Design and experiment of cryogenic loop heat pipe of two-dimensional pointing at liquid nitrogen zone

-

摘要:

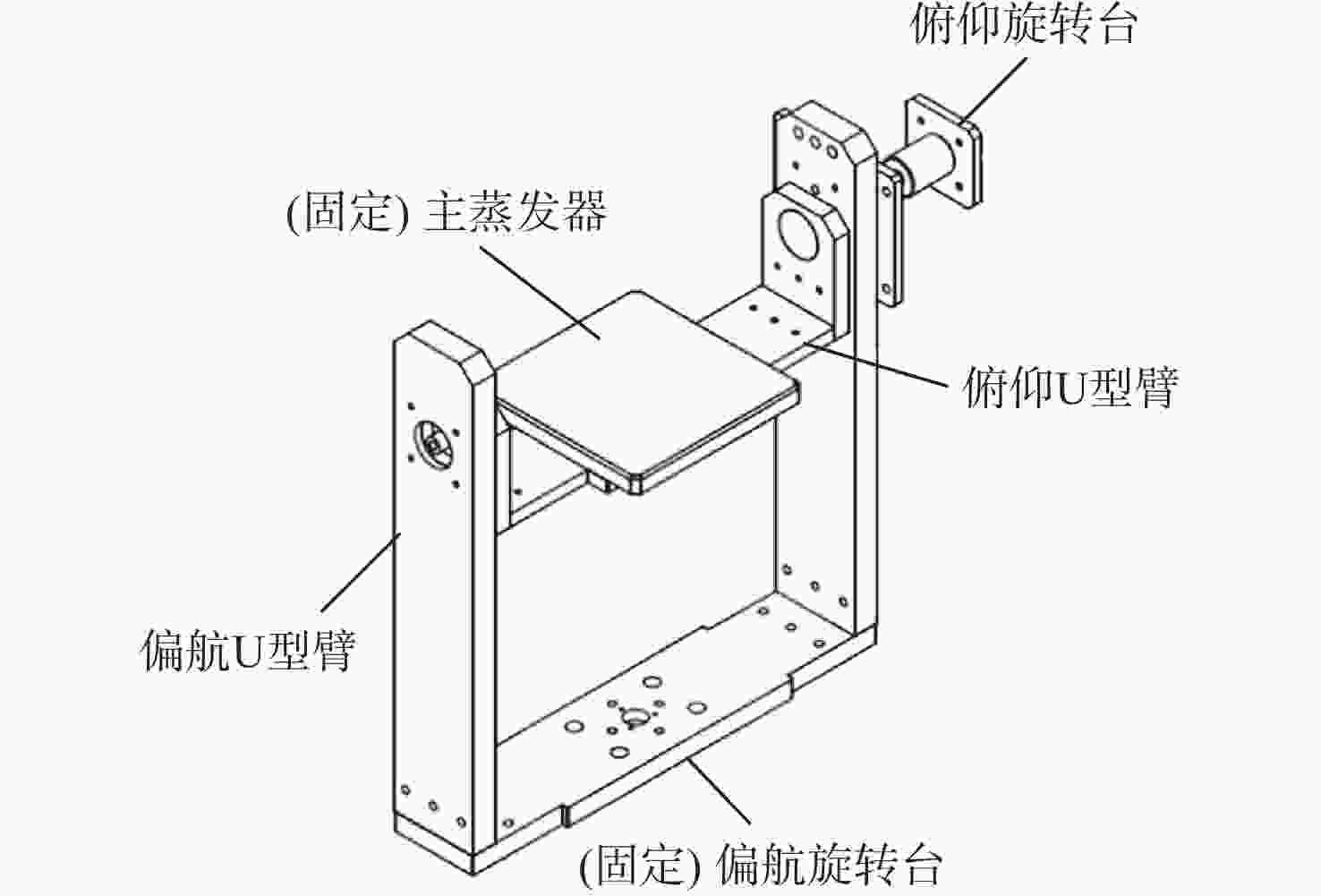

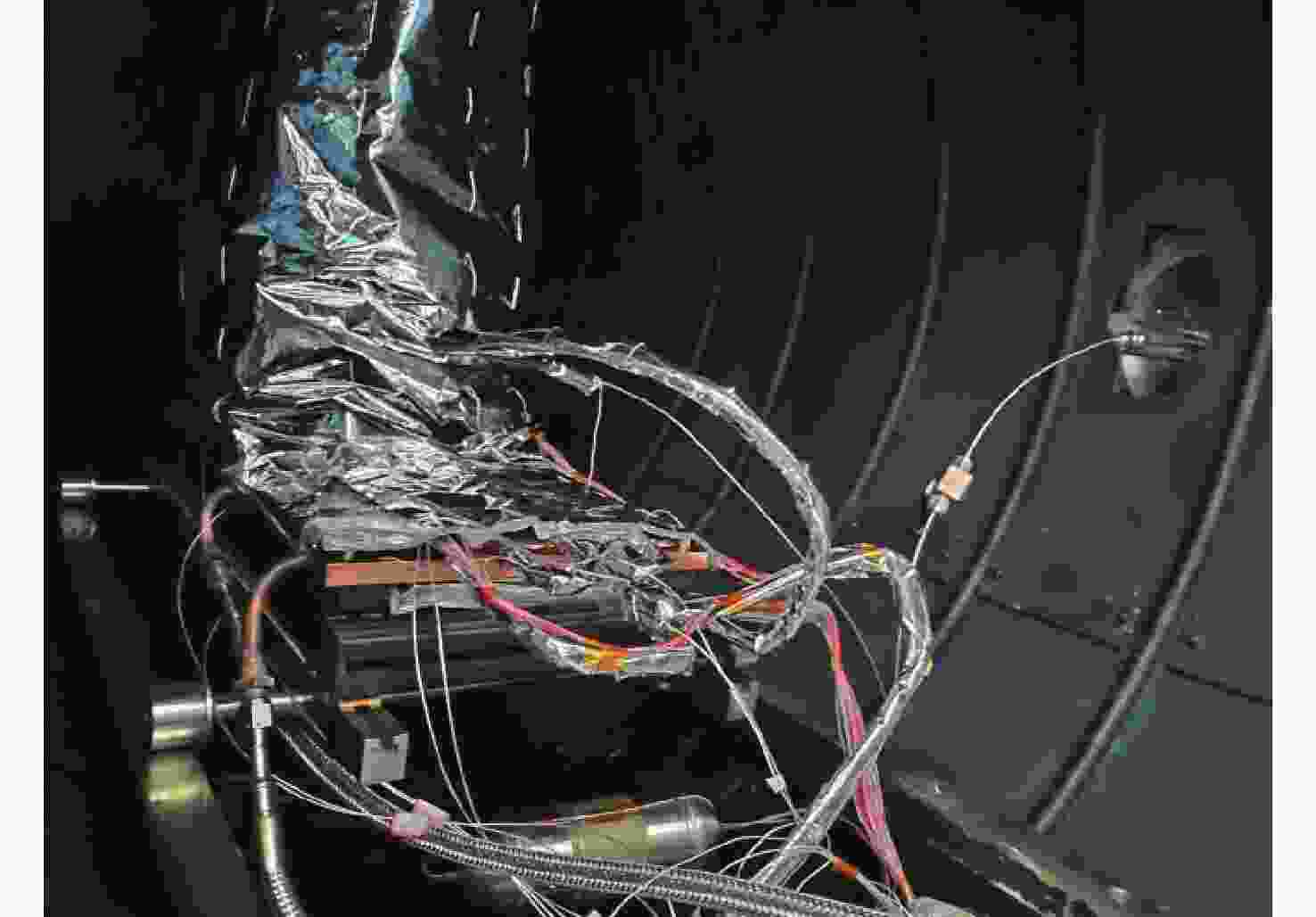

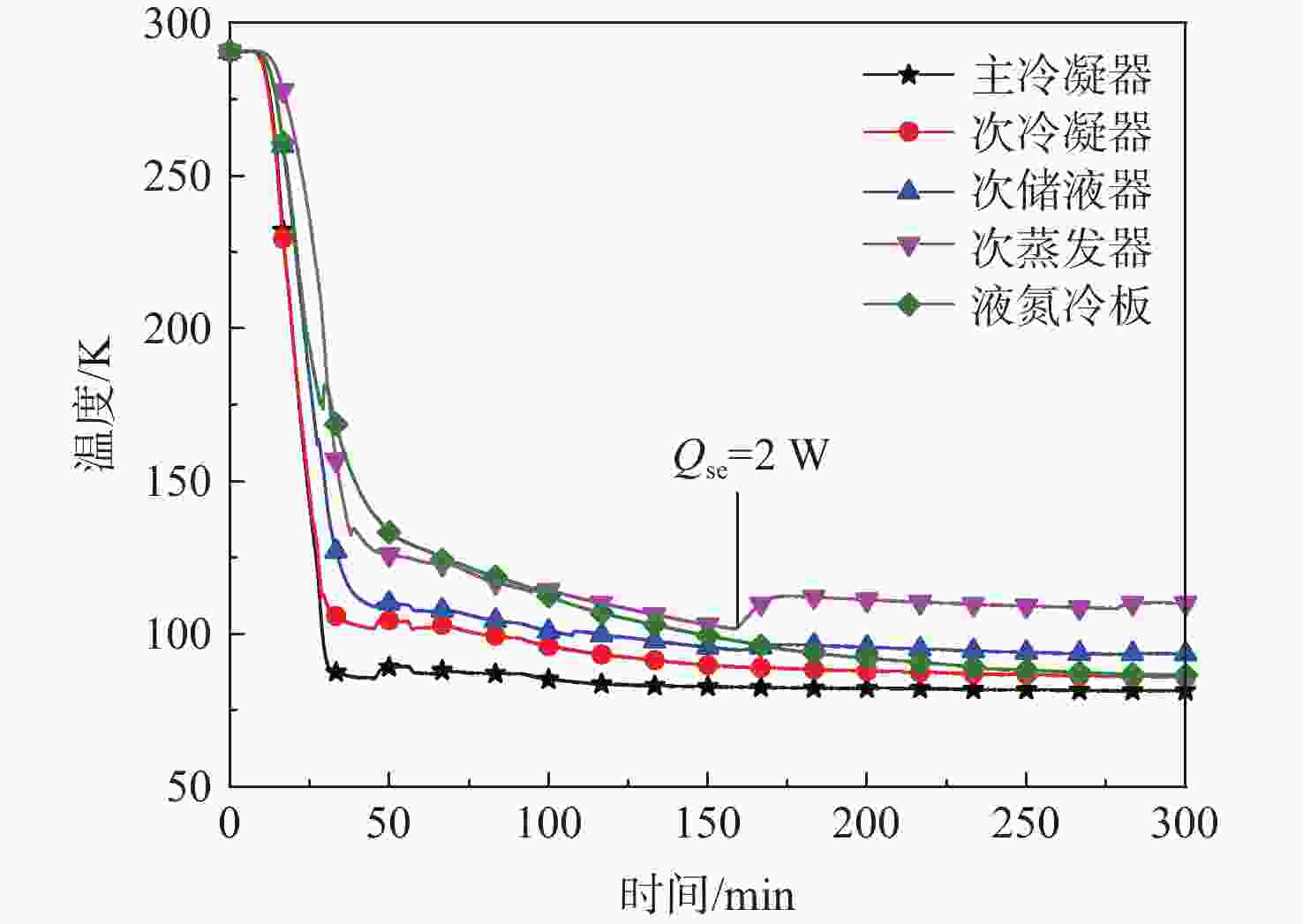

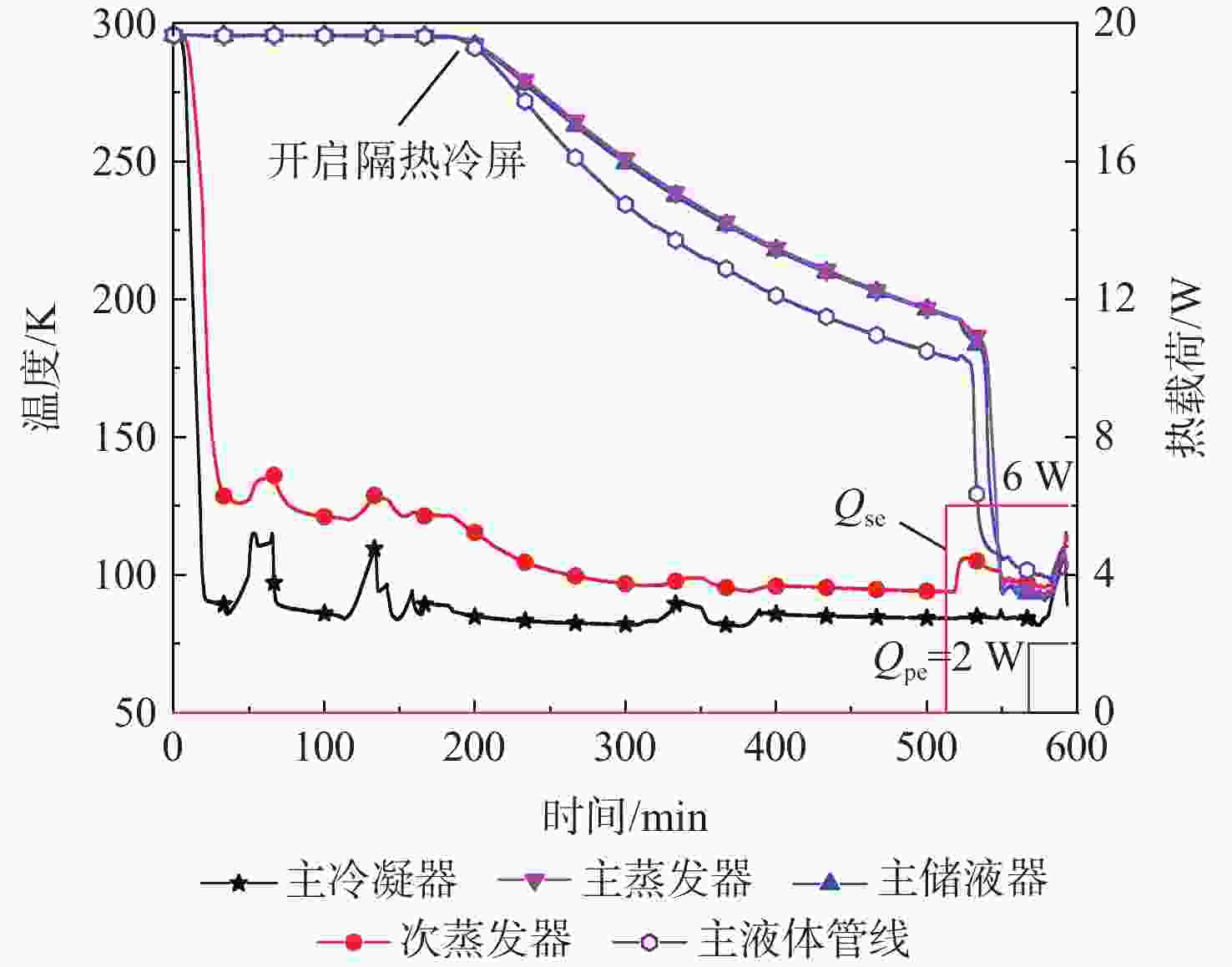

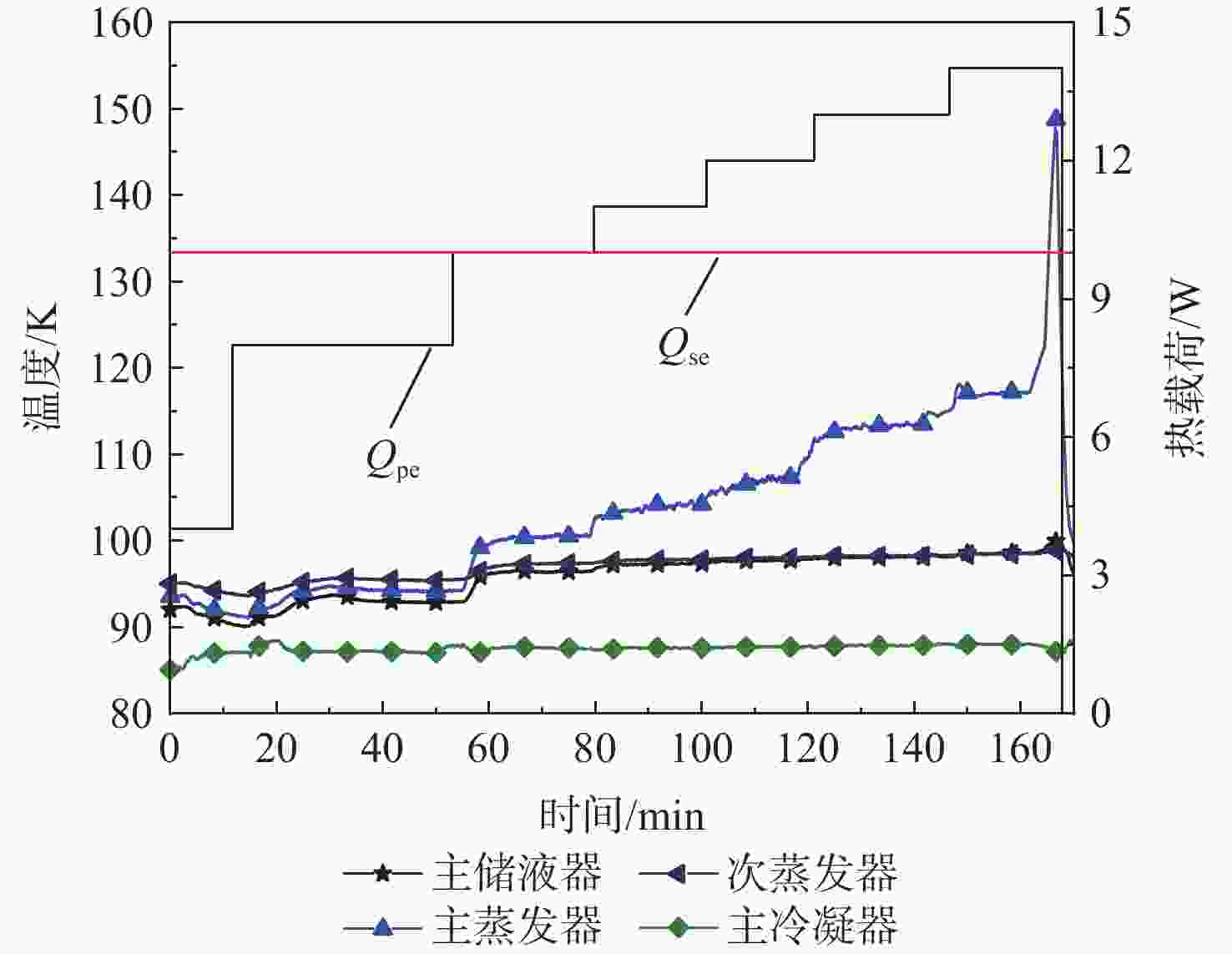

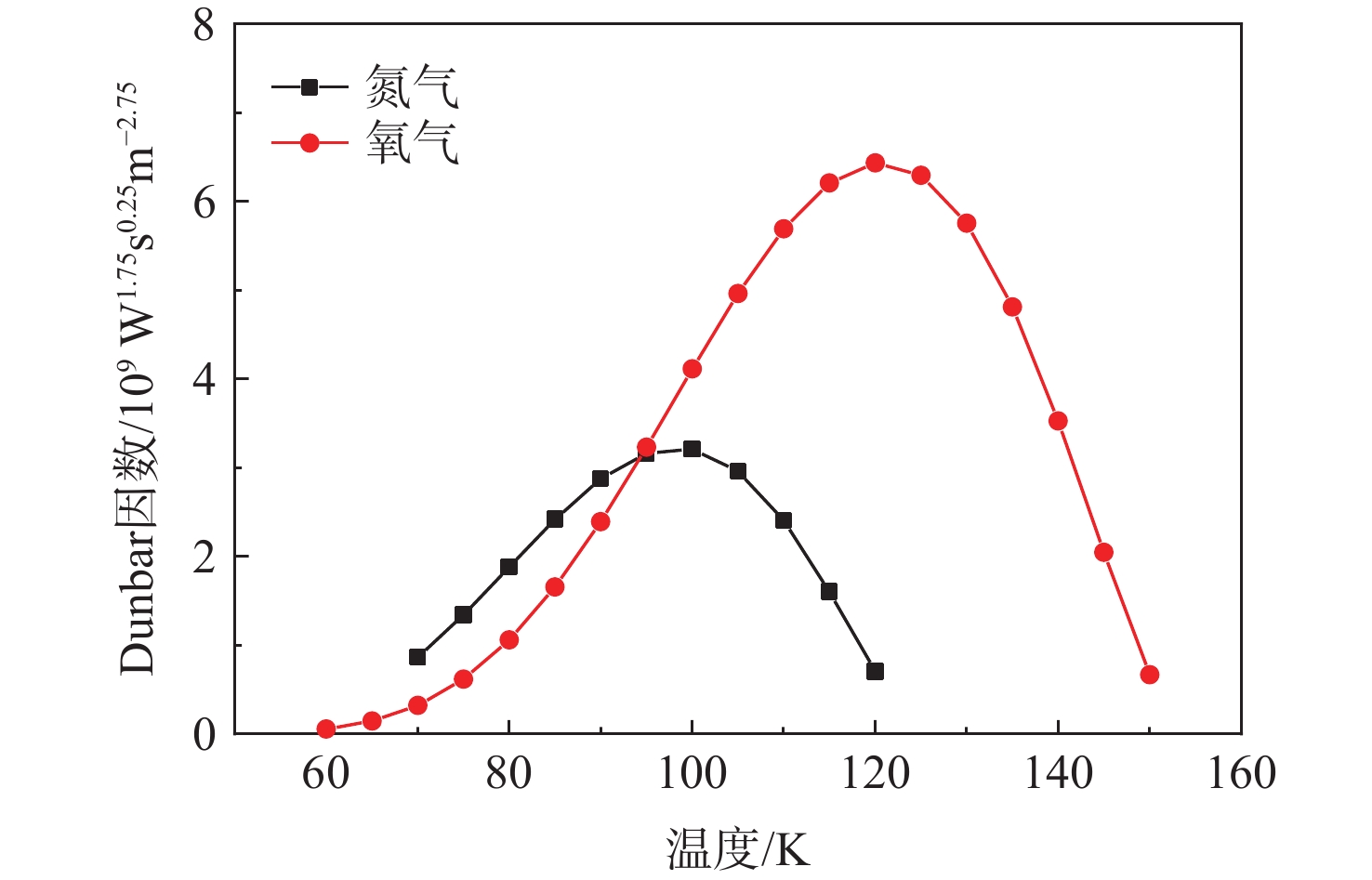

空间二维指向机构与红外探测器配合,有利于实现对空间目标大范围的动态追踪、指向、快速定位等功能。将深冷环路热管(CLHP)与二维指向机构耦合,可以大大降低系统机构的复杂程度,实现远距离热传输,提高探测精度和转向灵活性。为此,设计研制了液氮温区二维指向CLHP。对设计流程和部件参数进行了介绍,通过伺服电机驱动实现了俯仰、偏航±90°以上的转动。通过开展热真空实验,研究了不同工作参数对超临界启动和传热极限的影响。结果表明:所设计的系统具有最大13 W的传热能力,适当提高充装压力有利于提高系统的稳定性和传热能力,增大次蒸发器辅助载荷有助于提高最大传热能力。

Abstract:The cooperation of the two-dimensional pointing mechanism and the infrared detector is conducive to the realization of large-scale dynamic tracking, pointing, and rapid positioning of space targets. Coupling the cryogenic loop heat pipe (CLHP) with the two-dimensional pointing mechanism can greatly reduce system complexity, while achieving long-distance heat transmission, and improving detection accuracy and steering flexibility. A two-dimensional pointing CLHP working at the liquid nitrogen zone is designed and developed. The component parameters are introduced, and a pitch and yaw rotation of more than ±90° through the servo motor drive is realized. The thermal vacuum experiment was carried out, examining the effects of different working parameters on the supercritical start and heat transfer limit. The results show that the system designed has a maximum heat transfer capacity of 13 W. Appropriately increasing the filling pressure can help improve the stability and heat transfer capacity of the system, and increasing the auxiliary load of the secondary evaporator can increase the maximum heat transfer ability.

-

表 1 传输管线结构参数

Table 1. Structure parameters of transport line

部件 长度/

mm外径/mm 壁厚/mm 俯仰螺旋

直径/mm俯仰螺

旋匝数偏航螺旋

直径/mm俯仰螺

旋匝数主气体

管线10000 3 0.5 250 6 350 4 主液体

管线10000 3 0.5 250 6 350 4 次液体

管线10000 3 0.5 250 6 350 4 表 2 蒸发器与储液器结构参数

Table 2. Structure parameters of evaporator and compensation chamber

部件 参数 数值 主蒸发器 壳体长度×外径×厚度/

(mm×mm×mm)110×13×1 毛细芯外径×长度/

(mm×mm)11×100 主储液器 容积/mL 5 轴向槽道 槽深×槽宽×长度/

(mm×mm×mm)0.8×0.8×80 数量/个 4 次蒸发器 壳体长度×外径×厚度/

(mm×mm×mm)100×13×1 毛细芯外径×长度/

(mm×mm)11×90 次储液器 容积/mL 5 轴向槽道 槽深×槽宽×长度/

(mm×mm×mm)0.8×0.8×80 数量/个 4 表 3 储气室容积与工质充装范围

Table 3. Gas reservoir volume and working fluid filling range

储气室容积/mL 充装质量/g 300 K时充装压力/MPa 1200 45~65 2.8~3.6 表 4 不同充装压力下CLHP启动完成时主蒸发器温度及系统压力

Table 4. Primary evaporator temperature and system pressure under different filling pressures after startup

状态 温度/K 压力/MPa 临界状态 126 3.36 冷端温度及饱和压力 85 0.228 充装压力3.10 MPa 93.1 0.279 充装压力3.29 MPa 91.9 0.499 充装压力3.57 MPa 99.4 0.567 -

[1] 朱岩, 白云飞, 王连国, 等. 中国首次火星探测工程有效载荷总体设计[J]. 深空探测学报, 2017, 4(6): 510-514. doi: 10.15982/j.issn.2095-7777.2017.06.002ZHU Y, BAI Y F, WANG L G, et al. Integral technical scheme of payloads system for Chinese Mars-1 exploration[J]. Journal of Deep Space Exploration, 2017, 4(6): 510-514(in Chinese). doi: 10.15982/j.issn.2095-7777.2017.06.002 [2] 刘成, 谢荣建, 王仕越, 等. 丙烯环路热管补偿器的可视化实验研究[J]. 北京航空航天大学学报, 2020, 46(5): 933-940. doi: 10.13700/j.bh.1001-5965.2019.0322LIU C, XIE R J, WANG S Y, et al. Visualization experimental study of compensation chamber of a propylene loop heat pipe[J]. Journal of Beijing University of Aeronautics and Astronautics, 2020, 46(5): 933-940(in Chinese). doi: 10.13700/j.bh.1001-5965.2019.0322 [3] 孟庆亮, 杨涛, 于志, 等. 空间遥感器用环路热管瞬态数值模拟与在轨验证[J]. 北京航空航天大学学报, 2020, 46(11): 2045-2055. doi: 10.13700/j.bh.1001-5965.2019.0584MENG Q L, YANG T, YU Z, et al. Transient numerical simulation and on-orbit verification of loop heat pipe used for space remote sensor[J]. Journal of Beijing University of Aeronautics and Astronautics, 2020, 46(11): 2045-2055(in Chinese). doi: 10.13700/j.bh.1001-5965.2019.0584 [4] 薛好, 谢永奇, 戴华, 等. 加速度场中环路热管温度波动现象分析[J]. 北京航空航天大学学报, 2016, 42(7): 1502-1508. doi: 10.13700/j.bh.1001-5965.2015.0465XUE H, XIE Y Q, DAI H, et al. Investigation of temperature fluctuation in loop heat pipe under acceleration fields[J]. Journal of Beijing University of Aeronautics and Astronautics, 2016, 42(7): 1502-1508(in Chinese). doi: 10.13700/j.bh.1001-5965.2015.0465 [5] 郭元东. 15 K~40 K温区深冷环路热管技术的理论与实验研究[D]. 北京: 北京航空航天大学, 2019.GUO Y D. Theoretical and experimental investigation of cryogenic loop heat pipe technology operating in 15 K~40 K[D]. Beijing: Beihang University, 2019(in Chinese) . [6] BAI L, ZHANG L, LIN G, et al. Development of cryogenic loop heat pipes: A review and comparative analysis[J]. Applied Thermal Engineering, 2015, 89: 180-191. doi: 10.1016/j.applthermaleng.2015.06.010 [7] 何江, 苗建印, 张红星, 等. 航天器深低温热管技术研究现状及发展趋势[J]. 真空与低温, 2018, 24(1): 1-8.HE J, MIAO J Y, ZHANG H X, et al. Current status and development trend of cryogenic heat pipe technologies in spacecraft[J]. Vacuum and Cryogenics, 2018, 24(1): 1-8(in Chinese). [8] HOANG T T, O’CONNELL T A, KU J, et al. Performance demonstration of hydrogen advanced loop heat pipe for 20-30 K cryocooling of far infrared sensors[C]//Optics and Photonics 2005. Bellingham: SPIE, 2005: 590410. [9] HOANG T T, O’CONNELL T A, KU J, et al. Design optimization of a hydrogen advanced loop heat pipe for space-based IR sensor and detector cryocooling[C]//SPIE’s 48th Annual Meeting of Optical Science and Technology. Bellingham: SPIE, 2003: 86. [10] MO Q, LIANG J. Operational performance of a cryogenic loop heat pipe with insufficient working fluid inventory[J]. International Journal of Refrigeration, 2006, 29(4): 519-527. doi: 10.1016/j.ijrefrig.2005.10.011 [11] GULLY P, MO Q, YAN T, et al. Thermal behavior of a cryogenic loop heat pipe for space application[J]. Cryogenics, 2011, 51(8): 420-428. doi: 10.1016/j.cryogenics.2011.04.009 [12] ZHAO Y, YAN T, LIANG J, et al. A new way of supercritical startup of a cryogenic loop heat pipe[J]. International Journal of Heat and Mass Transfer, 2019, 145: 118793. doi: 10.1016/j.ijheatmasstransfer.2019.118793 [13] ZHAO Y, YAN T, LIANG J. Experimental study on a cryogenic loop heat pipe with high heat capacity[J]. International Journal of Heat and Mass Transfer, 2011, 54(15-16): 3304-3308. doi: 10.1016/j.ijheatmasstransfer.2011.03.056 [14] ZHAO Y, WANG N, YAN T, et al. Experimental study on operating characteristics of a cryogenic loop heat pipe without additional power consumption[J]. Applied Thermal Engineering, 2021, 184: 116262. doi: 10.1016/j.applthermaleng.2020.116262 [15] MO Q, LIANG J T. A novel design and experimental study of a cryogenic loop heat pipe with high heat transfer capability[J]. International Journal of Heat and Mass Transfer, 2006, 49(3-4): 770-776. doi: 10.1016/j.ijheatmasstransfer.2005.08.010 [16] 李强, 马路, 宣益民. 低温环路热管(CLHP)的实验研究[J]. 工程热物理学报, 2010, 31(1): 122-125.LI Q, MA L, XUAN Y M. Experimental investigation of cryogenic loop heat pipe[J]. Journal of Engineering Thermophysics, 2010, 31(1): 122-125(in Chinese). [17] 刘成志, 董德平, 杨帆. 乙烷温区低温环路热管设计与实验[J]. 低温工程, 2011, 28(6): 57-59. doi: 10.3969/j.issn.1000-6516.2011.06.012LIU C Z, DONG D P, YANG F. Design and experimental investigations of ethane cryogenic loop heat pipe[J]. Cryogenics, 2011, 28(6): 57-59(in Chinese). doi: 10.3969/j.issn.1000-6516.2011.06.012 [18] 张畅, 谢荣建, 张添, 等. 液氮温区平板蒸发器环路热管实验研究[J]. 北京航空航天大学学报, 2019, 45(6): 1211-1217. doi: 10.13700/j.bh.1001-5965.2018.0623ZHANG C, XIE R J, ZHANG T, et al. Experimental study on a liquid nitrogen temperature region loop heat pipe with flat evaporator[J]. Journal of Beijing University of Aeronautics and Astronautics, 2019, 45(6): 1211-1217(in Chinese). doi: 10.13700/j.bh.1001-5965.2018.0623 [19] BAI L, LIN G, ZHANG H, et al. Experimental study of a nitrogen-charged cryogenic loop heat pipe[J]. Cryogenics, 2012, 52(10): 557-563. doi: 10.1016/j.cryogenics.2012.07.005 [20] BAI L, LIN G, ZHANG H, et al. Operating characteristics of a miniature cryogenic loop heat pipe[J]. International Journal of Heat and Mass Transfer, 2012, 55(25-26): 8093-8099. doi: 10.1016/j.ijheatmasstransfer.2012.08.044 [21] GUO Y, LIN G, BAI L, et al. Experimental study on the supercritical startup of cryogenic loop heat pipes with redundancy design[J]. Energy Conversion and Management, 2016, 118: 353-363. doi: 10.1016/j.enconman.2016.04.022 [22] GUO Y, LIN G, HE J, et al. Experimental study on the supercritical startup and heat transport capability of a neon-charged cryogenic loop heat pipe[J]. Energy Conversion and Management, 2017, 134: 178-187. doi: 10.1016/j.enconman.2016.12.038 [23] GUO Y, LIN G, HE J, et al. Supercritical startup strategy of cryogenic loop heat pipe with different working fluids[J]. Applied Thermal Engineering, 2019, 155: 267-276. doi: 10.1016/j.applthermaleng.2019.04.008 [24] GUO Y, LIN G, BAI L, et al. Experimental study of the thermal performance of a neon cryogenic loop heat pipe[J]. International Journal of Heat and Mass Transfer, 2018, 120: 1266-1274. doi: 10.1016/j.ijheatmasstransfer.2017.12.138 [25] GUO Y, LIN G, ZHANG H, et al. Investigation on thermal behaviours of a methane charged cryogenic loop heat pipe[J]. Energy, 2018, 157: 516-525. doi: 10.1016/j.energy.2018.05.133 [26] 周顺涛, 莫青, 张红星, 等. 深冷环路热管传热性能研究[J]. 航天器工程, 2010, 19(3): 91-95. doi: 10.3969/j.issn.1673-8748.2010.03.014ZHOU S T, MO Q, ZHANG H X, et al. Experimental study on heat transfer performance of cryogenic loop heat pipe[J]. Spacecraft Engineering, 2010, 19(3): 91-95(in Chinese). doi: 10.3969/j.issn.1673-8748.2010.03.014 [27] 周顺涛, 莫青, 张红星, 等. 深冷环路热管超临界启动实验研究[J]. 低温工程, 2010(3): 18-22. doi: 10.3969/j.issn.1000-6516.2010.03.004ZHOU S T, MO Q, ZHANG H X, et al. Experimental investigation on supercritical startup of cryogenic loop heat pipe[J]. Cryogenics, 2010(3): 18-22(in Chinese). doi: 10.3969/j.issn.1000-6516.2010.03.004 [28] KU J, ROBINSON F. Thermal vacuum testing of a helium loop heat pipe for large area cryocooling[C]//46th International Conference on Environmental Systems. [S.1.]: [s.n.], 2016. [29] HOANG T T, O’CONNELL T A, KHRUSTALEV D K. Development of a flexible advanced loop heat pipe for across-gimball cryocooling[C]//SPIE 48th Annual Meeting of Optical Science and Technology. Bellingham: SPIE, 2003, 5172: 68-76. [30] SHAEFFER R, HU H, CHUNG J N. An experimental study on liquid nitrogen pipe chilldown and heat transfer with pulse flows[J]. International Journal of Heat and Mass Transfer, 2013, 67: 955-966. doi: 10.1016/j.ijheatmasstransfer.2013.08.037 -

下载:

下载: