Simulation of cavity flow at high Mach number based on adaptive unstructured hybrid mesh

-

摘要:

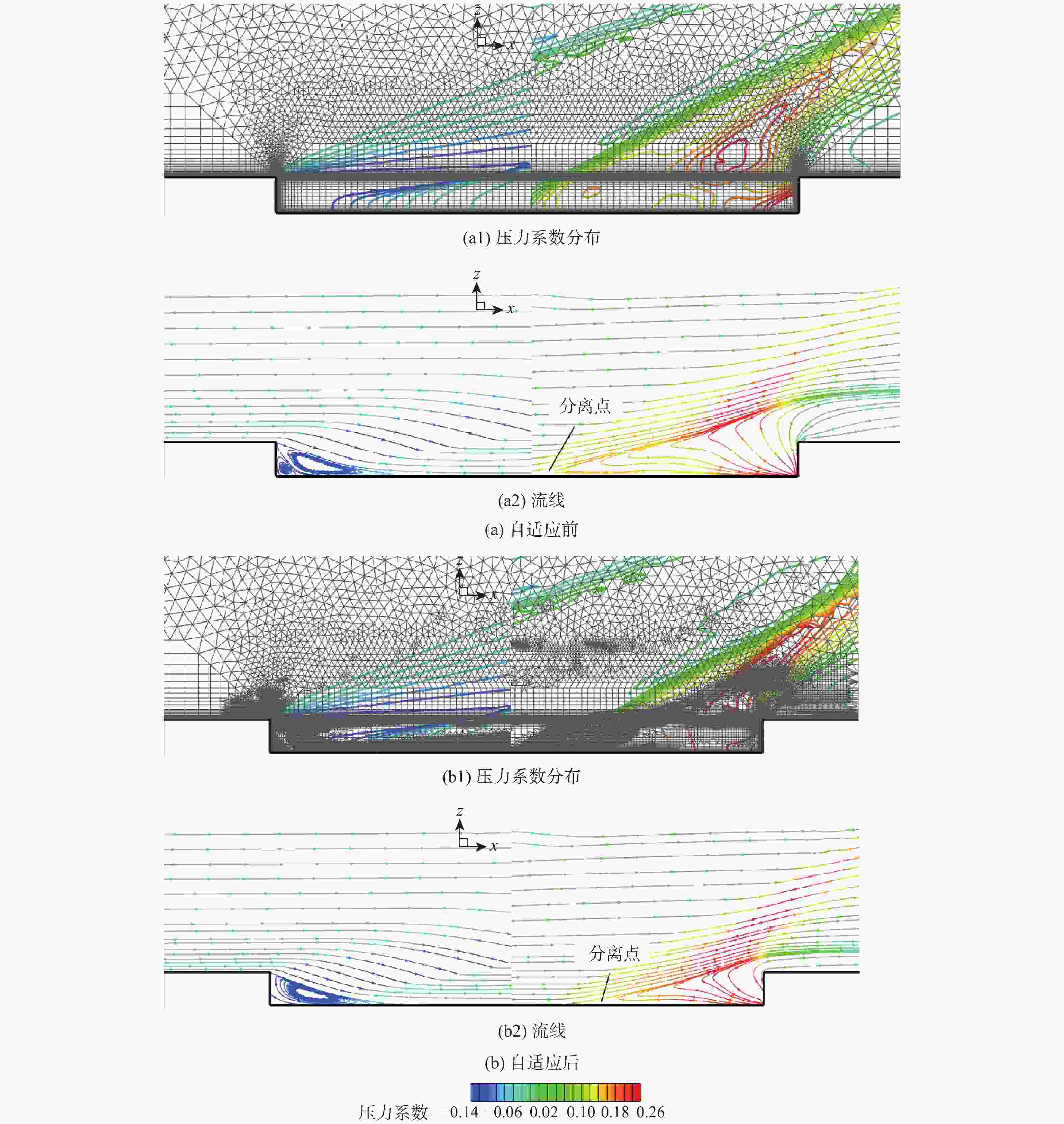

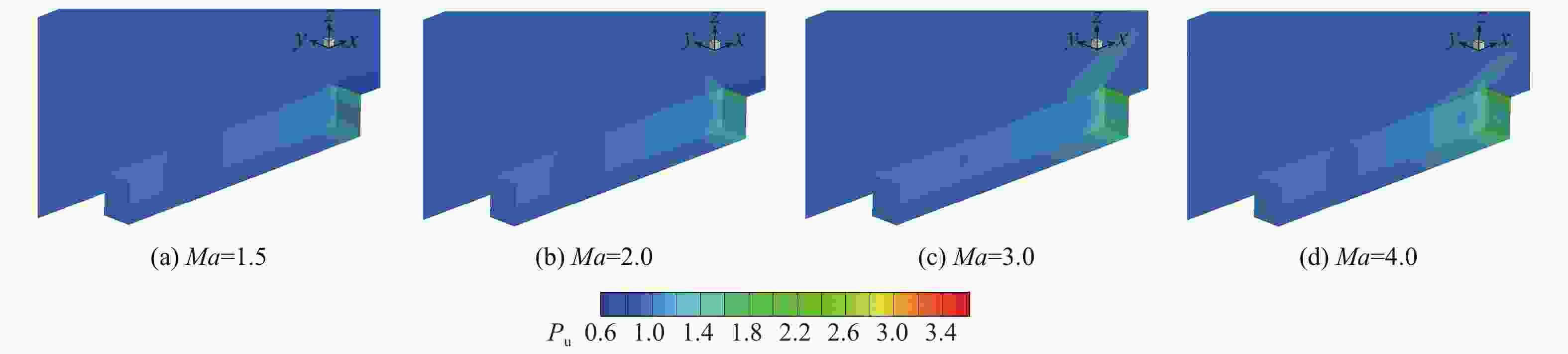

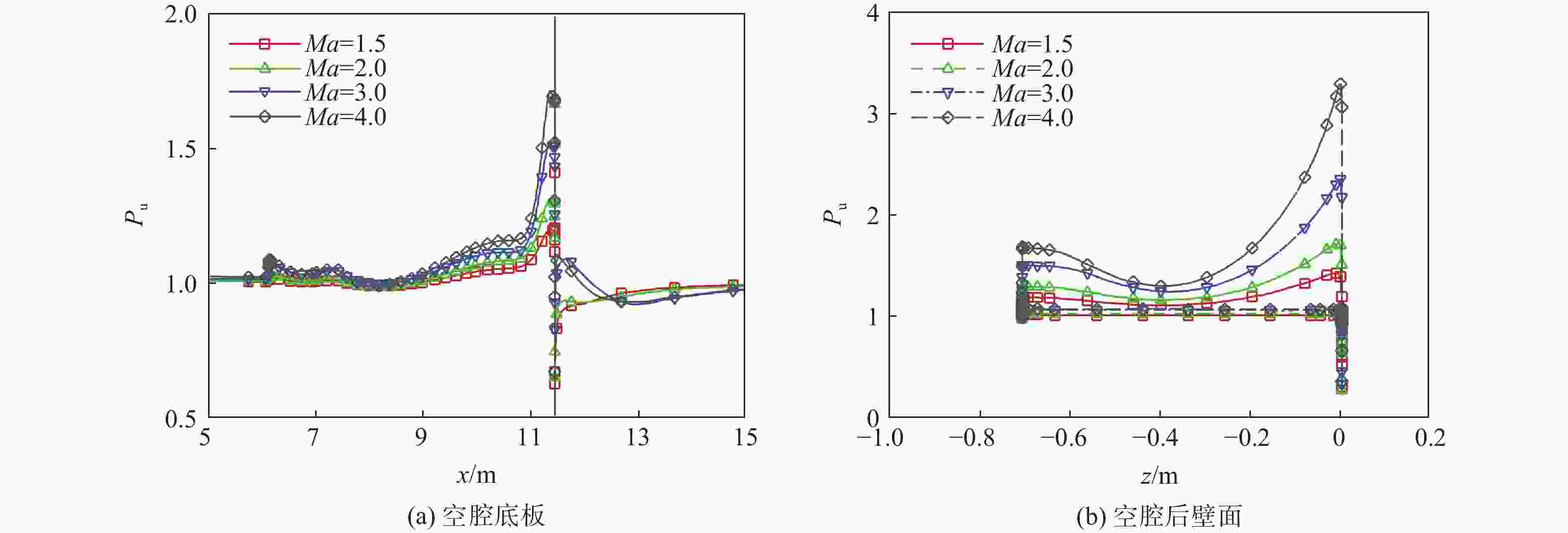

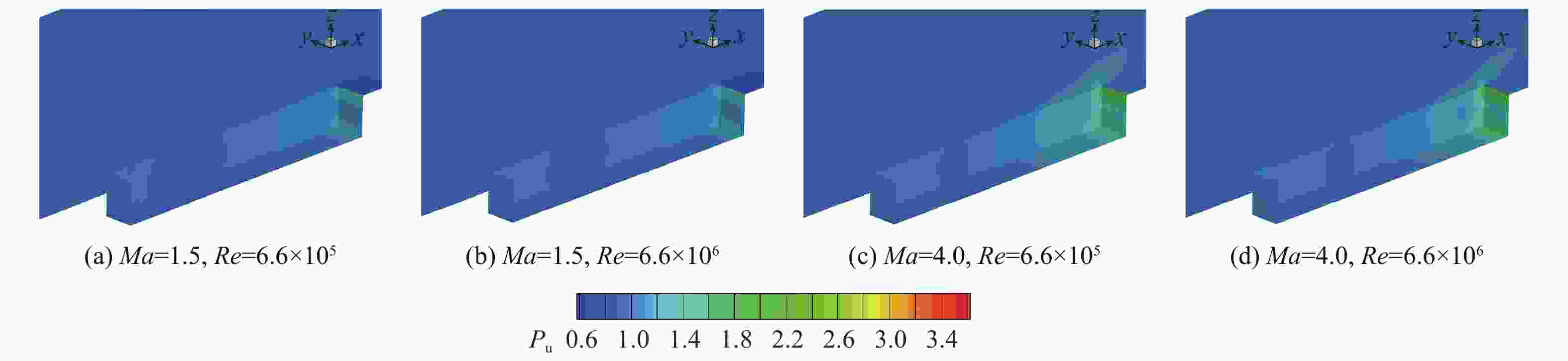

空腔流动尤其是高马赫数(

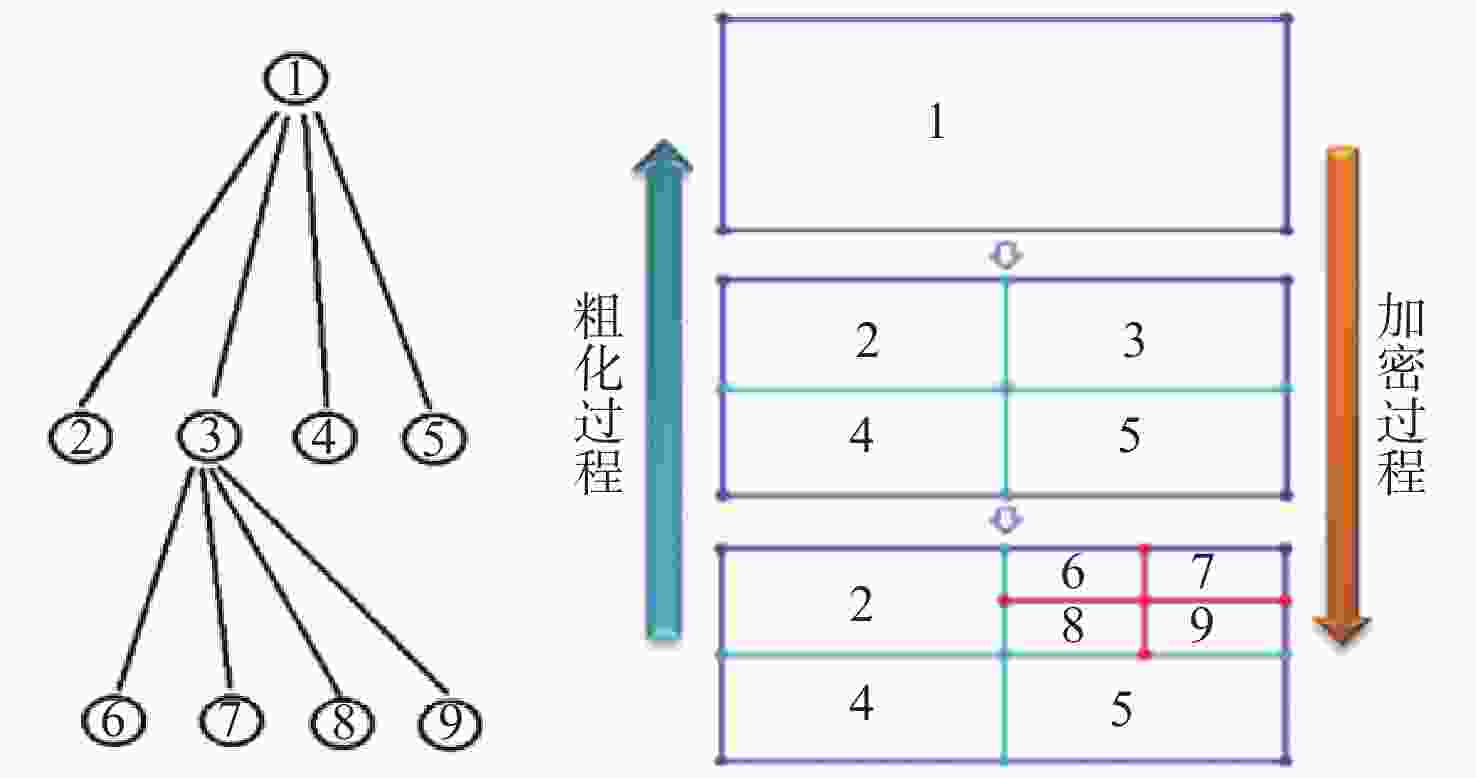

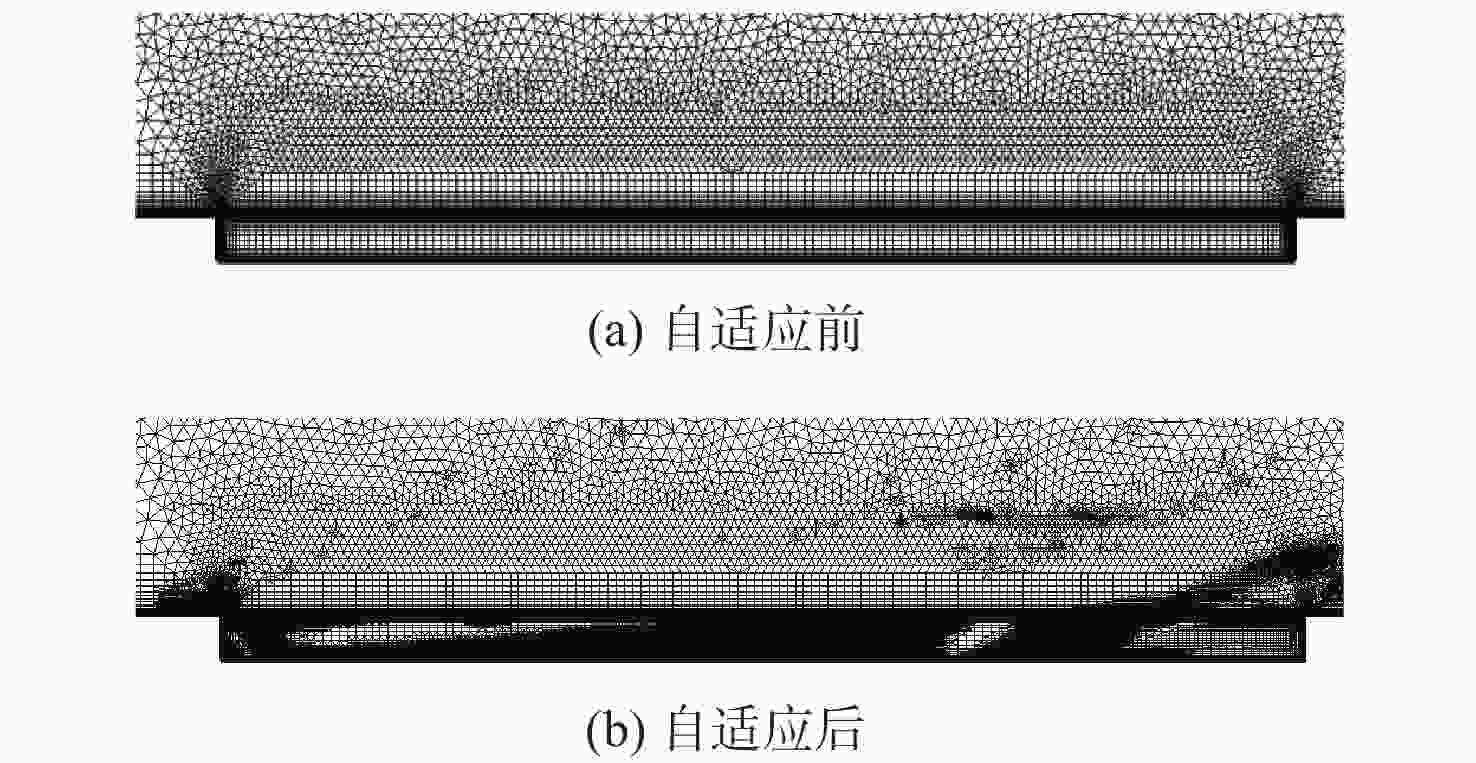

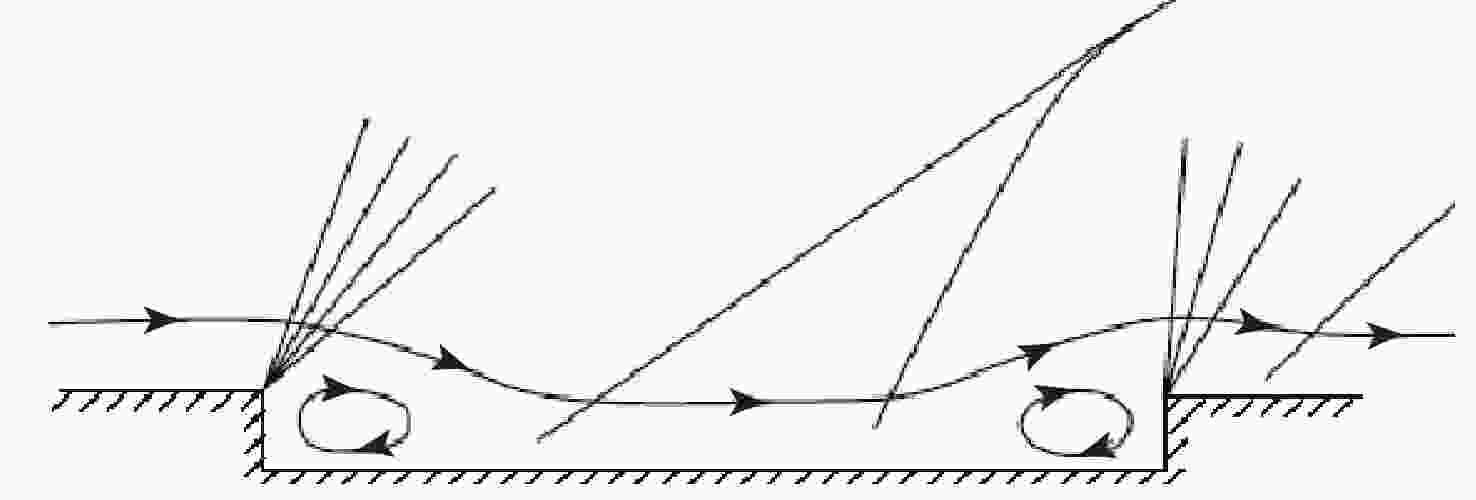

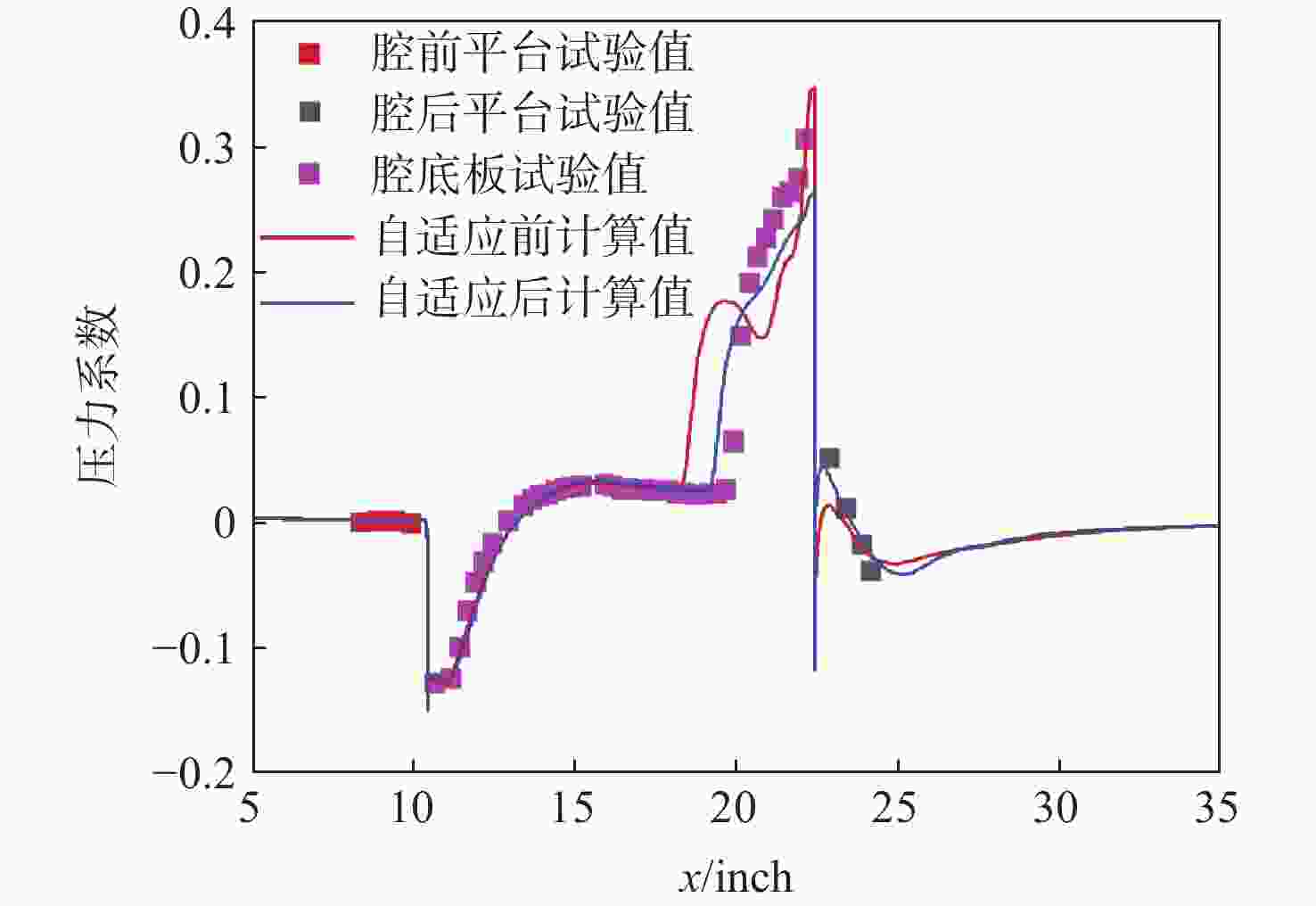

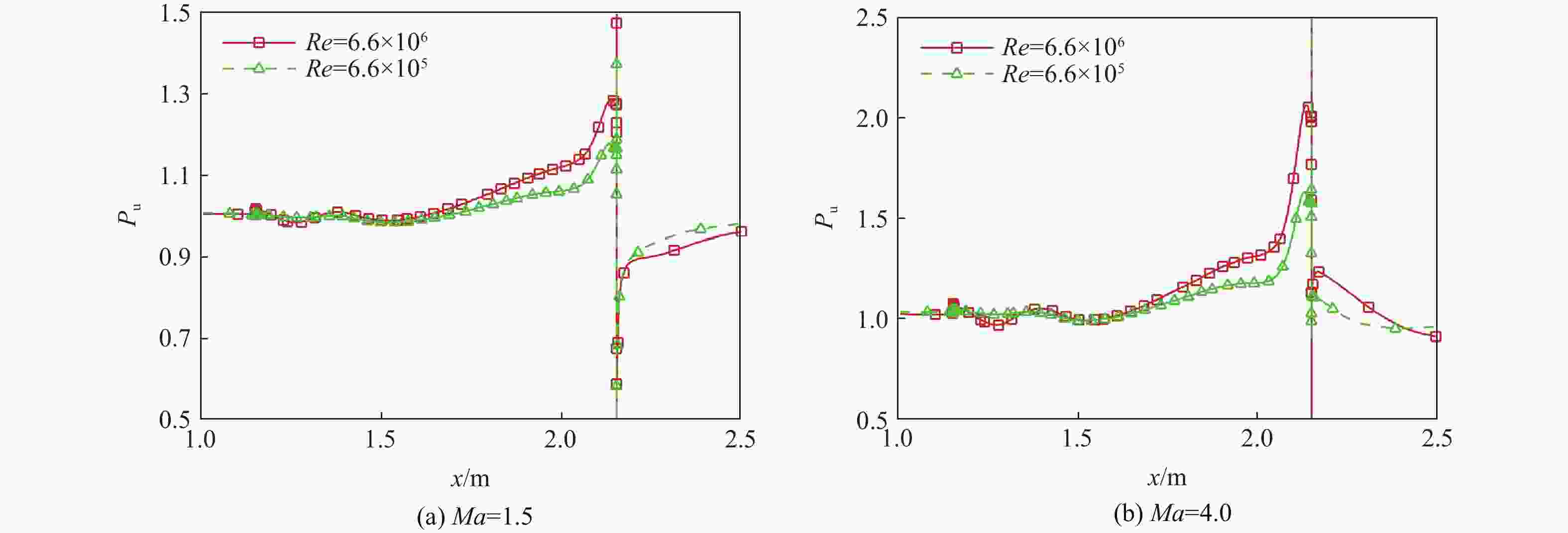

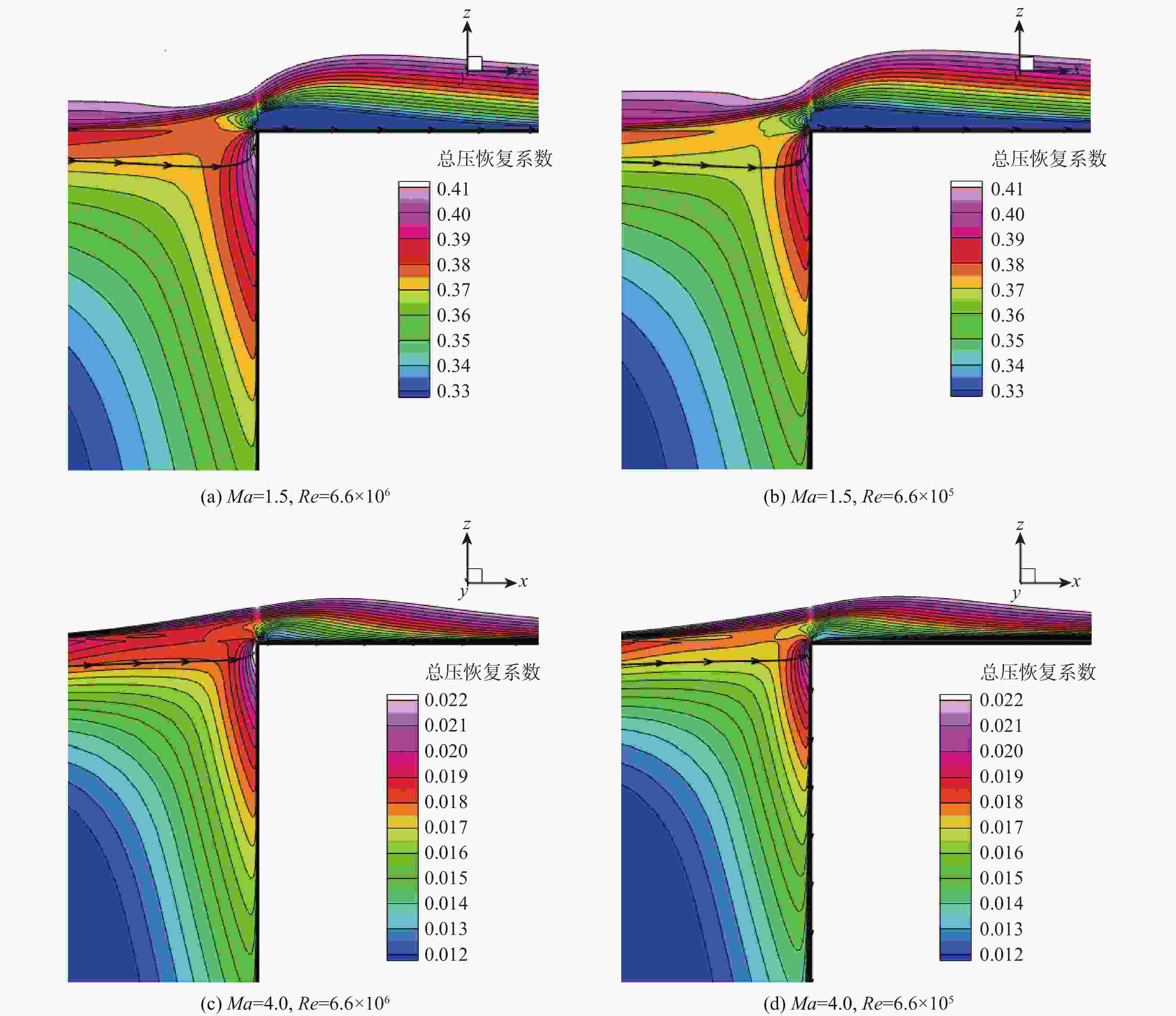

Ma >2)空腔流动,存在强激波、强剪切和分离涡,及其相互之间的干扰,流动复杂,网格分布及网格生成的质量对模拟结果影响很大。将建立的基于非结构混合网格的自适应探测器,应用到高马赫数空腔流动数值模拟中,通过空腔标模算例考核,验证了采用网格自适应技术可以更好地模拟存在大分离和强剪切的高马赫数空腔流动。开展了马赫数、雷诺数等流动参数对空腔流动特性影响的研究,随马赫数增大空腔内动压急剧升高,自由流和剪切层对后壁面的冲击效应明显增强,压力分布的不均匀程度提高,后壁面上的压力峰值均逐渐增大。雷诺数增大会使后壁面处的压力峰值增大,并且高马赫数条件相比于低马赫数条件下雷诺数对腔内压力分布的影响更显著。Abstract:The cavity flow, especially at high Mach numbers (

Ma >2), is complicated due to strong shock waves and shear, separation vortices, and their mutual interference. The mesh distribution and the quality of mesh generation thus significantly affect simulation results. The adaptive detector based on unstructured hybrid mesh established by our project team is applied to the numerical simulation of cavity flow at high Mach numbers. The evaluation of standard cavity model verifies that the high Mach number cavity flow with large separation and strong shear can be better simulated by mesh adaptive technique. The effect of flow parameters such as Mach number and Reynolds number on cavity flow characteristics are examined. With the increase of Mach numbers, the dynamic pressure in the cavity increases sharply, the shock effect of free flow and shear layer on the back wall increases obviously, the unevenness of pressure distribution increases, and the pressure peak on the back wall increases gradually. Increasing the Reynolds number leads to an increase in pressure peak at the back wall, and the effect of Reynolds numbers on the pressure distribution of the cavity becomes more significant at high Mach numbers than low Mach numbers.-

Key words:

- cavity flow /

- adaptation /

- Reynolds number /

- unstructured hybrid mesh /

- numerical simulation

-

-

[1] LAWSON S J, BARAKOS G N. Review of numerical simulations for high-speed, turbulent cavity flows[J]. Progress in Aerospace Sciences, 2011, 47(3): 186-216. doi: 10.1016/j.paerosci.2010.11.002 [2] ROSSITER J E. Wind-tunnel experimental on the flow over rectangular cavities at subsonic and transonic speeds: RAE Technical Report No. 64037[R]. London: REA, 1964. [3] SUHS N E. Computational of three-dimensional cavity flow at subsonic and supersonic Mach numbers: AIAA-87-1208[R]. Reston: AIAA, 1987: 1-9. [4] STALLINGS R L J, WILCOX F J J. Experimental cavity pressure distributions at supersonic speeds: NASA TP-2683[R]. Washington, D. C. : NASA, 1987: 1-75. [5] LARCHEVÊQUE L, SAGAUT P, LÊ T H, et al. Large-eddy simulation of a compressible flow in a three-dimensional open cavity at high Reynolds number[J]. Journal of Fluid Mechanics, 2004, 516: 265-301. doi: 10.1017/S0022112004000709 [6] 马明生, 张培红, 邓有奇, 等. 超声速空腔流动数值模拟研究[J]. 空气动力学学报, 2008, 26(3): 388-393. doi: 10.3969/j.issn.0258-1825.2008.03.021MA M S, ZHANG P H, DENG Y Q, et al. Numerical simulation investigation of supersonic cavity flow[J]. Acta Aerodynamica Sinica, 2008, 26(3): 388-393(in Chinese). doi: 10.3969/j.issn.0258-1825.2008.03.021 [7] 黎军, 张群峰, 曾宏刚, 等. 腔体闭式流动控制的实验和数值模拟[J]. 北京航空航天大学学报, 2008, 34(1): 96-99. doi: 10.13700/j.bh.1001-5965.2008.01.013LI J, ZHANG Q F, ZENG H G, et al. Experimental and numerical investigation of controls for closed cavity flow[J]. Journal of Beijing University of Aeronautics and Astronautics, 2008, 34(1): 96-99(in Chinese). doi: 10.13700/j.bh.1001-5965.2008.01.013 [8] 吴继飞, 罗新福, 范召林. 亚、跨、超声速下空腔流场特性实验研究[J]. 实验流体力学, 2008, 22(1): 71-75. doi: 10.3969/j.issn.1672-9897.2008.01.015WU J F, LUO X F, FAN Z L. Experimental investigation of cavity flow characteristics at subsonic, transonic and supersonic speeds[J]. Journal of Experiments in Fluid Mechanics, 2008, 22(1): 71-75(in Chinese). doi: 10.3969/j.issn.1672-9897.2008.01.015 [9] 吴继飞. 内埋武器舱系统气动特性研究[D]. 绵阳: 中国空气动力研究与发展中心, 2012: 1-178.WU J F. Investigation on aerodynamic characteristics of internal weapons bay system[D]. Mianyang: China Aerodynamics Research and Development Center, 2012: 1-178 (in Chinese) . [10] 谢露, 张彦军, 侯银珠, 等. 亚声速武器舱空腔流动压力特性及其控制方法[J]. 航空学报, 2020, 41(11): 123961.XIE L, ZHANG Y J, HOU Y Z, et al. Cavity flow pressure characteristics and flow control methods of subsonic weapon bay[J]. Acta Aeronautica et Astronautica Sinica, 2020, 41(11): 123961(in Chinese). [11] SHEPHARD M. Automatic and adaptive mesh generation[J]. IEEE Transactions on Magnetics, 1985, 21(6): 2484-2489. doi: 10.1109/TMAG.1985.1064241 [12] 张培红, 赵炜, 张耀冰, 等. CFD在飞翼标模支撑干扰影响研究中的应用[J]. 计算力学学报, 2020, 37(6): 743-749. doi: 10.7511/jslx20191112002ZHANG P H, ZHAO W, ZHANG Y B, et al. Application of CFD in the investigation on support interference of flying-wing calibration model[J]. Chinese Journal of Computational Mechanics, 2020, 37(6): 743-749(in Chinese). doi: 10.7511/jslx20191112002 [13] NAKAHASHI K, DEIWERT G S. Three-dimensional adaptive grid method[J]. AIAA Journal, 1986, 24(6): 948-954. doi: 10.2514/3.9369 [14] BAI W, QIU Z, LI L. Recent efforts to establish adaptive hybrid grid computing capability at ACTRI[J]. Computational Fluid Dynamics Journal, 2007, 7(4): 438-449. [15] 唐静, 崔鹏程, 贾洪印, 等. 非结构混合网格鲁棒自适应技术[J]. 航空学报, 2019, 40(10): 122894. doi: 10.7527/S1000-6893.2019.22894TANG J, CUI P C, JIA H Y, et al. Robust adaptation techniques for unstructured hybrid mesh[J]. Acta Aeronautica et Astronautica Sinica, 2019, 40(10): 122894(in Chinese). doi: 10.7527/S1000-6893.2019.22894 [16] 陈宣友, 董海涛, 李椿萱, 等. 3点逐步r型自适应网格算法[J]. 北京航空航天大学学报, 2006, 32(1): 13-17. doi: 10.3969/j.issn.1001-5965.2006.01.004CHEN X Y, DONG H T, LI C X, et al. Three-point step-by-step generating r-type adaptive grid technique[J]. Journal of Beijing University of Aeronautics and Astronautics, 2006, 32(1): 13-17(in Chinese). doi: 10.3969/j.issn.1001-5965.2006.01.004 [17] LENTINI M, PEREYRA V. An adaptive finite difference solver for nonlinear two-point boundary problems with mild boundary layers[J]. SIAM Journal on Numerical Analysis, 1977, 14(1): 91-111. doi: 10.1137/0714006 [18] BERGER M J, OLIGER J. Adaptive mesh refinement for hyperbolic partial differential equations[J]. Journal of Computational Physics, 1984, 53(3): 484-512. doi: 10.1016/0021-9991(84)90073-1 [19] BECKER R, RANNACHER R. An optimal control approach to a posteriori error estimation in finite element methods[J]. Acta Numerica, 2001, 10: 1-102. doi: 10.1017/S0962492901000010 [20] GILES M B, PIERCE N A. Adjoint error correction for integral outputs[M]. Berlin: Springer, 2002: 47-96. [21] BARTH T. Numerical methods and error estimation for conservation laws on structured and unstructured meshes: Von Karman Institute Lecture Series 04-2003[R]. Brussels: Von Karman Institute, 2003: 1-65. [22] VENDITTI D A, DARMOFAL D L. Grid adaptation for functional outputs: Application to two-dimensional inviscid flows[J]. Journal of Computational Physics, 2002, 176(1): 40-69. doi: 10.1006/jcph.2001.6967 [23] BALASUBRAMANIAN R, NEWMAN J C. Comparison of adjoint-based and feature-based grid adaptation for functional outputs[J]. International Journal for Numerical Methods in Fluids, 2007, 53(10): 1541-1569. doi: 10.1002/fld.1361 -

下载:

下载: