Fast leveling control technology of vehicle platform based on interference compensation

-

摘要:

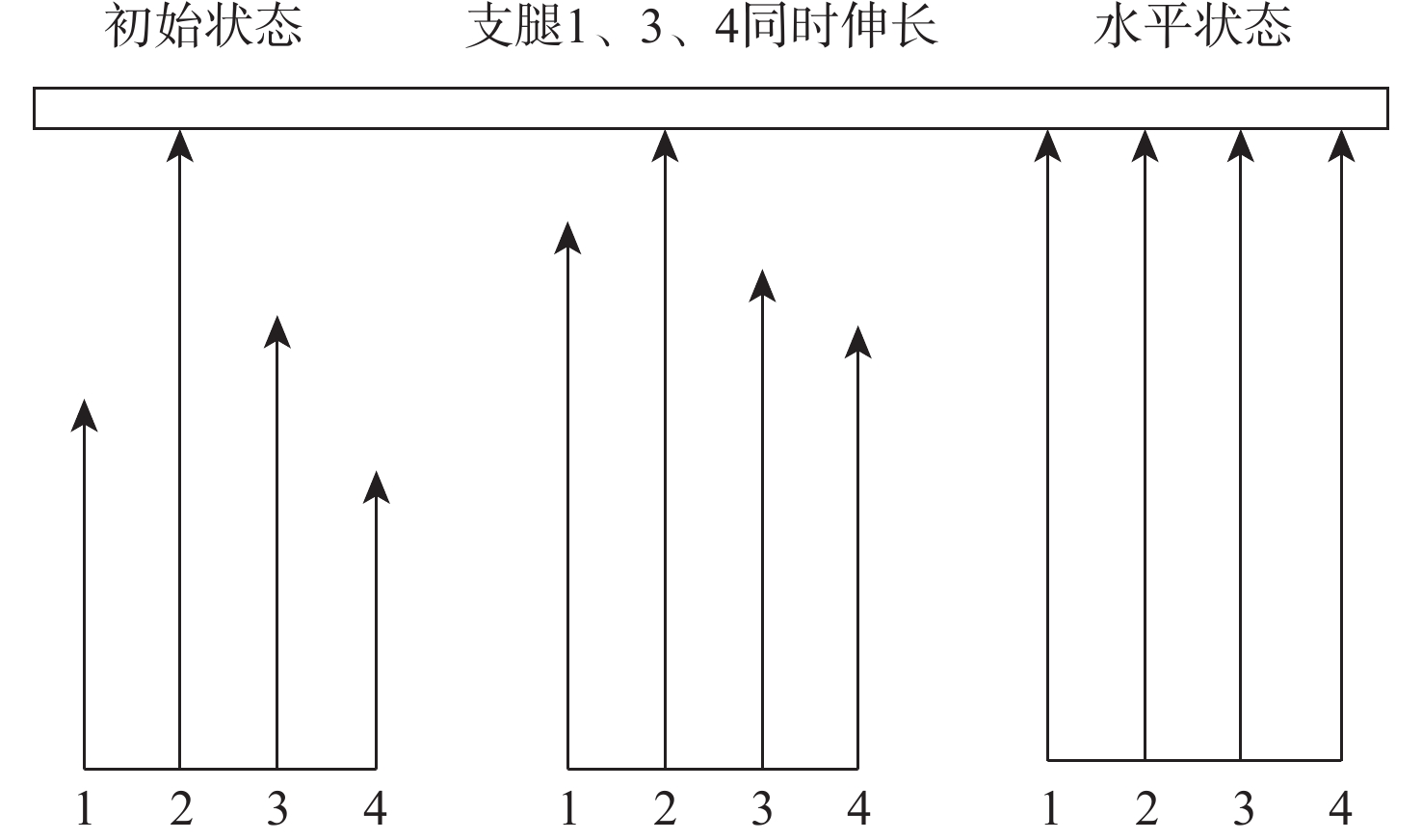

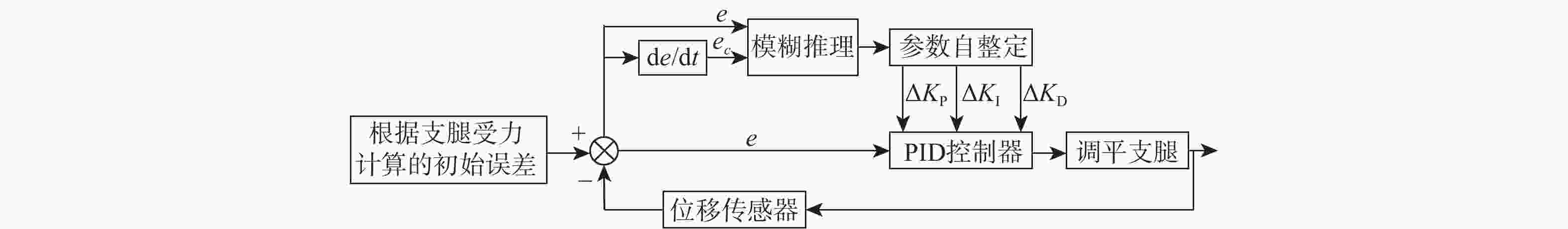

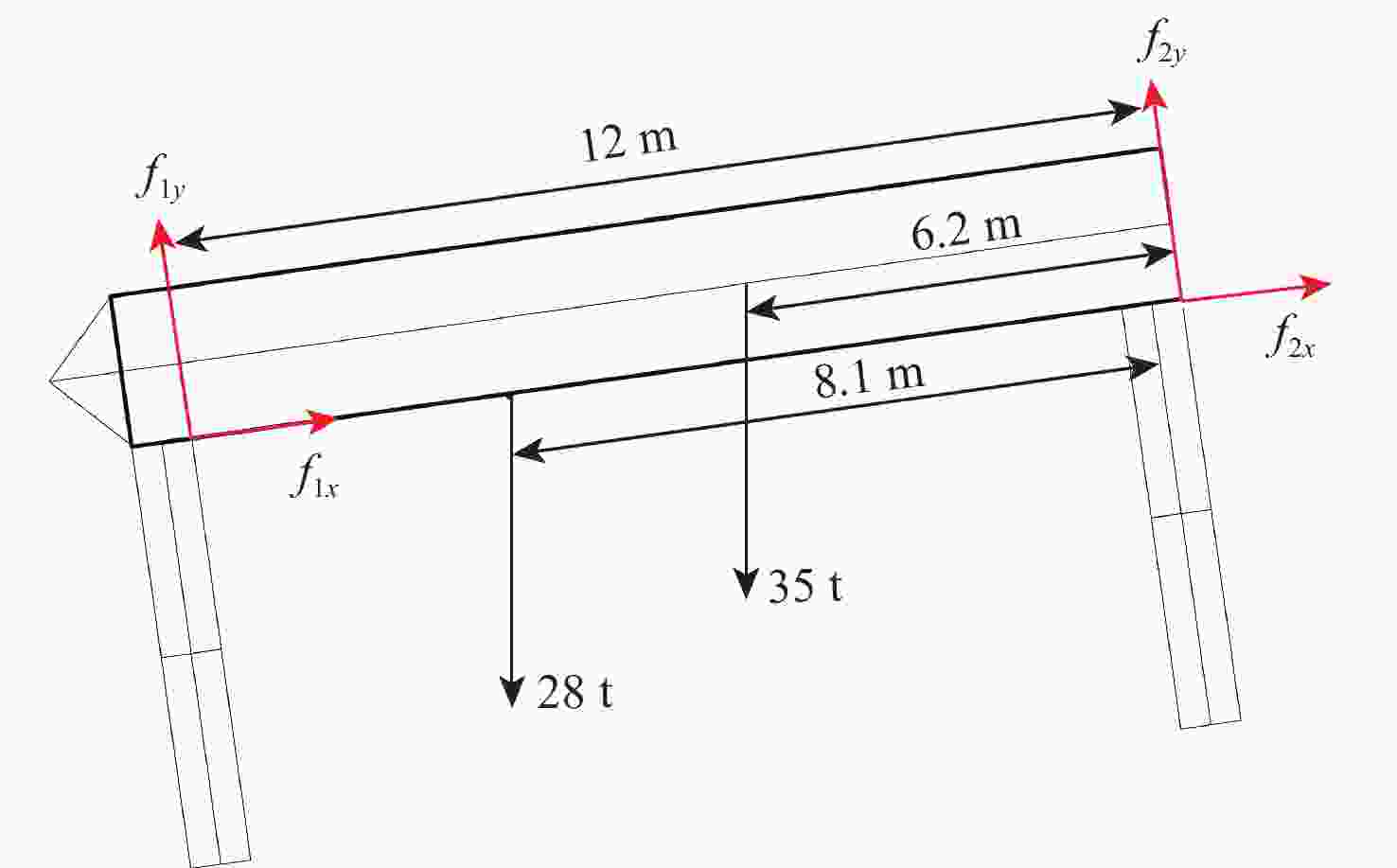

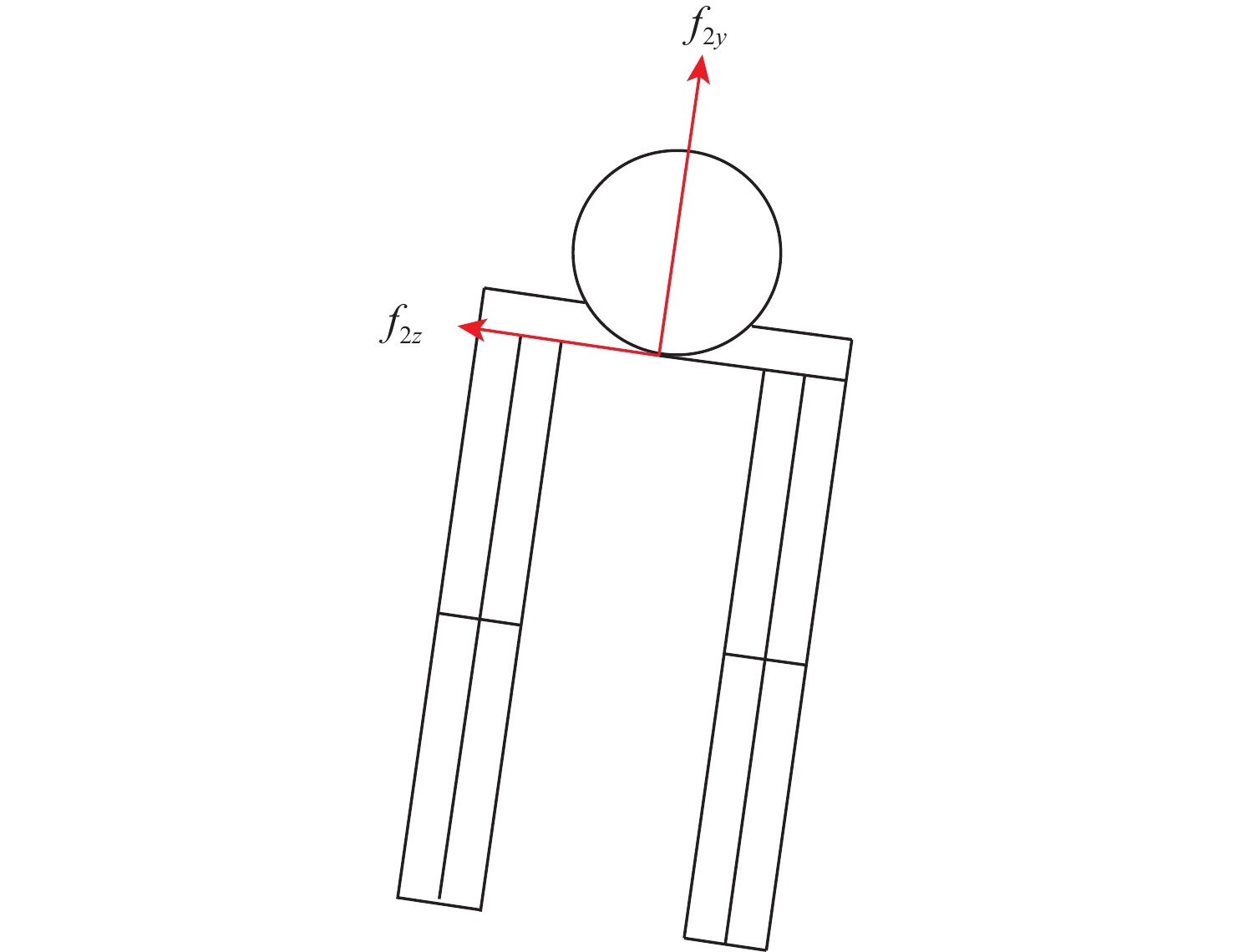

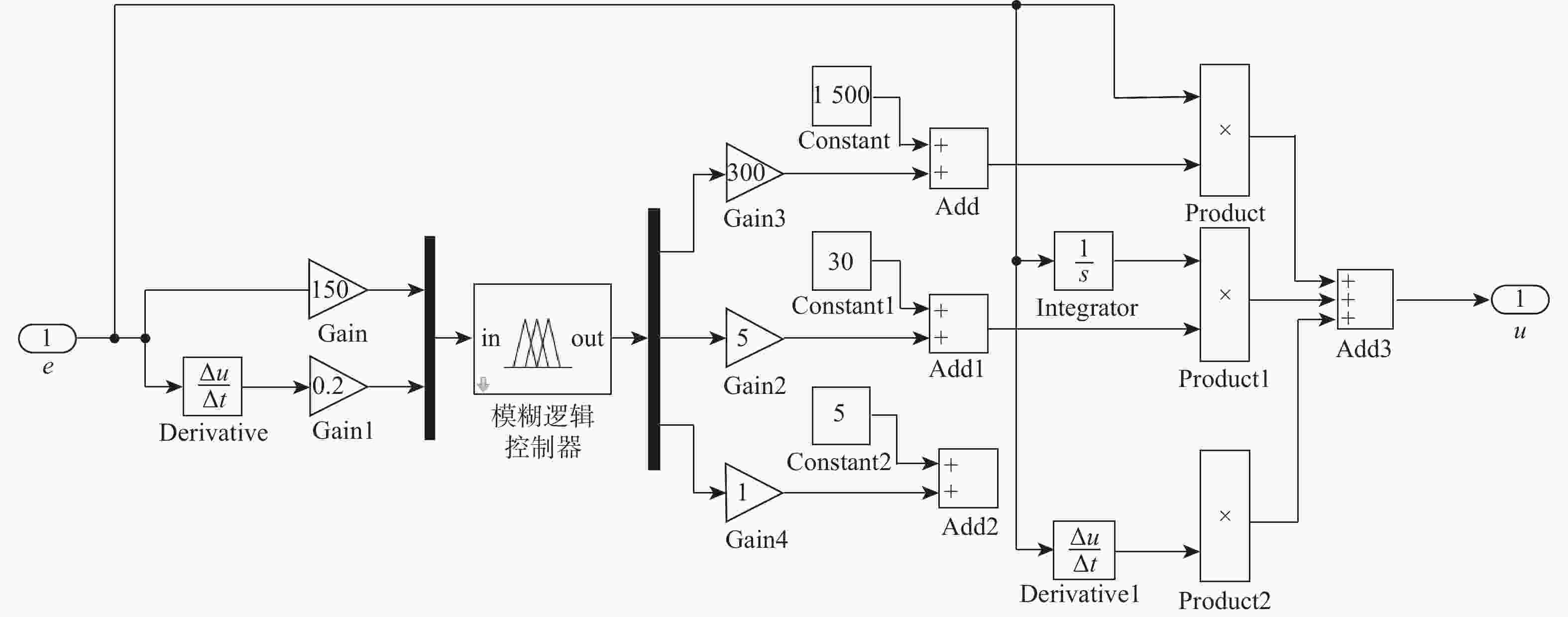

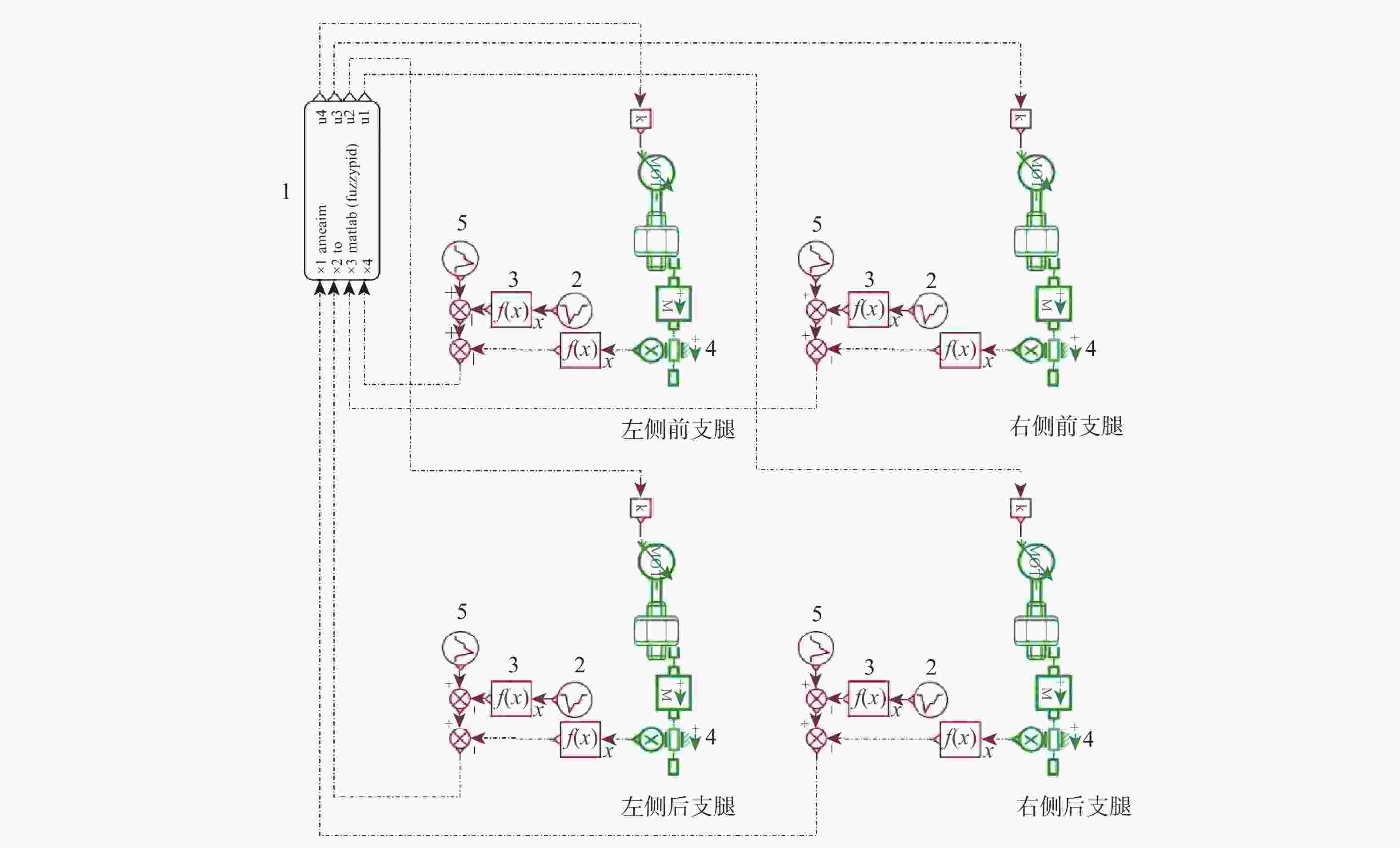

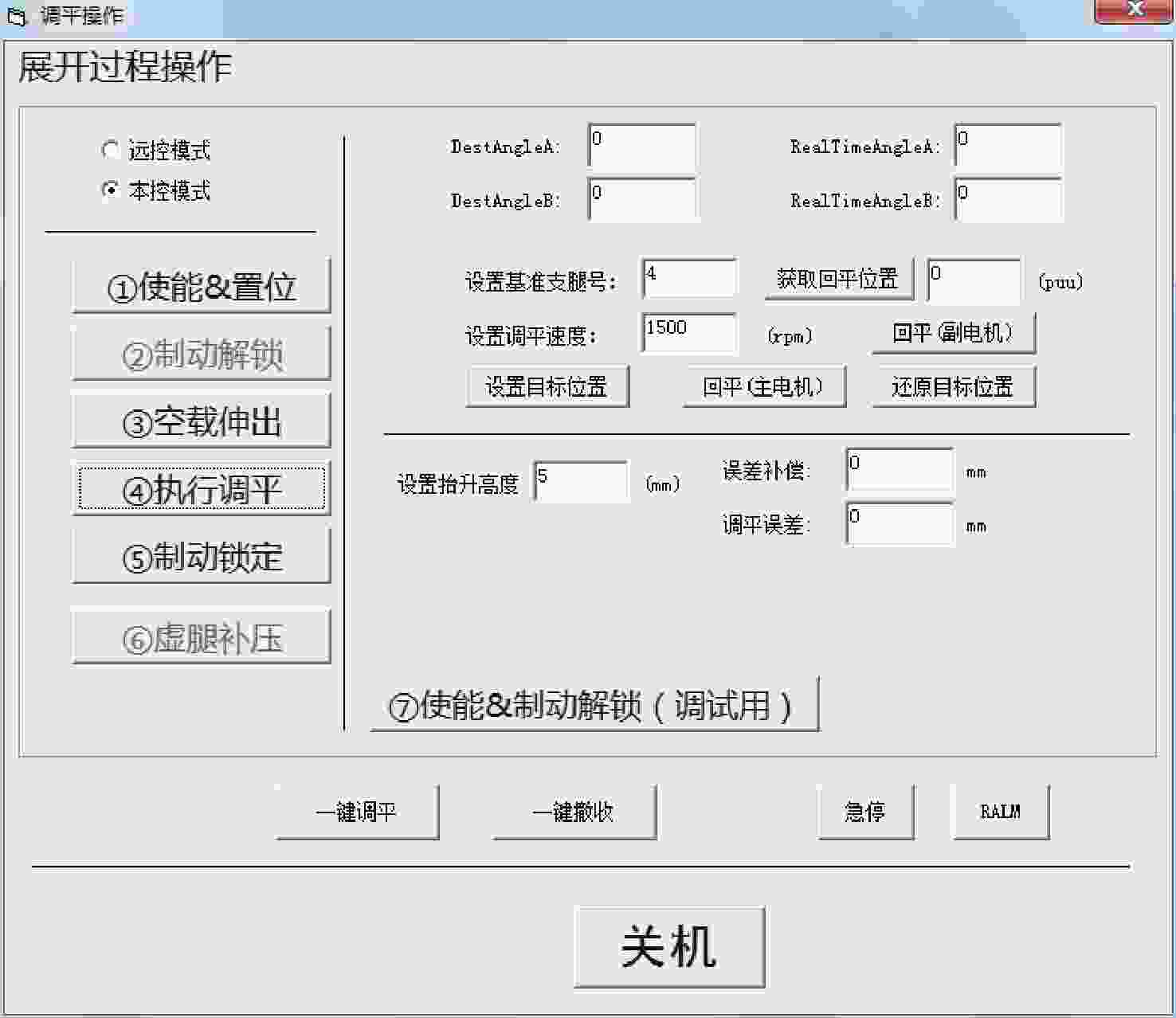

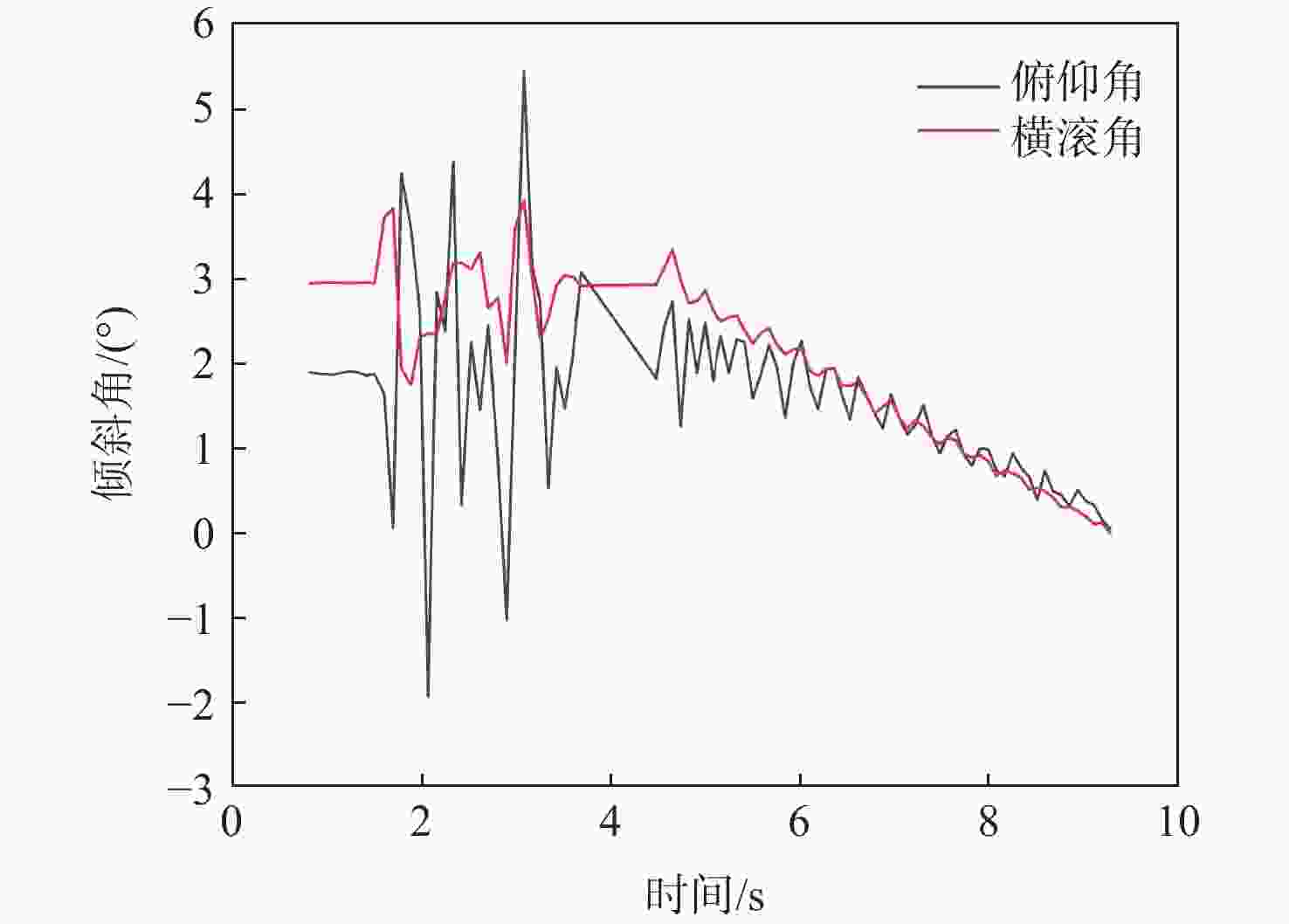

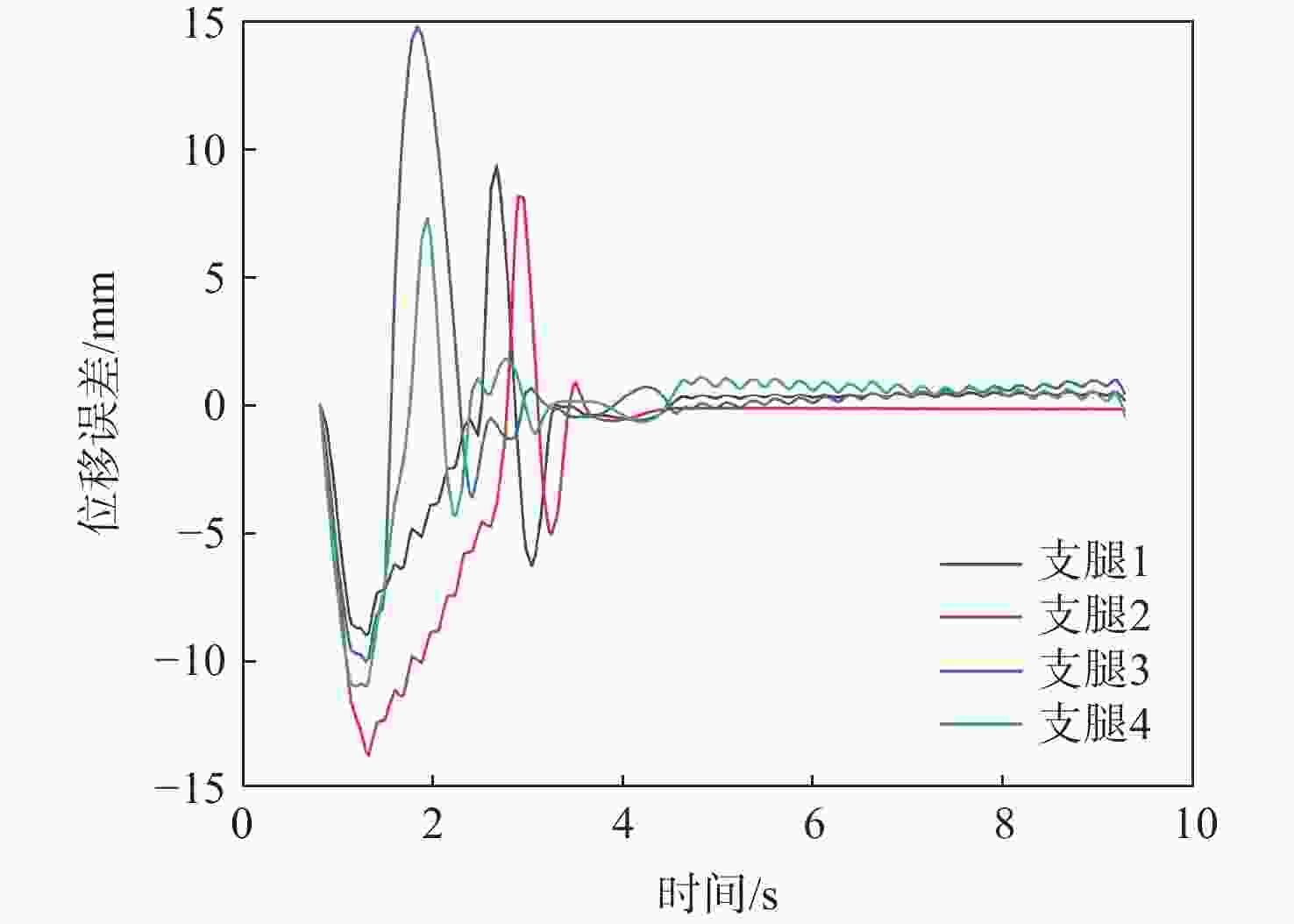

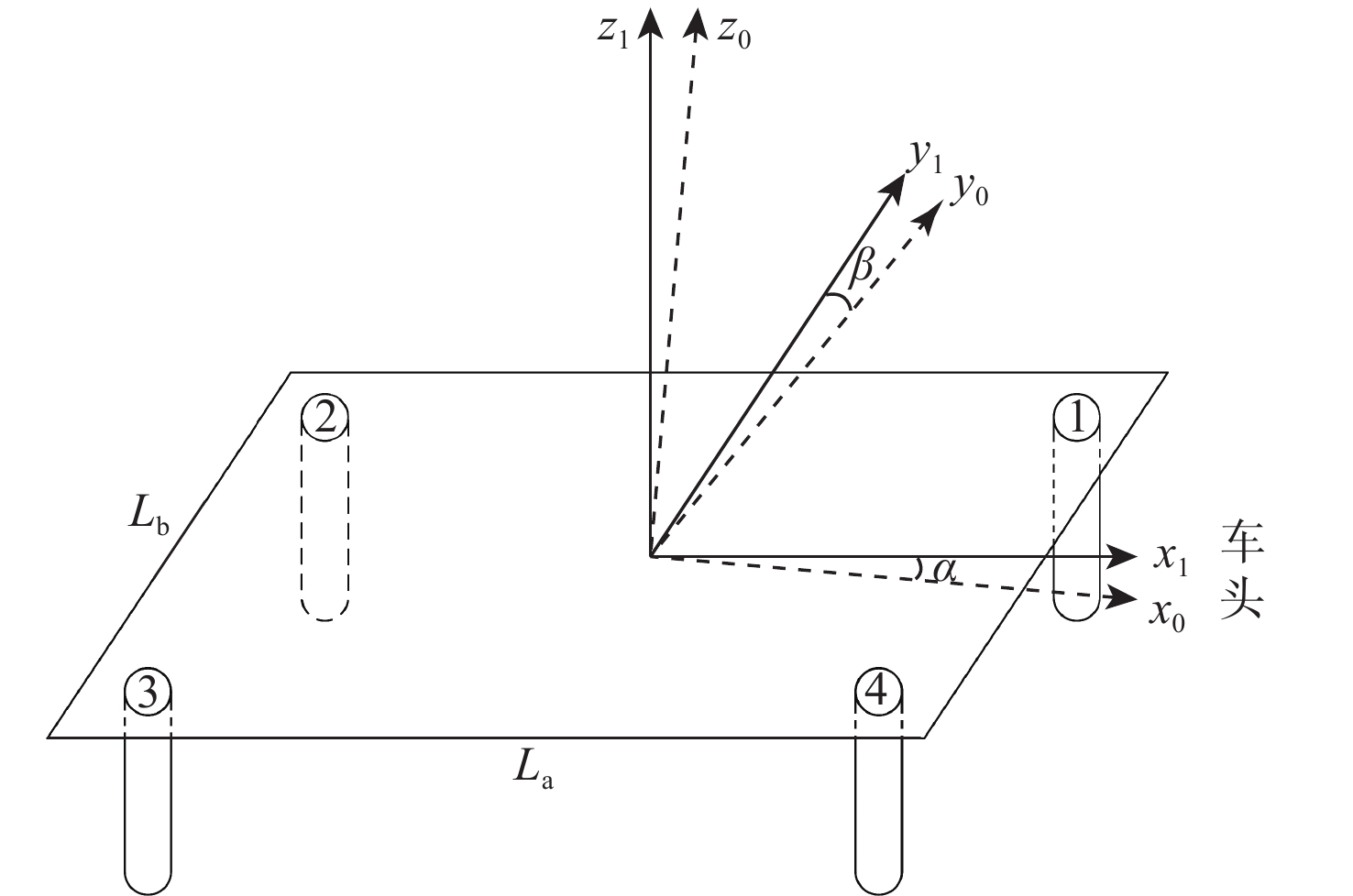

围绕车载平台重载工况下的快速调平需求,针对传统液压调平缸在大负载工况下调平精度不高的问题,采用电动缸使调平过程中由支腿变形产生的误差可以精确计算,提出了基于干扰补偿的车载平台快速调平控制策略。分析了4支点调平工况下的支腿缸负载特性,建立了电动缸形变误差模型,采用干扰补偿反馈方法修正调平误差,利用AMESim和MATLAB/Simulink软件对调平系统进行联合仿真验证,并搭建实验样机进行实验验证。结果表明:基于机械变形干扰补偿的4支点调平控制方法能使调平精度提高25%,调平时间缩短71.4%,使大负载大倾角情况下的车载平台在10 s内完成快速调平。

Abstract:Focusing on the fast leveling requirements of the vehicle-mounted platform under heavy load conditions, the error caused by the deformation of the legs during the leveling process can be accurately calculated by using electric cylinders. To solve the issue of the low leveling accuracy for traditional hydraulic leveling cylinders under heavy load conditions and increase accuracy, this study proposed a rapid leveling control strategy for the vehicle-mounted platform based on interference compensation. Moreover, the load characteristics of the outrigger cylinder under the four-point leveling condition were analyzed, the deformation error model of the electric cylinder was established, and the interference compensation feedback method was used to correct the leveling error. The leveling system was jointly simulated and verified by AMESim and MATLAB/Simulink software, and the experimental prototype was built for experimental verification. The results showed that the four-point leveling control method based on mechanical deformation interference compensation can increase the leveling accuracy by 25%, the leveling time can be shortened by 71.4%. Besides, the vehicle-mounted platform under the condition of large load and large inclination can be leveled quickly and completely in 10 s.

-

Key words:

- vehicle platform /

- electric cylinder /

- interference compensation /

- co-simulation /

- fast leveling

-

表 1 $\Delta {K}_{{\rm{P}}}$模糊规则

Table 1. Fuzzy rule of $\Delta {K}_{{\rm{P}}}$

e $ {e}_{{\rm{c}}} $ NB NM NS ZO PS PM PB NB PB PB PM PM PS ZO ZO NM PB PB PM PS PS ZO NS NS PM PM PM PS ZO NS NS ZO PM PM PS ZO NS NM NM PS PS PS ZO NS NS NM NM PM PS ZO NS NM NM NM NB PB ZO ZO NM NM NM NB NB 表 2 $\Delta {K}_{{\rm{I}}}$模糊规则

Table 2. Fuzzy rule of $\Delta {K}_{{\rm{I}}}$

e ${e}_{{\rm{c}}}$ NB NM NS ZO PS PM PB NB NB NB NM NM NS ZO ZO NM NB NB NM NS NS ZO ZO NS NB NM NS NS ZO PS PS ZO NM NM NS ZO PS PM PM PS NM NS ZO PS PS PM PB PM ZO ZO PS PS PM PB PB PB ZO ZO PS PM PM PB PB 表 3 $\Delta {K}_{{\rm{D}}}$模糊规则

Table 3. Fuzzy rule of $\Delta {K}_{{\rm{D}}}$

e ${e}_{{\rm{c}}}$ NB NM NS ZO PS PM PB NB PS NS NB NB NB NM PS NM PS NS NB NM NM NS ZO NS ZO NS NM NM NS NS ZO ZO ZO NS NS NS NS NS ZO PS ZO ZO ZO ZO ZO ZO ZO PM PB NS PS PS PS PS PB PB PB PM PM PM PS PS PB -

[1] 徐嵩. 发射车六点调平系统建模和控制算法研究[D]. 哈尔滨: 哈尔滨工业大学, 2017.XU S. Research on modeling and control algorithm of six-point leveling system of launch vehicle[D]. Harbin: Harbin Institute of Technology, 2017(in Chinese). [2] 徐瑞亮, 陈奎生, 刘洋, 等. 基于模糊PID算法的车载液压调平动态特性联合仿真研究[J]. 液压与气动, 2017(8): 112-117.XU R L, CHEN K S, LIU Y, et al. Co-simulation based on fuzzy PID algorithm for dynamic characteristic of vehicle hydraulic leveling[J]. Chinese Hydraulics & Pneumatics, 2017(8): 112-117(in Chinese). [3] 仕润霖, 冯永保, 李淑智, 等. 模糊PID控制的车载平台高精度动态调平仿真研究[J]. 机床与液压, 2013, 41(5): 150-153.SHI R L, FENG Y B, LI S Z, et al. High-precision dynamic leveling simulation of the vehicle platform controlled by fuzzy-PID[J]. Machine Tool & Hydraulics, 2013, 41(5): 150-153(in Chinese). [4] 陈晖, 汪启港, 杜恒, 等. 基于双阀并联控制的压机四角调平系统研究[J]. 液压与气动, 2021, 45(3): 127-134. doi: 10.11832/j.issn.1000-4858.2021.03.018CHEN H, WANG Q G, DU H, et al. Four-point leveling system of press based on double valve parallel control[J]. Chinese Hydraulics & Pneumatics, 2021, 45(3): 127-134(in Chinese). doi: 10.11832/j.issn.1000-4858.2021.03.018 [5] 罗艳蕾, 屠松庭, 石立明. 基于液压调平大阻尼系统的模糊PID控制研究[J]. 机床与液压, 2020, 48(15): 118-121.LUO Y L, TU S T, SHI L M. Research on fuzzy-PID control for large damping system based on hydraulic leveling[J]. Machine Tool & Hydraulics, 2020, 48(15) : 118-121(in Chinese). [6] 刘寒霜. 基于复杂环境下车载平台调平控制系统的研究[D]. 长沙: 中南林业科技大学, 2019: 15-35.LIU H S. Research on leveling control system of vehicle-mounted platform based on complex environment[D]. Changsha: Central South University of Forestry & Technology, 2019: 15-35(in Chinese). [7] 张启俊. 导弹发射车调平起竖系统建模及控制算法研究[D]. 哈尔滨: 哈尔滨工业大学, 2016: 12-30ZHANG Q J. Research on modeling and control algorithm of missile launch vehicle’s leveling and erecting system of missile launch vehicle[D]. Harbin: Harbin Institute of Technology, 2016: 12-30(in Chinese). [8] 刘更, 张文杰, 马尚君, 等. 行星滚柱丝杠副承载特性研究进展[J]. 机械科学与技术, 2017, 36(4): 598-604. doi: 10.13433/j.cnki.1003-8728.2017.0417LIU G, ZHANG W J, MA S J, et al. Review on load bearing characteristics of planetary roller screw mechanism[J]. Mechanical Science and Technology for Aerospace Engineering, 2017, 36(4): 598-604(in Chinese). doi: 10.13433/j.cnki.1003-8728.2017.0417 [9] 彭贺, 马文星, 王忠山, 等. 丘陵山地拖拉机车身调平控制仿真分析与试验[J]. 吉林大学学报(工学版), 2019, 49(1): 157-165.PENG H, MA W X, WANG Z S, et al. Simulation analysis and test of tractor body leveling control in hilly and mountainous areas[J]. Journal of Jilin University (Engineering and Technology Edition), 2019, 49(1): 157-165(in Chinese) . [10] 赵倩婷. 重载发射平台调平控制方法设计[D]. 南京: 南京理工大学, 2019: 10-25.ZHAO Q T. Design of leveling control method for heavy-duty launch platform[D]. Nanjing: Nanjing University of Science & Technology, 2019: 10-25(in Chinese). [11] 李翔宇, 肖峻, 潘运平, 等. 基于PSO的模糊PID车载平台调平控制系统研究[J]. 现代制造工程, 2021(2): 58-65.LI X Y, XIAO J, PAN Y P, et al. Research on leveling control system of fuzzy PID vehicle-mounted platform based on PSO[J]. Modern Manufacturing Engineering, 2021(2): 58-65(in Chinese). [12] 唐平建, 孙泽林, 宋鹏. 基于模糊PID的液压自动调平与升降控制系统研究[J]. 兵器装备工程学报, 2021, 42(2): 189-193.TANG P J, SUN Z L, SONG P. Research on hydraulic automatic leveling and lifting control system based on fuzzy PID[J]. Journal of Ordnance Equipment Engineering, 2021, 42(2): 189-193 (in Chinese). [13] 左都全, 钱利霞, 夏国峰, 等. 承重试验台同步加载系统设计计算及模糊PID耦合调平控制[J]. 计算力学学报, 2019, 36(2): 284-289.ZUO D Q, QIAN L X, XIA G F, et al. Coupling leveling controller design of a fuzzy PID-based synchronous loading system for load-bearing test rig[J]. Chinese Journal of Computational Mechanics, 2019, 36(2): 284-289(in Chinese). [14] 高歆杨, 柯芳, 邹伟, 等. 基于模糊控制策略的快速反射镜伺服控制[J]. 兵工学报, 2020, 41(8): 1529-1538. doi: 10.3969/j.issn.1000-1093.2020.08.007GAO X Y, KE F, ZOU W, et al. Servo control of fast steering mirror based on fuzzy control strategy[J]. Acta Armamentarii, 2020, 41(8): 1529-1538(in Chinese). doi: 10.3969/j.issn.1000-1093.2020.08.007 [15] 张杰, 袁东, 张朋, 等. 双侧电传动履带车辆模糊前馈-反馈转向控制[J]. 兵工学报, 2020, 41(8): 1688-1696. doi: 10.3969/j.issn.1000-1093.2020.08.023ZHANG J, YUAN D, ZHANG P, et al. Steering control based on fuzzy feedforward and feedback for dual-motor electric drive tracked vehicle[J]. Acta Armamentarii, 2020, 41(8): 1688-1696(in Chinese). doi: 10.3969/j.issn.1000-1093.2020.08.023 [16] 杨家军, 韦振兴, 朱继生, 等. 行星滚柱丝杠副载荷分布及刚度计算[J]. 华中科技大学学报(自然科学版), 2011, 39(4): 1-4.YANG J J, WEI Z X, ZHU J S, et al. Calculation of load distribution of planetary roller screws and static rigidity[J]. Journal of Huazhong University of Science and Technology (Natural Science Edition), 2011, 39(4): 1-4(in Chinese) . [17] 杨恺. 超大载荷电动缸技术及其在试验机上的应用研究[D]. 长春: 吉林大学, 2017.YANG K. Research on the technology of super-load electric cylinder technology and its application in testing machine[D]. Changchun: Jilin University, 2017(in Chinese) . [18] HARRIS T A, KOTZALAS M N. 滚动轴承分析: 轴承技术的基本概念[M]. 罗继伟, 马伟, 等译. 北京: 机械工业出版社, 2010.HARRIS T A, KOTZALAS M N. Essential concepts of bearing technology[M]. LUO J W, MA W, et al. translated. Beijing: China Machine Press, 2010(in Chinese). -

下载:

下载: