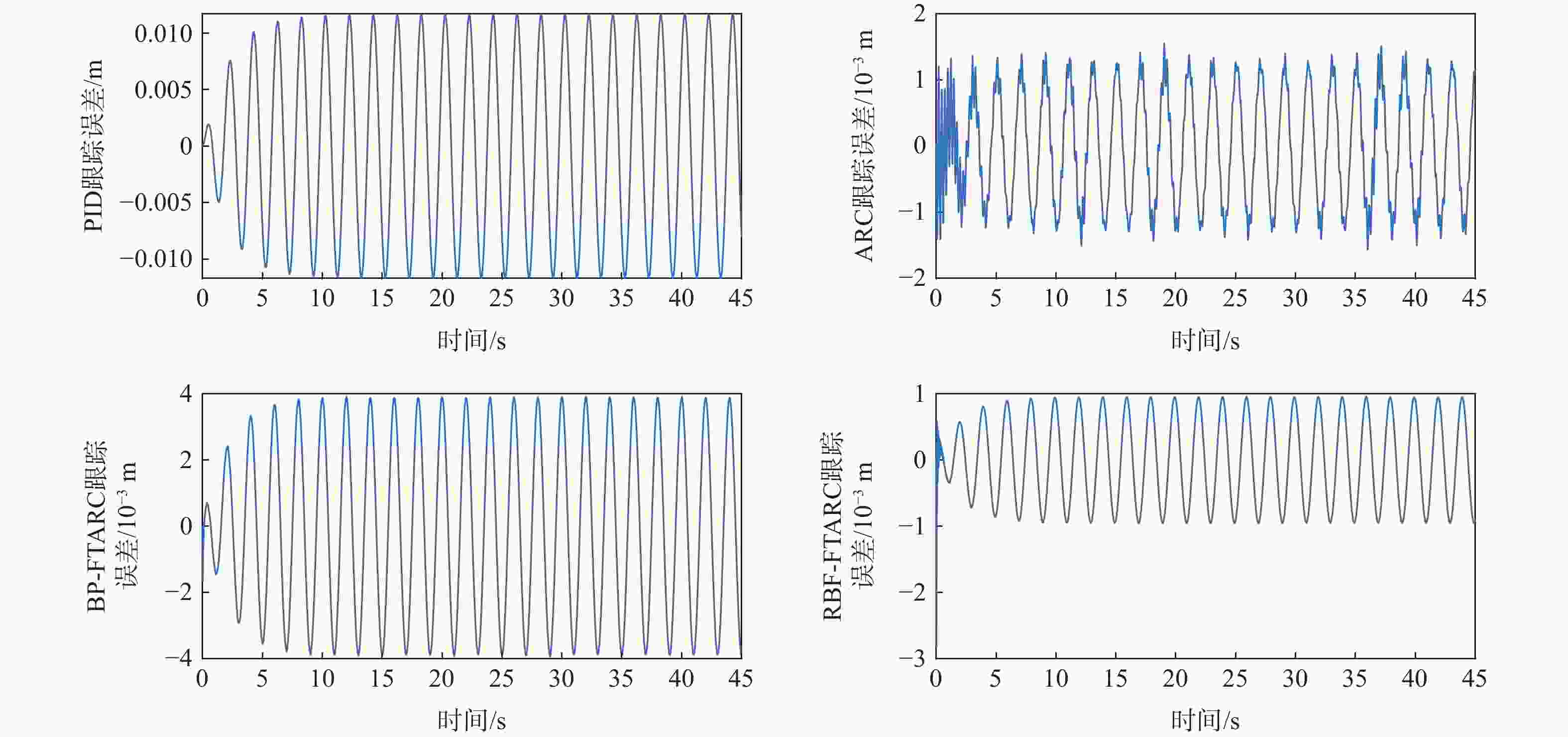

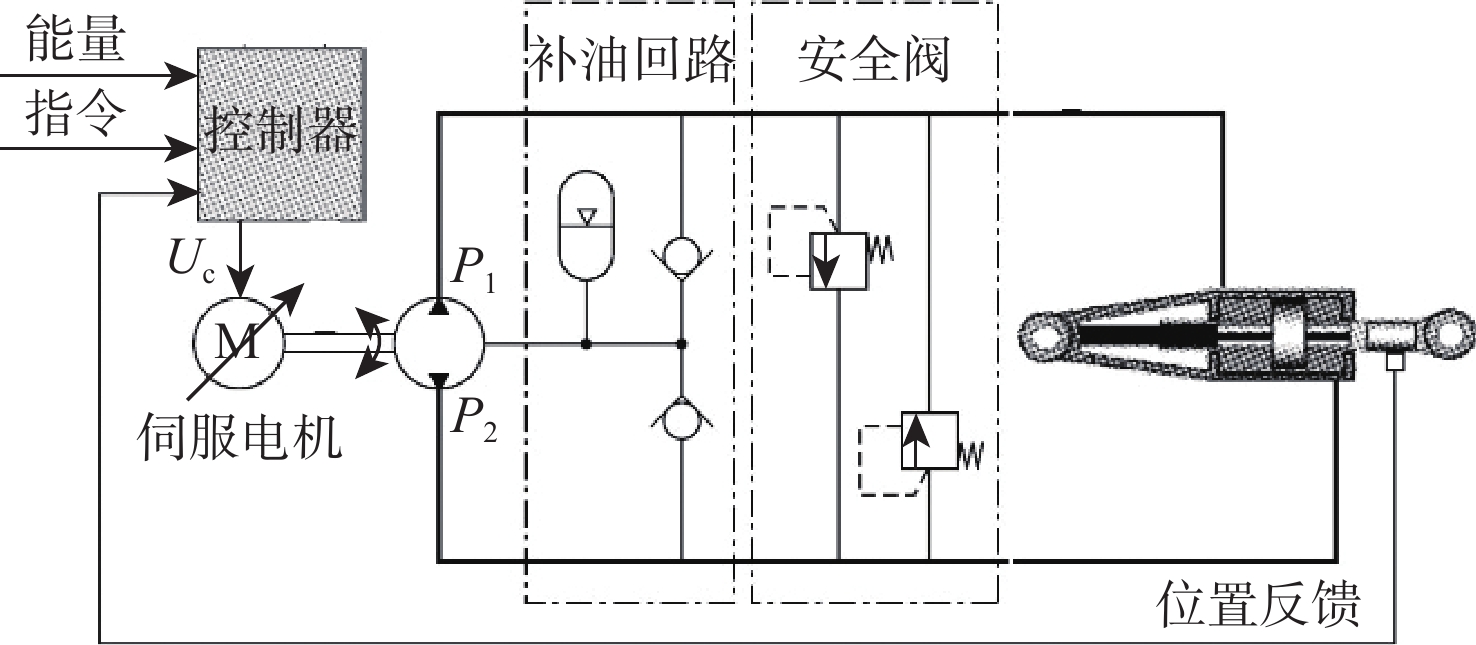

针对电静液作动器(EHA)功率密度高、工况复杂、元件集成度高、故障种类多的特点,设计了一种基于自适应神经网络鲁棒观测器的电静液作动器故障诊断与容错控制器。对模型的内部状态提出一种鲁棒观测器进行观测,对液压系统弹性模量等不确定性设计参数自适应率进行估计,对摩擦扰动等非线性设计径向基函数(RBF)神经网络予以逼近。通过前馈补偿的方法对故障和参数不确定性进行补偿,同时针对系统其他扰动设计鲁棒项加以克服。利用Lyapunov稳定性定理证明了所提出的控制器在存在故障的情况下可以实现系统的有界稳定。联合仿真结果表明:相对于传统的比例、积分、微分控制器(PID)和自适应鲁棒控制器(ARC),所提出的控制器具有更高的控制精度与鲁棒性。

Abstract:Aiming at the characteristics of high power density, complex working conditions, high integration of components and the wide variety of faults of electro hydrostatic actuator (EHA), a fault diagnosis and fault-tolerant controller of electro-hydro actuator based on an adaptive neural network robust observer is designed. A robust observer is proposed to observe the internal state of the model. The uncertain parameters, such as elastic modulus of hydraulic system is estimated by adaptive law; and the nonlinear, such as friction disturbance is approximated by radial basis function (RBF) neural network. The feedforward compensation method is used to compensate the fault and parameter uncertainty, and the robust term is designed to overcome other disturbances. By using Lyapunov stability theorem, it is proved that the proposed controller can realize the bounded stability of the system in the presence of faults. The co-simulation results show that the proposed controller has higher control accuracy and robustness than the traditional proportional, integral and differential controller (PID) and adaptive robust controller (ARC).

-

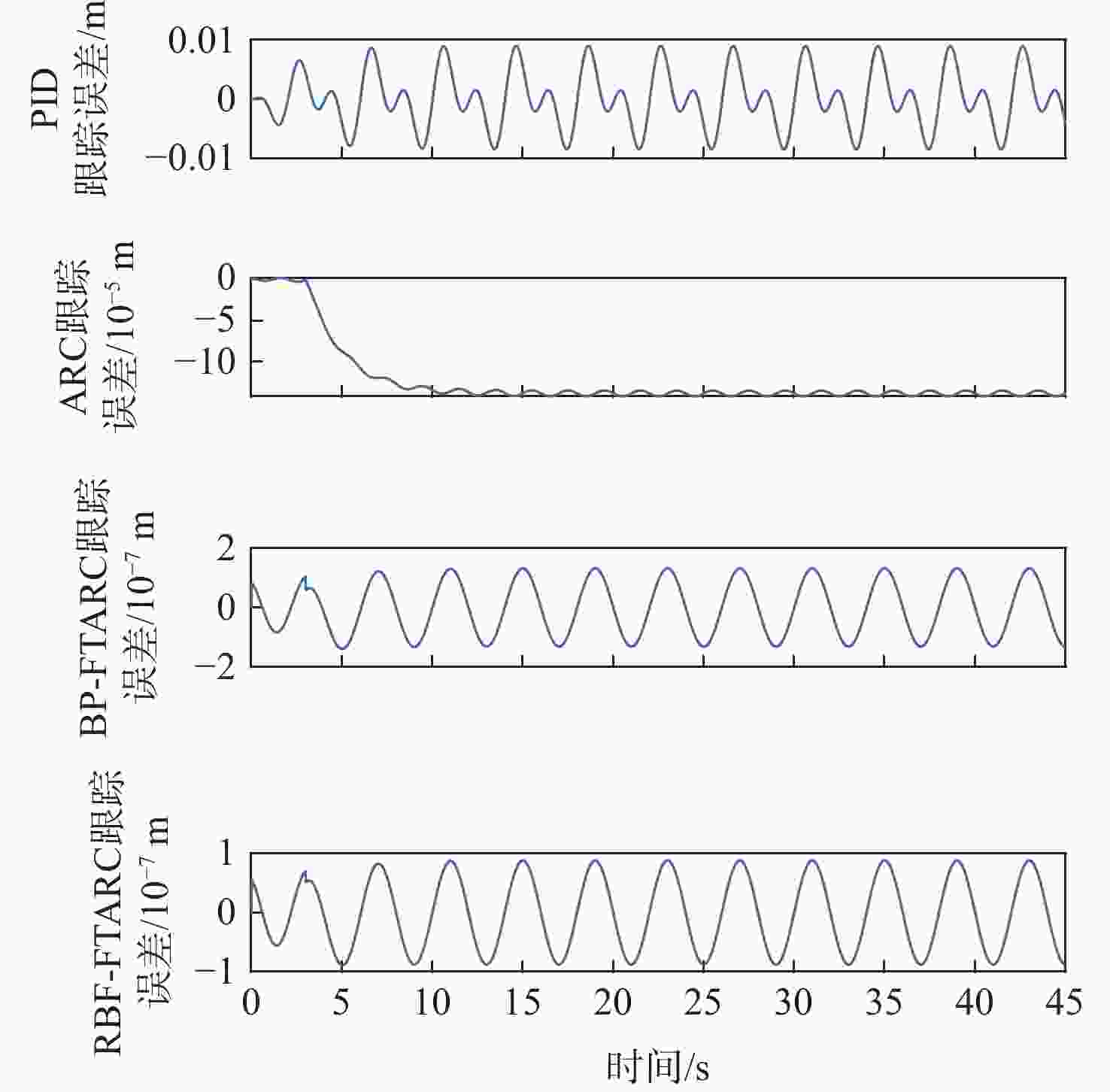

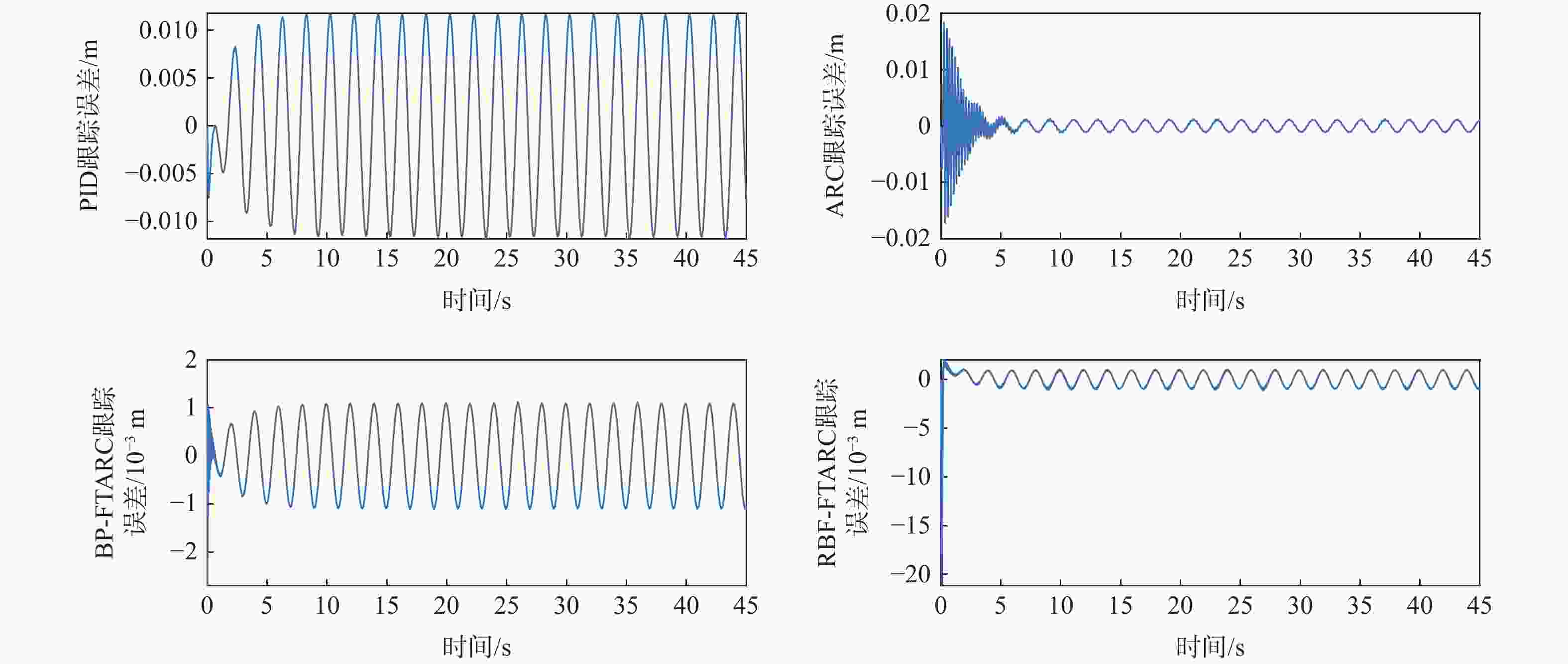

表 1 正弦信号工况下的性能指标

Table 1. Performance index under sinusoidal signal condition

控制器 $M_{{\rm{e}}}$ $ \mu $ $ \sigma $ PID 0.008 948 3.456×10−5 0.004 752 ARC 2.0×10−6 0.0001234 3.862×10−5 BP-FTARC 1.4×10−7 2.079×10−9 9.09×10−8 RBF-FTARC 8.355×10−8 8.619×10−10 6.033×10−8 表 2 联合仿真系统参数

Table 2. Parameter of co-simulation system

参数 数值 液压缸活塞和负载总质量$M$/kg 30 黏滞阻尼系数$B$/(N·(m·s−1)−1) 400 液压缸活塞面积$A$/${{\rm{m}}^2}$ 904.78×10−6 液压管路和油缸平均容积${V_{\rm{a} } }/{ { {\rm{m} }^{3} } }$ 398.1×10−7 等效弹性模量${\beta _{\rm{e}}}/ {{\rm{MPa}}}$ 700×106 泄漏系数$/({ {\rm{L·(min·MPa)} }^{-1} } )$ 1×10−12 泵排量${D_{\rm{p} } }/( { { {\rm{cm} }^{ 3} }\cdot{\rm{r}^{-1} } } )$ 19×10−6 表 3 工况1下各控制器性能指标

Table 3. Performance index of each controller under condition 1

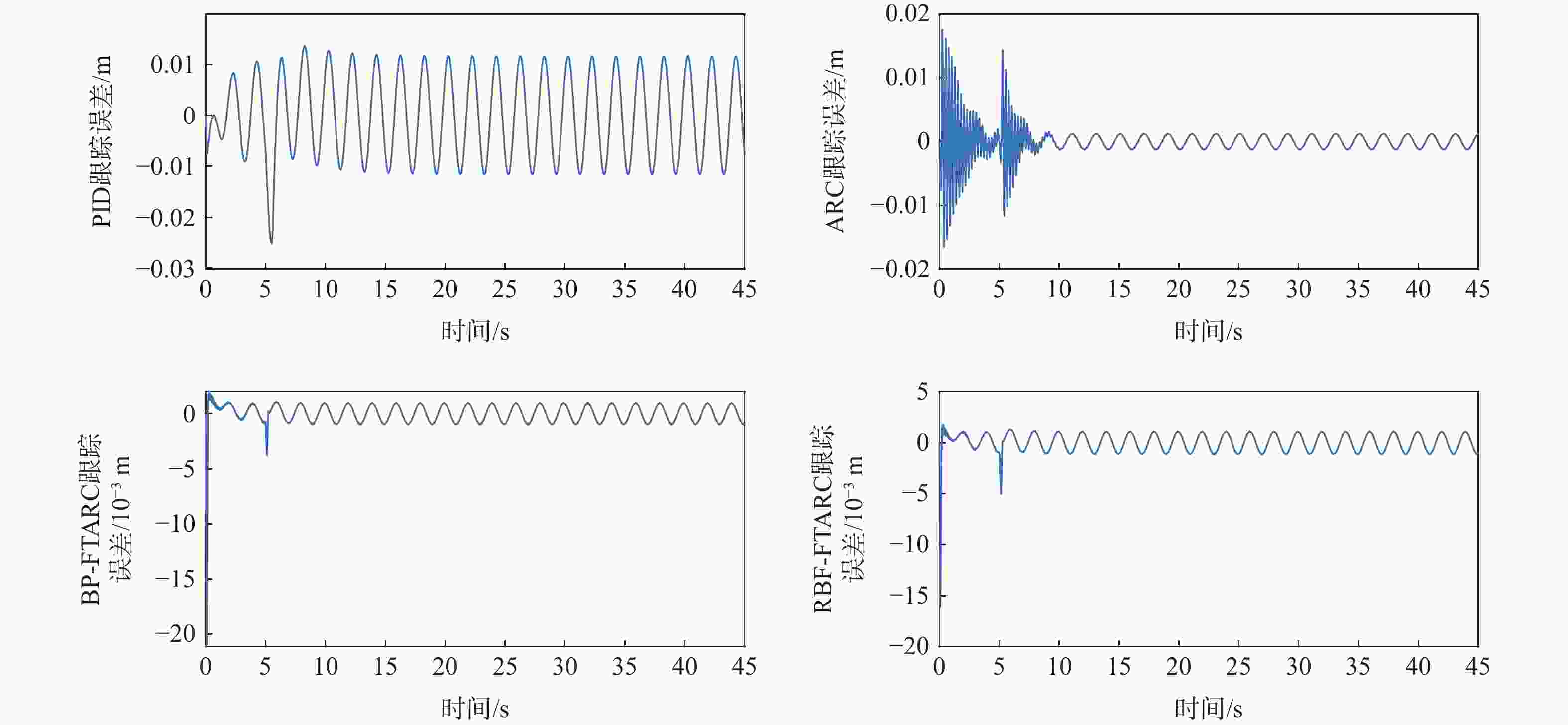

控制器 $M_{{\rm{e}}}$ $ \mu $ $ \boldsymbol{\sigma} $ PID 0.008 399 0.000 190 5 0.005 632 ARC 0.001 334 6.89×10−6 0.000 319 BP-FTARC 0.000 562 3 2.835×10−6 0.000 336 RBF-FTARC 0.000 409 3 2.625×10−6 0.000 176 表 4 工况2下各控制器性能指标

Table 4. Performance index of each controller under condition 2

控制器 $M_{{\rm{e}}}$ $ \mu $ $ \boldsymbol{\sigma} $ PID 0.01362 5.979×10−5 0.008 244 ARC 0.01763 3.603×10−6 0.002 419 BP-FTARC 0.004 623 2.364×10−6 0.001 556 RBF-FTARC 0.001 997 2.187×10−6 0.001 126 表 5 工况3下各控制器性能指标

Table 5. Performance index of each controller under condition 3

控制器 $M_{{\rm{e}}}$ $ \mu $ $ \sigma $ PID 0.034 58 0.000 493 5 0.01048 ARC 0.037 86 −3.829×10−6 0.003 736 BP-FTARC 0.006 982 −1.75×10−6 0.002 349 RBF-FTARC 0.003 972 9.379×10−7 0.000 638 2 表 6 工况4下各控制器性能指标

Table 6. Performance index of each controller under condition 3

控制器 $M_{{\rm{e}}}$ $ \mu $ $ \sigma $ PID 0.023 41 5.949×10−5 0.007 908 ARC 0.031 19 −3.605×10−6 0.000 855 2 BP-FTARC 0.007 868 1.759×10−6 0.002 65 RBF-FTARC 0.003 789 −9.339×10−7 0.000 650 2 -

[1] 权龙. 泵控缸电液技术研究现状、存在问题及创新解决方案[J]. 机械工程学报, 2008, 44(11): 87-92. doi: 10.3901/JME.2008.11.087QUAN L. Current state, problems and the innovative solution of electro-hydraulic technology of pump controlled cylinder[J]. Chinese Journal of Mechanical Engineering, 2008, 44(11): 87-92(in Chinese). doi: 10.3901/JME.2008.11.087 [2] 付永领, 韩旭, 杨荣荣, 等. 电动静液作动器设计方法综述[J]. 北京航空航天大学学报, 2017, 43(10): 1939-1952. doi: 10.13700/j.bh.1001-5965.2017.0195FU Y L, HAN X, YANG R R, et al. Review on design method of electro hydrostatic actuator[J]. Journal of Beijing University of Aeronautics and Astronautics, 2017, 43(10): 1939-1952(in Chinese). doi: 10.13700/j.bh.1001-5965.2017.0195 [3] 徐宝申, 刘涛. 新型电液伺服系统及其在飞机上的应用[J]. 飞航导弹, 2018(3): 90-95. doi: 10.16338/j.issn.1009-1319.2018.03.21XU B S, LIU T. New electro-hydraulic servo system and its application in aircraft[J]. Aerodynamic Missile Journal, 2018(3): 90-95(in Chinese). doi: 10.16338/j.issn.1009-1319.2018.03.21 [4] 陈经跃, 李奕宁, 苗蕾, 等. 民机用高压高速液压泵的研究[J]. 液压气动与密封, 2019, 39(6): 32-35. doi: 10.3969/j.issn.1008-0813.2019.06.011CHEN J Y, LI Y N, MIAO L, et al. Research on high pressure and high speed hydraulic pump for civil aircraft[J]. Hydraulics Pneumatics & Seals, 2019, 39(6): 32-35(in Chinese). doi: 10.3969/j.issn.1008-0813.2019.06.011 [5] 周汝胜, 焦宗夏, 王少萍. 液压系统故障诊断技术的研究现状与发展趋势[J]. 机械工程学报, 2006, 42(9): 6-14. doi: 10.3321/j.issn:0577-6686.2006.09.002ZHOU R S, JIAO Z X, WANG S P. Current research and developing trends on fault diagnosis of hydraulic systems[J]. Chinese Journal of Mechanical Engineering, 2006, 42(9): 6-14(in Chinese). doi: 10.3321/j.issn:0577-6686.2006.09.002 [6] 俞杭, 陈换过, 肖雪, 等. 基于SOM的电静压伺服机构油滤堵塞故障诊断[J]. 成组技术与生产现代化, 2019, 36(2): 11-16. doi: 10.3969/j.issn.1006-3269.2019.02.003YU H, CHEN H G, XIAO X, et al. SOM based fault diagnosis of the filter blockage in electro-hydrostatic actuator[J]. Group Technology & Production Modernization, 2019, 36(2): 11-16(in Chinese). doi: 10.3969/j.issn.1006-3269.2019.02.003 [7] 俞杭. 基于PCA-SOM的电静压伺服机构故障诊断研究[D]. 杭州: 浙江理工大学, 2020: 26-42.YU H. Research on fault diagnosis of the electro-hydrostatic actouators based on PCA-SOM[D]. Hangzhou: Zhejiang University of Technology, 2020: 26-42(in Chinese). [8] LOESCH VIANNA W O, DE SOUZA RIBEIRO L G, YONEYAMA T. Electro hydraulic servovalve health monitoring using fading extended Kalman filter[C]//IEEE Conference on Prognostics and Health Management (PHM). Piscataway: IEEE Press, 2015: 1-6. [9] 刘华, 汪成文, 郭新平, 等. 电液负载敏感位置伺服系统自抗扰控制方法[J]. 北京航空航天大学学报, 2020, 46(11): 2131-2139. doi: 10.13700/j.bh.1001-5965.2019.0569LIU H, WANG C W, GUO X P, et al. Active disturbance rejection control for position servo system based on electro-hydraulic load sensing[J]. Journal of Beijing University of Aeronautics and Astronautics, 2020, 46(11): 2131-2139(in Chinese). doi: 10.13700/j.bh.1001-5965.2019.0569 [10] 周萌, 王振华, 王昶, 等. Lipschitz非线性系统的H_/L∞故障检测观测器设计[J]. 控制理论与应用, 2018, 35(6): 778-785.ZHOU M, WANG Z H, WANG C, et al. H_/L∞ fault detection observer design for Lipschitz nonlinear systems[J]. Control Theory & Applications, 2018, 35(6): 778-785(in Chinese). [11] 张若青, 裘丽华. 基于动态神经网络的液压伺服系统故障检测[J]. 机械工程学报, 2002, 38(3): 46-49. doi: 10.3321/j.issn:0577-6686.2002.03.011ZHANG R Q, QIU L H. Fault detection of hydraulic servo system based on dynamic neural network[J]. Chinese Journal of Mechanical Engineering, 2002, 38(3): 46-49(in Chinese). doi: 10.3321/j.issn:0577-6686.2002.03.011 [12] 肖雪, 赵守军, 陈克勤, 等. 电静压伺服机构故障诊断中的主成分分析方法应用[J]. 导弹与航天运载技术, 2019(1): 94-100.XIAO X, ZHAO S J, CHEN K Q, et al. Application of principal component analysis in fault diagnosis of electro-hydrostatic actuators[J]. Missiles and Space Vehicles, 2019(1): 94-100(in Chinese). [13] KIM H M, PARK S H, SONG J H, et al. Robust position control of electro-hydraulic actuator systems using the adaptive back-stepping control scheme[J]. Proceedings of the Institution of Mechanical Engineers, Part I:Journal of Systems and Control Engineering, 2010, 224(6): 737-746. doi: 10.1243/09596518JSCE980 [14] YOON J T, YOUN B D, YOO M, et al. Life-cycle maintenance cost analysis framework considering time-dependent false and missed alarms for fault diagnosis[J]. Reliability Engineering & System Safety, 2019, 184: 181-192. [15] LIU J, ZHANG L X, LI H. Application of grey relation analysis in fault diagnosis of EHA-VSVP[C]//Proceedings of 2013 IEEE International Conference on Grey systems and Intelligent Services (GSIS). Piscataway: IEEE Press, 2014: 29-32. [16] 戴邵武, 罗鑫辉, 戴洪德. 基于状态反馈的执行器故障容错控制[J]. 海军航空工程学院学报, 2019, 34(2): 205-210. doi: 10.7682/j.issn.1673-1522.2019.02.005DAI S W, LUO X H, DAI H D. Actuator fault-tolerant control of actuator based on state feedback[J]. Journal of Naval Aeronautical and Astronautical University, 2019, 34(2): 205-210(in Chinese). doi: 10.7682/j.issn.1673-1522.2019.02.005 [17] ZHU Y Q, BO L, LI Y R, et al. Design of a electro-hydrostatic actuator controller based on disturbance observer[C]//43rd Annual Conference of the IEEE Industrial Electronics Society. Piscataway: IEEE Press, 2017: 4137-4142. [18] 李仿华. 基于神经网络的实时故障检测研究[D]. 合肥: 安徽大学, 2012: 32-37.LI F H. Research of real-time fault detection based on neural networks[D]. Hefei: Anhui University, 2012: 32-37(in Chinese). [19] 何静. 基于观测器的非线性系统鲁棒故障检测与重构方法研究[D]. 长沙: 国防科学技术大学, 2009: 74-91.HE J. On observer-based robust fault detection and reconstruction for nonlinear systems[D]. Changsha: National University of Defense Science Technology, 2009: 74-91(in Chinese). [20] RAHIMILARKI R, GAO Z, ZHANG A, et al. Robust neural network fault estimation approach for nonlinear dynamic systems with applications to wind turbine systems[J]. IEEE Transactions on Industrial Informatics, 2019, 15(12): 6302-6312. doi: 10.1109/TII.2019.2893845 [21] YAO J Y, JIAO Z X, MA D W. Adaptive robust control of DC motors with extended state observer[J]. IEEE Transactions on Industrial Electronics, 2014, 61(7): 3630-3637. doi: 10.1109/TIE.2013.2281165 [22] 宋豫. 锻造油压机开式泵控液压系统研究[D]. 秦皇岛: 燕山大学, 2016: 85-99.SONG Y. Research on open circuit pump-controlled hydraulic system of forging press[D]. Qinhuangdao: Yanshan University, 2016: 85-99(in Chinese). [23] 陈革新, 赵鹏辉, 刘小胜, 等. 电液伺服闭式泵控系统位置前馈补偿控制研究[J]. 液压与气动, 2019(12): 28-32. doi: 10.11832/j.issn.1000-4858.2019.12.004CHEN G X, ZHAO P H, LIU X S, et al. Position feedforward compensation control of electro hydraulic servo closed pump control system[J]. Chinese Hydraulics & Pneumatics, 2019(12): 28-32(in Chinese). doi: 10.11832/j.issn.1000-4858.2019.12.004 [24] 刘金琨. 智能控制: 理论基础、算法设计与应用[M]. 北京: 清华大学出版社, 2019: 137-150.LIU J K. Intelligent control[M]. Beijing: Tsinghua University Press, 2019: 137-150(in Chinese). [25] 韩松杉, 焦宗夏, 尚耀星, 等. 基于舵机指令前馈的电液负载模拟器同步控制[J]. 北京航空航天大学学报, 2015, 41(1): 124-132.HAN S S, JIAO Z X, SHANG Y X, et al. Synchronizing compensation control of electro-hydraulic load simulator using command signal of actuator[J]. Journal of Beijing University of Aeronautics and Astronautics, 2015, 41(1): 124-132(in Chinese). -

下载:

下载: