Numerical study of blood pump weaning effects on hemocompatibility of centrifugal blood pump

-

摘要:

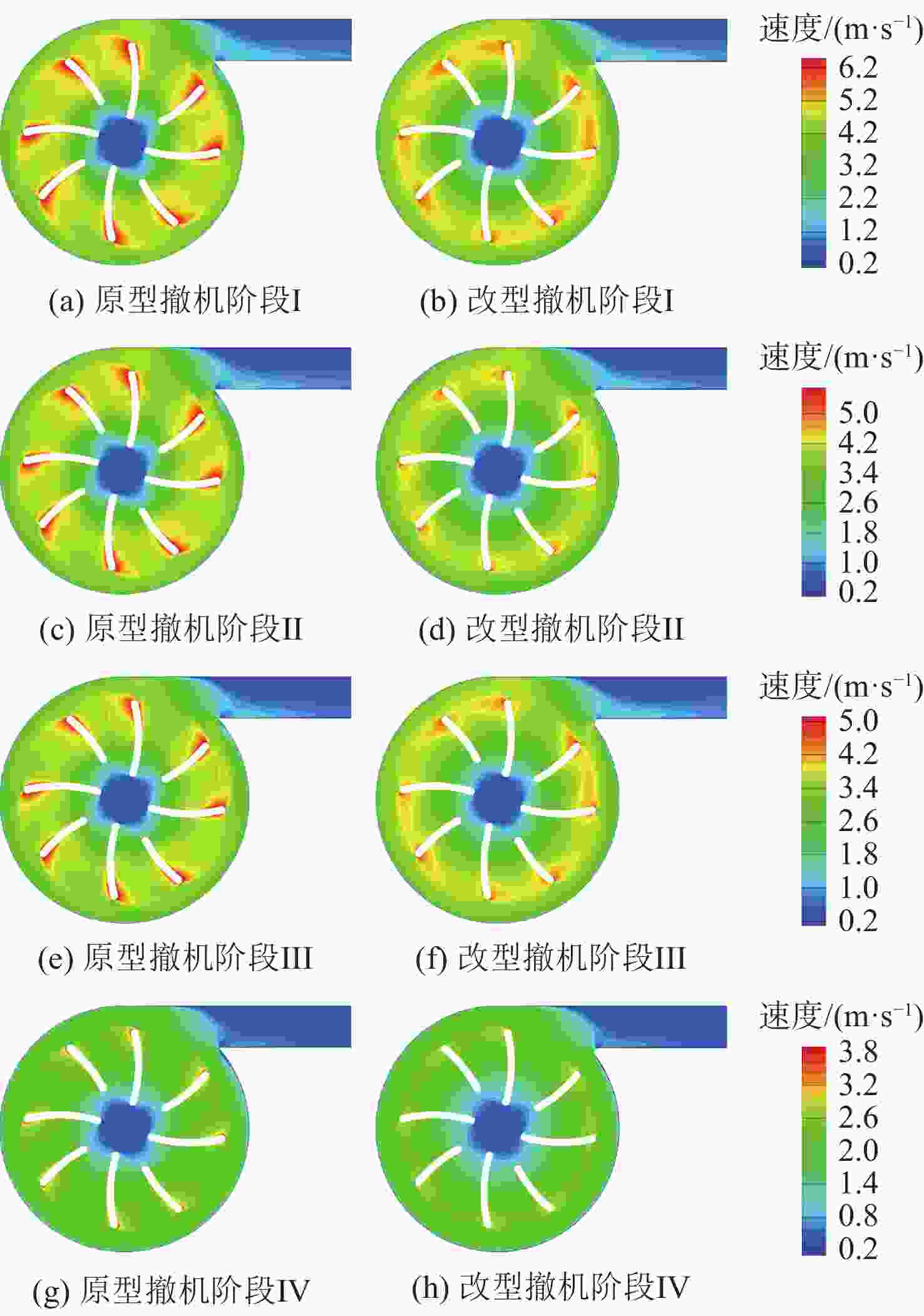

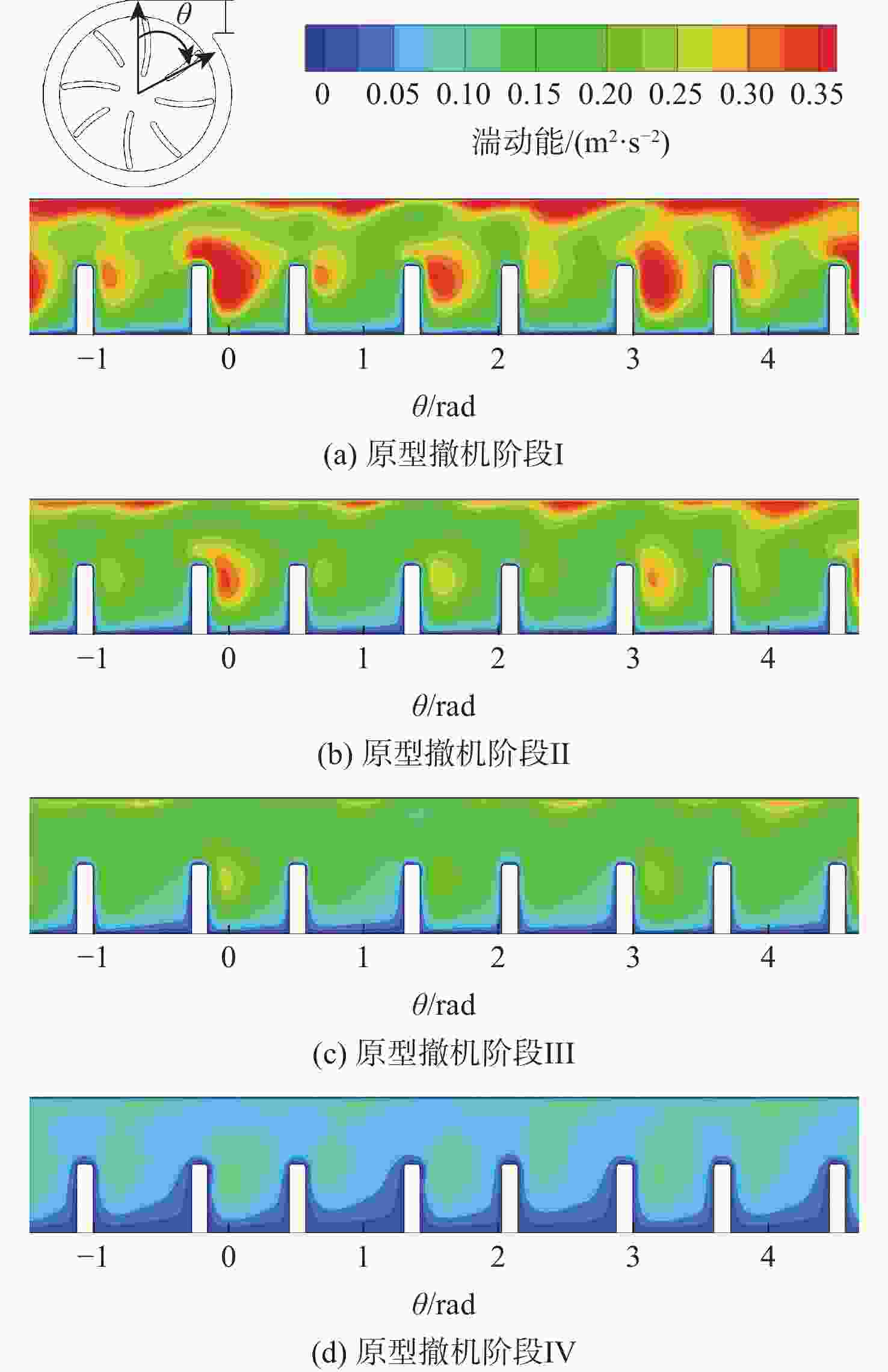

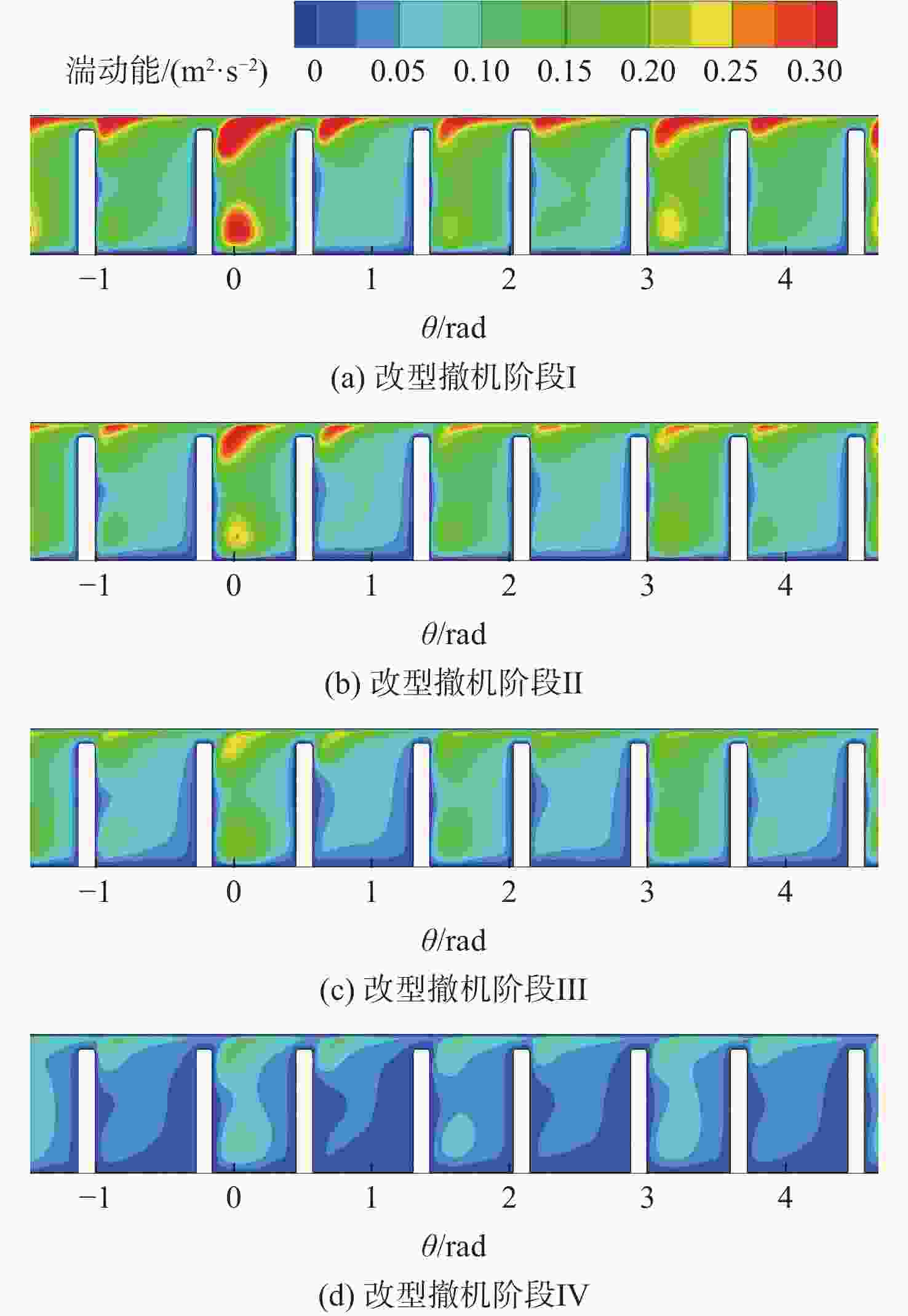

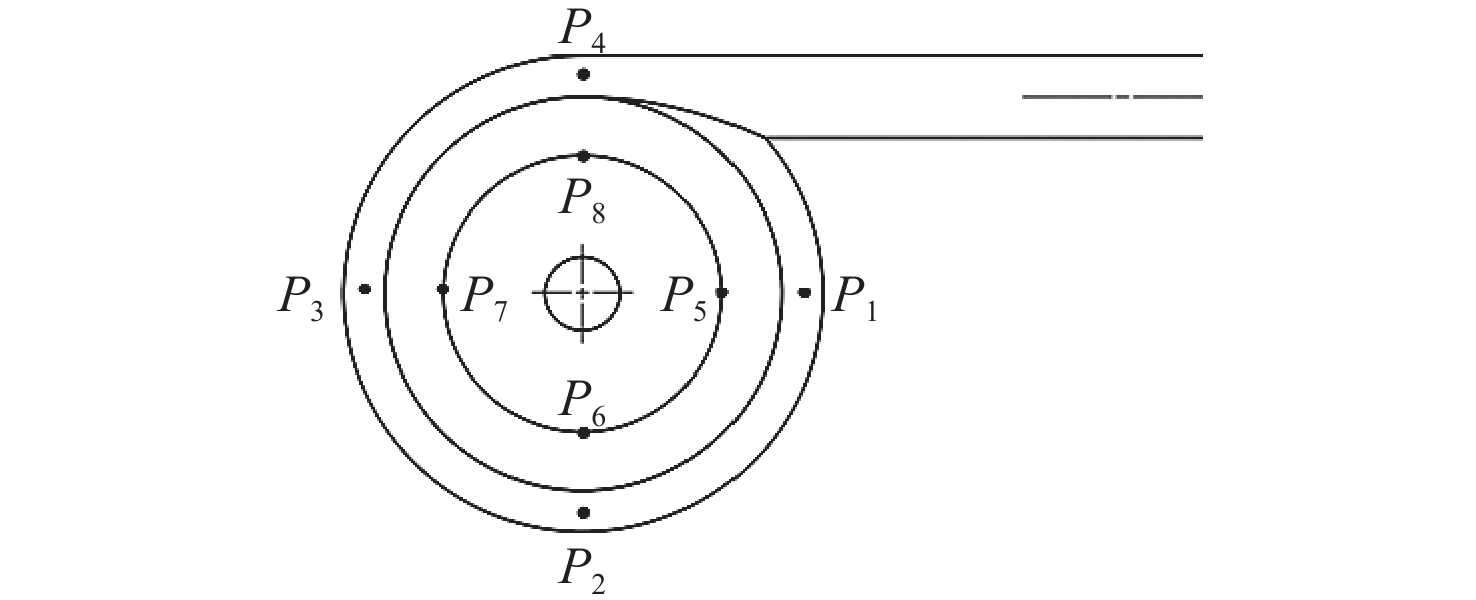

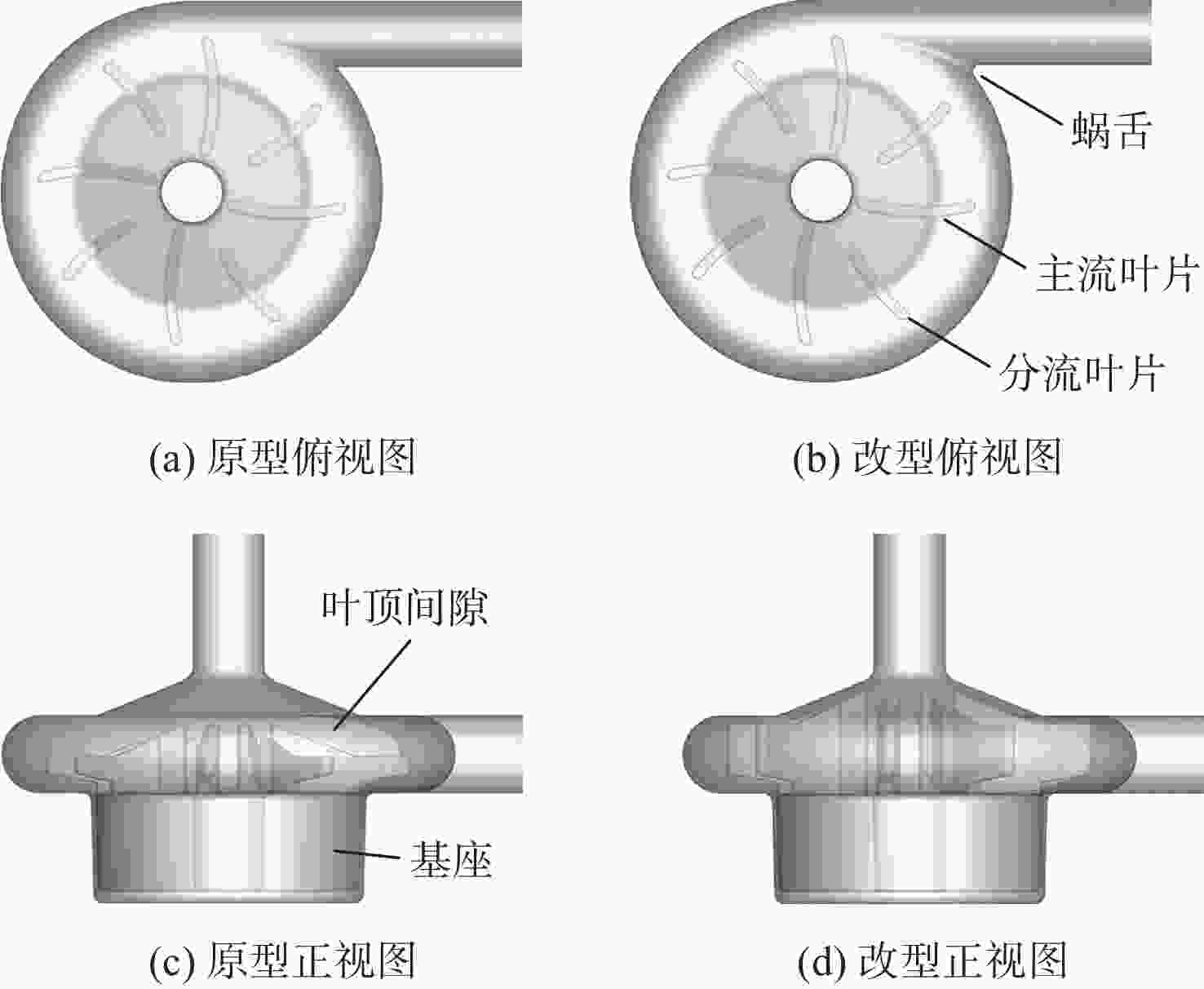

采用非定常数值模拟方法系统评估某离心血泵原型与改型在4个撤机阶段的血流动力学特性和血液相容性。对速度、湍动能、叶表压力的分布规律及不同撤机阶段的血液损伤进行研究,并对各监测点的压力脉动进行分析。研究结果表明:在降低心脏泵流量和供压的第1阶段(撤机阶段Ⅰ),原型和改型均有较好的血液相容性,满足抗溶血和抗血栓的性能要求,间隙泄漏涡是造成溶血主要的流动特征;随着撤机的进行,间隙泄漏涡强度明显减弱,溶血值呈显著的下降趋势,其脉动幅度也大大降低,改型的溶血值比原型减少30%以上;各监测点压力频谱呈现典型的离散特征,相较于原型,改型的转静干涉作用更加强烈,对血泵的电磁控制技术提出更高的要求。

Abstract:The four stages of blood pump weaning are used to methodically assess the hemodynamic performance and hemocompatibility of the datum and modified centrifugal blood pumps. The distribution of parameters and the changes of normalized index of hemolysis in four stages of weaning are researched, the pressure pulsation of each monitoring point is also analyzed. Results show that both the datum pump and the modified pump own good hemocompatibility, and it satisfies the requirement of anti-hemolysis and anti-thrombosis in the first blood pump weaning stage. The leakage vortex formed in clearance is the main flow characteristic that induces hemolysis. The intensity of leakage vortex becomes weaken, and the index of hemolysis as well as its pulsation decrease significantly during the blood pump weaning process. Compared with the datum pump, the NIH of the modified pump is reduced by more than 30%. The pressure spectrum exhibits typical discrete characteristics, and the modified pump's rotor-stator interaction is stronger than that of the datum pump, indicating a high need for the blood pump's electromagnetic control technology.

-

Key words:

- centrifugal blood pump /

- blood pump weaning /

- hemocompatibility /

- hemolysis /

- numerical simulation

-

表 1 血泵撤机阶段运行工况

Table 1. Operating conditions in blood pump weaning stage

撤机阶段 流量

/

(L·min−1)供压

/

Pa原型转速/

(r·min−1)改型转速/

(r·min−1)I 3.0 26707 3200 2622 II 2.5 19620 2750 2255 III 2.0 14892 2400 1971 IV 1.0 5728 1500 1237 -

[1] 《中国心血管健康与疾病报告2020》编写组. 《中国心血管健康与疾病报告2020》概述[J]. 中国心血管病研究, 2021, 19(7): 582-590.The Writing Committee of the Report on Cardiovascular Health and Diseases in China 2020. Key points of report on cardiovascular health and diseases in China 2020[J]. Chinese Journal of Cardiovascular Research, 2021, 19(7): 582-590(in Chinese). [2] 高洁, 李建朝, 程兆云, 等. 体外膜氧合辅助9例危重型新型冠状病毒肺炎患者疗效分析[J]. 中国体外循环杂志, 2020, 18(4): 203-207. doi: 10.13498/j.cnki.chin.j.ecc.2020.04.03GAO J, LI J C, CHENG Z Y, et al. Clinical analysis of COVID-19 patients supported by extracorporeal membrane oxygenation treatment[J]. Chinese Journal of Extracorporeal Circulation, 2020, 18(4): 203-207(in Chinese). doi: 10.13498/j.cnki.chin.j.ecc.2020.04.03 [3] 王军红, 马青变. 体外心肺复苏撤机应注意的问题[J]. 中国急救医学, 2021, 41(7): 610-612. doi: 10.3969/j.issn.1002-1949.2021.07.016WANG J H, MA Q B. Problems needing attention in cardiopulmonary resuscitation[J]. Chinese Journal of Critical Care Medicine, 2021, 41(7): 610-612(in Chinese). doi: 10.3969/j.issn.1002-1949.2021.07.016 [4] 马纪梅. 人工心脏的经皮传能系统的研究[D]. 天津: 河北工业大学, 2011.MA J M. Transcutaneous energy transmission system for artificial heart[D]. Tianjin: Hebei University of Technology, 2011 (in Chinese). [5] 李永乐. 离心式心脏泵流场数值计算与分析[D]. 兰州: 兰州理工大学, 2011.LI Y L. Numerical calculation and analysis about the flow field of centrifugal cardio pump[D]. Lanzhou: Lanzhou University of Technology, 2011 (in Chinese). [6] LIU Y W, YU X J, LIU B J. Turbulence models assessment for large-scale tip vortices in an axial compressor rotor[J]. Journal of Propulsion and Power, 2008, 24: 15-25. doi: 10.2514/1.26134 [7] LIU Y W, ZHONG L Y, LU L P. Comparison of DDES and URANS for unsteady tip leakage flow in an axial compressor rotor[J]. Journal of Fluids Engineering, 2019, 141(12): 121405. doi: 10.1115/1.4043774 [8] 展昭, 张岩, 桂幸民. 某轴流式血液泵的实验与改进设计[J]. 航空动力学报, 2008, 23(6): 1061-1066.ZHAN Z, ZHANG Y, GUI X M. Experiment and design improvement of an axial flow blood pump[J]. Journal of Aerospace Power, 2008, 23(6): 1061-1066(in Chinese). [9] 杨晓琛, 张岩, 桂幸民. 叶轮式辅助心脏泵装置优化设计[J]. 航空动力学报, 2011, 26(6): 1370-1376.YANG X C, ZHANG Y, GUI X M. Optimization and design of an impeller assist heart pump device[J]. Journal of Aerospace Power, 2011, 26(6): 1370-1376(in Chinese). [10] 张岩, 薛嵩, 桂幸民, 等. 运用三维数值模拟对人工心脏轴流血泵的设计和改进[J]. 中国生物医学工程学报, 2007, 26(1): 35-41. doi: 10.3969/j.issn.0258-8021.2007.01.007ZHANG Y, XUE S, GUI X M, et al. Digital simulation to the development of axial blood pump for artificial heart[J]. Chinese Journal of Biomedical Engineering, 2007, 26(1): 35-41(in Chinese). doi: 10.3969/j.issn.0258-8021.2007.01.007 [11] 谢楠, 唐雨萌, 柳阳威, 等. 叶顶间隙对人工心脏泵血液相容性影响的数值研究[J]. 航空动力学报, 2021, 36(6): 1304-1314.XIE N, TANG Y M, LIU Y W, et al. Numerical research on effects of blade tip clearances on the hemocompatibility of artificial heart pump[J]. Journal of Aerospace Power, 2021, 36(6): 1304-1314(in Chinese). [12] ZHANG J T, GELLMAN B, KOERT A, et al. Computational and experimental evaluation of the fluid dynamics and hemocompatibility of the CentriMag blood pump[J]. Artificial Organs, 2006, 30(3): 168-177. doi: 10.1111/j.1525-1594.2006.00203.x [13] FUNG Y C. Biomechanics: Mechanical properties of living tissues[M]. New York: Springer-Verlag, 1981. [14] MULHOLLAND J W, SHELTON J C, LUO X Y. Blood flow and damage by the roller pumps during cardiopulmonary bypass[J]. Journal of Fluids and Structures, 2005, 20(1): 129-140. doi: 10.1016/j.jfluidstructs.2004.10.008 [15] HUANG C R, FABISIAK W. A rheological equation characterizing both the time dependent and the steady state viscosity of whole human blood[J]. AIChE Symp Series, 1978, 74(1): 19-21. [16] BLUDSZUWEIT C. Model for a general mechanical blood damage prediction[J]. Artificial Organs, 1995, 19(7): 583-589. doi: 10.1111/j.1525-1594.1995.tb02385.x [17] ZHANG J F, ZHANG P, FRASER K H, et al. Comparison and experimental validation of fluid dynamic numerical models for a clinical ventricular assist device[J]. Artificial Organs, 2013, 37(4): 380-389. doi: 10.1111/j.1525-1594.2012.01576.x [18] BLACKSHEAR P L, DORMAN F D, STEINBACH J H. Some mechanical effects that influence hemolysis[J]. Transactions American Society for Artificial Internal Organs, 1965, 11: 112-117. doi: 10.1097/00002480-196504000-00022 [19] GIERSIEPEN M, WURZINGER L J, OPITZ R, et al. Estimation of shear stress-related blood damage in heart valve prostheses: In vitro comparison of 25 aortic valves[J]. The International Journal of Artificial Organs, 1990, 13(5): 300-306. doi: 10.1177/039139889001300507 [20] GARON A, FARINAS M I. Fast three-dimensional numerical hemolysis approximation[J]. Artificial Organs, 2004, 28(11): 1016-1025. doi: 10.1111/j.1525-1594.2004.00026.x [21] BLUDSZUWEIT C. Three-dimensional numerical prediction of stress loading of blood particles in a centrifugal pump[J]. Artificial Organs, 1995, 19(7): 590-596. doi: 10.1111/j.1525-1594.1995.tb02386.x [22] 高雁飞. 压气机转子叶尖泄漏湍流机理与数值模拟方法研究[D]. 北京: 北京航空航天大学, 2020.GAO Y F. Study of turbulence mechanism and numerical methods in compressor tip leakage flow[D]. Beijing: Beihang University, 2020 (in Chinese). [23] MARSDEN A L, BAZILEVS Y, LONG C C, et al. Recent advances in computational methodology for simulation of mechanical circulatory assist devices[J]. Wiley Interdisciplinary Reviews Systems Biology and Medicine, 2014, 6(2): 169-188. doi: 10.1002/wsbm.1260 [24] FARINAS M I, GARON A, LACASSE D, et al. Asymptotically consistent a numerical approximation of hemolysis[J]. Journal of Biomechanical Engineering, 2006, 128(5): 688-696. doi: 10.1115/1.2241663 [25] GOUBERGRITS L, AFFELD K. Numerical estimation of blood damage in artificial organs[J]. Artificial Organs, 2004, 28(5): 496-517. doi: 10.1111/j.1525-1594.2004.07154.x [26] YELESWARAPU K K, ANTAKI J F, KAMENEVA M V, et al. A mathematical model for shear-induced hemolysis[J]. Artificial Organs, 1995, 19(7): 576-582. doi: 10.1111/j.1525-1594.1995.tb02384.x [27] 云忠, 谭建平. 基于血液剪切损伤机理的高速螺旋血泵仿真分析[J]. 中山大学学报(自然科学版), 2008, 47(1): 47-50. doi: 10.3321/j.issn:0529-6579.2008.01.012YUN Z, TAN J P. Simulation analysis of the high-speed spiral blood pump based on the shear injure principle of blood[J]. Acta Scientiarum Naturalium Universitatis Sunyatseni, 2008, 47(1): 47-50(in Chinese). doi: 10.3321/j.issn:0529-6579.2008.01.012 [28] 云忠, 石芬, 向闯, 等. 混流血泵血液压差损伤机理分析及仿真[J]. 机械设计与研究, 2010, 26(3): 29-32. doi: 10.13952/j.cnki.jofmdr.2010.03.023YUN Z, SHI F, XIANG C, et al. Study on the injury principle of the blood prossure differevce in the mixed blood pump and its simulation analysis[J]. Machine Design and Research, 2010, 26(3): 29-32(in Chinese). doi: 10.13952/j.cnki.jofmdr.2010.03.023 -

下载:

下载: