Simulation analysis of reduction effect of symmetrical winding method for multi-polar fiber ring on Shupe error

-

摘要:

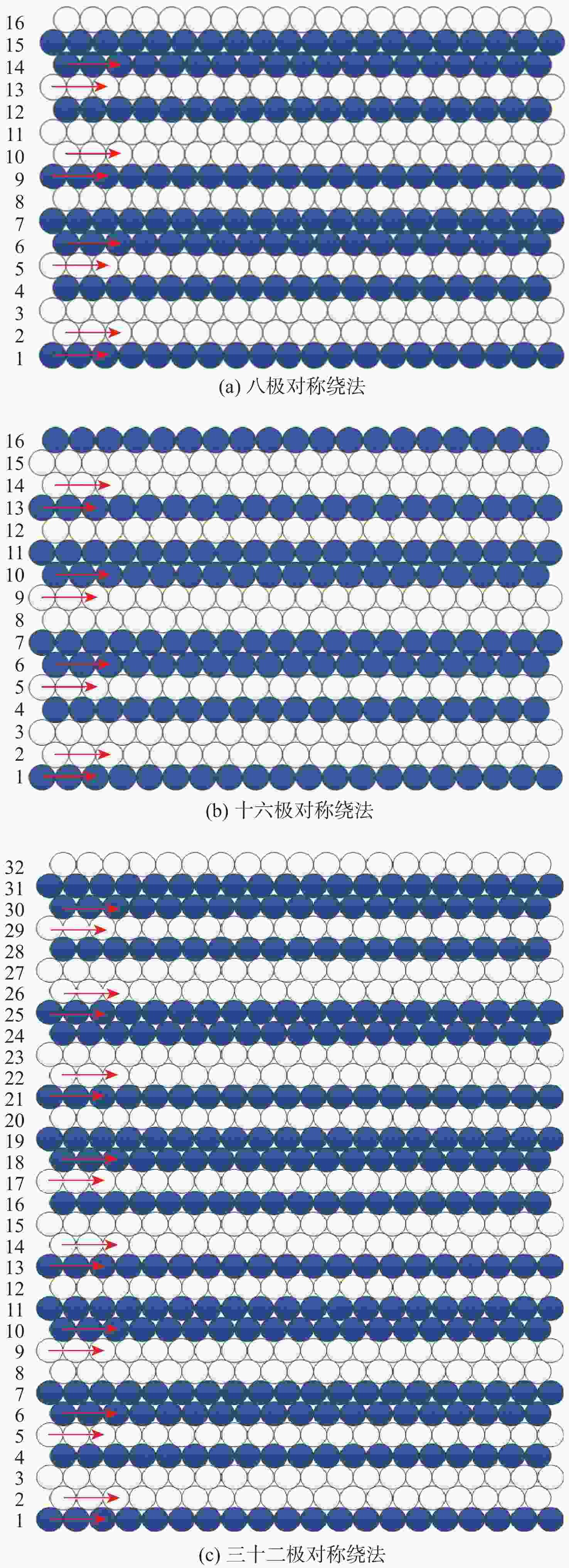

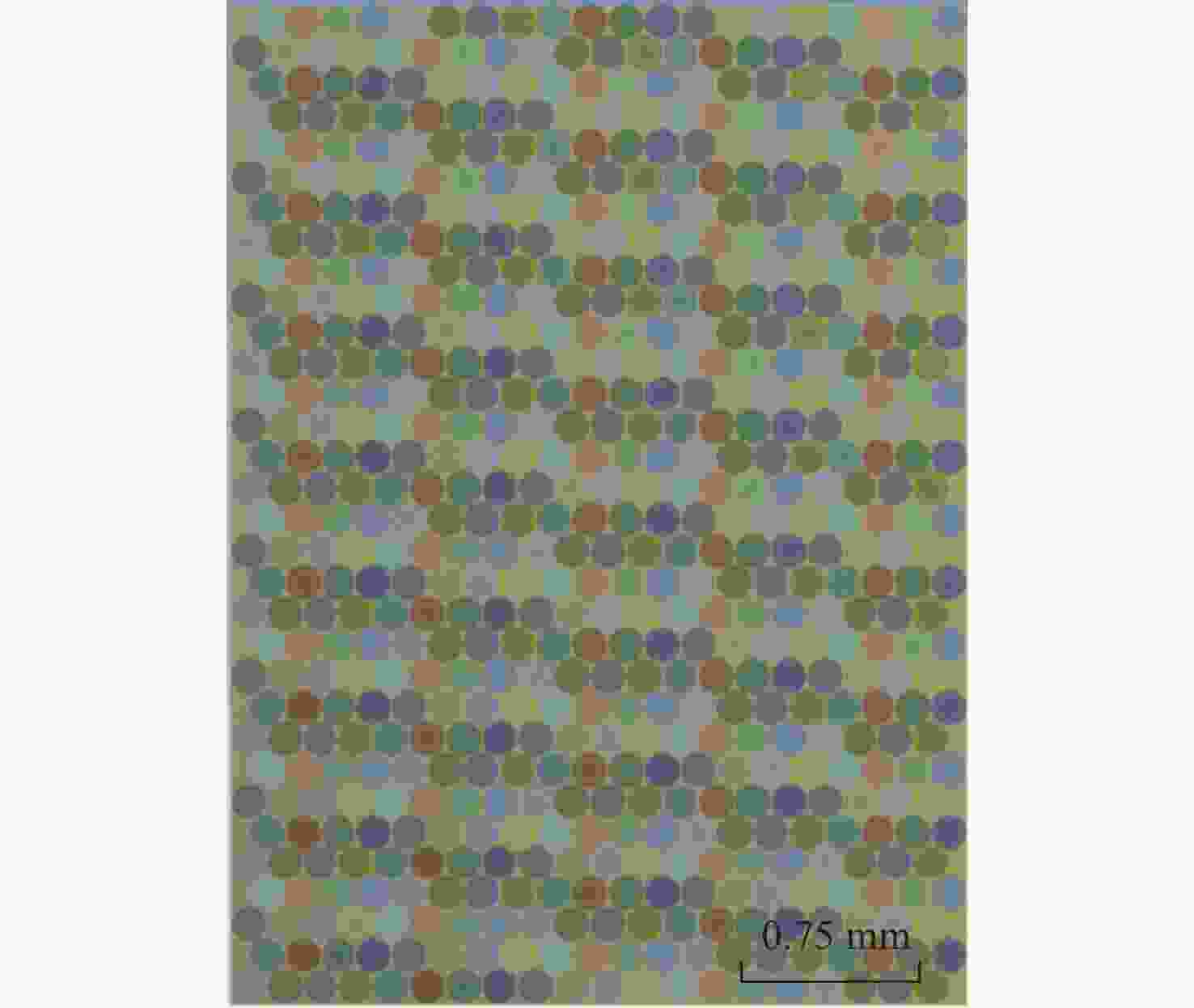

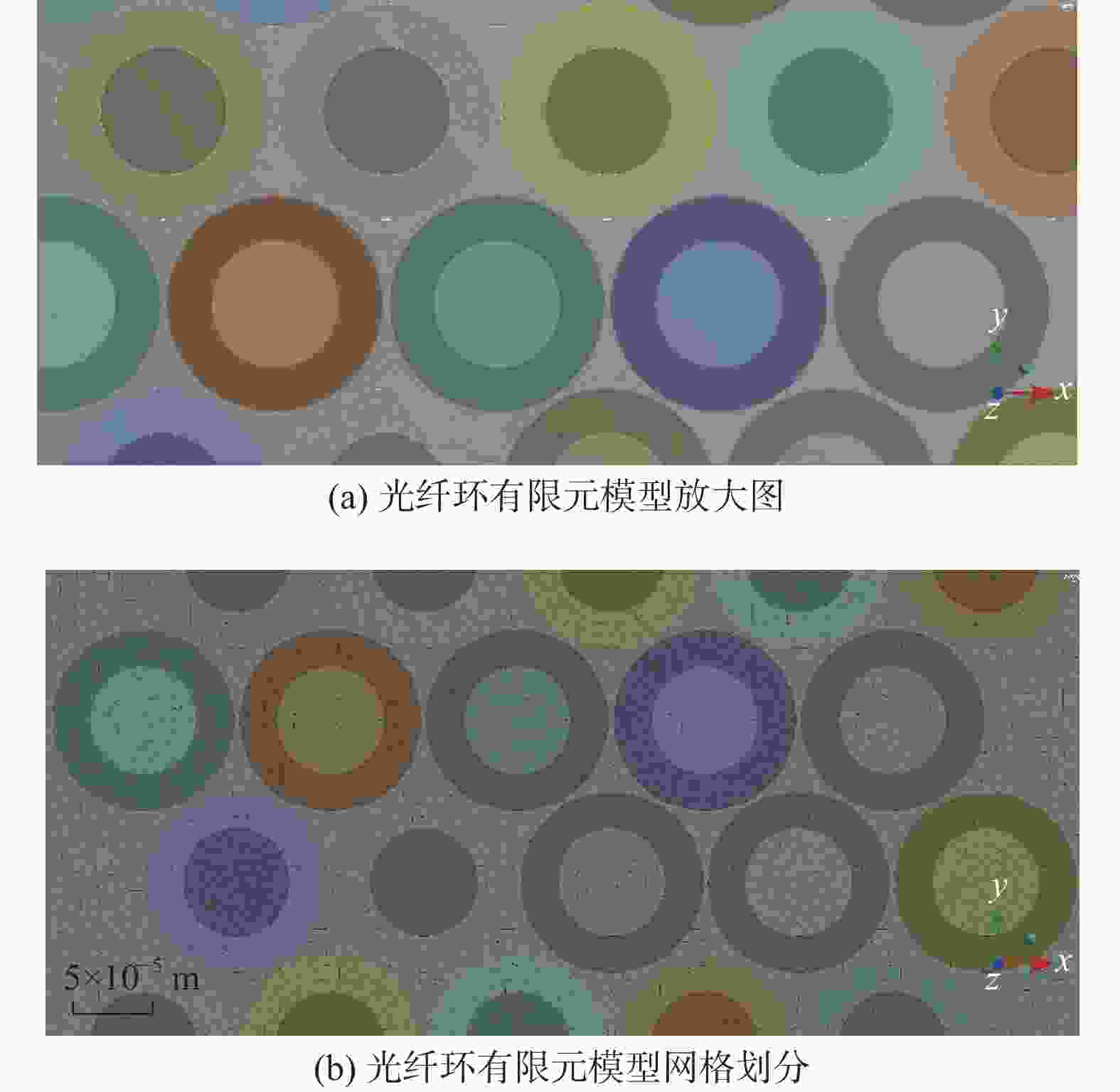

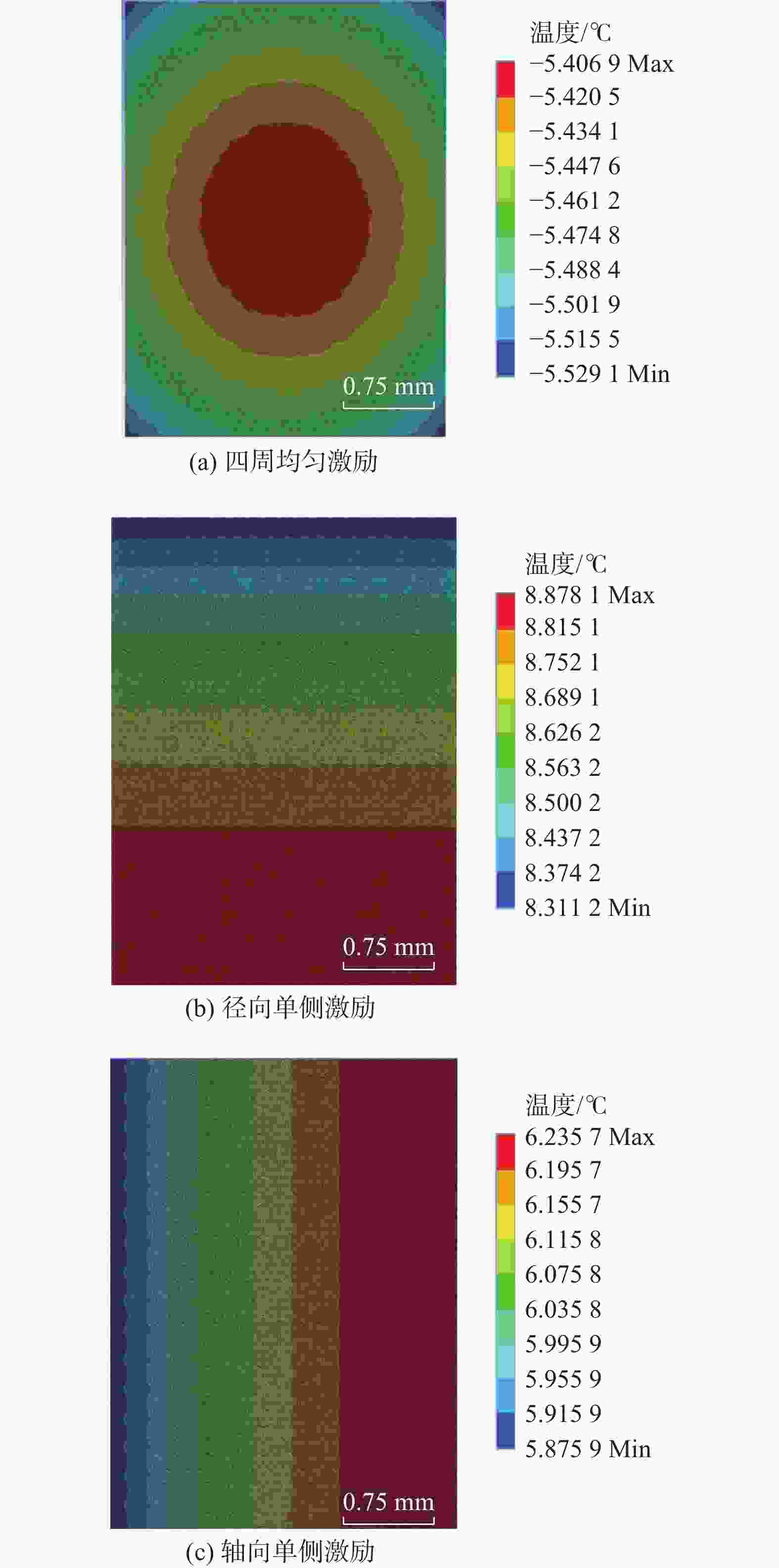

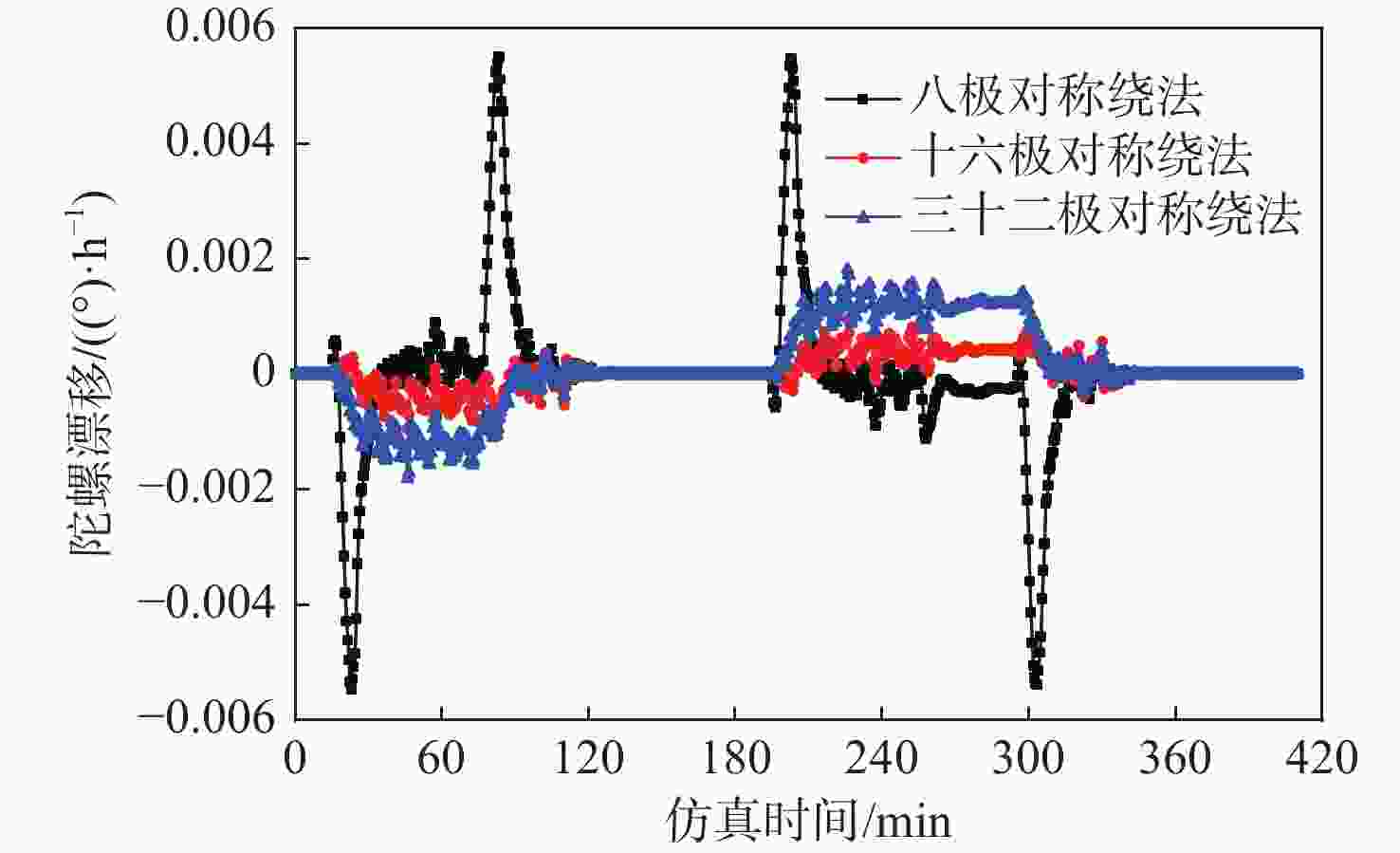

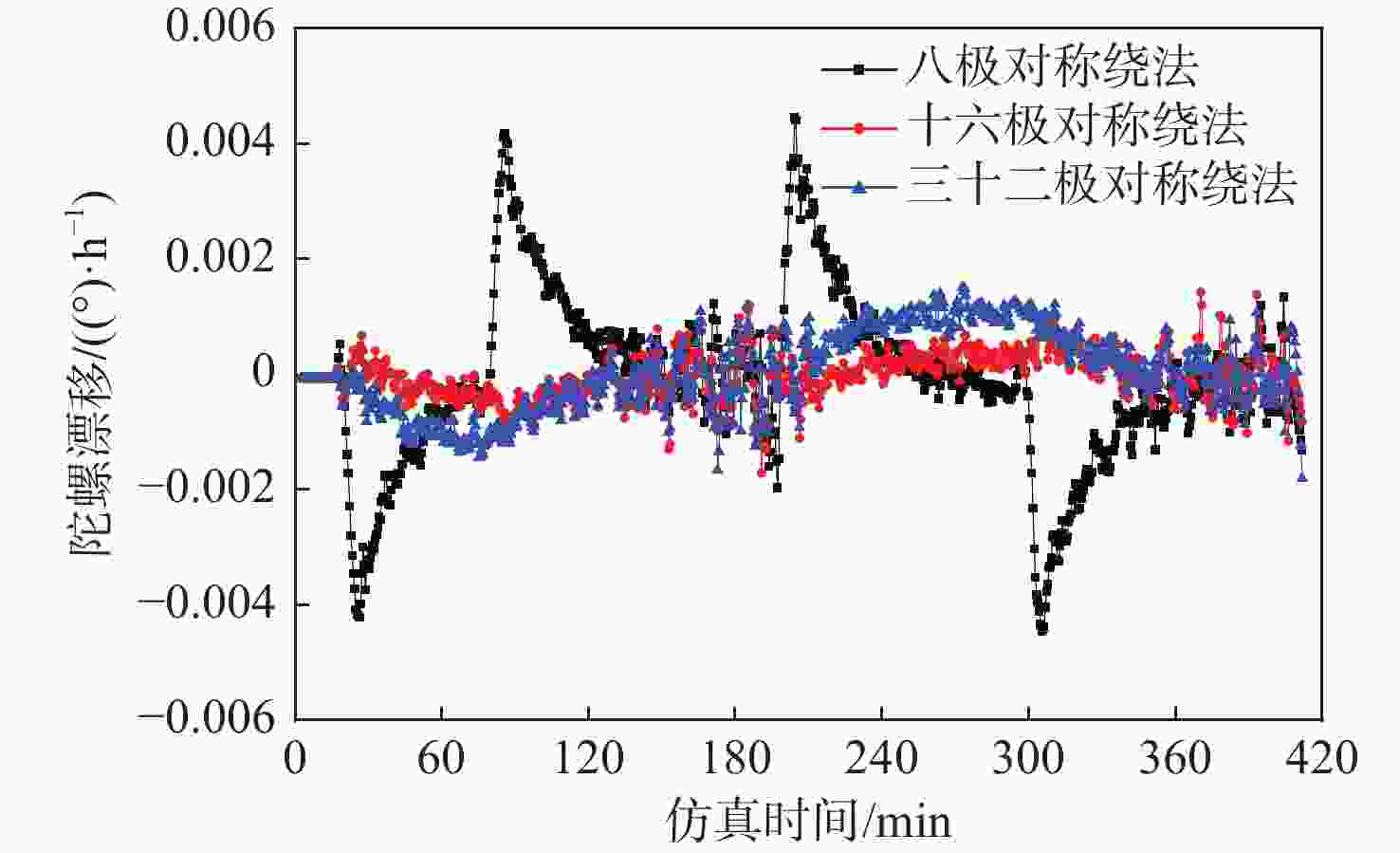

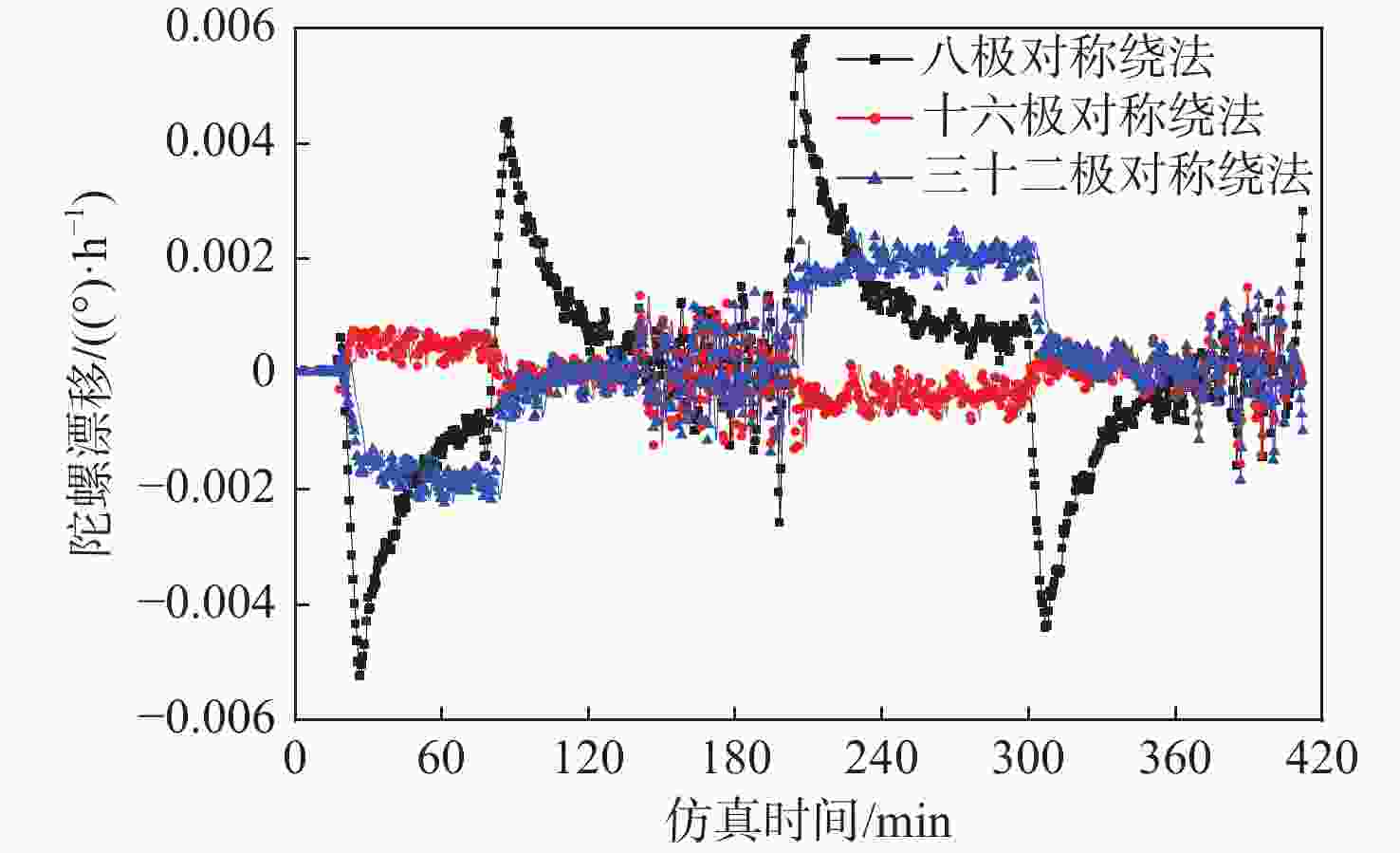

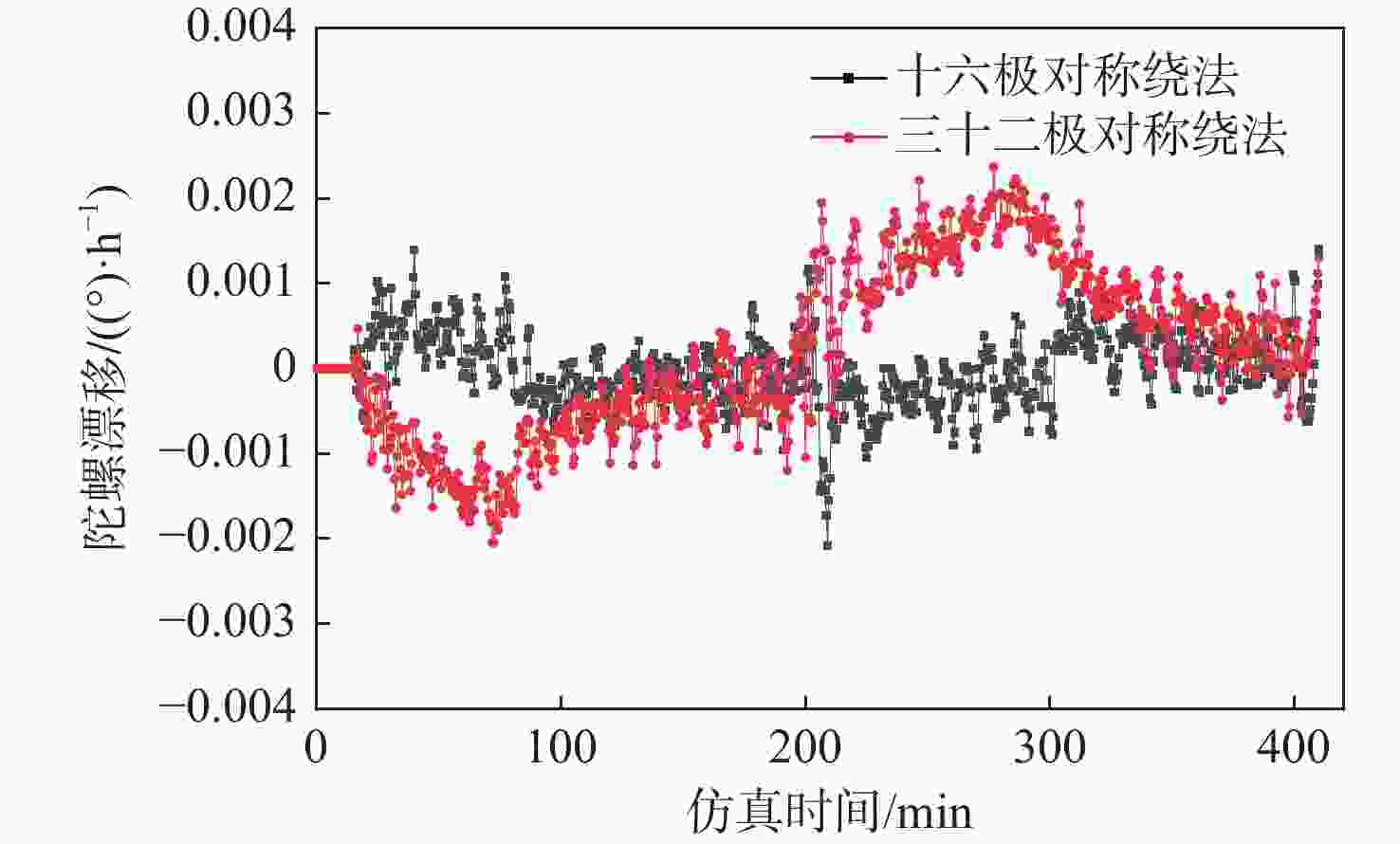

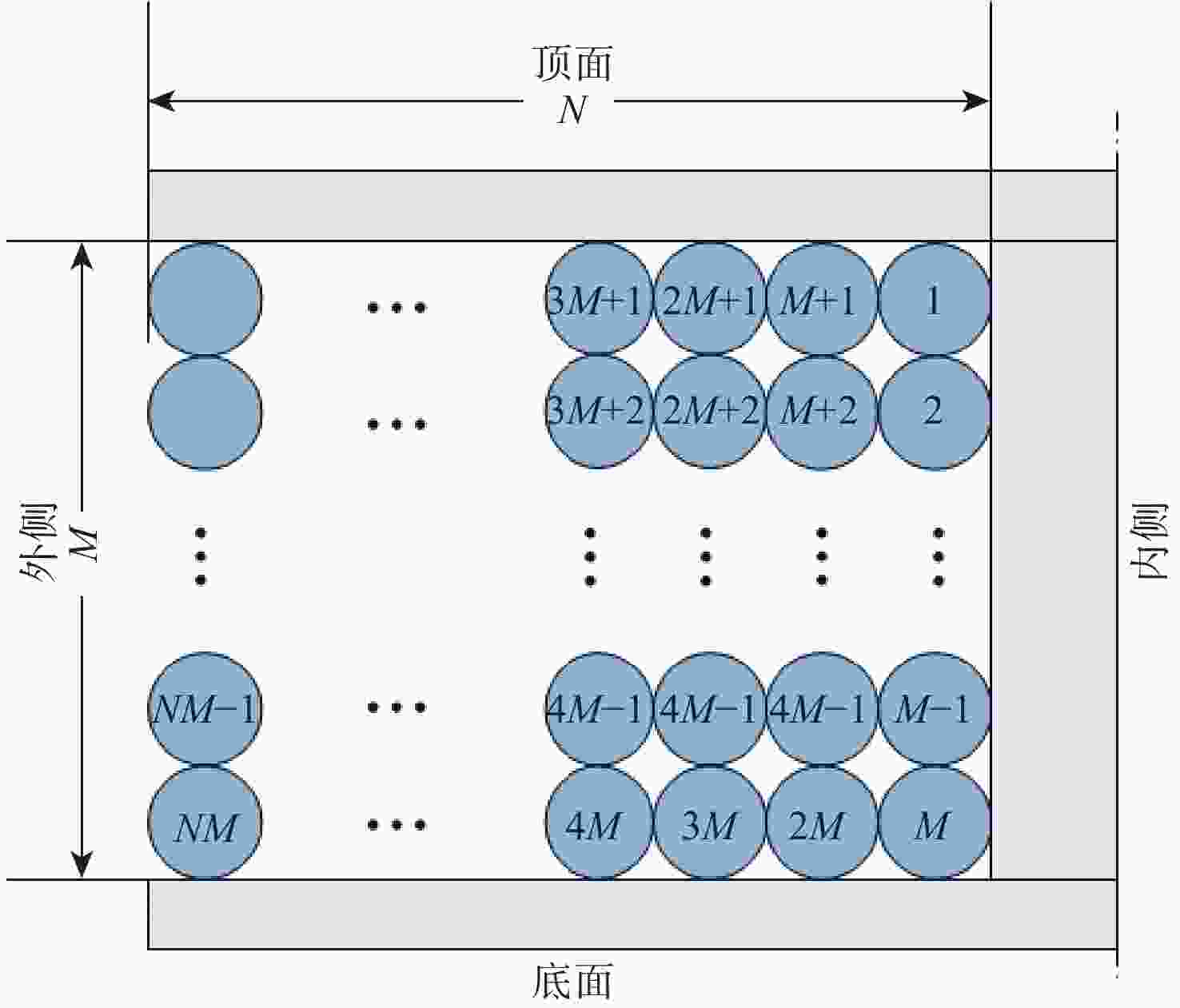

Shupe误差是高精度光纤陀螺(IFOG)工程化过程中的最大瓶颈问题之一。建立一个精确到匝的光纤环有限元模型,基于此模型,并在不同温度激励下分析八极、十六极和三十二极对称绕法的温度性能。仿真结果表明:相对于八极对称绕法,采用十六极对称绕法和三十二极对称绕法的光纤陀螺能够有效抑制热致陀螺漂移,且十六极对称绕法的抑制效果最好。这对高精度IFOG的光纤环绕制方法的选择提供了指导。

Abstract:The Shupe bias error is one of the biggest bottleneck problems in the engineering application of interferometric fiber optic gyroscope (IFOG). A turn-by-turn finite element model for fiber coils is established in this article. Based on this model, analyze the temperature performance of the 8 level, 16 level and 32 level symmetric winding method are analyzed under different temperature excitations. The results show that compared with octupolar symmetrical winding methods, the 16-polar and 32-polar symmetrical winding methods can effectively reduce the thermally induced gyro drift, and that the 16-polar symmetrical winding methods have the best temperature performance among the three methods. This conclusion provides guidance for the selection of fiber coil winding method for high precision IFOG.

-

表 1 仿真采用的光纤环结构参数

Table 1. Fiber coil structure parameter for simulation

参数 数值 层数 32 匝数 20 包层直径/m 0.000135 纤芯直径/m 0.00008 光纤环直径/m 0.1128 光纤总长/m 230.72 表 2 材料参数

Table 2. Material parameters

材料 密度ρ/

(kg·m−3)比热c/

( J·(kg·K)−1)导热率λ/

( W·(K·m2)−1)纤芯 2203 1 990 1.38 包层 1 900 1400 0.21 胶 970 1 600 0.21 表 3 各绕法不同温度激励方式热致陀螺漂移标准差

Table 3. Gyro drift SD of different temperature excitations and winding methods

(°)/h 绕制方法 四周均匀激励 径向单侧激励 轴向单侧激励 八极对称 0.00125 0.00149 0.00181 十六极对称 0.00029 0.00043 0.00045 三十二极对称 0.00073 0.00072 0.00123 表 4 64层光纤环各绕法热致陀螺漂移标准差

Table 4. Gyro drift SD of different winding methods with 64 layer fiber coil

(°)/h 绕制方法 标准差 十六极对称 0.00042 三十二极对称 0.00099 -

[1] VALI V, SHORTHILL R W. Fiber ring interferometer[J]. Applied Optics, 1976, 15(5): 1099-1100. doi: 10.1364/AO.15.001099 [2] 霍雷, 谢良平, 谌尧周, 等. 光纤陀螺的发展与应用[J]. 电子科技, 2015, 28(8): 174-177. doi: 10.16180/j.cnki.issn1007-7820.2015.08.049HUO L, XIE L P, CHEN Y Z, et al. Development and application of fiber optic gyroscopes[J]. Electronic Science and Technology, 2015, 28(8): 174-177(in Chinese). doi: 10.16180/j.cnki.issn1007-7820.2015.08.049 [3] SHUPE D. Thermally induced nonreciprocity in the fiber optic interferometer[J] Applied Optics, 1980, 19(5): 654-655. [4] FRIGO N J. Compensation of linear source of non-reciprocity in Sagnac interferometers[J]. Fiber Optic and Laser Sensor I, 1983, 412: 268-271. [5] MOHR F. Thermooptically induced bias drift in fiber optical Sagnac interferometers[J]. Journal of Lightwave Technology, 1995, 14(1): 27-41. [6] GAO Z X, ZHANG Y G, WANG G C, et al. Analysis and simulation for the thermal performance of the octupolar fiber coil[J]. Optical Engineering, 2014, 53(1): 016114. doi: 10.1117/1.OE.53.1.016114 [7] WILLIAMS M . Optical fiber placement for crossover-free fiber optic gyros[C]//Conference on Photorefractive Fiber and Crystal Devices. Materials, Optical Properties, and Applications, 2006, 6314: 108-118. [8] DU S S, GUAN Y M, JIN J, et al. Finite element model of thermal transient effect for crossover-free fiber optic gyros[J]. Optik, 2012, 123(8): 748-751. doi: 10.1016/j.ijleo.2011.06.036 [9] DYOTT R. Reduction of the Shupe effect in fibre optic gyros, the random-wound coil[J]. Electronics Letters, 1996, 32(23): 2177-2178. [10] 万洵, 谢良平. 光纤陀螺温度场仿真分析与陀螺外罩结构优化设计[J]. 应用光学, 2016, 37(3): 353-358. doi: 10.5768/JAO201637.0301006WAN X, XIE L P. Temperature field analysis and structure redesign of fiber optic gyroscope[J]. Journal of Applied Optics, 2016, 37(3): 353-358(in Chinese). doi: 10.5768/JAO201637.0301006 [11] 陈军, 王巍, 李晶, 等. 光纤线圈固化对光纤陀螺性能的影响[J]. 中国惯性技术学报, 2012, 20(6): 709-714. doi: 10.3969/j.issn.1005-6734.2012.06.018CHEN J, WANG W, LI J, et al. Effect caused by potted adhesive on FOG performance[J]. Journal of Chinese Inertial Technology, 2012, 20(6): 709-714(in Chinese). doi: 10.3969/j.issn.1005-6734.2012.06.018 [12] 黄云柯, 李强, 胡梦纯, 等. 光纤捷联惯性测量组合热设计及温度控制技术[J]. 上海航天, 2016, 33(S1): 122-126. doi: 10.19328/j.cnki.1006-1630.2016.S1.023HUANG Y K, LI Q, HU M C, et al. Research on temperature control and thermal design of FOG inertial measurement unit[J]. Aerospace Shanghai, 2016, 33(S1): 122-126(in Chinese). doi: 10.19328/j.cnki.1006-1630.2016.S1.023 [13] 冯卡力, 李安, 覃方君, 等. 光纤陀螺温度误差自适应神经模糊补偿方法[J]. 兵工学报, 2016, 37(4): 641-647. doi: 10.3969/j.issn.1000-1093.2016.04.010FENG K L, LI A, QIN F J, et al. Temperature error compensation method based on adaptive neuro fuzzy inference for fiber-optic gyro[J]. Acta Armamentarii, 2016, 37(4): 641-647(in Chinese). doi: 10.3969/j.issn.1000-1093.2016.04.010 [14] 李绪友, 张春梅, 刘华兵, 等. 光纤环十六极对称绕法温度性能的仿真与分析[J]. 中国惯性技术学报, 2016, 24(6): 780-785. doi: 10.13695/j.cnki.12-1222/o3.2016.06.015LI X Y, ZHANG C M, LIU H B, et al. Simulation and analysis on temperature performance of fiber ring by 16-polar symmetrical winding method[J]. Journal of Chinese Inertial Technology, 2016, 24(6): 780-785(in Chinese). doi: 10.13695/j.cnki.12-1222/o3.2016.06.015 [15] 李绪友, 凌卫伟, 许振龙, 等. 基于交叉法绕制的光纤环的槽体设计[J]. 光学学报, 2015, 36(6): 0606002. doi: 10.3788/AOS201535.0606002LI X Y, LING W W, XU Z L, et al. Design of a new spool for fiber coil based on cross winding pattern[J]. Acta Optica Sinica, 2015, 36(6): 0606002(in Chinese). doi: 10.3788/AOS201535.0606002 [16] 王玥泽, 陈晓冬, 张桂才, 等. 八极绕法对光纤陀螺温度性能的影响[J]. 中国惯性技术学报, 2012, 20(5): 617-620. doi: 10.3969/j.issn.1005-6734.2012.05.023WANG Y Z, CHEN X D, ZHANG G C, et al. Effect of octupole winding on temperature performance of fiber optic gyroscope[J]. Journal of Chinese Inertial Technology, 2012, 20(5): 617-620(in Chinese). doi: 10.3969/j.issn.1005-6734.2012.05.023 -

下载:

下载: