-

摘要:

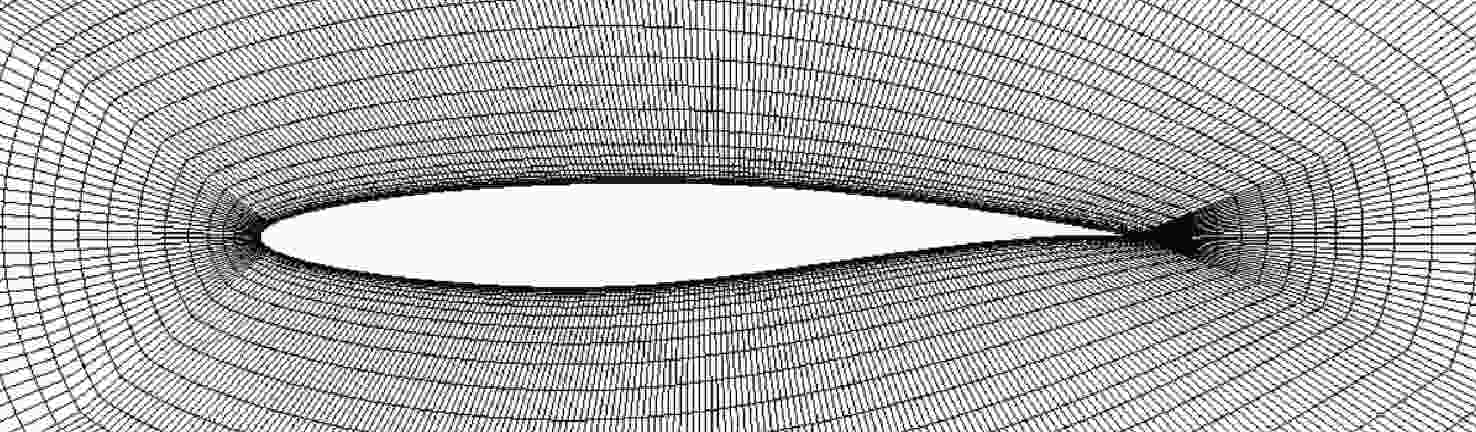

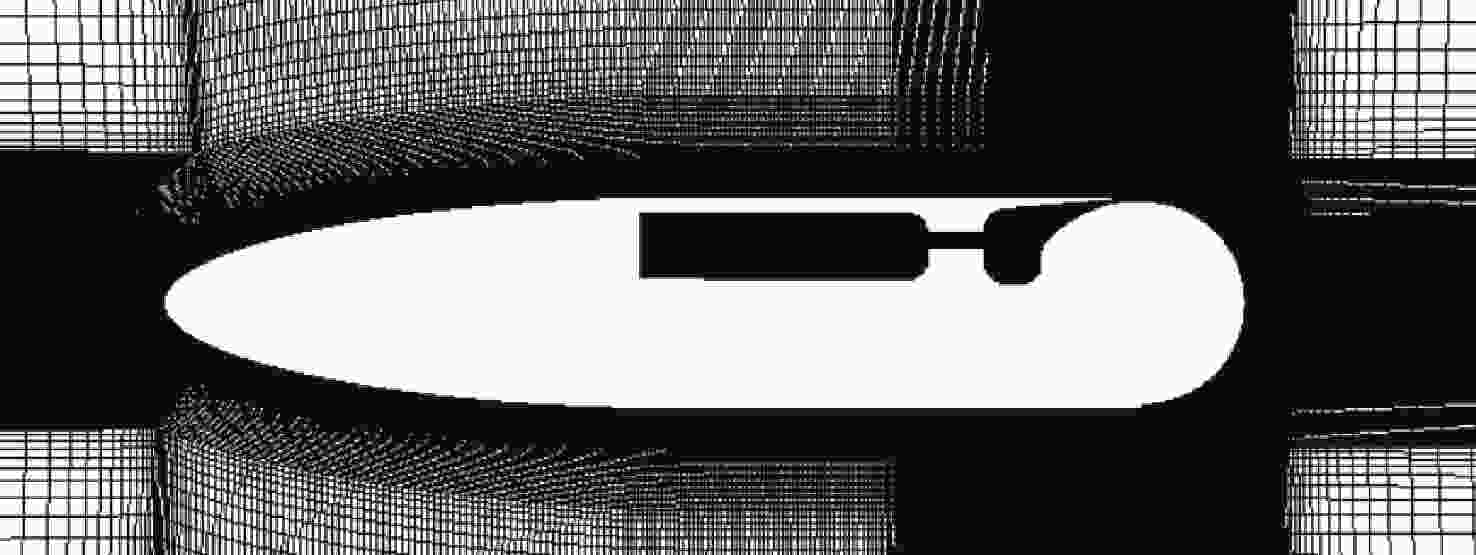

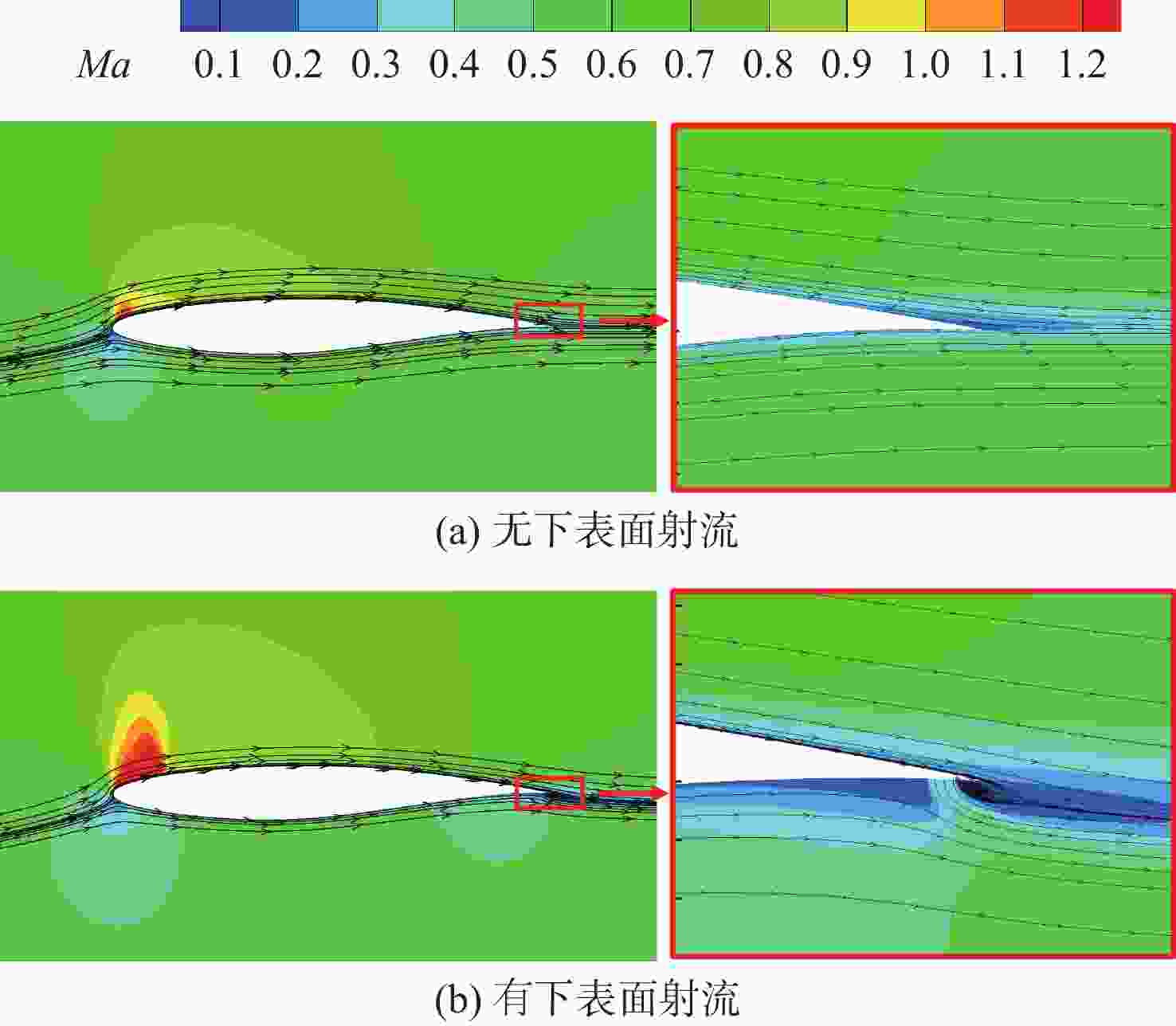

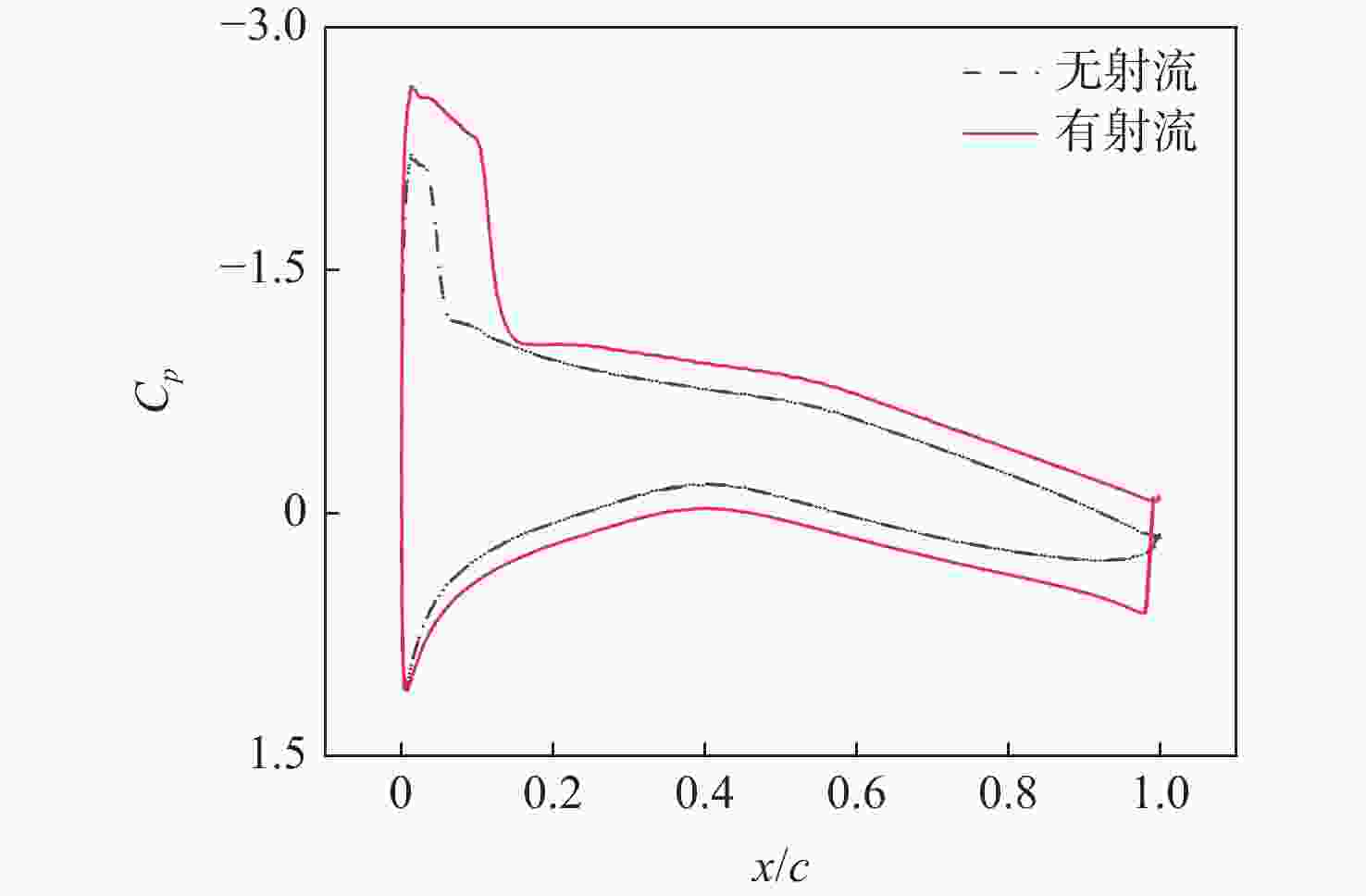

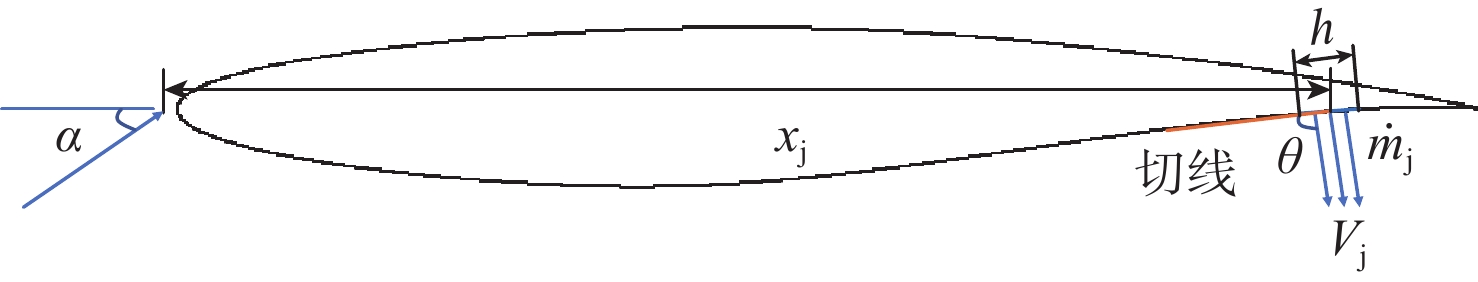

为探究下表面射流关键参数对超临界翼型气动性能的影响,采用雷诺平均Navier-Stokes (RANS)方程与Spalart-Allmaras (S-A)湍流模型进行数值模拟。通过比较基准RAE2822翼型与下表面射流翼型的流场,验证下表面射流能够在翼型后缘诱导产生逆时针分离涡,带动流线向下偏折,增加了翼型的等效弯度,同时加大前缘的吸力峰,从而提高翼型的气动性能。进一步探究射流位置、射流动量系数、射流角度、马赫数等关键参数对RAE2822翼型气动性能的影响规律。结果表明:给定状态下,下表面射流的位置越靠后,动量系数越大,翼型的气动性能越优。下表面射流在

α =0°和2°时的最优射流角度为110°,在α =4°时的最优射流角度为160°,且在最优射流角度下能有效提高翼型马赫数在0.3~0.6范围内的气动性能。-

关键词:

- 主动流动控制 /

- 下表面射流 /

- 超临界翼型 /

- 气动性能 /

- 雷诺平均Navier-Stokes

Abstract:To investigate the influence of key parameters of the lower surface jet on aerodynamic performance of supercritical airfoil, a numerical simulation is performed using Reynolds average Navier-Stokes (RANS) equation and Spalart-Allmaras (S-A) turbulence model. By comparing the flow field between the benchmark RAE2822 airfoil and the lower surface jet airfoil, the lower surface jet induces a counterclockwise separation vortex at the trailing edge of the airfoil, deflecting the streamlines downward. This deflection increases the equivalent camber of the airfoil and the suction peak of the leading edge, leading to the aerodynamic performance enhancement of the airfoil. The effects of key parameters such as the jet position, the jet momentum coefficient, the jet angle and the Mach number on the aerodynamic performance of RAE2822 airfoil are explored. The results show that under given conditions, the closer the lower surface jet is to the trailing edge and the greater the momentum coefficient is, the better the aerodynamic performance of the airfoil. The optimal angle of the lower surface jet is 110° at

α =0° and 2°, and 160° atα =4°. The aerodynamic performance of the airfoil can be effectively improved at the optimal angles with the Mach number varied from 0.3 to 0.6. -

表 1 RAE2822翼型网格参数与气动力系数的对比

Table 1. Comparison of grid parameters and aerodynamic coefficients of RAE2822 airfoil

网格 网格数量 CL CD 实验值[21] 0.803 0.0168 粗网格 23324 0.76031 0.016989 中等网格 40964 0.76652 0.017031 细网格 69188 0.76928 0.017094 注:3套网格与实验值相比,CL误差5.3%,4.5%,4.2%,CD误差为1.1%,1.3%,1.8%。 表 2 CC020-010EJ翼型气动力系数的对比

Table 2. Comparison of aerodynamic coefficients of CC020-010EJ airfoil

表 3 下表面射流计算参数

Table 3. Computational parameters of lower surface jet

Ma Re α/(°) cμ xj θ/(°) 0.6 5.35×106 4 0.005 0.98c 90 表 4 不同射流位置下的计算参数

Table 4. Computational parameters of different jet positions

Ma Re α/(°) cμ xj θ/(°) 0.6 5.35×106 −4~16 0.005 0.8c,0.9c,0.98c 90 表 5 不同射流动量系数下的计算参数

Table 5. Computational parameters of different jet momentum coefficients

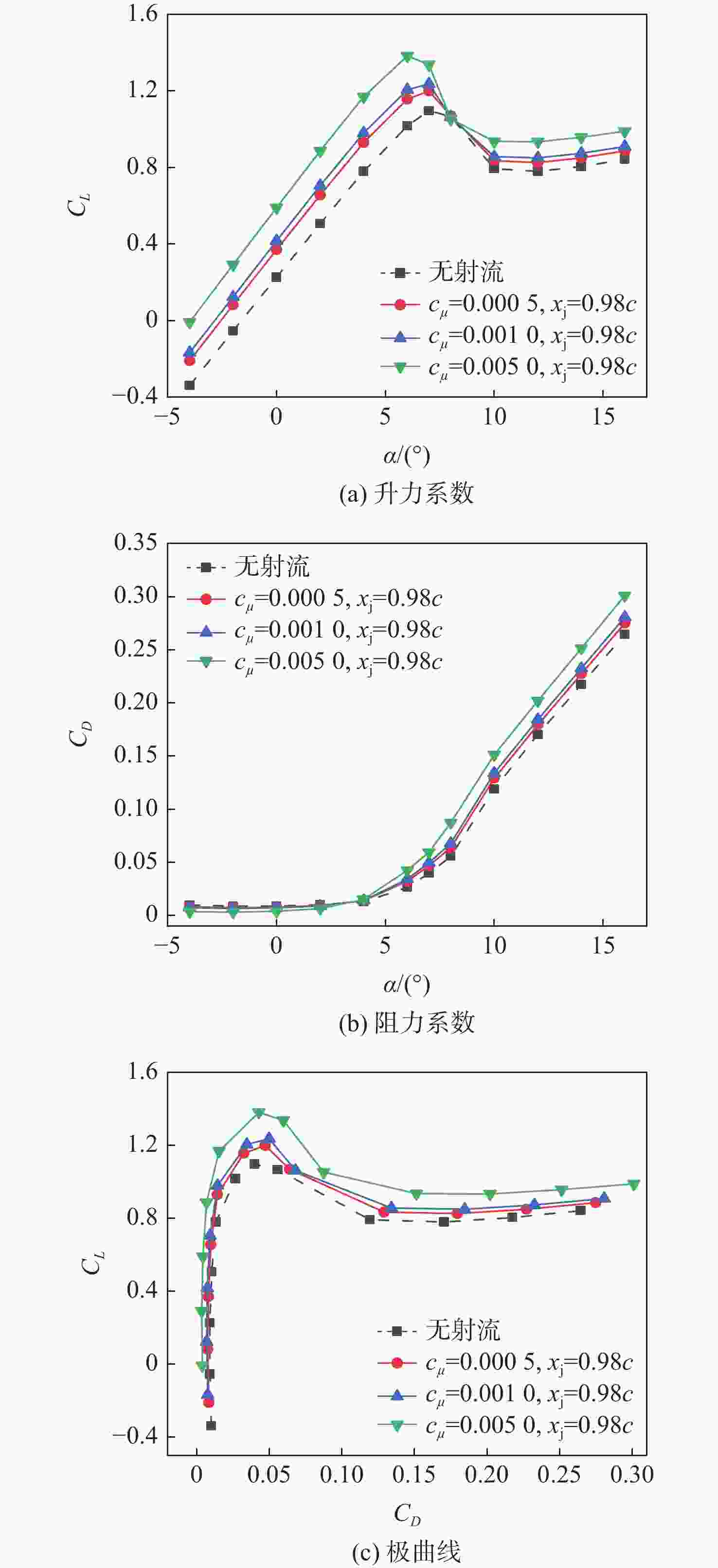

Ma Re α/(°) cμ xj θ/(°) 0.6 5.35×106 −4~16 0.0005,0.001,0.005 0.98c 90 表 6 4°迎角下不同射流动量系数翼型的气动力系数

Table 6. Aerodynamic coefficients of airfoil with different jet momentum coefficients at angle of attack 4°

cμ CL CD CL /CD 0 0.77982 0.013095 59.55 0.0005 0.93005 0.014121 65.86 0.001 0.98081 0.014366 68.27 0.005 1.1701 0.015337 76.29 表 7 不同射流角度计算参数

Table 7. Computational parameters of different jet angles

Ma Re α/(°) cμ xj θ/(°) 0.6 5.35×106 0,2,4 0.005 0.98c 10~170 表 8 不同马赫数下的计算参数

Table 8. Computational parameters of different Mach numbers

Ma Re α/(°) cμ xj θ/(°) 0.3~0.6 2.68×106~5.35×106 0、2、4 0.005 0.98c 110,160 -

[1] SCOTT COLLIS S, JOSLIN R D, SEIFERT A, et al. Issues in active flow control: Theory, control, simulation, and experiment[J]. Progress in Aerospace Sciences, 2004, 40(4-5): 237-289. doi: 10.1016/j.paerosci.2004.06.001 [2] ASHILL P R, FULKER J L, HACKETT K C. A review of recent developments in flow control[J]. The Aeronautical Journal, 2005, 109(1095): 205-232. doi: 10.1017/S0001924000005200 [3] SHMILOVICH A, YADLIN Y. Active flow control for practical high-lift systems[J]. Journal of Aircraft, 2009, 46(4): 1354-1364. doi: 10.2514/1.41236 [4] FU Z J, CHU Y W, CAI Y S, et al. Numerical investigation of circulation control applied to flapless aircraft[J]. Aircraft Engineering and Aerospace Technology, 2020, 92(6): 879-893. doi: 10.1108/AEAT-10-2019-0208 [5] REN F, HU H, TANG H. Active flow control using machine learning: A brief review[J]. Journal of Hydrodynamics, 2020, 32(2): 247-253. doi: 10.1007/s42241-020-0026-0 [6] 朱自强, 吴宗成. 环量控制技术研究[J]. 航空学报, 2016, 37(2): 411-428.ZHU Z Q, WU Z C. Study of the circulation control technology[J]. Acta Aeronautica et Astronautica Sinica, 2016, 37(2): 411-428(in Chinese). [7] XU H Y, QIAO C L, YANG H Q, et al. Active circulation control on the blunt trailing edge wind turbine airfoil[J]. AIAA Journal, 2017, 56: 554-570. [8] SHI Z W, ZHU J C, DAI X X, et al. Aerodynamic characteristics and flight testing of a UAV without control surfaces based on circulation control[J]. Journal of Aerospace Engineering, 2019, 32(1): 04018134. doi: 10.1061/(ASCE)AS.1943-5525.0000947 [9] 雷玉昌, 张登成, 张艳华. 环量控制翼型非定常气动力建模[J]. 北京航空航天大学学报, 2021, 47(10): 209-219. doi: 10.13700/j.bh.1001-5965.2020.0360LEI Y C, ZHANG D C, ZHANG Y H. Unsteady aerodynamic modeling of circulation control airfoil[J]. Journal of Beijing University of Aeronautics and Astronautics, 2021, 47(10): 209-219(in Chinese). doi: 10.13700/j.bh.1001-5965.2020.0360 [10] 雷玉昌, 张登成, 张艳华, 等. 脉冲射流对环量控制翼型气动性能的影响[J]. 北京航空航天大学学报, 2022, 48(3): 485-494.LEI Y C, ZHANG D C, ZHANG Y H, et al. Effect of pulsed jet on aerodynamic performance of circulation control airfoil[J]. Journal of Beijing University of Aeronautics and Astronautics, 2022, 48(3): 485-494(in Chinese). [11] ZHA G C, CARROLL B F, PAXTON C D, et al. High-performance airfoil using coflow jet flow control[J]. AIAA Journal, 2007, 45(8): 2087-2090. doi: 10.2514/1.20926 [12] LEFEBVRE A, DANO B, BARTOW W B, et al. Performance and energy expenditure of coflow jet airfoil with variation of mach number[J]. Journal of Aircraft, 2016, 53(6): 1757-1767. doi: 10.2514/1.C033113 [13] XU K W, ZHA G C. High control authority three-dimensional aircraft control surfaces using coflow jet[J]. Journal of Aircraft, 2021, 58(1): 72-84. doi: 10.2514/1.C035727 [14] 刘沛清, 旷建敏, 屈秋林. 联合射流控制技术的增升效果和机理[J]. 北京航空航天大学学报, 2009, 35(6): 737-740. doi: 10.13700/j.bh.1001-5965.2009.06.011LIU P Q, KUANG J M, QU Q L. Effect and mechanism of lift-enhancement of the co-flow jet technology[J]. Journal of Beijing University of Aeronautics and Astronautics, 2009, 35(6): 737-740(in Chinese). doi: 10.13700/j.bh.1001-5965.2009.06.011 [15] 许建华, 李凯, 宋文萍, 等. 低雷诺数下协同射流关键参数对翼型气动性能的影响[J]. 航空学报, 2018, 39(8): 122018.XU J H, LI K, SONG W P, et al. Influence of co-flow jet key parameters on airfoil aerodynamic performance at low Reynolds number[J]. Acta Aeronautica et Astronautica Sinica, 2018, 39(8): 122018(in Chinese). [16] 张志勇, 王团团, 陈志华, 等. 低雷诺数下吹吸气射流对NACA0012翼型气动性能的影响[J]. 空气动力学学报, 2020, 38(1): 58-65.ZHANG Z Y, WANG T T, CHEN Z H, et al. The effect of blowing/suction jet on the aerodynamic performance of airfoil NACA0012 at low Reynolds number[J]. Acta Aerodynamica Sinica, 2020, 38(1): 58-65(in Chinese). [17] HUANG L, HUANG P G, LEBEAU R P, et al. Numerical study of blowing and suction control mechanism on NACA0012 airfoil[J]. Journal of Aircraft, 2004, 41(5): 1005-1013. doi: 10.2514/1.2255 [18] GENÇ M, KAYNAK Ü. Control of flow separation and transition point over an aerofoil at low Re number using simultaneous blowing and suction[C]//19th AIAA Computational Fluid Dynamics. Reston: AIAA, 2009: 3672. [19] 付云豪, 章卫国, 史静平, 等. 下表面射流对翼型气动性能影响的数值模拟[J]. 哈尔滨工业大学学报, 2021, 53(6): 48-53. doi: 10.11918/201912027FU Y H, ZHANG W G, SHI J P, et al. Numerical simulation of influence of jet at lower surface on aerodynamic performance of airfoil[J]. Journal of Harbin Institute of Technology, 2021, 53(6): 48-53(in Chinese). doi: 10.11918/201912027 [20] XU H Y, QIAO C L, YANG H Q, et al. Active circulation control on the blunt trailing edge wind turbine airfoil[J]. AIAA Journal, 2018, 56(2): 554-570. doi: 10.2514/1.J056223 [21] COOK P, MCDONALD M A, FIRMIN M C P. Aerofoil RAE2822 pressure distributions, and boundary layer and wake measurements, experimental data base for computer program assessment: AGARD Report AR-138[R]. Advanced Guidance for Alliance Research and Development, Part of NATO Science & Technology Organization, 1979, 138: 47. [22] ENGLAR R, JONES G, ALLAN B, et al. 2-D circulation control airfoil benchmark experiments intended for CFD code validation[C]//47th AIAA Aerospace Sciences Meeting Including the New Horizons Forum and Aerospace Exposition. Reston: AIAA, 2009: 902. -

下载:

下载: