-

摘要:

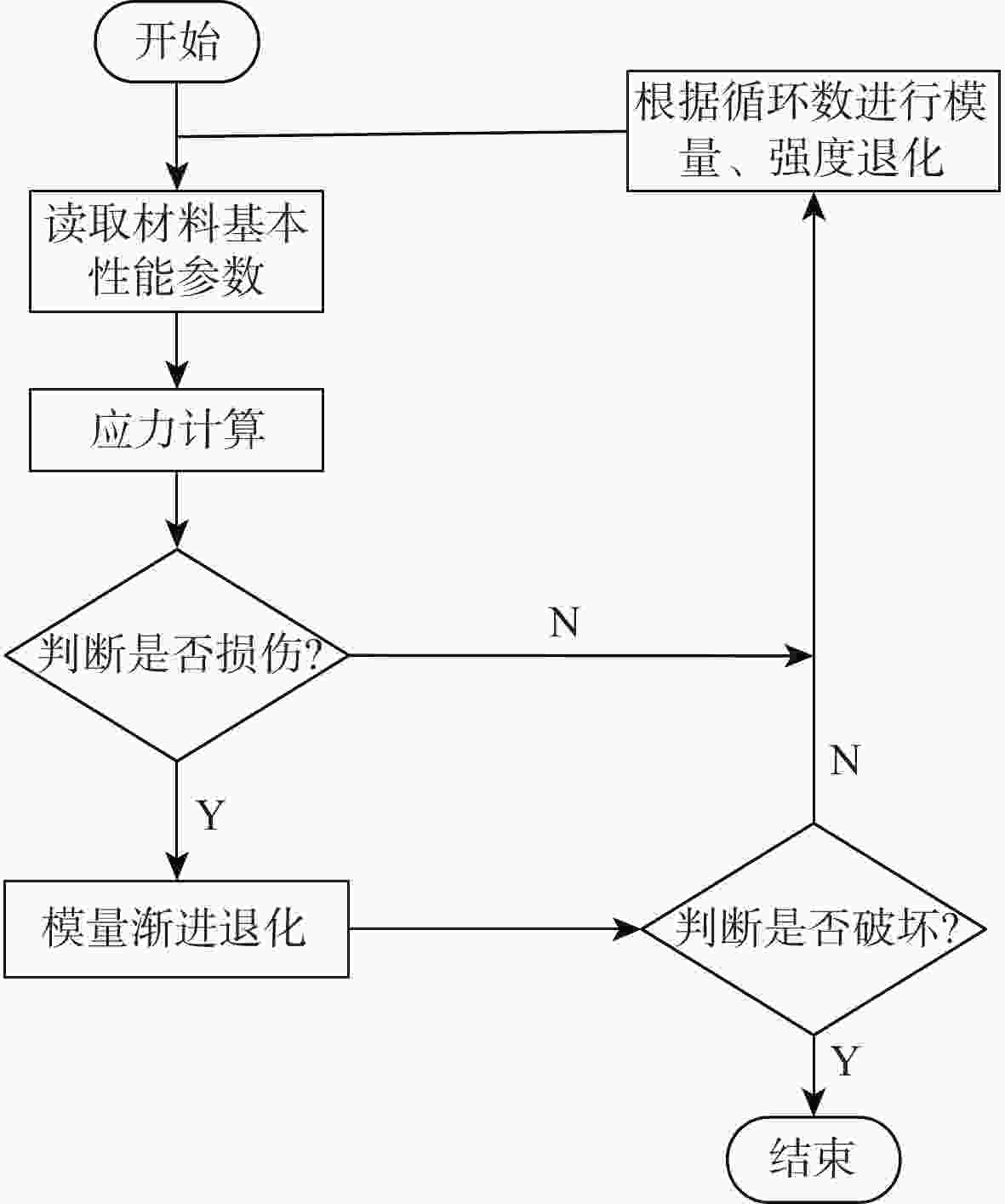

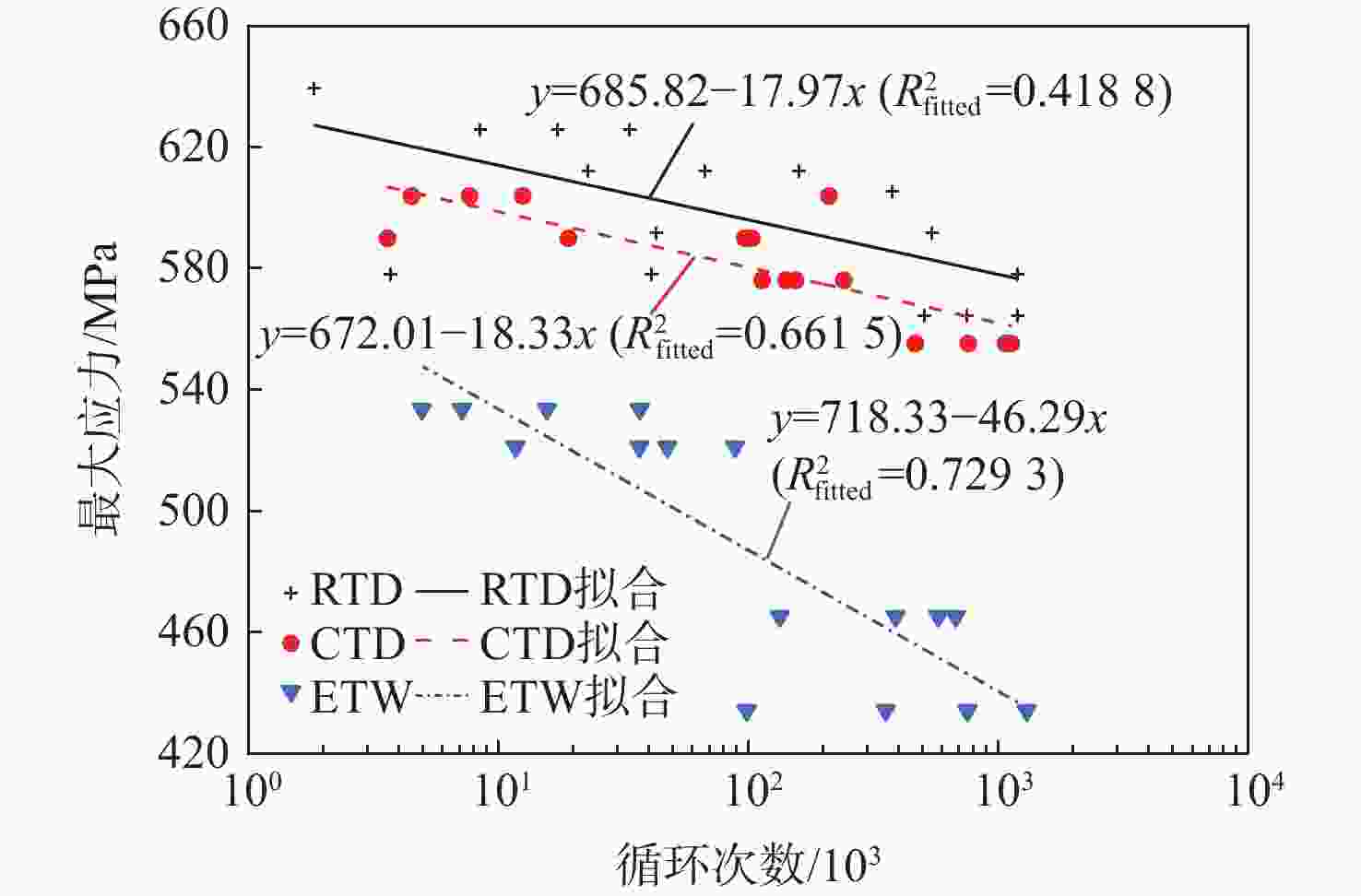

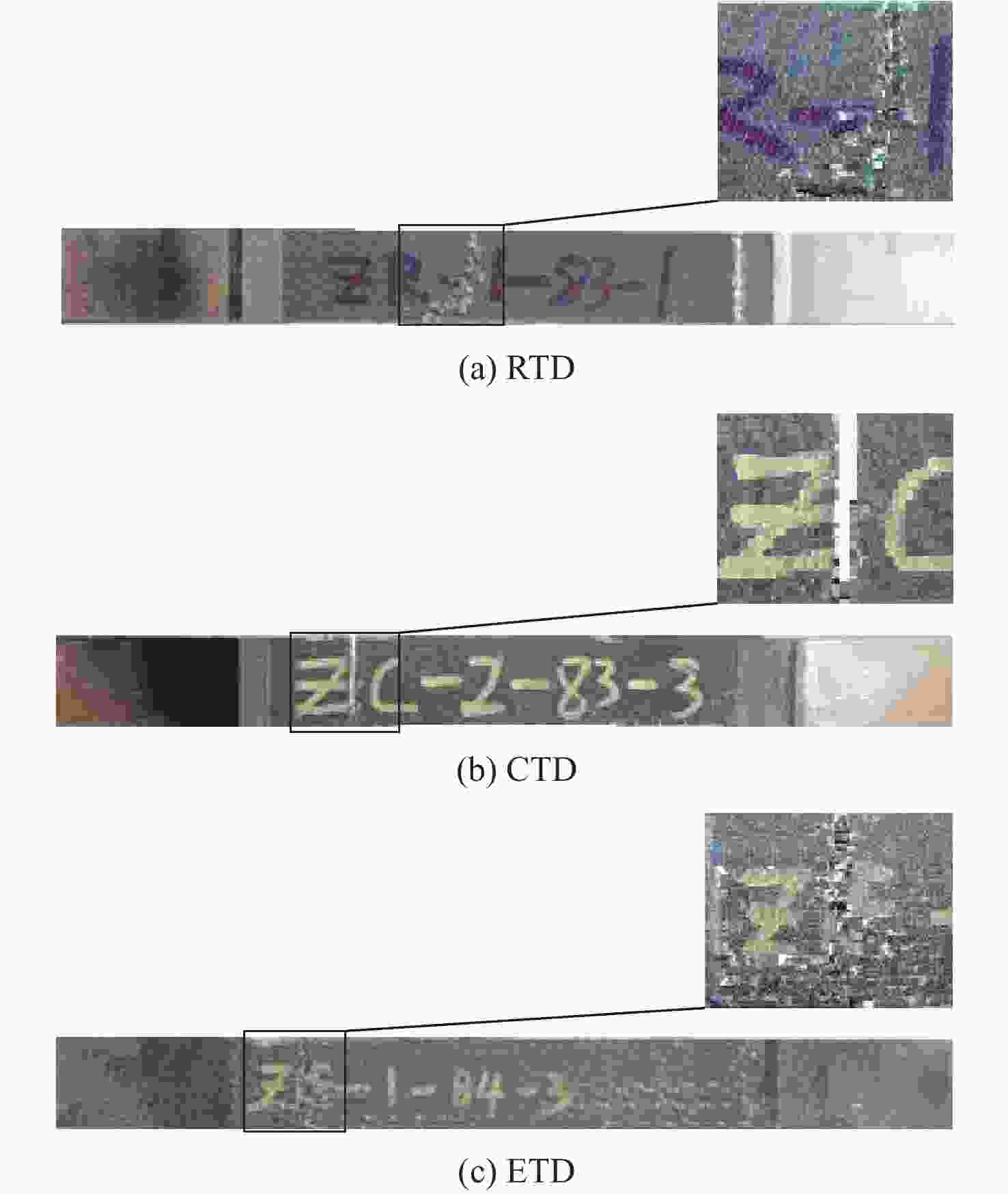

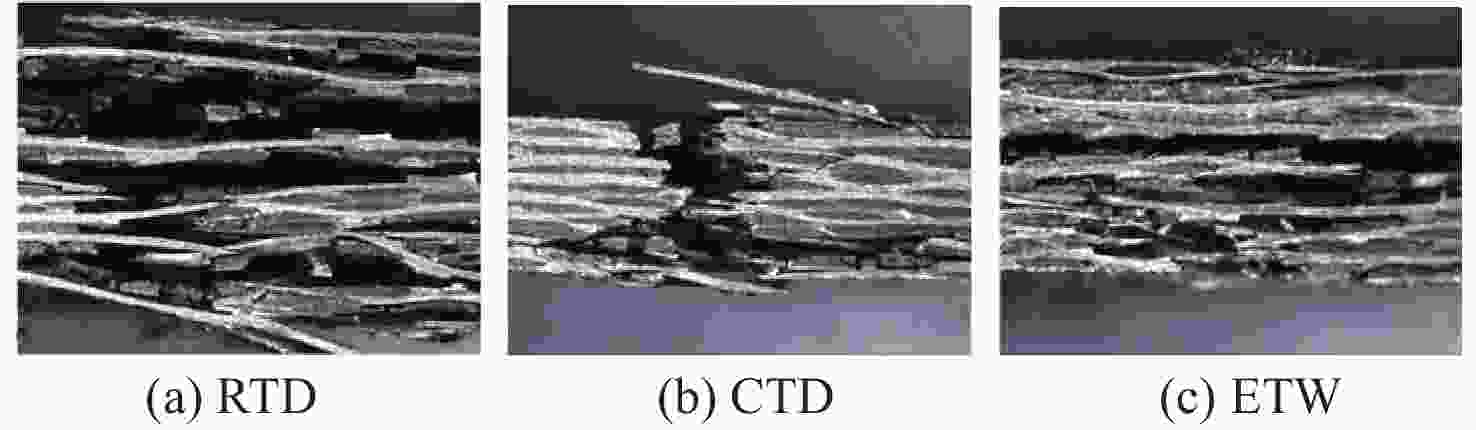

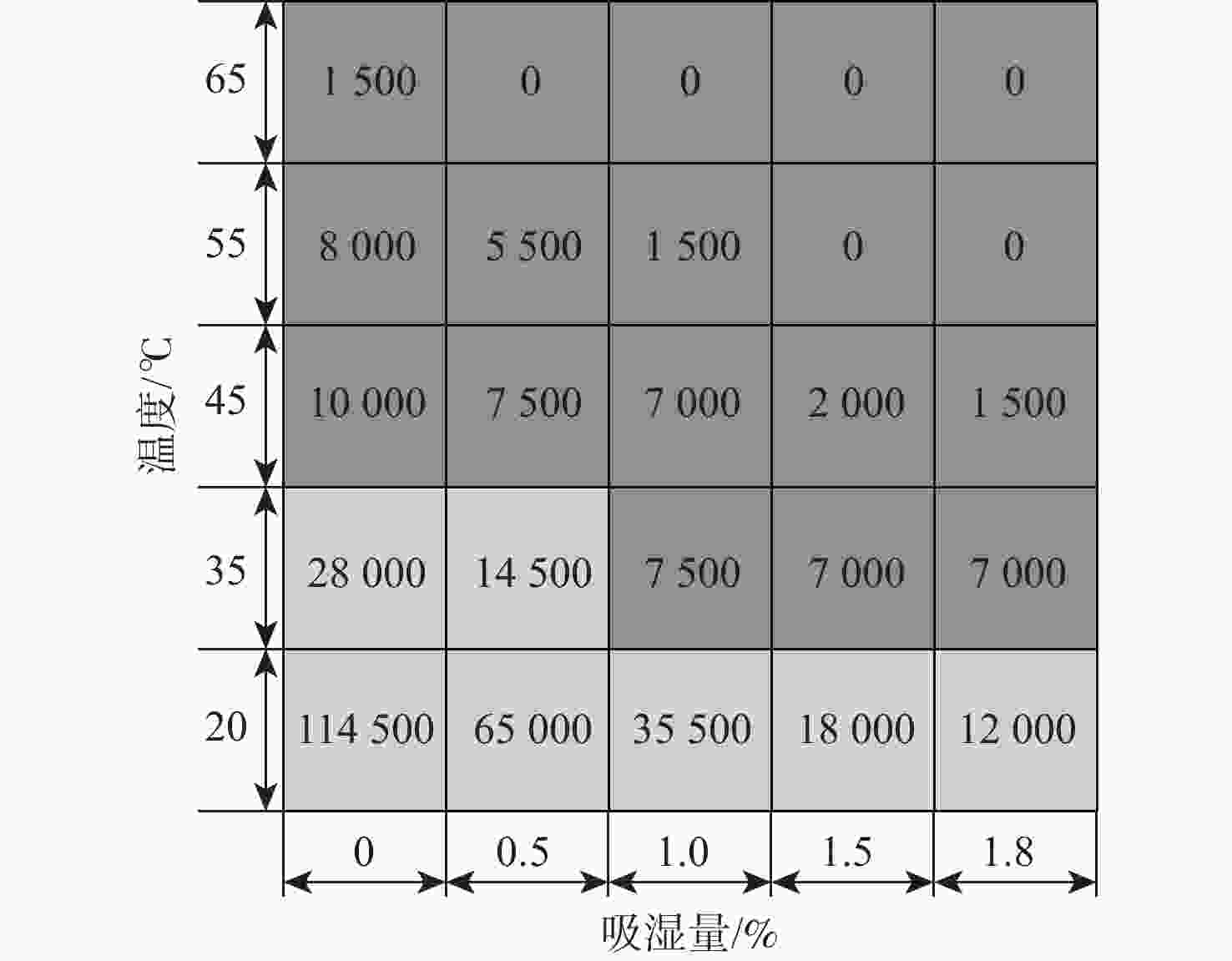

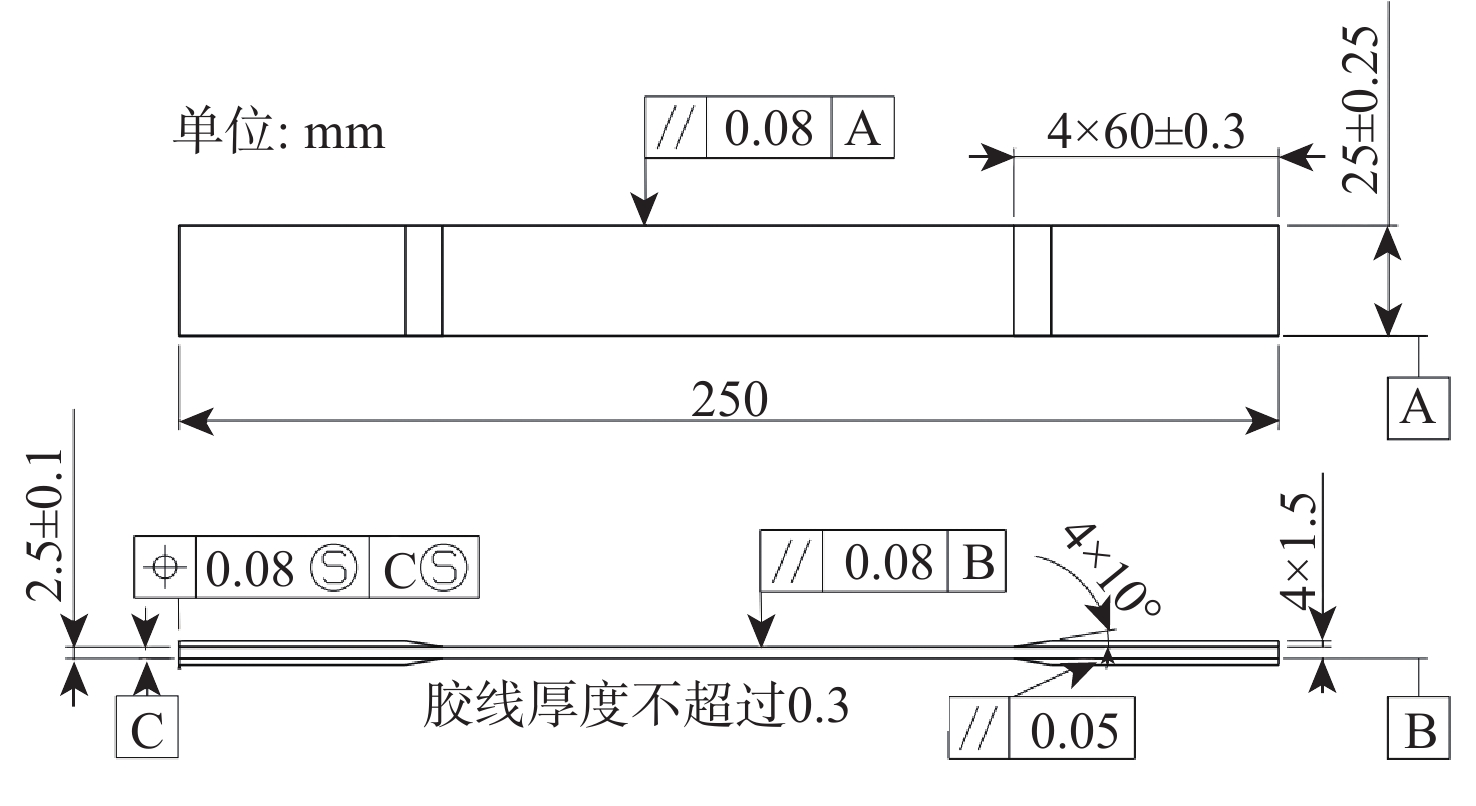

湿热环境是影响复合材料层合板力学性能的主要因素之一,研究湿热环境对复合材料结构的影响对于保证飞行结构安全具有非常重要的工程应用意义。研究碳纤维复合材料层合板在室温干态(RTD)、低温干态(CTD)和高温湿态(ETW)3种环境条件下的拉伸疲劳性能,获得3种环境下的S-N曲线与层合板疲劳破坏模式。在此基础上,建立层合板有限元分析模型,对其疲劳性能进行研究,分析讨论温度及湿度对层合板疲劳性能的影响,建立层合板疲劳寿命环境影响因子的确定方法。结果表明:湿热环境对正交层合板的拉伸疲劳性能影响很大,疲劳寿命为106次时,与RTD环境相比,CTD环境下层合板的疲劳强度下降了2.76%,而ETW环境下下降达到23.77%;ETW和RTD环境下破坏模式以纤维断裂和分层为主,而CTD环境下却几乎全为纤维断裂破坏;S-N曲线包括疲劳强度快速下降和缓慢下降2个阶段;温度对疲劳性能的影响要明显强于湿度,温度超过45 ℃时湿度对疲劳性能的影响进入强影响区。

Abstract:The hygrothermal environment is one of the main factors affecting the mechanical properties of composite laminates. To maintain the safety of the flight structures, it is crucial to study how hygrothermal conditions affect composite structures.The tensile fatigue properties of carbon fiber composite laminates (CFRP) in room temperature and dry (RTD) condition, cool temperature and dry (CTD) condition and elevated temperature and wet (ETW) condition were experimentally studied, then the S-N curves and fatigue damage modes of CFRP laminates in three different environments were obtained. This served as the foundation for the development of the laminate finite element analysis model, the study of laminate fatigue performance, the analysis and discussion of the effects of temperature and humidity on laminate fatigue performance, and the development of a method for determining the environmental factors influencing the fatigue life of laminates. The results show that the tensile fatigue properties of orthometric laminates are greatly affected by the environment of ETW condition. Compared with the RTD condition, the fatigue strength of orthometric laminates decreases by 2.76% in CTD condition when the fatigue life equates to 106, while the fatigue strength of orthometric laminates decreases by 23.77% ETW condition. The damage modes in RTD condition and in ETW condition are mainly fiber fracture and delamination, while the damage mode in CTD condition is almost fiber fracture. The S-N curve includes two stages of rapid and slow reduction for fatigue strength. The influence of temperature on fatigue performance is obviously stronger than that of humidity. When the temperature exceeds 45 ℃, the influence of humidity on fatigue performance enters the strong influence zone.

-

Key words:

- composite materials /

- hygrothermal environment /

- fatigue life /

- S-N curve /

- fatigue strength

-

表 1 试验类型和试验件数量

Table 1. Test type and number of test specimer

试验类型 试验件数量 RTD CTD ETW 吸湿试验 3 拉伸静力试验 3 3 3 拉-拉疲劳试验 16 16 16 表 2 材料参数

Table 2. Material parameters

$ E_{{11}}^{0} $/GPa $ E_{{22}}^{0} $/GPa $ X_T^{0} $/MPa $ Y_T^{0} $/MPa $ G_{{12}}^{0} $/GPa 54.3 54.3 680 680 3.26 $ S_{{12}}^{0} $/GPa $ \rho $/(g.cm−3) ${\rho _{{\rm{m}}} }$/(g.cm−3) ${V_{{\rm{m}}} }$/% 116 1.42 1.23 45 表 3 经验常数

Table 3. Empirical constants

Tg0 /℃ T0 /℃ g /℃ a b c d 120 20 5 0.05 0.15 0.22 0.56 表 4 材料弹性工程常数

Table 4. Elastic engineering constants of materials

E1/GPa E2/GPa E3/GPa G12/GPa G13/GPa G23/GPa 54.3 54.3 3300 3.26 2.17 2.17 ν12 ν13 ν23 XT/MPa XC/MPa YT/MPa 0.04 0.01 0.01 680 614.29 680 YC/MPa S12/MPa S13/MPa S23/MPa 614.29 115.98 73.5 73.5 表 5 3种湿热环境条件下拉伸静力试验结果

Table 5. Tensile static test results under three different hygrothermal environments

环境 最大载荷/kN 拉伸强度均值/MPa 弹性模量/GPa RTD 48.39 679.58 54.3 CTD 50.53 694.24 54.1 ETW 45.05 620.41 52.5 表 6 3种湿热环境下的疲劳试验结果(应力比R=0.052 6)

Table 6. Fatigue test results under three different hygrothermal environments (Stress ratio R=0.052 6)

湿热环境 应力水平/% 最大应力/MPa 疲劳寿命/次 RTD 85.1, 83.1, 83.1, 83.1 578, 564.4, 564.4, 564.4, 3 699, 508 210, 753 116, 1 200 331 87.1, 87.1, 85.1, 85.1 591.6, 591.6, 578, 578 43 027, 545 041, 1 200 200, 41 123 90.1, 90.1, 90.1, 89.1 612, 612, 612, 605.2 159 724, 22 975, 67 479, 378 378 94.1, 92.1, 92.1, 92.1 639.2, 625.6, 625.6, 625.6 1 836, 33 665, 8 491, 17 341 CTD 80 555.2 1 130 123, 1 072 928, 466 931, 760 758 83 576.02 113 964, 141 959, 241 866, 155 203 85 589.9 97 129, 103 678, 19 140, 3 610 87 603.78 12 530, 211 101, 7 681, 4 500 ETW 70 555.2 1 305 108, 356 100, 98 753, 755 874 75 576.0 133 981, 678 850, 578 040, 390 576 84 589.9 47 578, 36 791, 11 762, 88 784 86 603.8 36 877, 15 680, 7 160, 4 955 表 7 有限元模拟预测值与试验值对比

Table 7. Comparison between predicted values of finite element simulation and test values

有限元数值 循环次数 对数寿命 试验值 1# 1200200 6.08 2# 753 116 5.87 3# 508 210 5.71 均值 820 509 5.89 预测值 635 074 5.80 注:有限元预测值与试验值均值的循环次数误差为22.6%,对数寿命误差为1.5%。 -

[1] 陈浩然, 息志臣, 贺晓东. 复合材料层合板的热变形非线性分析[J]. 大连理工大学学报, 1994, 34(3): 280-286.CHEN H R, XI Z C D, HE X D. Nonlinear analysis of thermal deformations of composite laminates under transient thermal loading[J]. Journal of Dalian University of Technology, 1994, 34(3): 280-286 (in Chinese). [2] LIU S F, CHENG X Q, ZHANG Q, et al. An investigation of hygrothermal effects on adhesive materials and double lap shear joints of CFRP composite laminates[J]. Composites Part B:Engineering, 2016, 91: 431-440. doi: 10.1016/j.compositesb.2016.01.051 [3] SETHI S, RAY B C. Environmental effects on fibre reinforced polymeric composites: Evolving reasons and remarks on interfacial strength and stability[J]. Advances in Colloid and Interface Science, 2015, 217: 43-67. doi: 10.1016/j.cis.2014.12.005 [4] ZHANG Q, CHENG X Q, ZHANG J, et al. Experimental and numerical investigation of composite box joint under tensile load[J]. Composites Part B:Engineering, 2016, 107: 75-83. doi: 10.1016/j.compositesb.2016.09.056 [5] 沙勐, 熊欣, 许名瑞, 等. 湿热环境对复合材料疲劳性能的影响[J]. 高科技纤维与应用, 2017, 42(4): 37-43. doi: 10.3969/j.issn.1007-9815.2017.04.007SHA M, XIONG X, XU M R, et al. Effect of hygrothermal environment on fatigue properties of composite materials[J]. Hi-Tech Fiber and Application, 2017, 42(4): 37-43(in Chinese). doi: 10.3969/j.issn.1007-9815.2017.04.007 [6] MEZIERE Y, BUNSELL A R, FAVRY Y, et al. Large strain cyclic fatigue testing of unidirectional carbon fibre reinforced epoxy resin[J]. Composites Part A:Applied Science and Manufacturing, 2005, 36(12): 1627-1636. doi: 10.1016/j.compositesa.2005.03.020 [7] COSTA M L, REZENDE M C, DE ALMEIDA S F M. Strength of hygrothermally conditioned polymer composites with voids[J]. Journal of Composite Materials, 2005, 39(21): 1943-1961. doi: 10.1177/0021998305051807 [8] SHEN C H, SPRINGER G S. Effects of moisture and temperature on the tensile strength of composite materials[J]. Journal of Composite Materials, 1977, 11(1): 2-16. doi: 10.1177/002199837701100102 [9] 李嘉禄, 杨红娜, 寇长河. 三维编织复合材料的疲劳性能[J]. 复合材料学报, 2005, 22(4): 172-176. doi: 10.3321/j.issn:1000-3851.2005.04.029LI J L, YANG H N, KOU C H. Fatigue properties of three dimensional braiding composites[J]. Acta Materiae Compositae Sinica, 2005, 22(4): 172-176(in Chinese). doi: 10.3321/j.issn:1000-3851.2005.04.029 [10] 马丽婷, 陈新文, 邓立伟, 等. 复合材料疲劳性能研究[J]. 航空制造技术, 2013, 53(23): 73-74. doi: 10.3969/j.issn.1671-833X.2013.23.010MA L T, CHEN X W, DENG L W, et al. Fatigue performance of composites[J]. Aeronautical Manufacturing Technology, 2013, 53(23): 73-74(in Chinese). doi: 10.3969/j.issn.1671-833X.2013.23.010 [11] KAWAI M, YAJIMA S, HACHINOHE A, et al. High-temperature off-axis fatigue behaviour of unidirectional carbon-fibre-reinforced composites with different resin matrices[J]. Composites Science and Technology, 2001, 61(9): 1285-1302. doi: 10.1016/S0266-3538(01)00027-6 [12] TURON A, COSTA J, CAMANHO P P, et al. Simulation of delamination in composites under high-cycle fatigue[J]. Composites Part A:Applied Science and Manufacturing, 2007, 38(11): 2270-2282. doi: 10.1016/j.compositesa.2006.11.009 [13] MUSTAFA G, CRAWFORD C, SULEMAN A. Fatigue life prediction of laminated composites using a multi-scale M-LaF and Bayesian inference[J]. Composite Structures, 2016, 151: 149-161. doi: 10.1016/j.compstruct.2016.02.024 [14] 张文姣. 纤维增强复合材料的疲劳损伤模型及分析方法[D]. 哈尔滨: 哈尔滨工业大学, 2015 : 79-90.ZHANG W J. Fatigue damage model and analysis method of fiber reinforced composites[D]. Harbin: Harbin Institute of Technology, 2015: 79-90 (in Chinese). [15] 张祥林, 孟庆春, 许名瑞, 等. 吸湿后碳纤维复合材料正交层板拉伸疲劳性能[J]. 材料工程, 2021, 49(8): 169-177. doi: 10.11868/j.issn.1001-4381.2020.000662ZHANG X L, MENG Q C, XU M R, et al. Tensile fatigue properties of carbon fiber reinforced composite orthogonal laminates after moisture absorption[J]. Journal of Materials Engineering, 2021, 49(8): 169-177(in Chinese). doi: 10.11868/j.issn.1001-4381.2020.000662 [16] 国防科学技术工业委员会. 碳纤维树脂基复合材料层合板疲劳试验方法: GJB 2637-96[S]. 北京: 中国航空工业总公司, 1996: 1-7.Commission of Science, Technology and Industry for National Defense. Test methods for fatigue of carbon fiber resin matrix composite laminates: GJB 2637-96[S]. Beijing: Aviation Industry Corporation of China, 1996:1-7(in Chinese). [17] American Society of Testing Materials International. D3479 Stanard test method for tension-tension fatigue of polymer matrix composite materials: ASTM D3479/D3479M-2012[S]. West Conshohocken: American Society of Testing Materials International, 2012: 1-6 [18] REIFSNIDER K L, HENNEKE E G, STINCHCOMB W W, et al. Damage mechanics and nde of composite laminates[M]. Mechanics of Composite Materials. Amsterdam: Elsevier, 1983: 399-420. [19] 吴富强, 姚卫星. 纤维增强复合材料剩余强度衰减模型[J]. 南京航空航天大学学报, 2008, 40(4): 517-520. doi: 10.3969/j.issn.1005-2615.2008.04.020WU F Q, YAO W X. Residual strength degradation model of fiber reinforced plastic[J]. Journal of Nanjing University of Aeronautics and Astronautics, 2008, 40(4): 517-520(in Chinese). doi: 10.3969/j.issn.1005-2615.2008.04.020 [20] XU M R, HUANG J J, ZENG B Y, et al. Effect of Notch on static and fatigue properties of T800 fabric reinforced composites[J]. Science and Engineering of Composite Materials, 2020, 27(1): 335-345. [21] SPINDEL J, HAIBACH E. Some considerations in the statistical determination of the slope of SN curves[M]. Statistical Analysis of Fatigue Data. West Conshohocken: American Society of Testing Materials International, 1981. -

下载:

下载: