Detection of debonding defect in CFRP laminates using infrared pulse thermal wave tomography

-

摘要:

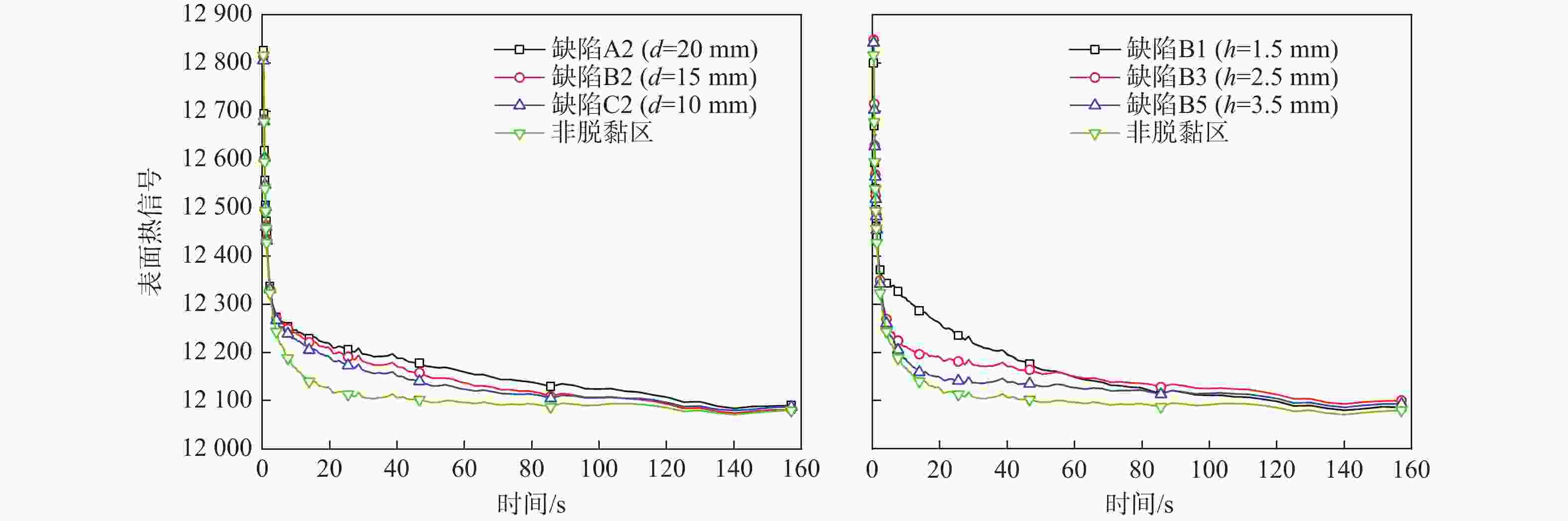

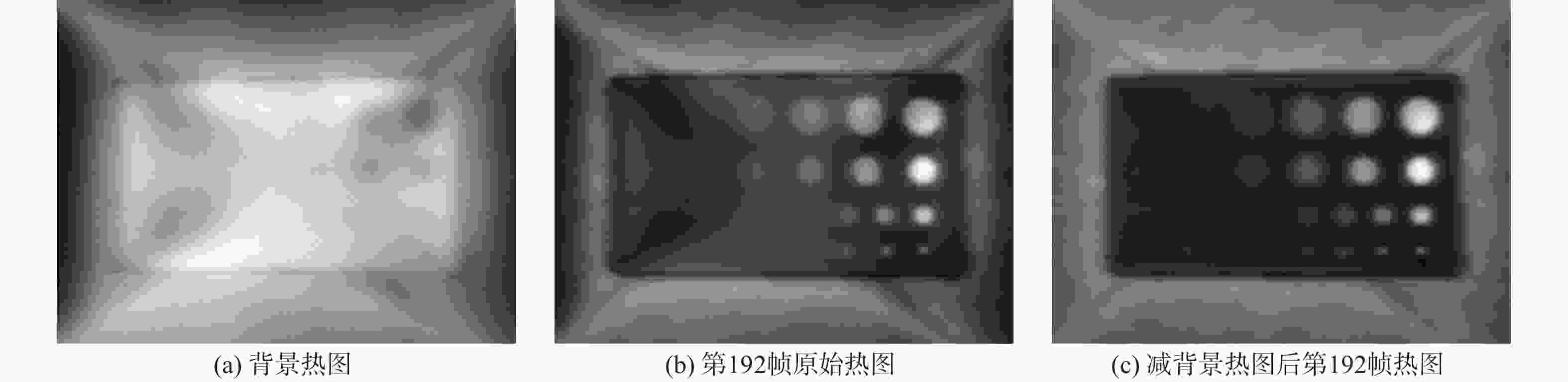

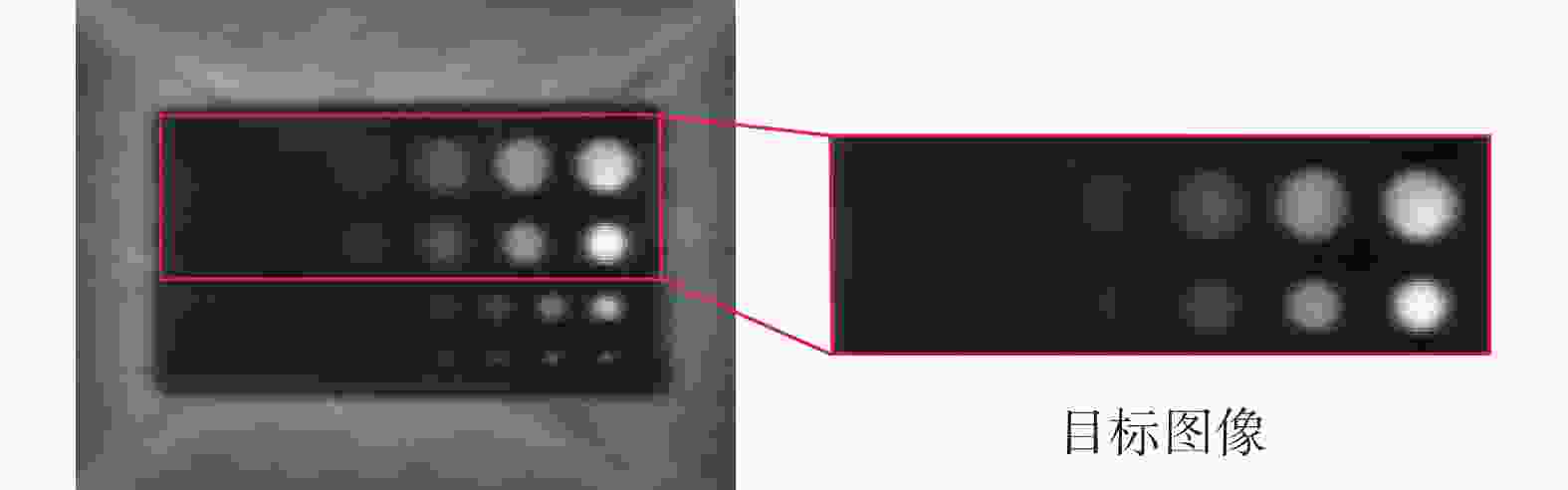

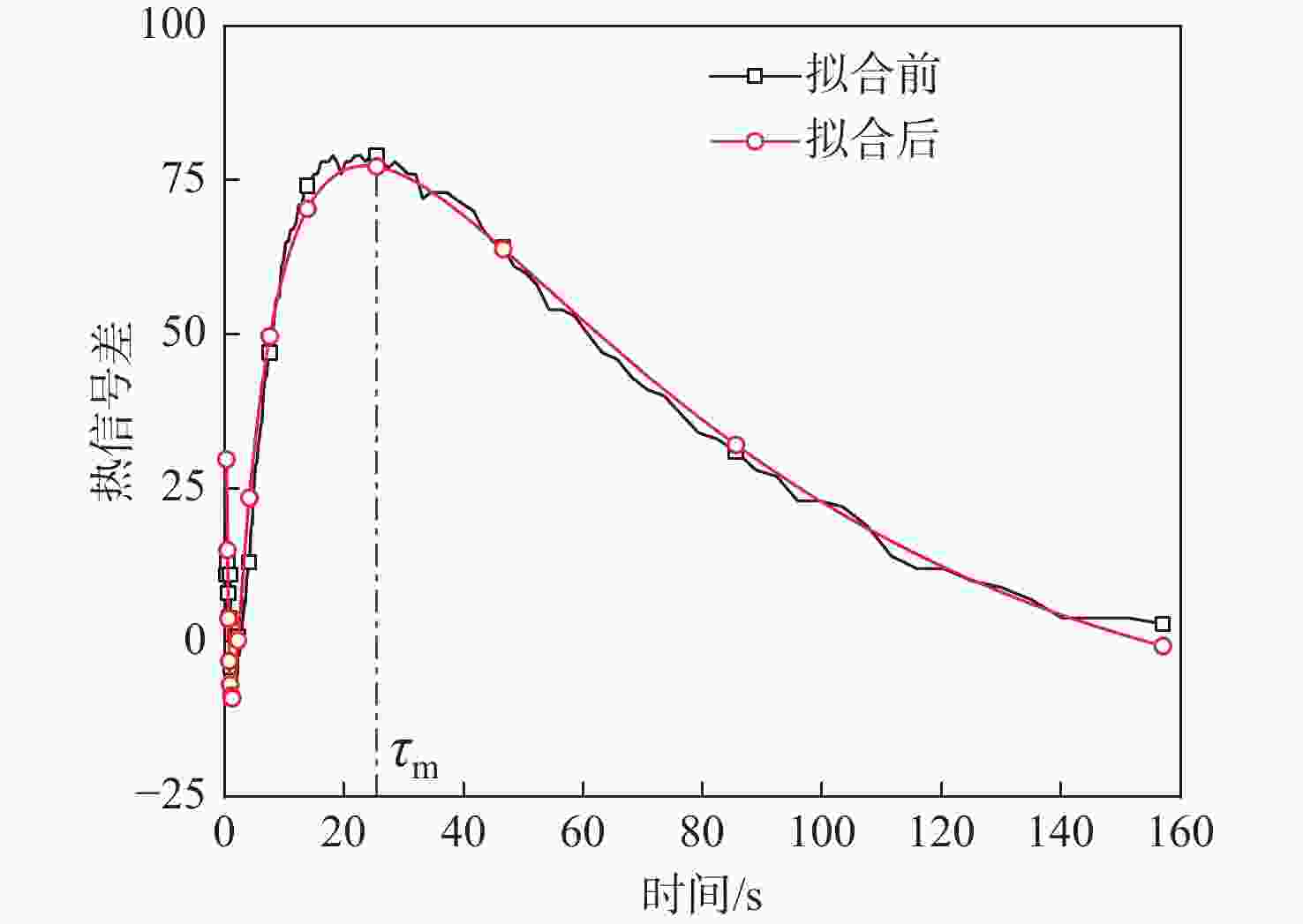

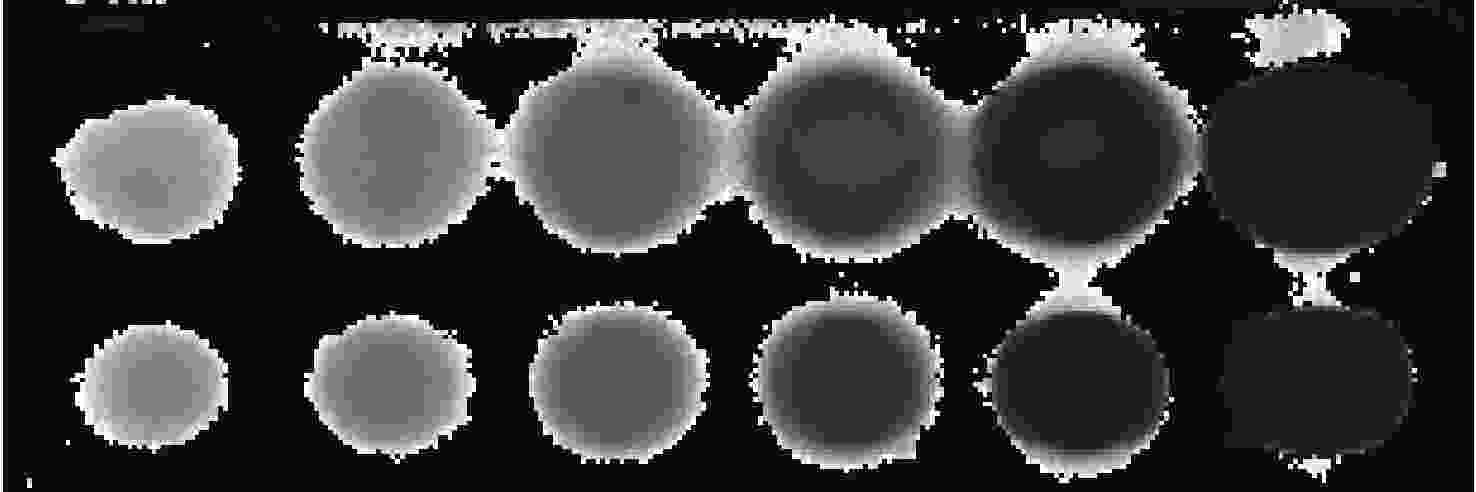

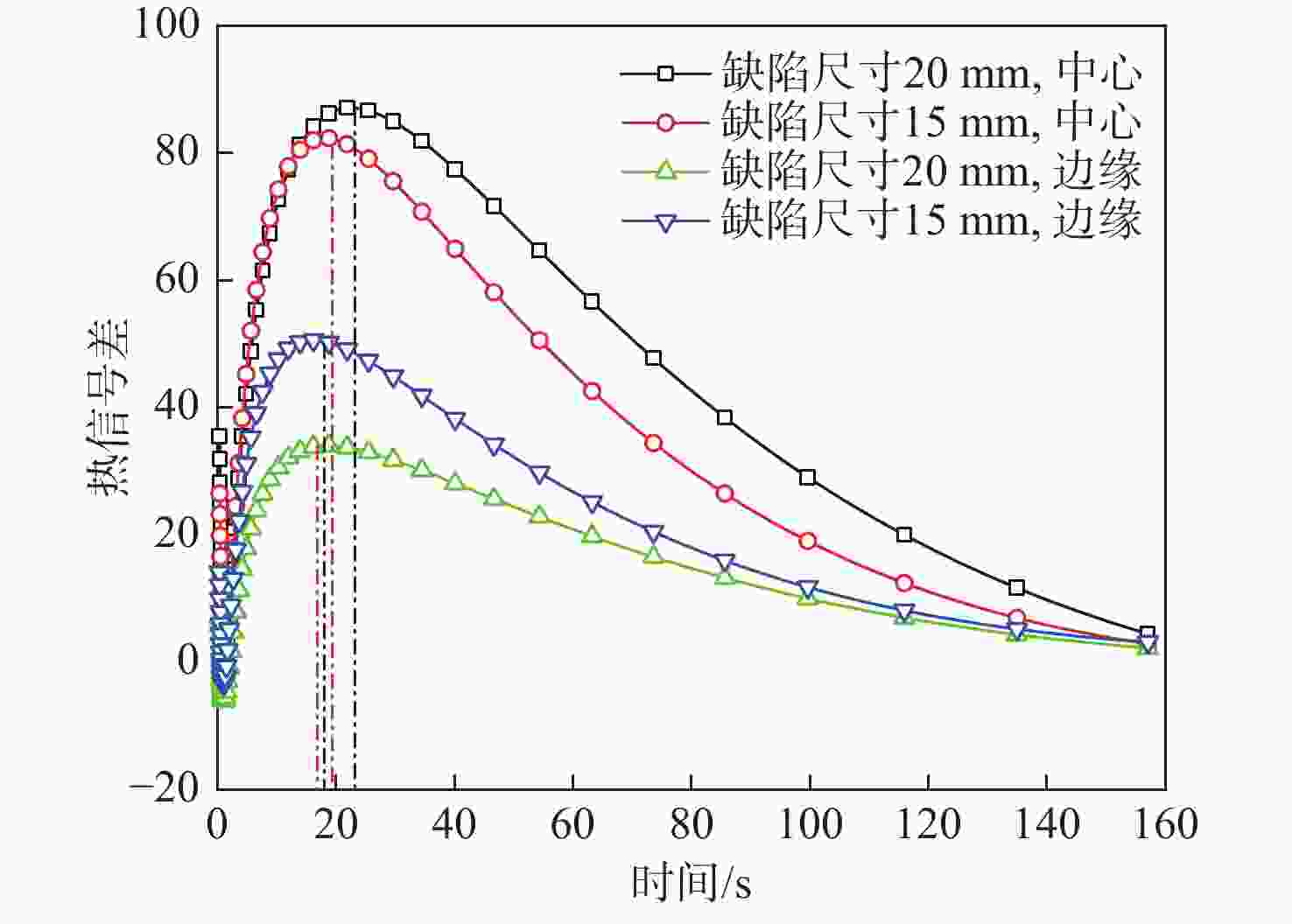

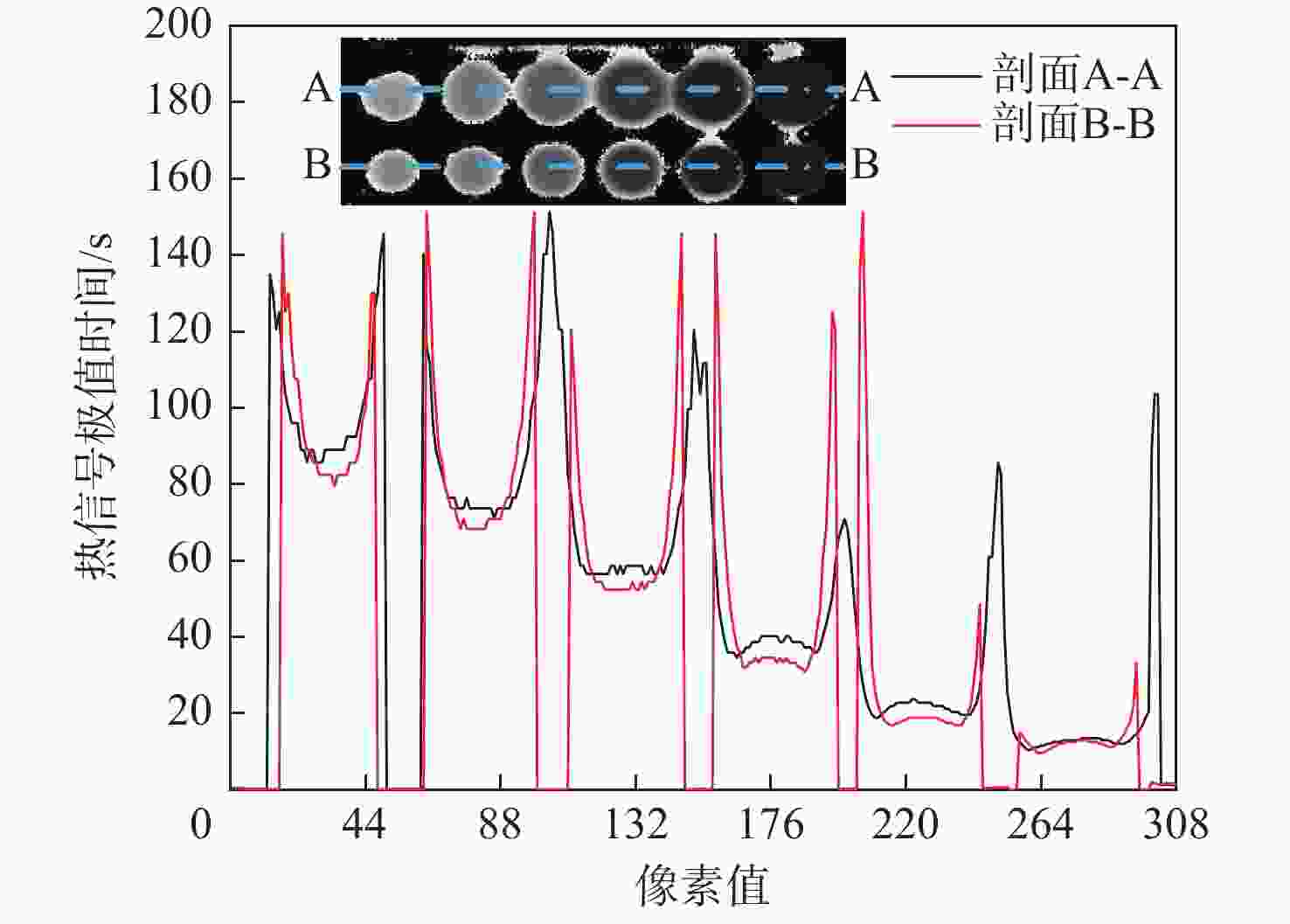

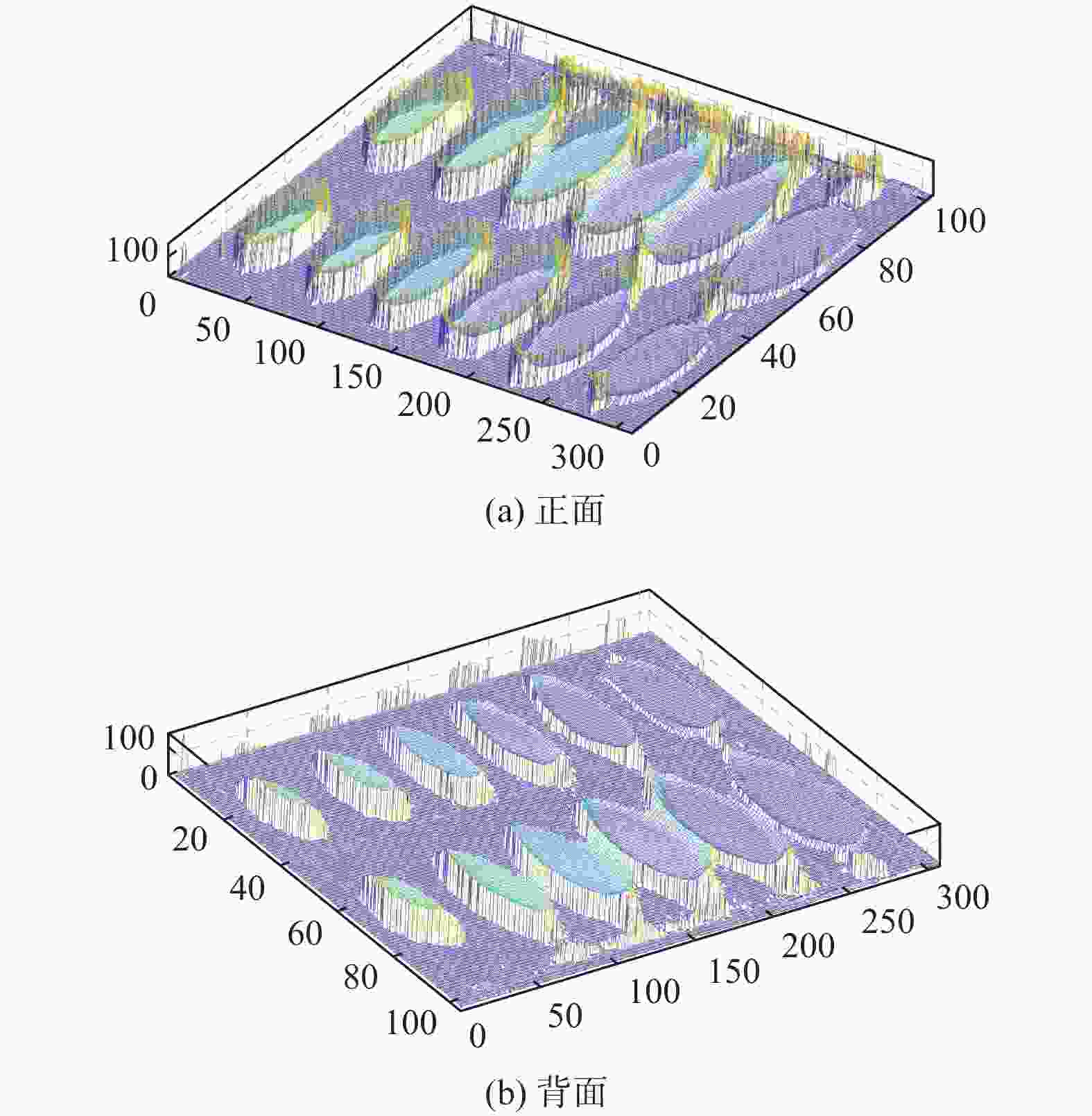

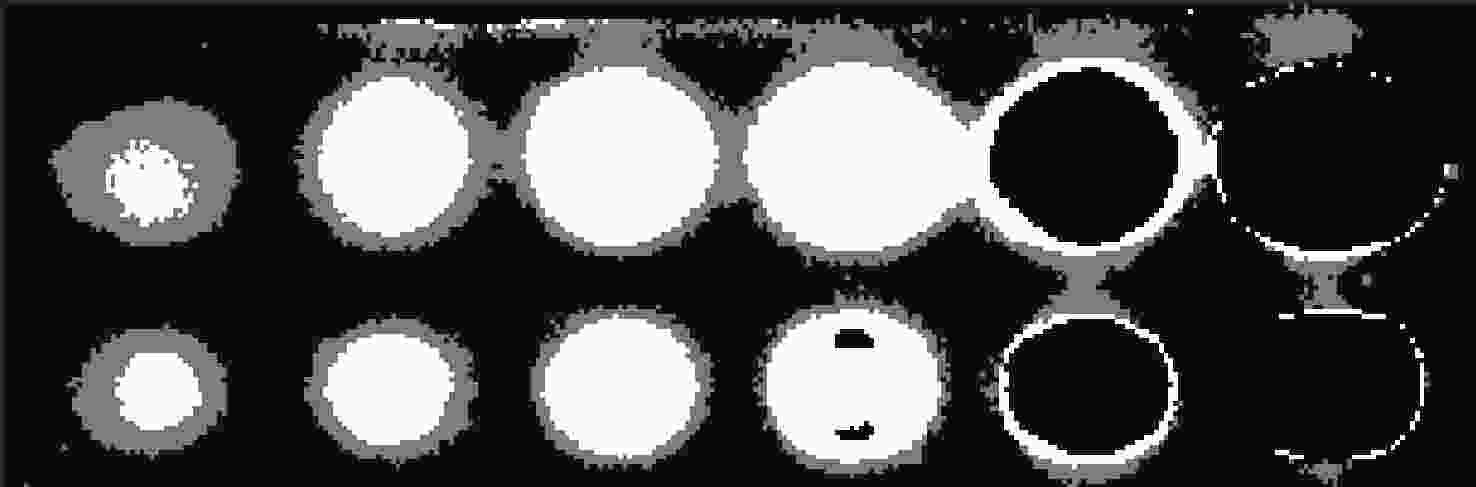

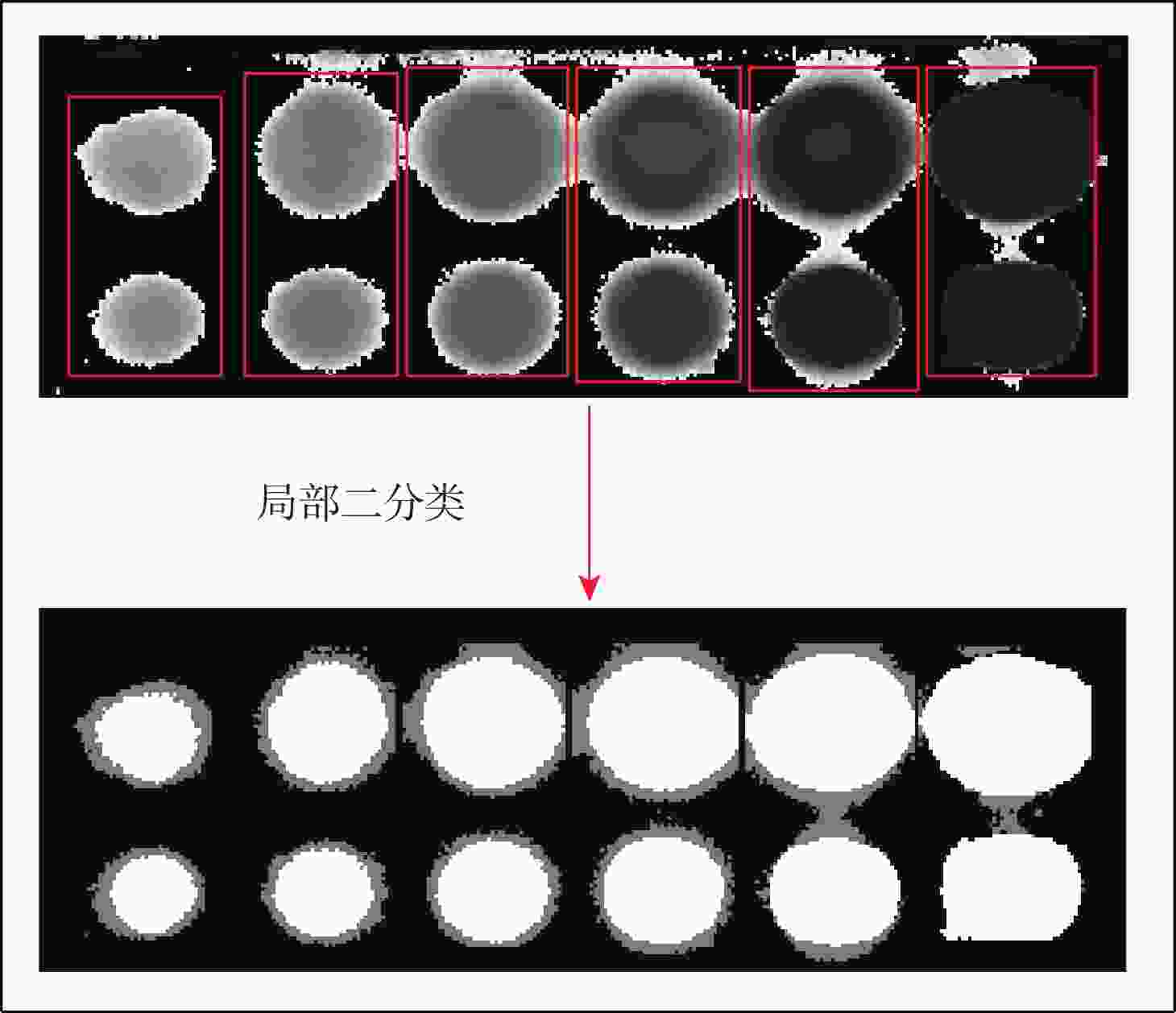

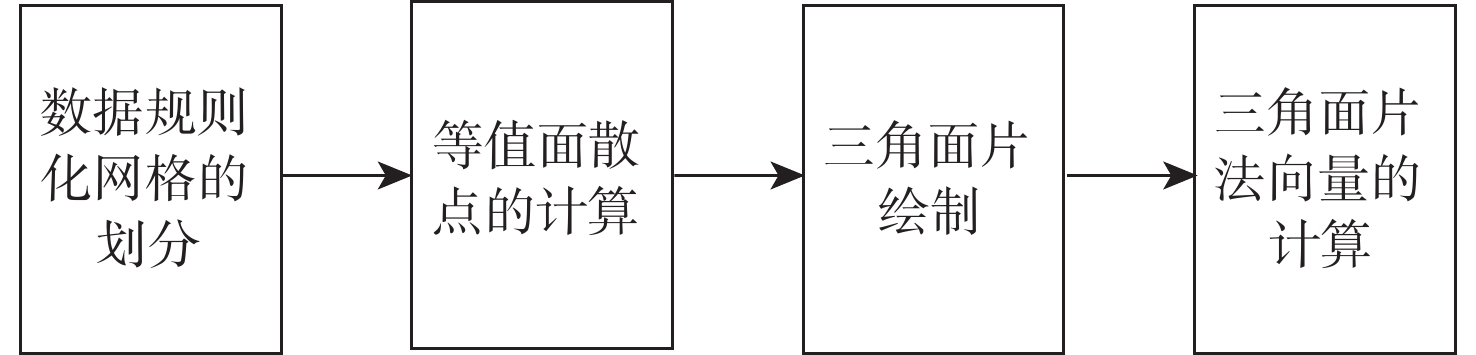

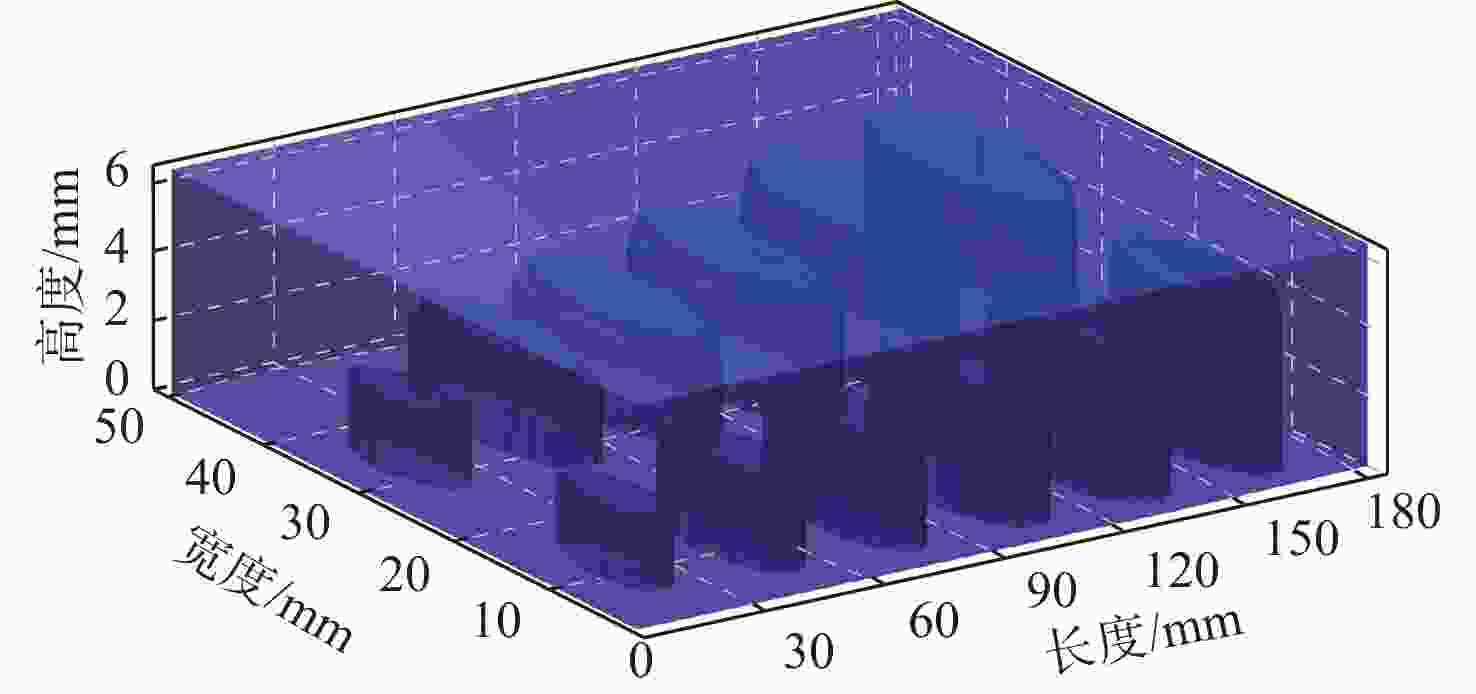

为实现基于红外脉冲热波成像检测碳纤维增强塑料(CFRP)层压板脱黏缺陷的三维层析成像,完善外场定量检测保障体系,提高层压板在服役过程中的安全性和可靠性,开展了红外脉冲热波层析成像方法与检测技术研究。制备了一种人工脱粘缺陷试样,采用红外脉冲热波层析成像检测技术对脱粘缺陷进行检测,分析了脱粘区和非脱粘区的表面热信号瞬态响应过程及红外脉冲热波层析成像对脱粘缺陷的检测能力。通过脱粘区与非脱粘区基于对数多项式拟合的重构热信号差,计算得到热信号极值时间图像,分析了脱粘区极值时间变化规律及缺陷状态;采用核函数模糊C均值聚类对相同缺陷深度对应的极值时间数组进行二分类,由此计算数组平均值作为缺陷对应极值时间;将该时间与脱粘区极值时间数组建立统计关系来构造断层图像序列,并计算其对应的缺陷深度;在此基础上,利用等值面绘制方法实现层压板脱粘缺陷三维可视化。研究表明,红外脉冲热波层析成像能够定量检测CFRP层压板脱粘缺陷,准确可靠显示层压板内部缺陷的分布和形貌,检测缺陷深度与实际缺陷深度的最大相对偏差低于15%,对工程应用具有一定指导意义。

Abstract:To achieve the three-dimensional tomography for detecting debonding defects of carbon fiber reinforced plastic (CFRP) laminates based on infrared pulse thermal wave imaging, consummate the out-field quantitative detection guarantee system, and improve the safety and reliability of laminates in service, research on infrared pulse thermal wave tomography method and detection technology is carried out. A specimen with artificial debonding defects was prepared, infrared pulse thermal wave imaging technology is employed to detect debonding defects. The transient response process of surface thermal signal in debonding and sound region and detection ability of infrared pulse thermal wave imaging are analyzed. Through reconstructed thermal signal difference between debonding and sound region based on logarithmic polynomial fitting, extreme time of thermal signal are calculated, and the change law of debonding region extreme time and defect state are analyzed;. Kernel fuzzy C-means clustering is used to classify extreme time array corresponding to the same defect depth, and the array average value is calculated as defect extreme time. Statistical relationship between the time and debonding region extreme time array is established to construct tomographic images sequence, and the corresponding defect depth is calculated. Three-dimensional visualization of debonding defects in laminate is achieved by isosurface drawing method. Research shows that infrared pulse thermal wave tomography can detect debonding defects of CFRP laminate. This method can accurately and reliably display distribution and morphology of internal defects in laminate. Maximum relative deviation between detected and actual defect depth is less than 15%, which has certain guiding significance for engineering application.

-

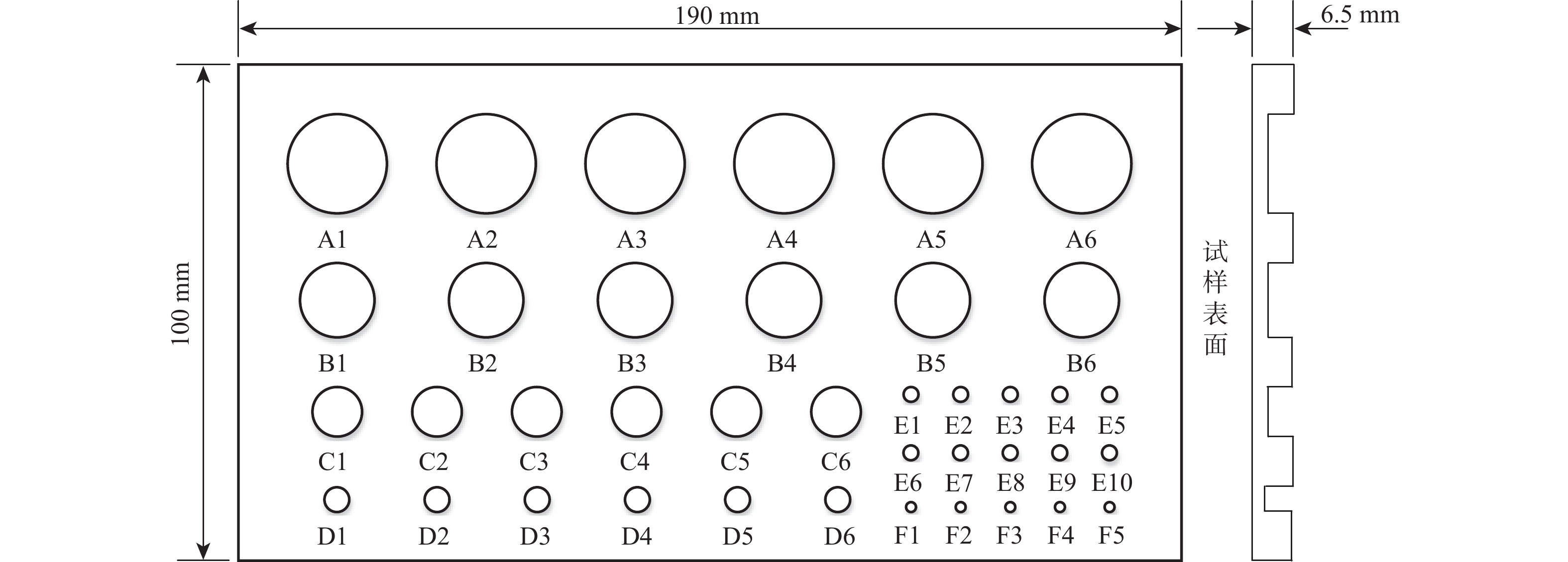

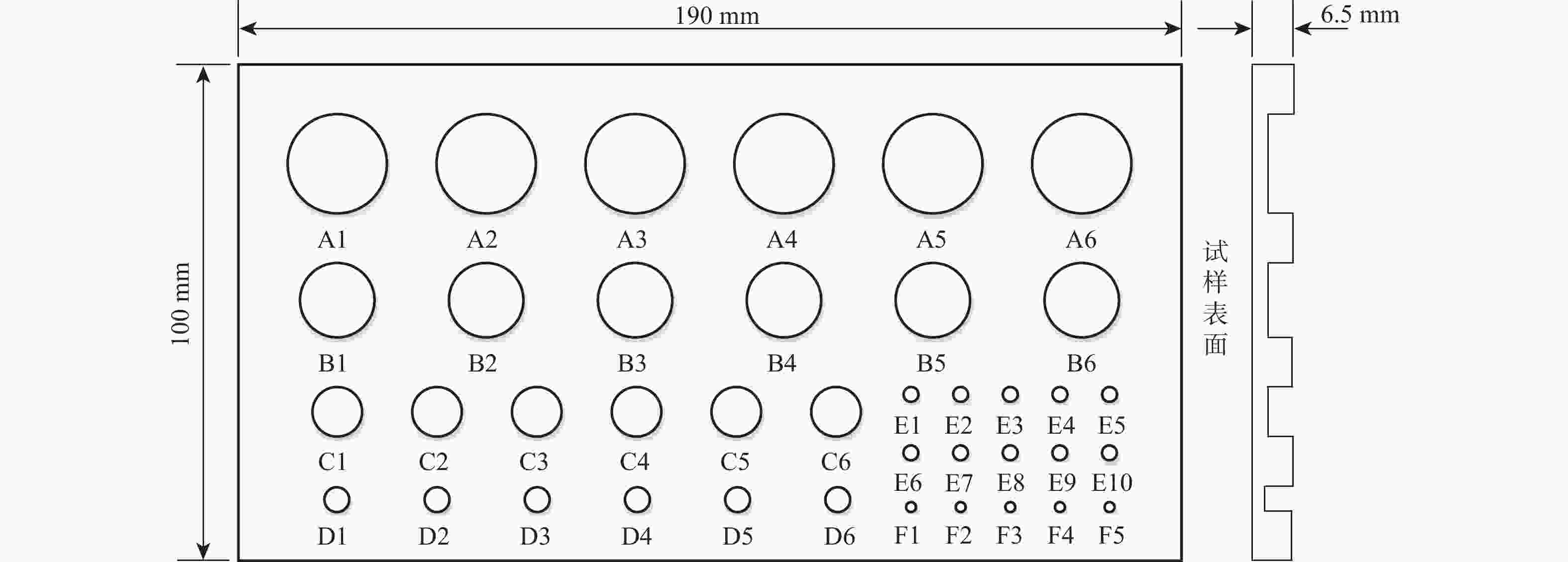

表 1 试样孔深度h

Table 1. Sample hole depth h

mm 编号 A($ d = 20 $ mm) B($ d = 15 $ mm) C($ d = 10 $ mm) D($ d = 5 $ mm) E($ d = 3 $ mm) F($ d = 2 $ mm) 1 $ 1.5 $ $ 1.5 $ $ 1.5 $ $ 1 $ $ 1 $ $ 1 $ 2 $ 2 $ $ 2 $ $ 2 $ $ 1.5 $ $ 1.25 $ $ 1.25 $ 3 $ 2.5 $ $ 2.5 $ $ 2.5 $ $ 2 $ $ 1.5 $ $ 1.5 $ 4 $ 3 $ $ 3 $ $ 3 $ $ 2.5 $ $ 1.75 $ $ 1.75 $ 5 $ 3.5 $ $ 3.5 $ $ 3.5 $ $ 3 $ $ 2 $ $ 2 $ 6 $ 4 $ $ 4 $ $ 4 $ $ 3.5 $ $ 2.25 $ 7 $ 2.5 $ 8 $ 2.75 $ 9 $ 3 $ 10 $ 3.25 $ 表 2 缺陷深度计算结果

Table 2. Calculation results of defect depth

编号 实际缺陷深度/mm 计算缺陷深度/mm 绝对误差/mm 相对误差/% A6、B6 4 4.376 0.376 9.40 A5、B5 3.5 3.835 0.335 9.57 A4、B4 3 3.402 0.402 13.40 A3、B3 2.5 2.773 0.273 10.92 A2、B2 2 2.165 0.165 8.25 A1、B1 1.5 1.672 0.172 11.47 -

[1] 尚金龙, 李思海, 陈贻明. 纤维增强塑料在航空航天领域中的应用[J]. 塑料工业, 2019, 47(1): 148-151. doi: 10.3969/j.issn.1005-5770.2019.01.032SHANG J L, LI S H, CHEN Y M. Application of fiber reinforced plastic in aerospace field[J]. China Plastics Industry, 2019, 47(1): 148-151(in Chinese). doi: 10.3969/j.issn.1005-5770.2019.01.032 [2] 薄纯强. 碳纤维机翼缺陷的锁相红外无损检测研究[D]. 哈尔滨: 哈尔滨工业大学, 2019: 1.BO C Q. Non-destructive testing research of CFRP airfoil defects based on lock-in infrared thermography[D]. Harbin: Harbin Institute of Technology, 2019: 1(in Chinese). [3] 梁涛. 复合材料脱粘缺陷红外热成像无损检测定量分析研究[D]. 成都: 电子科技大学, 2017: 1.LIANG T. Quantitative analysis of infrared thermal imaging nondestructive testing for debonding defects of composite materials[D]. Chengdu: University of Electronic Science and Technology of China, 2017: 1(in Chinese). [4] 李晓霞, 伍耐明, 段玉霞, 等. 碳纤维层合板低速冲击后的红外热波检测分析[J]. 复合材料学报, 2010, 27(6): 88-93. doi: 10.13801/j.cnki.fhclxb.2010.06.022LI X X, WU N M, DUAN Y X, et al. Infrared thermal wave imaging for carbon fiber laminated boards after low velocity impact[J]. Acta Materiae Compositae Sinica, 2010, 27(6): 88-93(in Chinese). doi: 10.13801/j.cnki.fhclxb.2010.06.022 [5] PENG W, WANG F, MENG X L, et al. Dynamic thermal tomography based on continuous wavelet transform for debonding detection of the high silicon oxygen phenolic resin cladding layer[J]. Infrared Physics & Technology, 2018, 92(5): 115-121. [6] 赵洪宝, 马丹, 马超群, 等. 航空用碳纤维复合材料典型缺陷无损检测技术研究[J]. 电子制作, 2020(24): 35-37. doi: 10.3969/j.issn.1006-5059.2020.24.014ZHAO H B, MA D, MA C Q, et al. Study on nondestructive testing technology of typical defects of aviation carbon fiber composites for aviation[J]. Practical Electronics, 2020(24): 35-37(in Chinese). doi: 10.3969/j.issn.1006-5059.2020.24.014 [7] 南方, 肖鹏. 复合材料结构表面状态的红外热成像检测影响研究[J]. 航空制造技术, 2019, 62(14): 83-87. doi: 10.16080/j.issn1671-833x.2019.14.083NAN F, XIAO P. Research of composites surface influence on thermography detection technology[J]. Aeronautical Manufacturing Technology, 2019, 62(14): 83-87(in Chinese). doi: 10.16080/j.issn1671-833x.2019.14.083 [8] 王扬, 李科, 刘俊岩. CFRP复合材料层板缺陷的红外热波成像检测方法[J]. 航空制造技术, 2016, 59(4): 36-42. doi: 10.16080/j.issn1671-833x.2016.04.036WANG Y, LI K, LIU J Y. Nondestructive testing and evaluation (NDT&E) for CFRP laminate with subsurface defects using infrared thermal wave imaging[J]. Aeronautical Manufacturing Technology, 2016, 59(4): 36-42(in Chinese). doi: 10.16080/j.issn1671-833x.2016.04.036 [9] 张金玉, 杨正伟, 田干, 等. 红外热波检测及其图像序列处理技术[M]. 北京: 国防工业出版社, 2015: 16-17.ZHANG J Y, YANG Z W, TIAN G, et al. Infrared thermal wave testing and images sequence processing technology[M]. Beijing: National Defense Industry Press, 2015: 16-17(in Chinese). [10] 姜千辉, 姜长胜, 葛庆平, 等. 红外热波序列图像的图像分割与三维显示[J]. 无损检测, 2008, 30(2): 100-103. doi: 10.3969/j.issn.1000-6656.2008.02.010JIANG Q H, JIANG C S, GE Q P, et al. Segmentation and 3D display of infrared thermal image[J]. Nondestructive Testing, 2008, 30(2): 100-103(in Chinese). doi: 10.3969/j.issn.1000-6656.2008.02.010 [11] TOIVANEN J M, TARVAINEN T, HUTTUNEN J M J, et al. Thermal tomography utilizing truncated Fourier series approximation of the heat diffusion equation[J]. International Journal of Heat and Mass Transfer, 2017, 108: 860-867. doi: 10.1016/j.ijheatmasstransfer.2016.12.060 [12] TAVAKOLIAN P, SIVAGURUNATHAN K, MANDELIS A. Enhanced truncated-correlation photothermal coherence tomography with application to deep subsurface defect imaging and 3-dimensional reconstructions[J]. Journal of Applied Physics, 2017, 122(2): 023103. doi: 10.1063/1.4992807 [13] MELNYK S I, MELNYK S S, TULUZOV I G. Method of projection dynamic thermal tomography (PDTT)[C]//International Conference on Quantitative Infrared Thermography. [S.1.]:[s.n.], 2012: 1-6. [14] ELHASSNAOUI A, SAHNOUN S. A three-dimensional reconstruction algorithm for pulsed thermography[J]. Journal of Materials and Environmental Science, 2014, 5(4): 983-988. [15] VAVILOV V P, NESTERUK D A, SHIRYAEV V V, et al. Thermal (infrared) tomography: Terminology, principal procedures, and application to nondestructive testing of composite materials[J]. Russian Journal of Nondestructive Testing, 2010, 46(3): 151-161. doi: 10.1134/S1061830910030010 [16] 彭伟. 药柱包覆层缺陷红外脉冲成像及动态层析检测技术研究[D]. 哈尔滨: 哈尔滨工业大学, 2020: 79-80.PENG W. Study on infrared pulse imaging and dynamic chromatography detection technology for coating defects of grain[D]. Harbin: Harbin Institute of Technology, 2020: 79-80(in Chinese). [17] VAVILOV V, MALDAGUE X, DUFORT B, et al. Thermal nondestructive testing of carbon epoxy composites: Detailed analysis and data processing[J]. NDT & E International, 1993, 26(2): 85-95. [18] VAVILOV V. Dynamic thermal tomography: Recent improvements and applications[J]. NDT & E International, 2015, 71: 23-32. [19] PAWAR S S, VAVILOV V P. Applying the heat conduction-based 3D normalization and thermal tomography to pulsed infrared thermography for defect characterization in composite materials[J]. International Journal of Heat and Mass Transfer, 2016, 94: 56-65. doi: 10.1016/j.ijheatmasstransfer.2015.11.018 [20] PENG W, WANG F, LIU J Y, et al. Pulse phase dynamic thermal tomography investigation on the defects of the solid-propellant missile engine cladding layer[J]. International Journal of Thermophysics, 2018, 39(4): 48-59. doi: 10.1007/s10765-018-2366-3 -

下载:

下载: