Influence of mistuning bolted joints on dynamic characteristics of thin-walled cylinder

-

摘要:

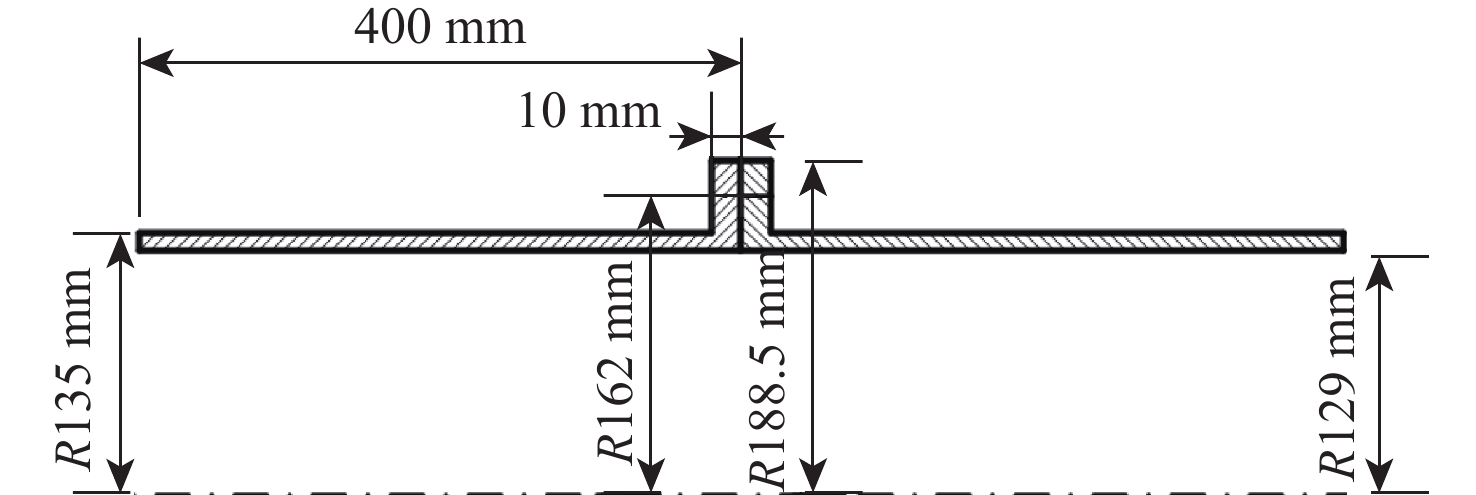

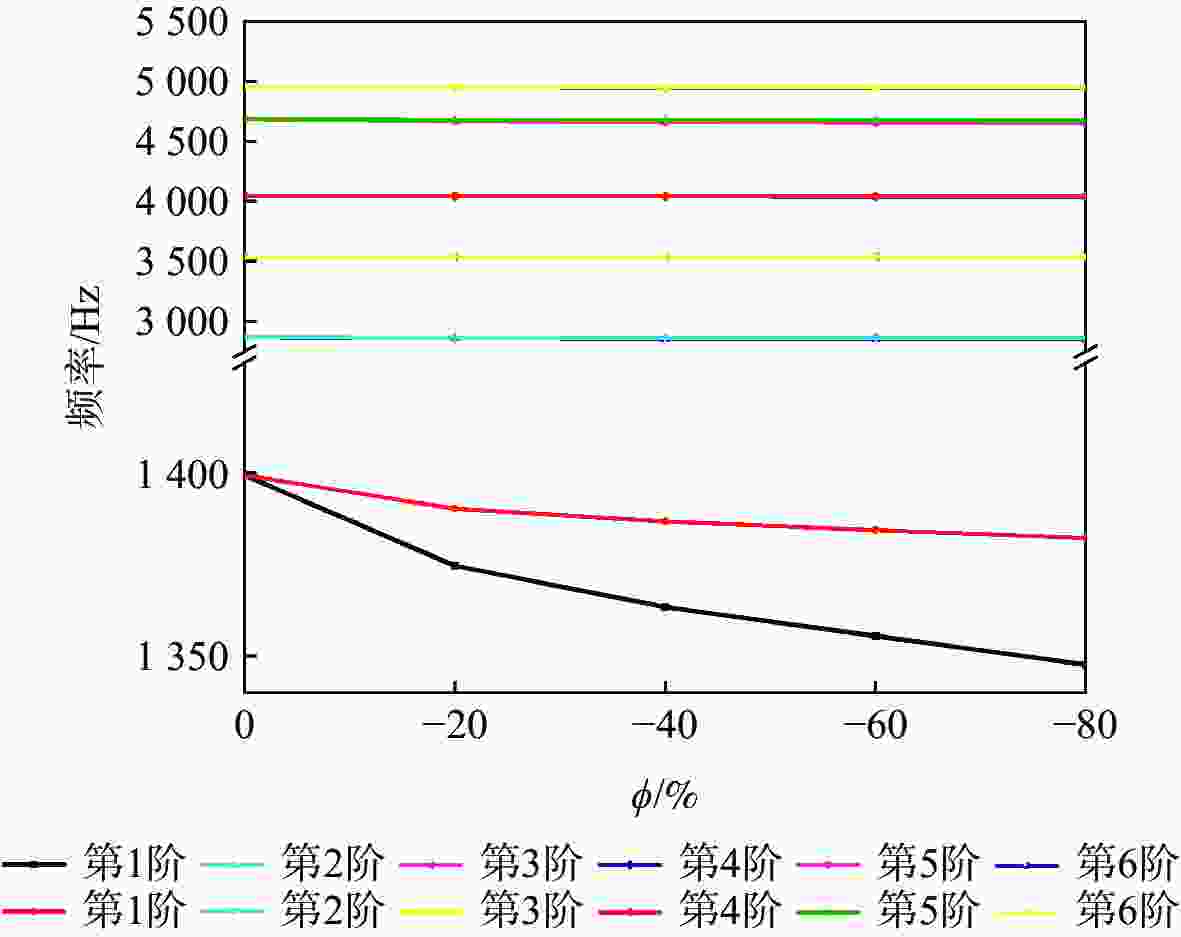

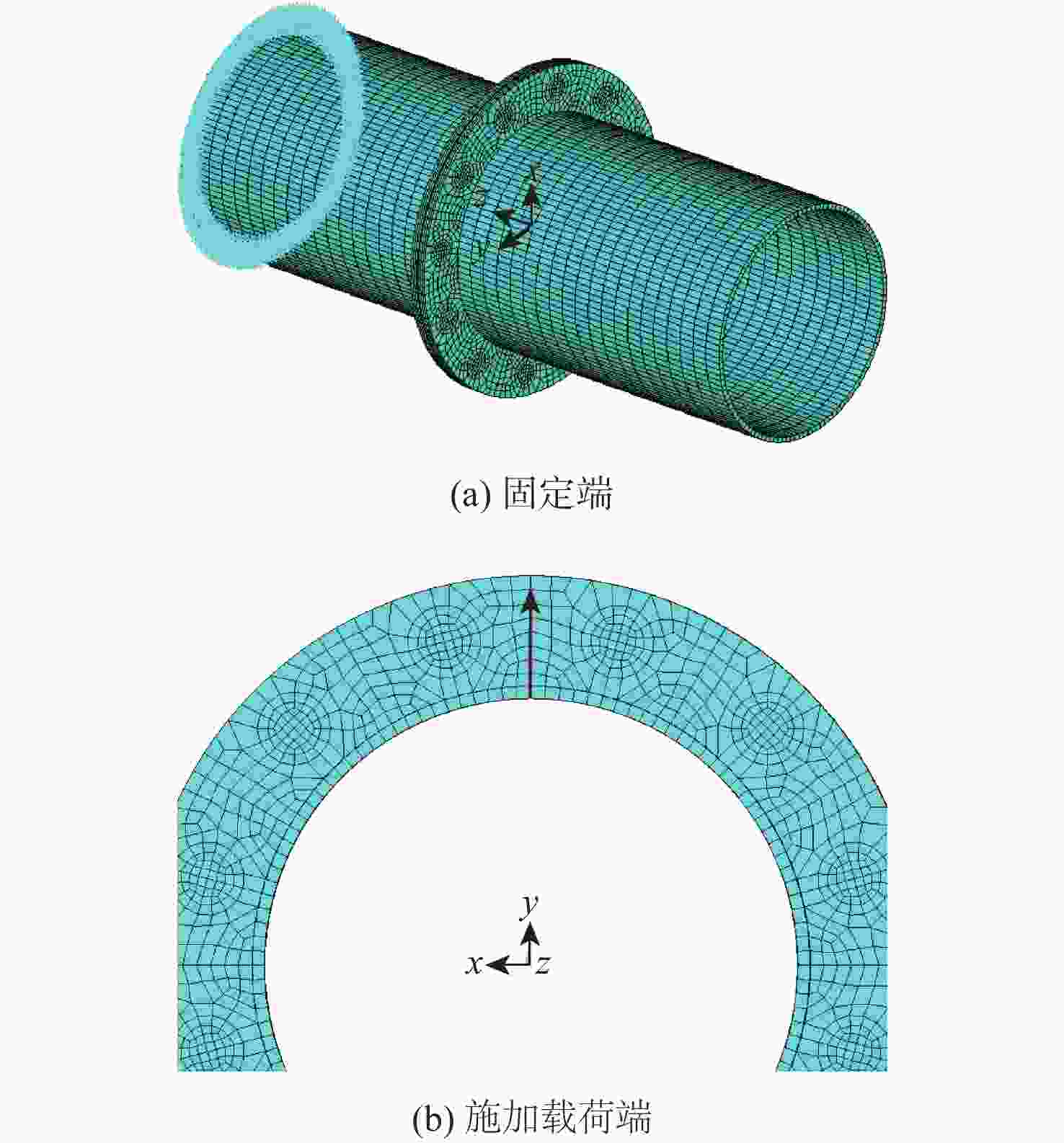

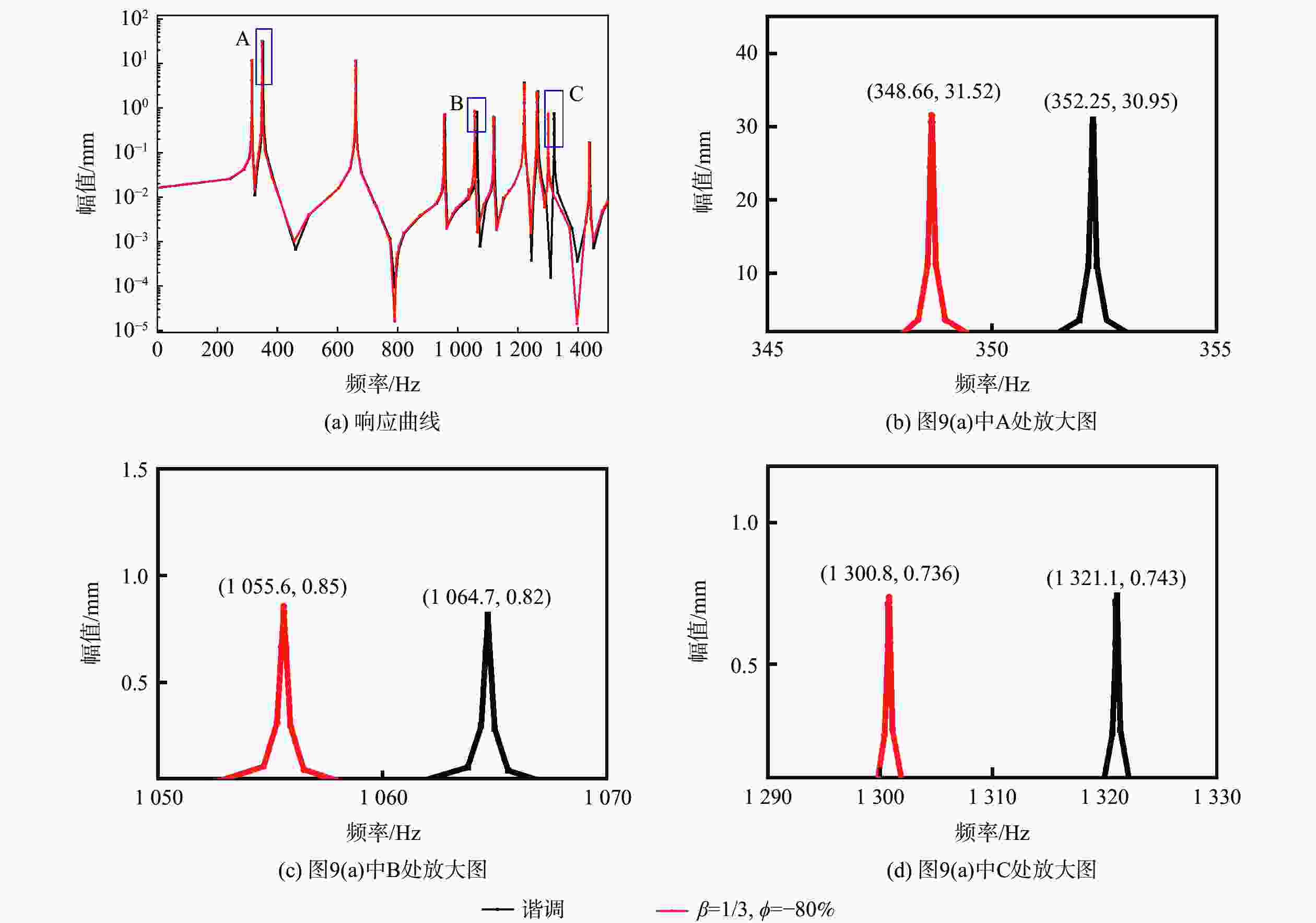

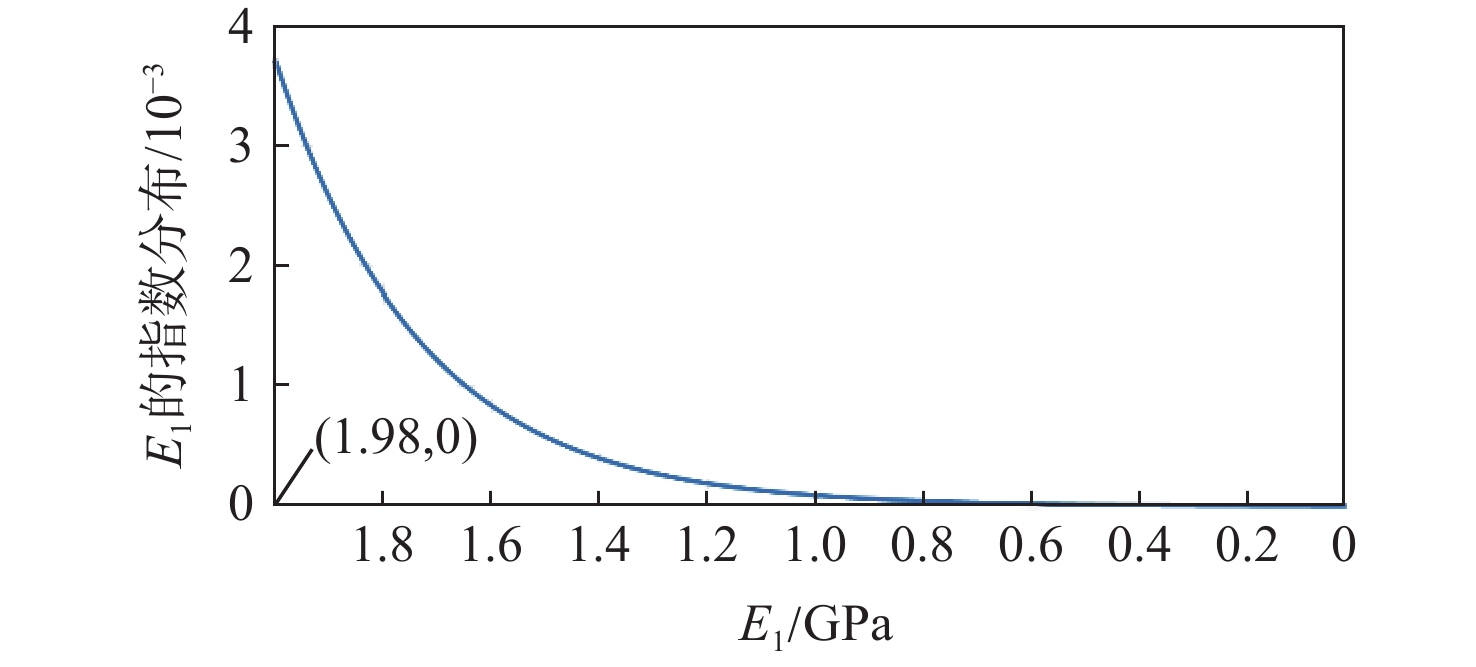

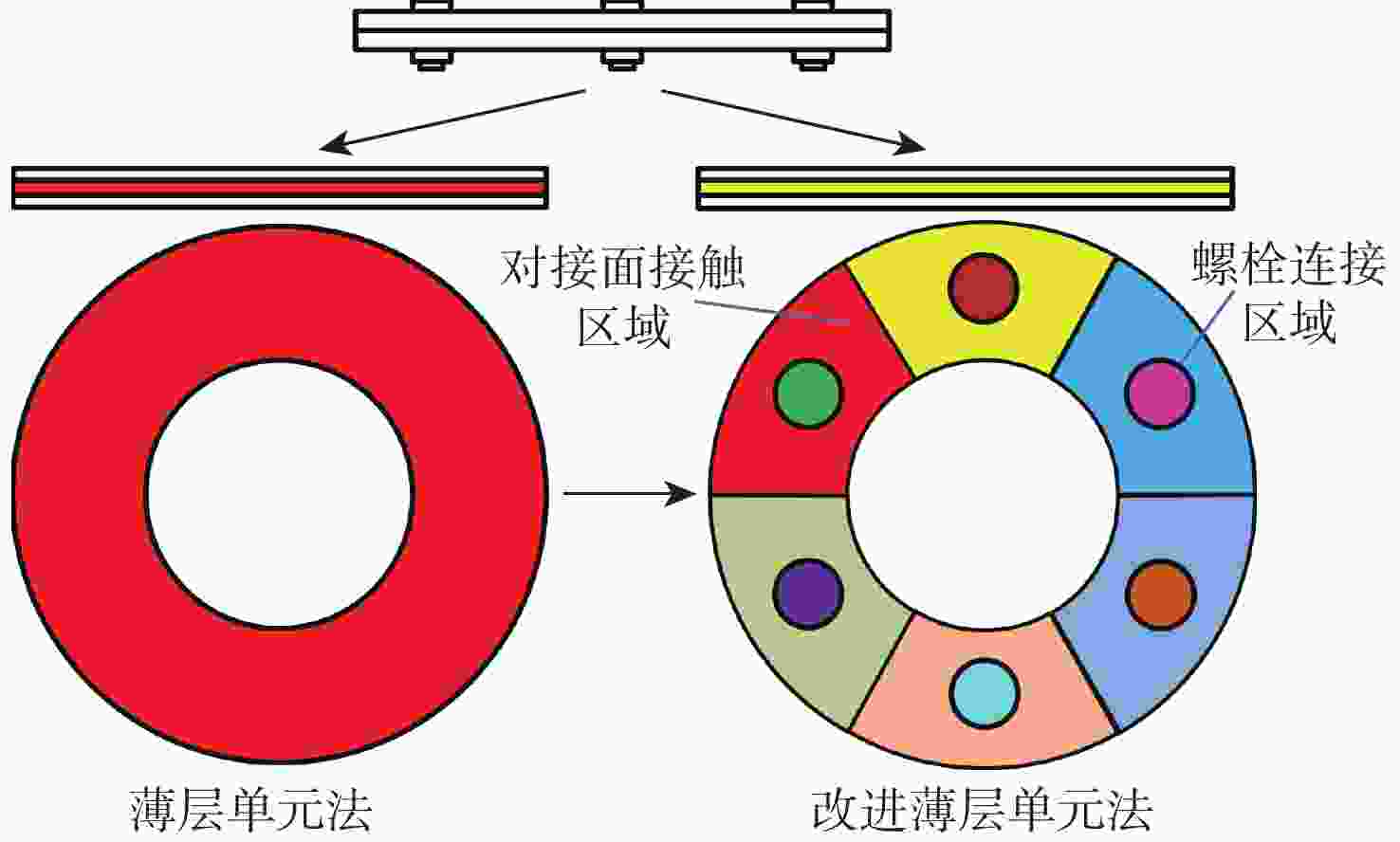

螺栓连接结构的性能退化是航空发动机安全运行必须考虑的问题,螺栓连接预紧失谐这个概念可以表征螺栓连接结构的性能退化,并用预紧失谐量和预紧失谐比例说明预紧失谐的状态。在此基础上,将预紧失谐的概念与螺栓连接改进薄层单元法相结合,研究失谐螺栓连接对薄壁圆筒动力特性的影响。针对预紧失谐对薄壁圆筒的确定性动力特性进行分析,包括固有特性、稳态响应的影响,考虑螺栓预紧力的随机性,研究失谐螺栓连接对薄壁圆筒的概率性动力特性分析。研究结果表明:薄壁圆筒同阶固有频率的分离程度随着预紧失谐量的减小而增大,随着预紧失谐比例的增大呈现“双峰”特点;预紧失谐使得薄壁圆筒响应峰值对应的频率减小但幅值增大,随机预紧失谐使得响应峰值点的频带更宽,并且输入参数为指数分布时,输出参数为威布尔分布。

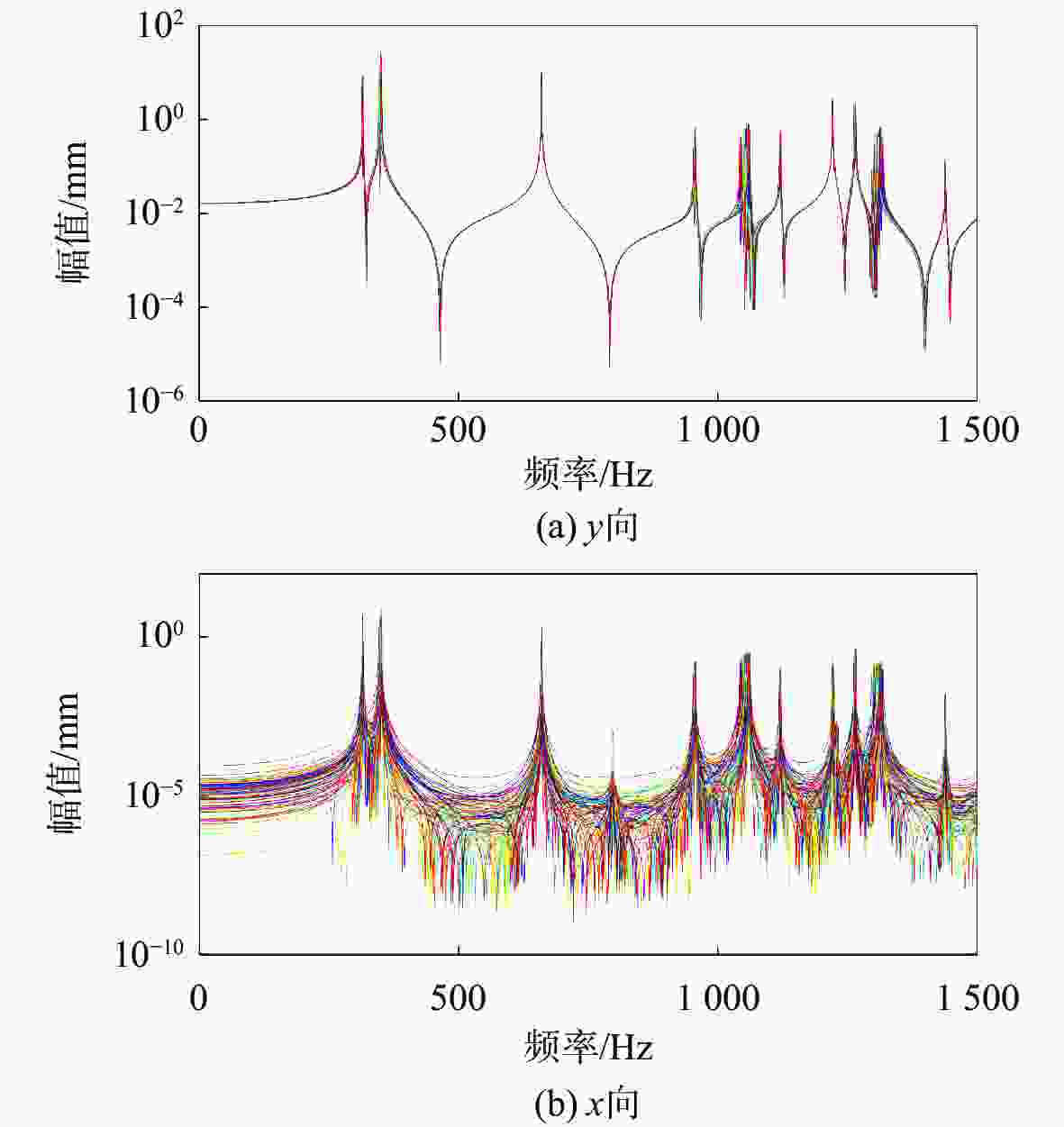

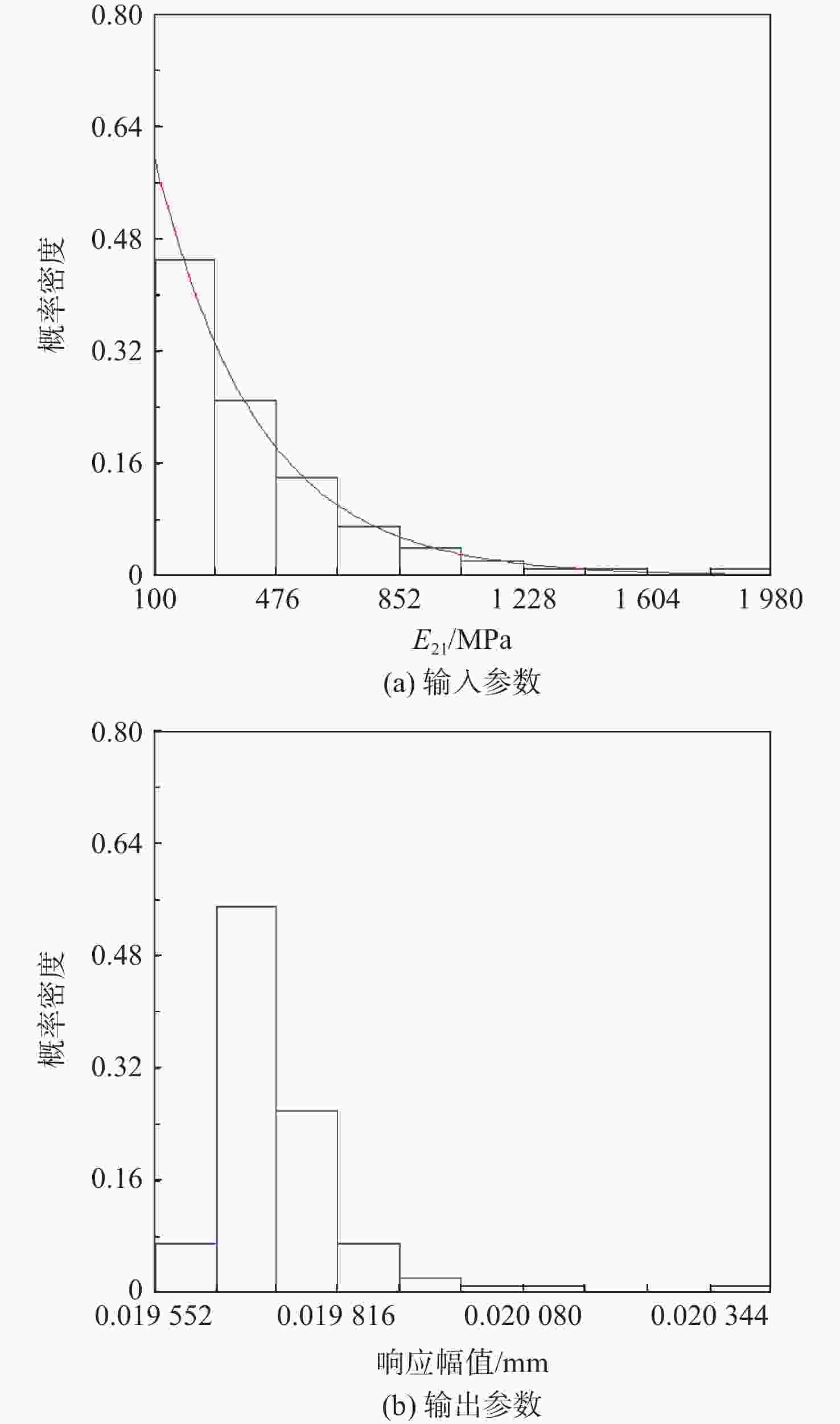

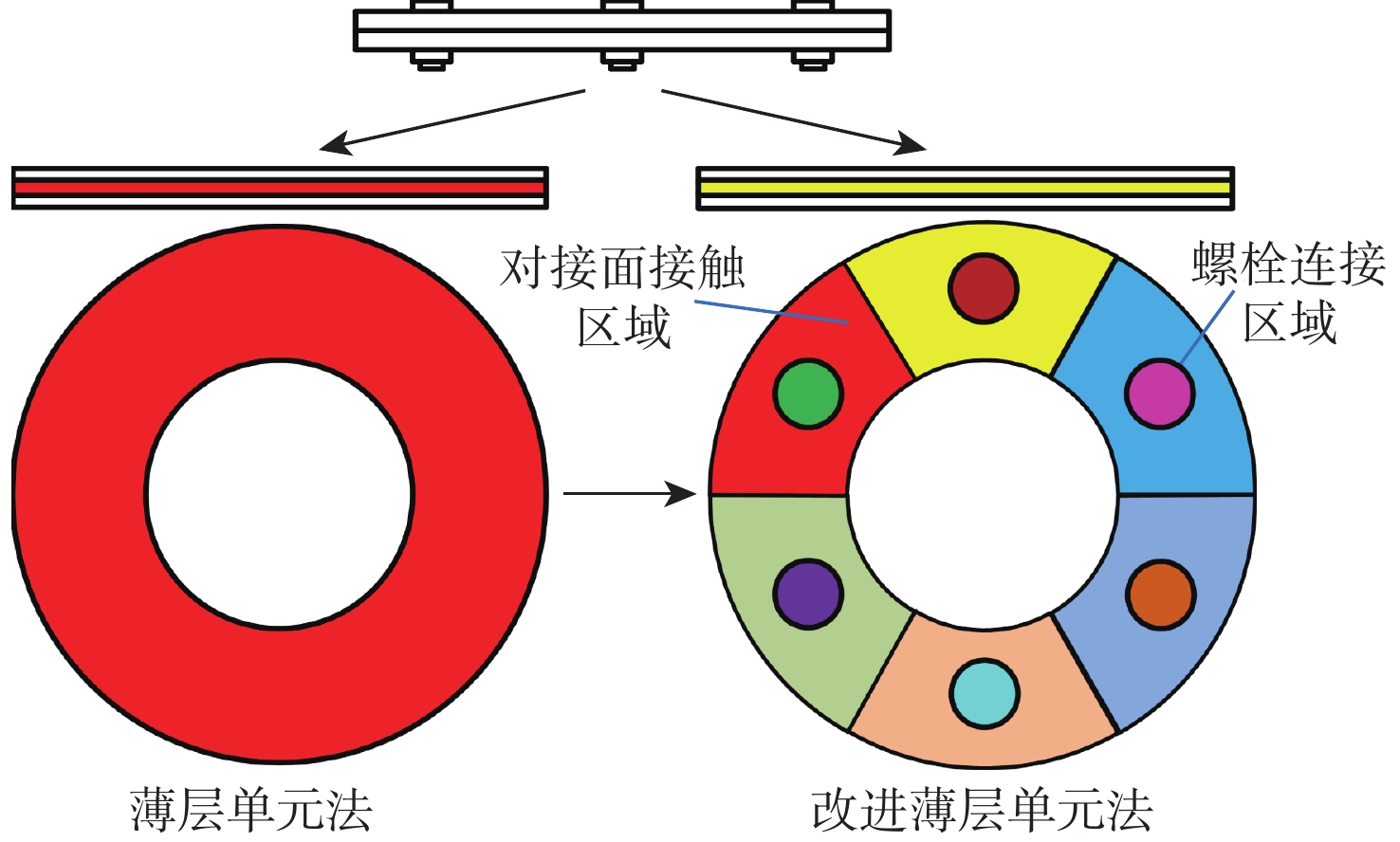

Abstract:The performance degradation of bolted joints is a problem which should be considered for the safety of aero-engine. The concept of preload mistuning of bolted joints can characterize the performance degradation, and the preload mistuning amplitude and the preload mistuning ratio are used to illustrate the state of the preload mistuning. The influence of mistuning bolted joints on the dynamic characteristics of thin-walled cylinder was studied based on the combination of preload mistuning with the improved thin-layer element method of bolted joints. First of all, the deterministic analysis of the influence of preload mistuning on the thin-walled cylinder was proposed, including the influence of the natural frequency and steady-state response. Moreover, the influence of preload mistuning on the probabilistic response characteristics of thin-walled cylinder was researched considering the randomness of bolt preload. The results indicate that the separation degree of the same-order natural frequency of thin-walled cylinder increases with the decrease of preload mistuning amplitude, and presents a “double peak” characteristic with the increase of preload mistuning ratio. The preload mistuning makes the frequency corresponding to the response peak of thin-walled cylinder reduce but the amplitude increase. The random preload mistuning makes the frequency band of the response peak point wider, and when the input parameter is exponential distribution, the output parameter is Weibull distribution.

-

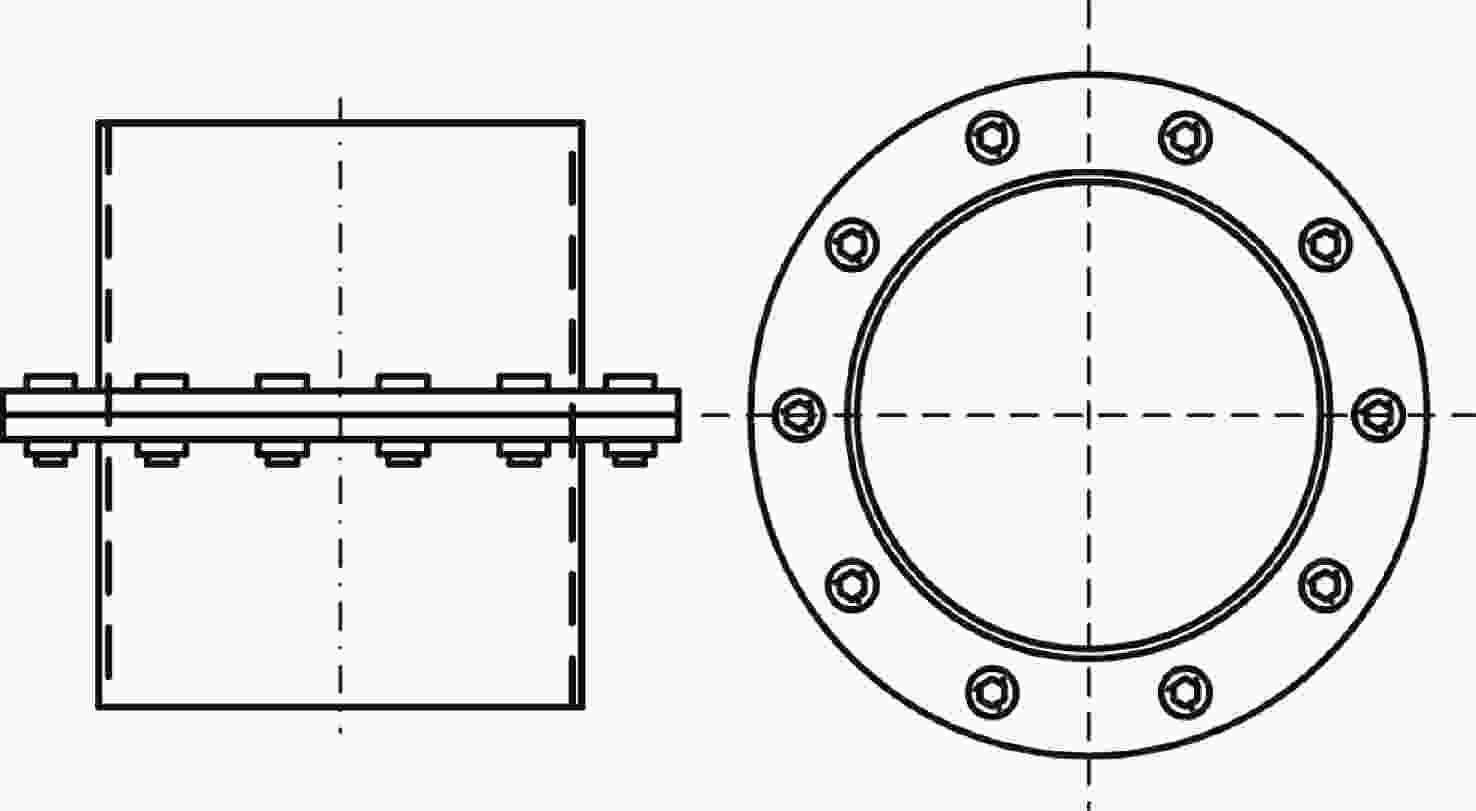

表 1 圆筒和螺栓的材料参数

Table 1. Material parameters of cylinder and bolts

参数 数值 弹性模量 E/GPa 195 泊松比 $\nu $ 0.3 密度 $\rho $/(kg·m−3) 7850 表面粗糙度 ${R_{\rm{a}}}$/${\text{μm} }$ 0.9 屈服极限 ${\sigma _{0.2}}$/MPa 355 硬度 H/MPa 570 表 2 薄层单元的材料参数

Table 2. Material parameters of thin-layer elements

F/N E/GPa G/GPa 螺栓连接

区域对接面接触

区域螺栓连接

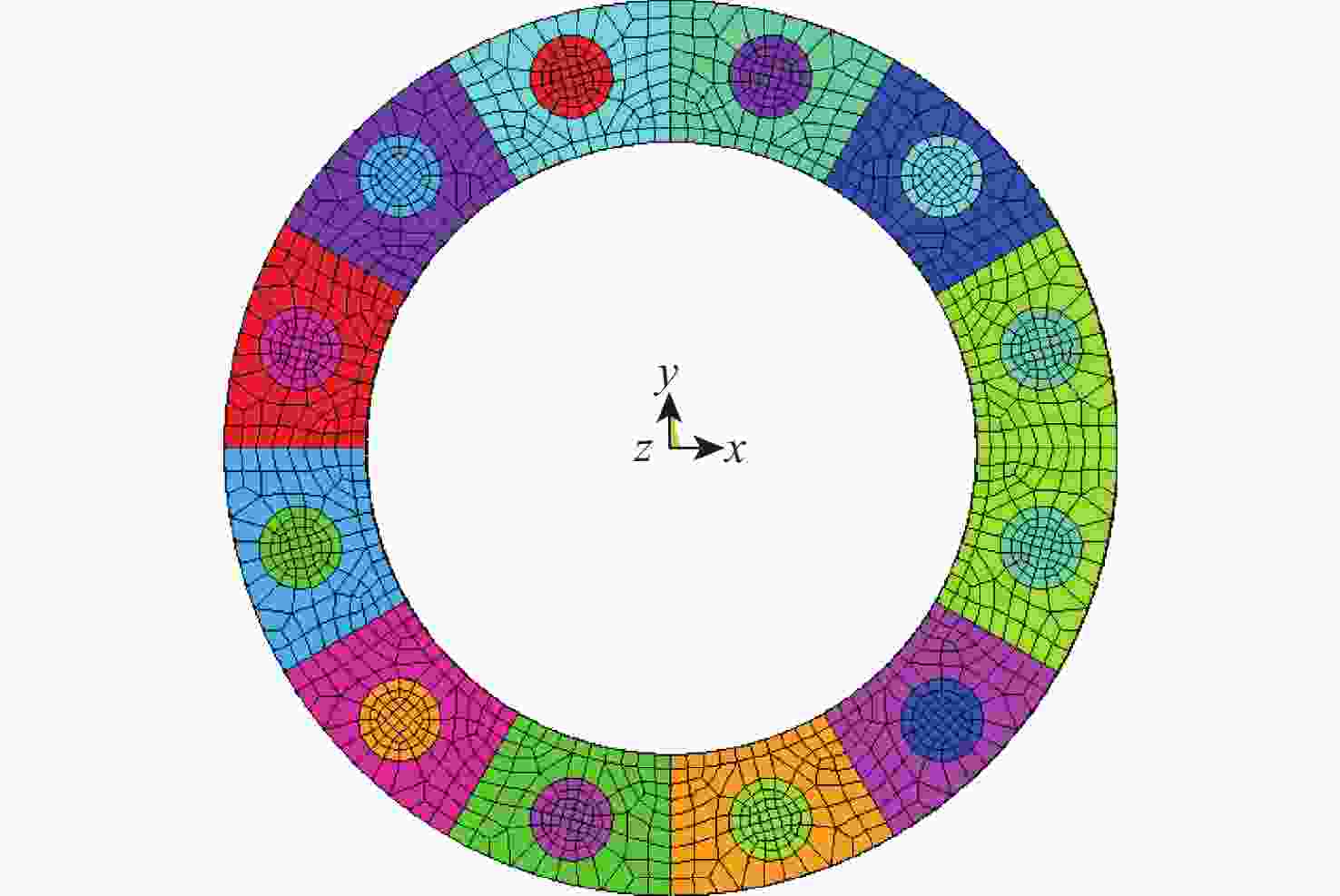

区域对接面接触

区域25 000 14.13 1.976 4.39 0.760 20 000 14.80 1.132 5.69 0.435 15 000 15.72 0.911 6.05 0.350 10 000 16.25 0.791 6.25 0.304 5 000 16.75 0.691 6.44 0.266 表 3 不同

$\beta $ 和$\phi $ 下薄壁圆筒的前6阶固有频率Table 3. The first 6-order natural frequencies of thin-walled cylinder under different

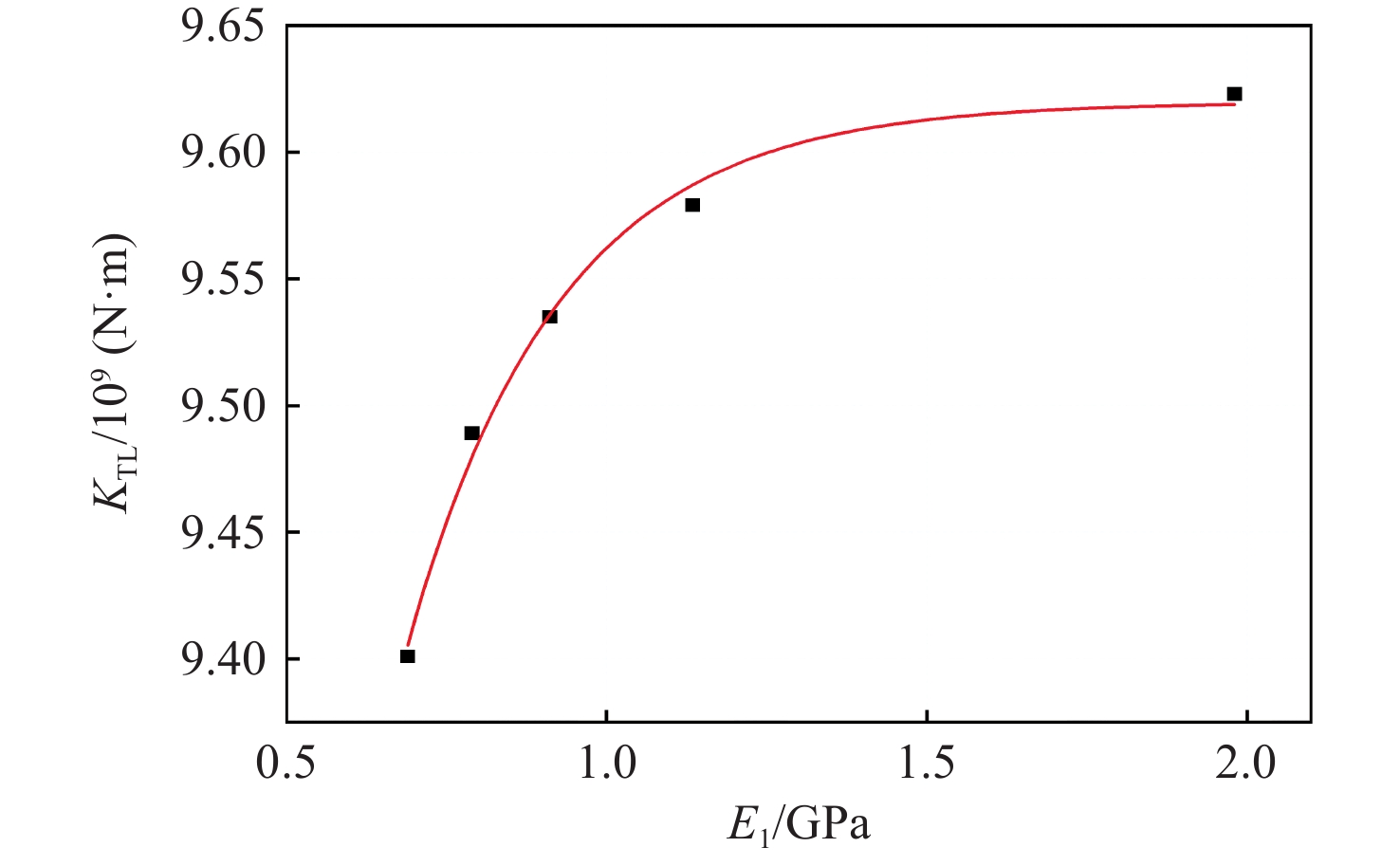

$\beta $ and$\phi $ $\beta $ $\phi $/% 固有频率/Hz 第1阶 第2阶 第3阶 第4阶 第5阶 第6阶 0 0 1 399.28 2 864.41 3 536.57 4045.11 4685.78 4 956.10 1/6 −20 1 384.42 2 859.87 3 536.48 4 044.03 4 675.44 4 952.45 1 398.16 2 863.85 3 536.58 4 044.39 4 684.99 4 955.62 −40 1 378.25 2 858.42 3 536.44 4 043.66 4 671.14 4 951.28 1 397.71 2 863.68 3 536.57 4 044.12 4 684.67 4 955.47 −60 1 374.14 2 857.54 3 536.41 4 043.45 4 668.26 4 950.58 1 397.43 2 863.58 3 536.57 4 043.96 4 684.47 4 955.38 −80 1 370.21 2 856.73 3 536.39 4 043.25 4 665.50 4 949.95 1 397.18 2 863.49 3 536.57 4 043.82 4 684.29 4 955.29 1/3 −20 1 374.61 2 857.12 3536.42 4 042.99 4 668.81 4 950.14 1 390.24 2 861.32 3536.52 4 043.36 4 679.39 4 953.57 −40 1 363.38 2 854.69 3 536.35 4 042.28 4 661.21 4 948.11 1 386.70 2 860.34 3 536.49 4 042.77 4 676.84 4 952.76 −60 1 355.51 2 853.19 3 536.30 4 041.86 4 655.94 4 946.85 1 384.41 2 859.74 3 536.47 4 042.41 4 675.17 4 952.88 −80 1 347.69 2 851.80 3 536.26 4 041.48 4 650.74 4 945.67 1 382.27 28 59.19 3 536.45 4 042.09 4 673.59 4 951.83 1/2 −20 1 372.46 2 856.47 3 536.40 4 042.13 4 667.48 4 949.54 1 374.66 2 856.70 3 536.40 4 042.15 4 668.30 4 949.77 −40 1 359.79 2 853.78 3 536.32 4 041.15 4 659.13 4 947.25 1 364.37 2 854.12 3 536.33 4 041.17 4 660.80 4 947.67 −60 1 350.74 2 852.11 3 536.27 4 040.55 4 653.28 4 945.80 1 357.46 2 852.63 3 536.28 4 040.59 4 653.69 4 946.38 −80 1 341.57 2 850.55 3 536.22 4 040.02 4 647.45 4 944.44 1 350.82 2 851.20 3 536.23 4 040.06 4 650.73 4 945.18 2/3 −20 1 358.51 2 851.94 3 536.28 4 040.94 4 656.59 4 946.04 1 371.43 2 855.93 3 536.39 4 041.29 4 666.58 4 949.08 −40 1 340.96 2 847.80 3 536.15 4 039.58 4 643.47 4 942.73 1 358.56 2 853.07 3 536.30 4 040.03 4 657.91 4 946.65 −60 1329.11 2 845.25 3 536.07 4 038.77 4 634.36 4 940.73 1349.44 2 851.29 3 536.25 4 039.27 4 651.86 4 945.12 −80 1317.80 2 842.89 3 535.98 4 038.04 4 625.33 4 938.95 1340.23 2 849.63 3 536.20 4 038.58 4 625.85 4 943.68 表 4 不同预紧力F下螺栓连接处的数据

Table 4. Data of bolted joints under different preloads F

F/kN 螺栓区域

半径/mm${A_2}$

/mm2${A_1}$

/mm2${K_{{\text{TL}}}}$/

(109 N·m)${E_2}$

/GPa${E_1}$

/GPa5 17.63 976.46 3969.26 9.351 16.350 0.689 10 17.63 976.46 3969.26 9.439 16.121 0.790 15 17.63 976.46 3969.26 9.485 15.722 0.911 20 17.63 976.46 3969.26 9.529 14.908 1.130 25 17.63 976.46 3969.26 9.573 11.559 1.980 -

[1] 陈予恕, 张华彪. 航空发动机整机动力学研究进展与展望[J]. 航空学报, 2011, 32(8): 1371-1391.CHEN Y S, ZHANG H B. Review and prospect on the research of dynamics of complete aero-engine systems[J]. Acta Aeronautica et Astronautica Sinica, 2011, 32(8): 1371-1391(in Chinese). [2] 曹鹏. 带非线性支承转子系统动力学特性研究[D]. 北京: 北京航空航天大学, 2013.CAO P. Research on dynamic characteristics of rotor system with nonlinear supports[D]. Beijing: Beihang University, 2013(in Chinese). [3] 樊宁. 航空发动机连接结构刚度非线性及其对转子动力学的影响[D]. 北京: 北京航空航天大学, 2013.FAN N. Studies on dynamic characteristics of the joint in the aero-engine rotor system[D]. Beijing: Beihang University, 2013(in Chinese). [4] IBRAHIM R A, PETTIT C L. Uncertainties and dynamic problems of bolted joints and other fasteners[J]. Journal of Sound and Vibration, 2005, 279(3-5): 857-936. [5] 姚星宇, 程涵. 谐调螺栓连接对航空发动机静子系统动力学特性影响[J]. 科学技术与工程, 2021, 21(16): 6913-6922. doi: 10.3969/j.issn.1671-1815.2021.16.054YAO X Y, CHENG H. Influence of tuned bolted joints on dynamic characteristics of aero-engine stator system[J]. Science Technology and Engineering, 2021, 21(16): 6913-6922(in Chinese). doi: 10.3969/j.issn.1671-1815.2021.16.054 [6] 苏永雷. 拉杆松弛与组合转子性能退化的关联性研究[D]. 长沙: 中南大学, 2014.SU Y L. The correlation research of rod relaxation and performance degradation of combined rotor[D]. Changsha: Central South University, 2014(in Chinese). [7] 苏永雷, 王艾伦, 曾海楠. 拉杆松弛导致预紧失谐组合转子性能退化研究[J]. 振动与冲击, 2015, 34(20): 21-26. doi: 10.13465/j.cnki.jvs.2015.20.005SU Y L, WANG A L, ZENG H N. Performance degradation of mistuned combined rotor considering rod relaxation[J]. Journal Vibration and Shock, 2015, 34(20): 21-26(in Chinese). doi: 10.13465/j.cnki.jvs.2015.20.005 [8] GAUL L, LENZ J. Nonlinear dynamics of structures assembled by bolted joints[J]. Acta Mechanica, 1997, 125(1-4): 169-181. [9] WANG C, ZHANG D Y, ZHU X B, et al. Study on the stiffness loss and the dynamic influence on rotor system of the bolted flange joint[C]//ASME Turbo Expo 2014: Turbine Technical Conference and Exposition. New York: ASME, 2014. [10] MCCARTHY M A, MCCARTHY C T, LAWLOR V P, et al. Three-dimensional finite element analysis of single-bolt, single-lap composite bolted joints: Part I-Model development and validation[J]. Composite Structures, 2005, 71(2): 140-158. [11] AHMADIAN H, JALALI H. Identification of bolted lap joints parameters in assembled structures[J]. Mechanical Systems and Signal Processing, 2007, 21(2): 1041-1050. [12] SCHWINGSHACKL C W, MAIO D D, SEVER I, et al. Modeling and validation of the nonlinear dynamic behavior of bolted flange joints[J]. Journal of Engineering for Gas Turbines and Power, 2013, 135(12): 122504. [13] 姚星宇, 王建军, 翟学. 航空发动机螺栓连接薄层单元建模方法[J]. 北京航空航天大学学报, 2015, 41(12): 2269-2279. doi: 10.13700/j.bh.1001-5965.2014.0796YAO X Y, WANG J J, ZHAI X. Modeling method of bolted joints of aero-engine based on thin-layer element[J]. Journal of Beijing University of Aeronautics and Astronautics, 2015, 41(12): 2269-2279(in Chinese). doi: 10.13700/j.bh.1001-5965.2014.0796 [14] 郭宁, 黄庆, 曹善成, 等. 基于模型修正的螺栓连接板结构动力学建模方法[J]. 工程力学, 2021, 38(6): 1-9. doi: 10.6052/j.issn.1000-4750.2020.04.ST01GUO N, HUANG Q, CAO S C, et al. Structural dynamic modeling method of bolted joint plates based on model updating[J]. Engineering Mechanics, 2021, 38(6): 1-9(in Chinese). doi: 10.6052/j.issn.1000-4750.2020.04.ST01 [15] YAO X Y, WANG J J, ZHAI X. Research and application of improved thin-layer element method of aero-engine bolted joints[J]. Proceedings of the Institution of Mechanical Engineers, Part G:Journal of Aerospace Engineering, 2017, 231(5): 823-839. doi: 10.1177/0954410016643978 -

下载:

下载: