-

摘要:

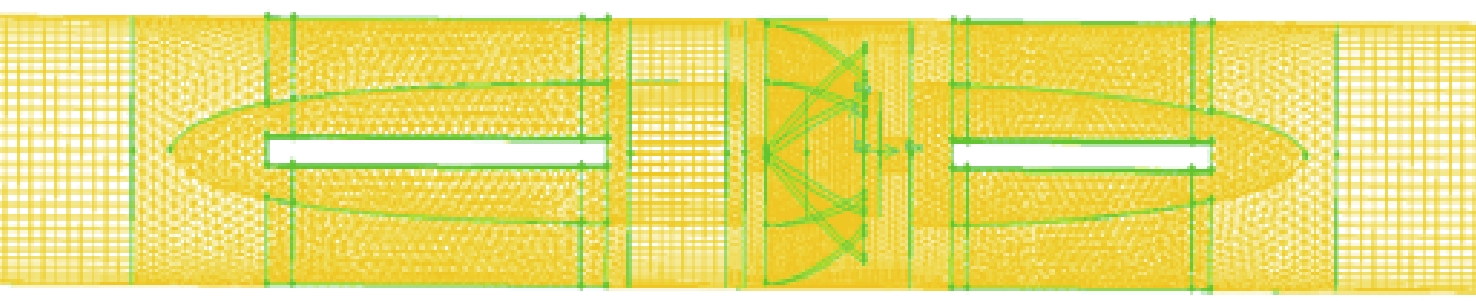

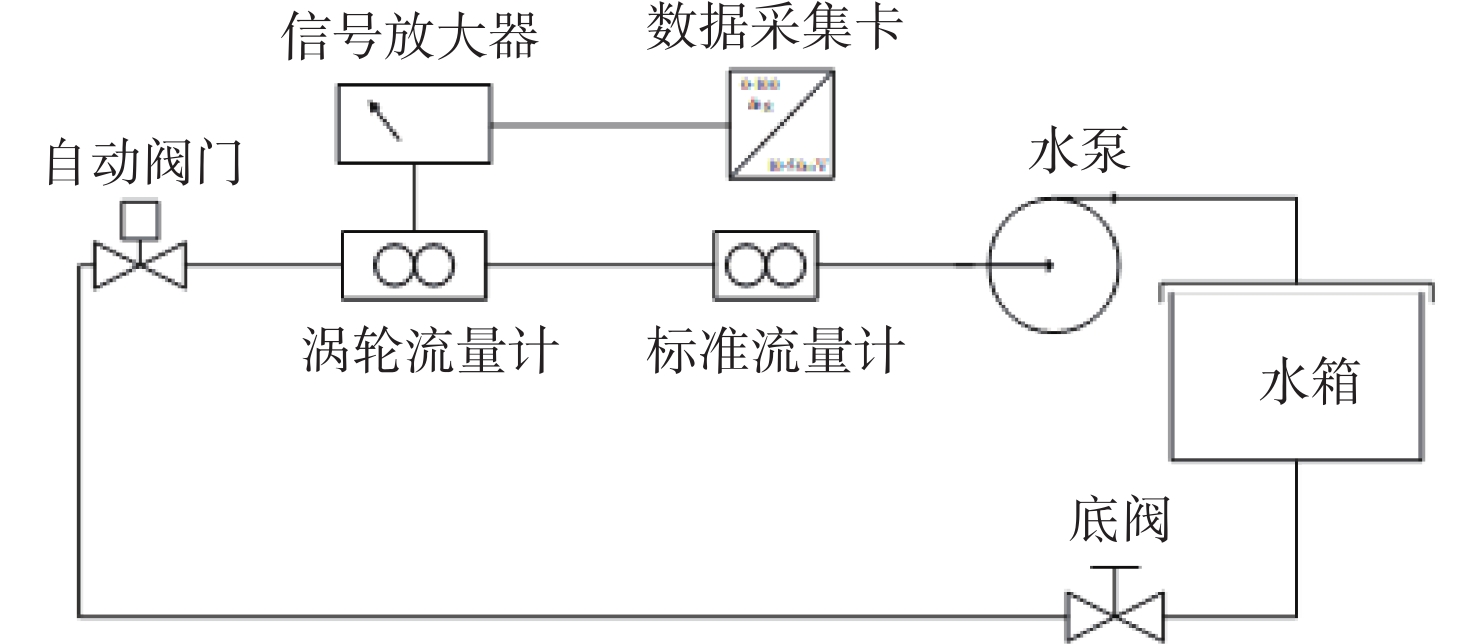

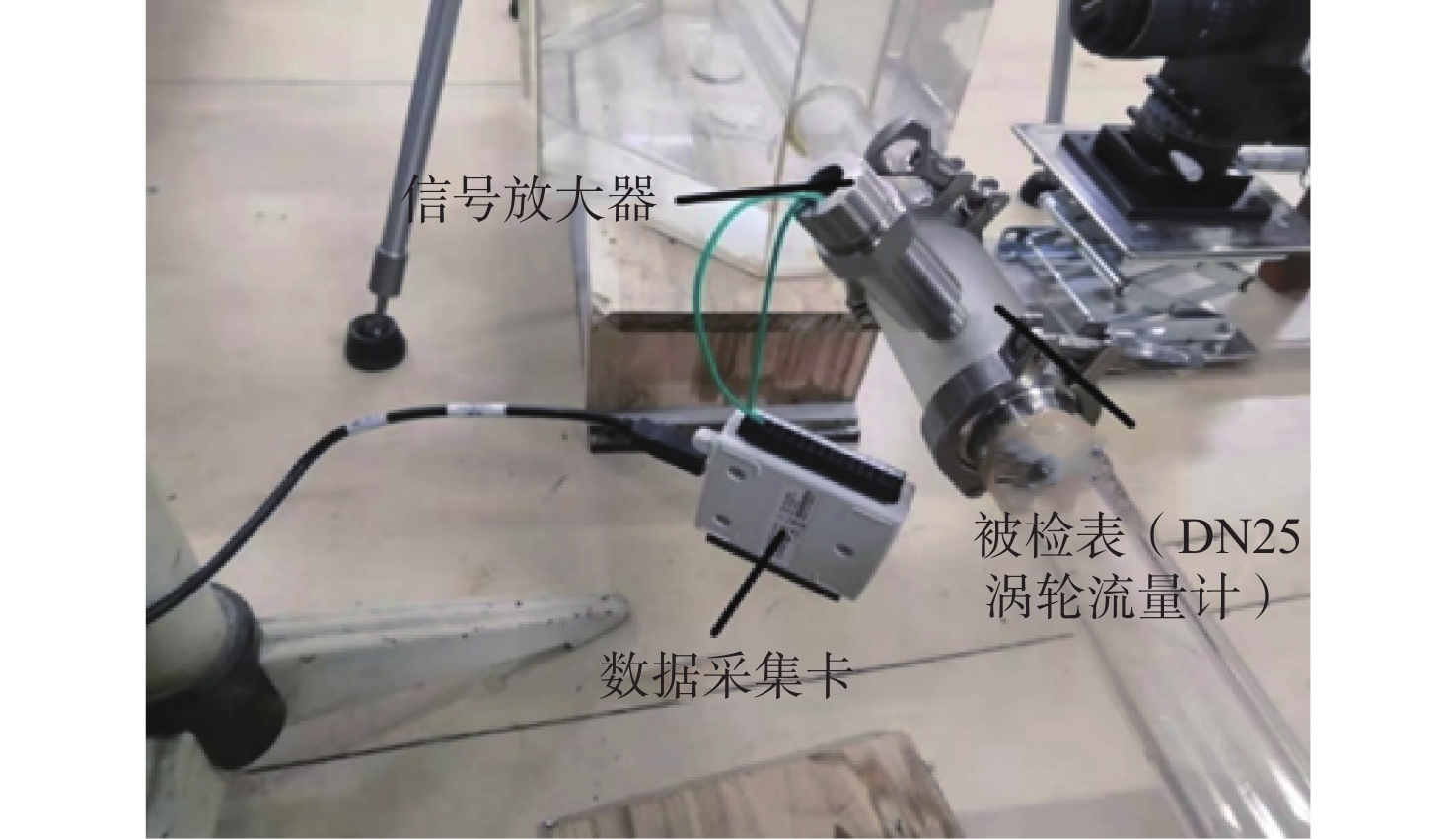

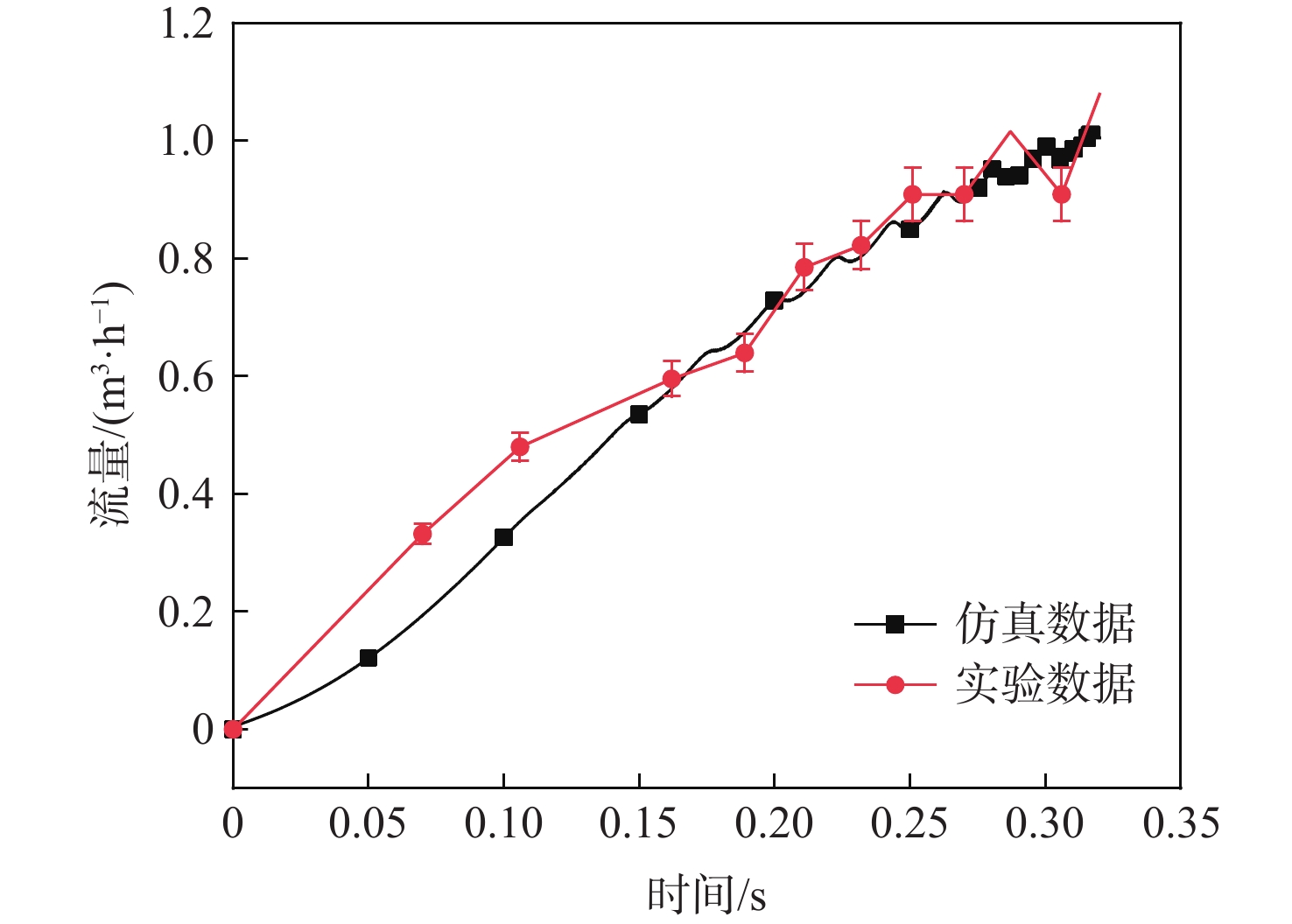

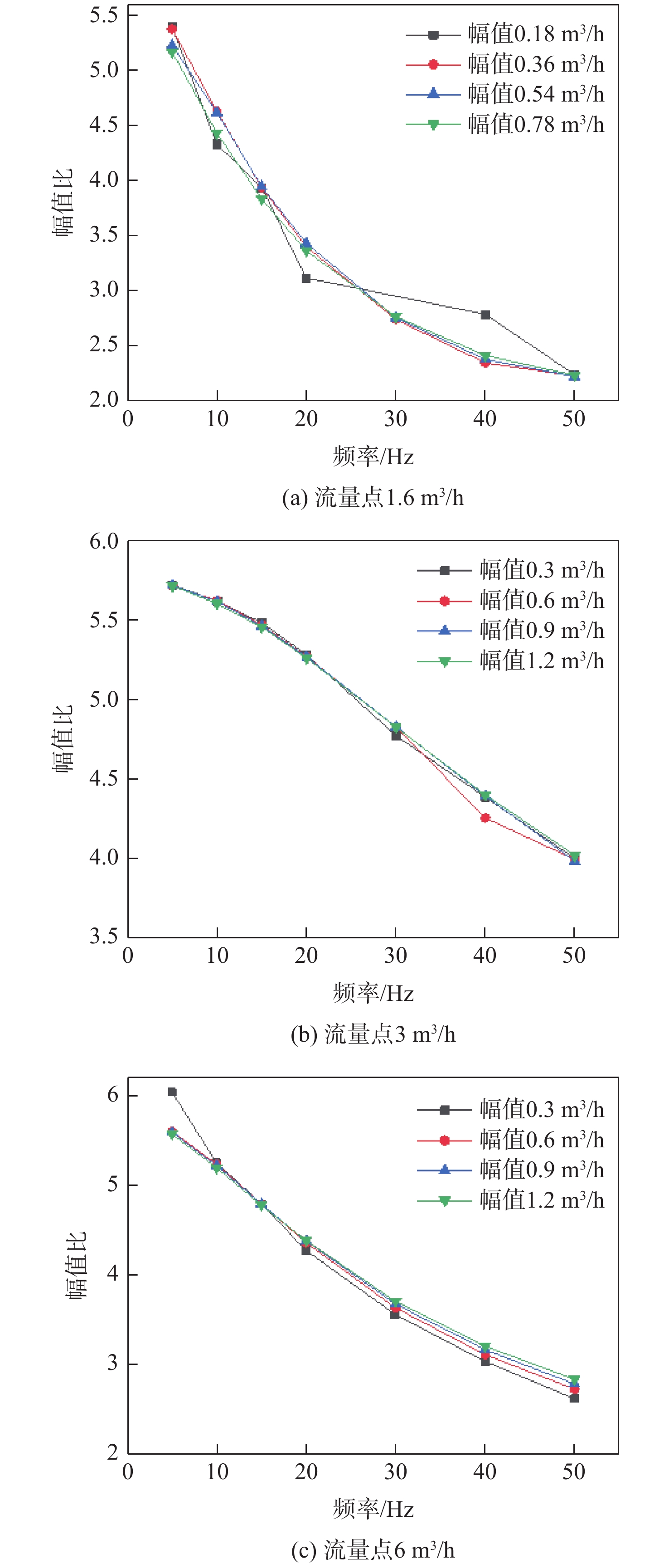

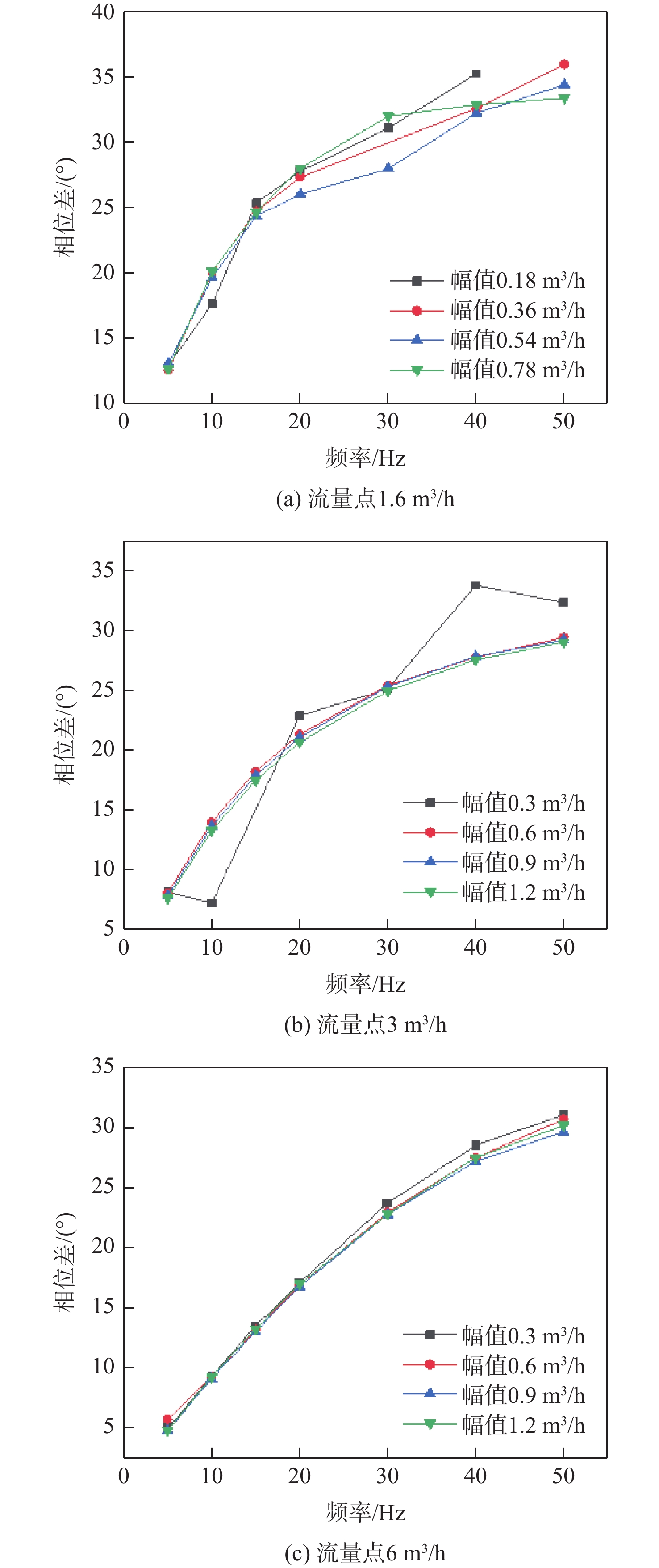

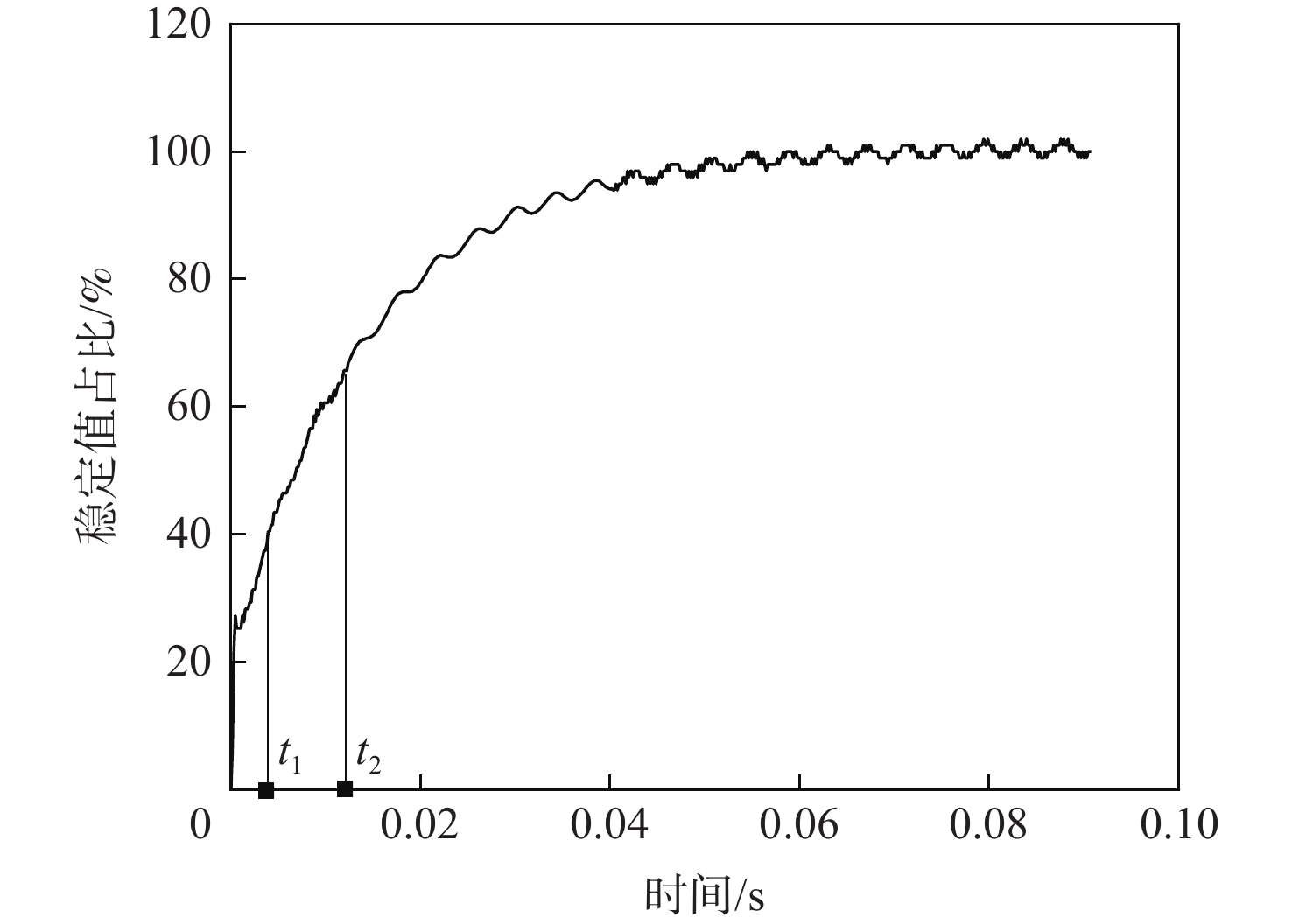

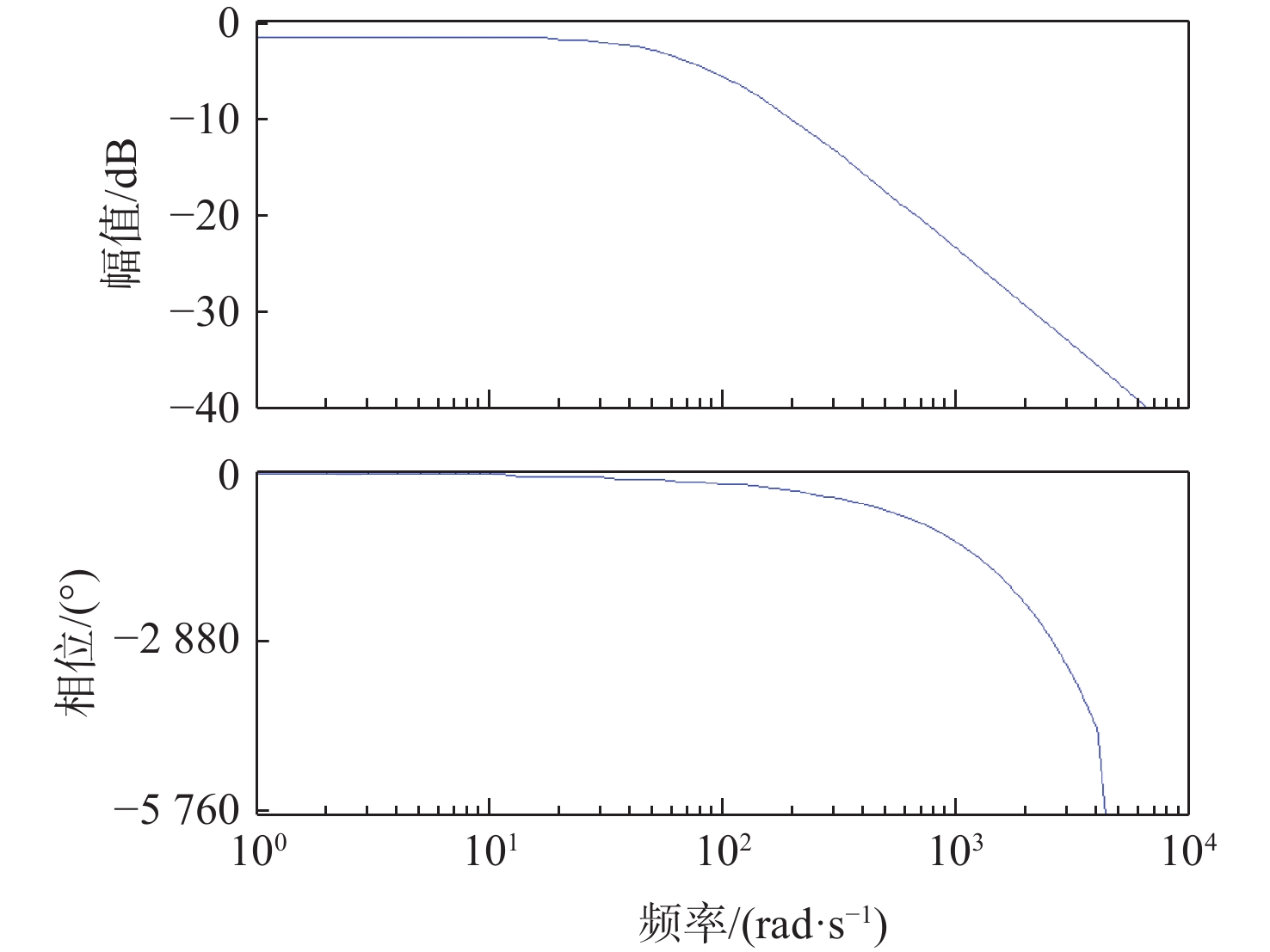

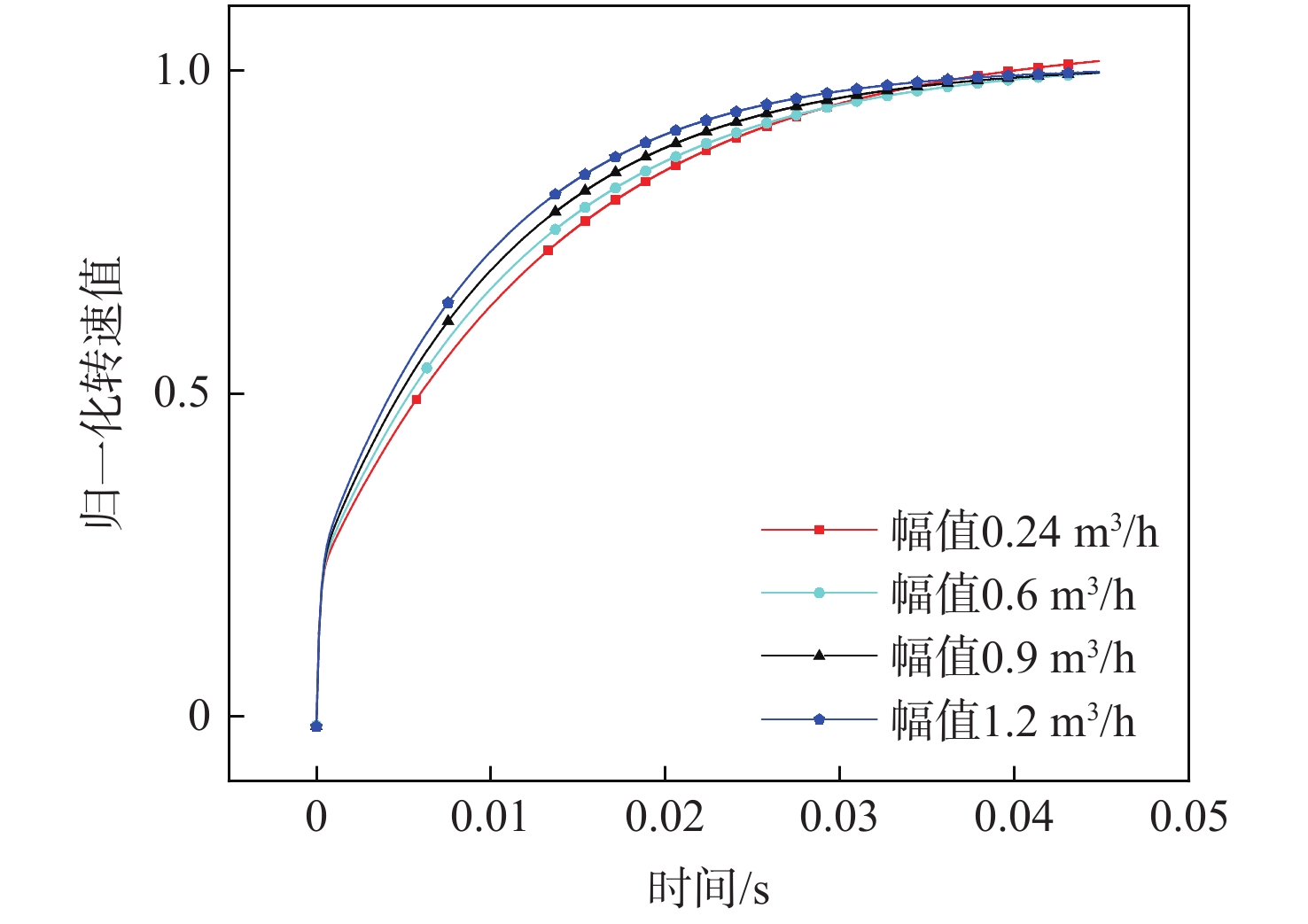

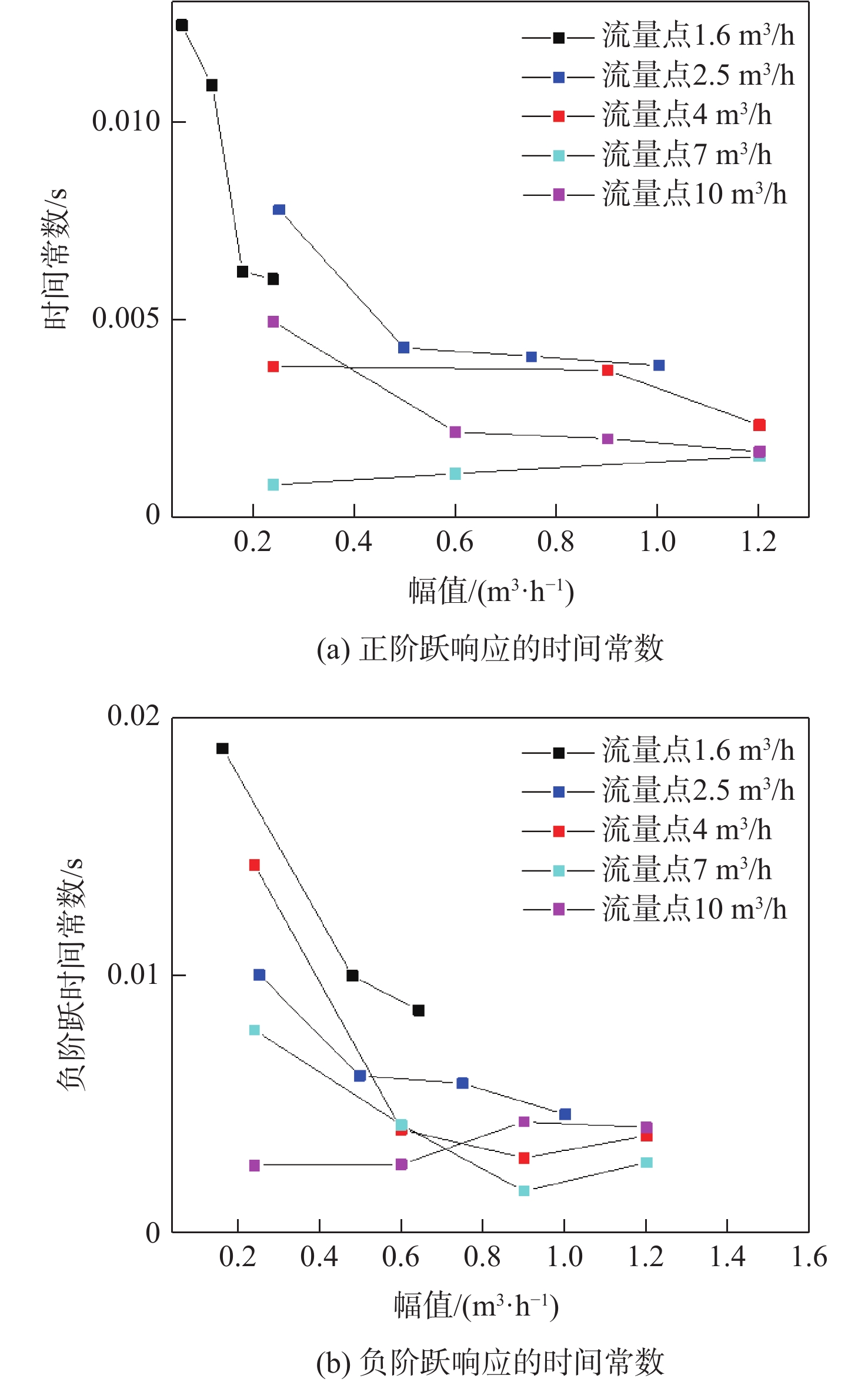

航空航天领域对于流量计量的要求愈发严格,研究流量计的动态特性对于提高其在各类环境下的测量性能和在线测量性能具有重要意义。以涡轮流量计为例,通过数值仿真研究了其动态性能。在涡轮流量计入口处分别施加脉冲和阶跃2种干扰信号,通过数据处理,得到系统的幅频特性、相频特性、传递函数和阶跃响应曲线。结果表明:涡轮流量计可以作为一阶系统进行分析,脉动流的频率是影响涡轮流量计性能的主要因素;与5 Hz工况相比,50 Hz工况下幅值比降低了60%;相位差随频率的增加而增大,最大相位差近40°;阶跃响应的速度和阶跃流的大小与阶跃幅值有关,负阶跃产生的时间常数大于正阶跃产生的时间常数。

Abstract:Currently, the aerospace industry has increasingly strict requirements for flow measuring, and therefore, studying the dynamic characteristics of the flowmeter is of great significant for improving the measurement performance and online measurement performance in various environments. In this paper, the dynamic performance of the turbine flow meter is studied by the numerical simulation. Two interference signals are applied at the turbine flowmeter inlet, and by data processing, the amplitude frequency characteristics, phase frequency characteristics, transfer functions, and step response curves of the system are obtained. The results show that the turbine flowmeter can be analyzed as a first-order system, and the frequency of pulsating flow is the main factor affecting the performance of turbine flowmeter.Compared with 5 Hz, 60% reduction in amplitude ratio under 50 Hz operating condions. The phase difference increases with the increase of frequency, the maximum phase difference reaches a nearly 40°, the speed of the step response is related to the size of the step stream, and the temporal constant generated by the negative step is greater than the time constant generated by the positive step.

-

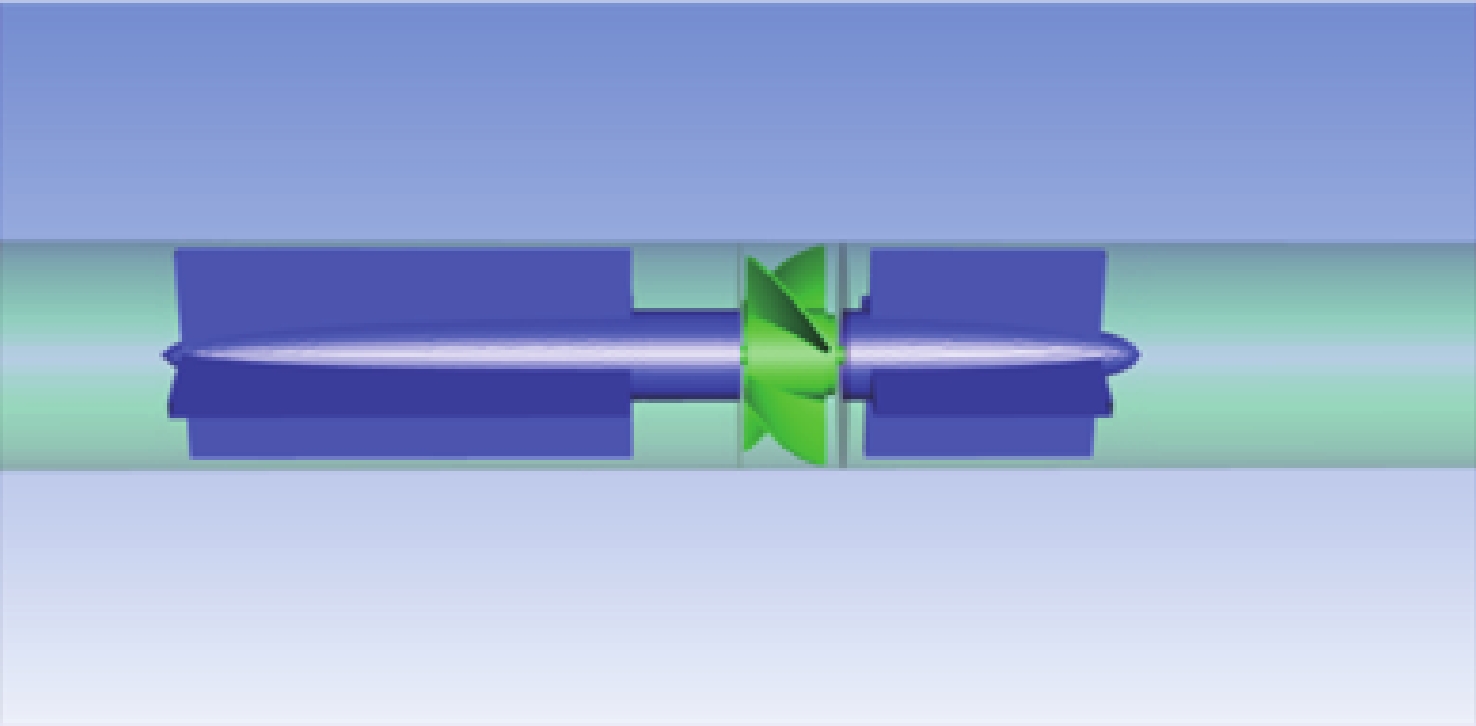

表 1 涡轮流量计尺寸参数

Table 1. Turbine flowmeter dimension parameters

参数 数值 涡轮口径/mm 25 叶片个数 4 叶轮长度/mm 9.00 叶片厚度/mm 0.60 导程/mm 41.00 外缘半径/mm 12.00 轮毂半径/mm 5.40 涡轮总长/mm 20.2 壳体半径/mm 5.30 轴半径/mm 1.00 前轴长/mm 8.70 后轴长/mm 5.60 表 2 正弦脉动流动中各工况点参数

Table 2. Parameters of each working point in sinusoidal pulsating flow

流量点q0/(m3·h−1) 幅值qA/(m3·h−1) 脉动频率f/Hz 1.6 0.18,0.36,0.54,0.78 5/10/15/20/30/40/50 3 0.3,0.6,0.9,1.2 6 0.3,0.6,0.9,1.2 表 3 阶跃流动中各工况点参数

Table 3. Parameters of each working point in step flow

流量点q0/(m3·h−1) 幅值qA/(m3·h−1) 1.6 0.162,0.318,0.48,0.642 2.5 0.252,0.498,0.75,1.002 4 0.24,0.6,0.9,1.2 7 0.24,0.6,0.9,1.2 10 0.24,0.6,0.9,1.2 -

[1] 于洋, 宗光华, 丁凤林. 超声波流量测量中流速计算方法的对比[J]. 北京航空航天大学学报, 2013, 39(1): 37-41. doi: 10.13700/j.bh.1001-5965.2013.01.010YU Y, ZONG G H, DING F L. Comparison of flow rate calculation method for ultrasonic flow measurement[J]. Journal of Beijing University of Aeronautics and Astronautics, 2013, 39(1): 37-41(in Chinese). doi: 10.13700/j.bh.1001-5965.2013.01.010 [2] 樊尚春, 宋明刚. 直管式科氏质量流量计对脉动流响应的研究[J]. 北京航空航天大学学报, 2003, 29(1): 67-71. doi: 10.3969/j.issn.1001-5965.2003.01.018FAN S C, SONG M G. Analysis on response of straight tube Coriolis mass-flow meter under pulsating flow[J]. Journal of Beijing University of Aeronautics and Astronautics, 2003, 29(1): 67-71(in Chinese). doi: 10.3969/j.issn.1001-5965.2003.01.018 [3] THOMPSON R E, GREY J. Turbine flowmeter performance model[J]. Journal of Fluids Engineering, 1968, 92(4): 712-722. [4] 冯畅, 龚家彪. 评涡轮流量计Thompson-Grey的理论模型[J]. 宇航计测技术, 1991(2): 63-67.FENG C, GONG J B. Criticisms on Thompson-Grey model of the turbine flowmeter[J]. Journal of Astronautic Metrology and Measurement, 1991(2): 63-67(in Chinese). [5] SABOOHI Z, SORKHKHAH S, SHAKERI H. Developing a model for prediction of helical turbine flowmeter performance using CFD[J]. Flow Measurement and Instrumentation, 2015, 42: 47-57. doi: 10.1016/j.flowmeasinst.2014.12.009 [6] 李丽红, 刘艳芳, 徐向阳, 等. 水泵叶轮的流动叠加设计方法与CFD仿真[J]. 北京航空航天大学学报, 2010, 36(6): 704-707. doi: 10.13700/j.bh.1001-5965.2010.06.005LI L H, LIU Y F, XU X Y, et al. Flow superposition design method and CFD simulation for the impeller of water pump[J]. Journal of Beijing University of Aeronautics and Astronautics, 2010, 36(6): 704-707(in Chinese). doi: 10.13700/j.bh.1001-5965.2010.06.005 [7] WANG B, ZHANG N, CAO Q W, et al. Evaluation approach to dynamic characteristic of turbine flowmeters considering calibration system response[J]. Flow Measurement and Instrumentation, 2018, 64: 126-132. [8] WANG B, DU Y, YE Z. Excitation of piezoelectrically actuated nozzle-Flapper valve and its potential for fuel flowmeter dynamic calibration[J]. IEEE/ASME Transactions on Mechatronics, 2020, 25(2): 848-858. doi: 10.1109/TMECH.2019.2963501 [9] DŽEMIĆ Z, ŠIROK B, BIZJAN B. Turbine flowmeter response to transitional flow regimes[J]. Flow Measurement and Instrumentation, 2018, 59: 18-22. [10] 李文, 应启戛. 涡轮流量计在脉动流中的特性研究[J]. 仪器仪表学报, 2001(S2): 129-130. doi: 10.3321/j.issn:0254-3087.2001.z1.063LI W, YING Q J. A study for the performance of the turbine flowmeter under the pulsation[J]. Chinese Journal of Scientific Instrument, 2001(S2): 129-130(in Chinese). doi: 10.3321/j.issn:0254-3087.2001.z1.063 [11] 李文, 应启戛. 脉动流对涡轮流量计测量误差的影响[J]. 自动化仪表, 2002, 23(2): 22-24. doi: 10.3969/j.issn.1000-0380.2002.02.007LI W, YING Q J. The influence of pulsating flow on measuring error of turbine flowmeter[J]. Process Automation Instrumentation, 2002, 23(2): 22-24(in Chinese). doi: 10.3969/j.issn.1000-0380.2002.02.007 [12] STEVENS G H. Dynamic calibration of turbine flowmeters[J]. Instruments & Control Systems, 1970, 43(4): 69. [13] STEVENS G H. Dynamic calibration of turbine flowmeters by means of frequency response tests[J]. War & Society, 1969, 10(2): 119-138. [14] LEE B, CHEESEWRIGHT R, CLARK C. The dynamic response of small turbine flowmeters in liquid flows[J]. Flow Measurement and Instrumentation, 2004, 15(5-6): 239-248. doi: 10.1016/j.flowmeasinst.2004.07.002 [15] 姜非欧. 涡轮流量计的动态流量测量方法研究[D]. 长春: 长春理工大学, 2012.JIANG F O. Study on measurement method of dynamic flow of turbine flowmeter[D]. Changchun: Changchun University of Science and Technology, 2012(in Chinese). -

下载:

下载: