Study on temperature control characteristics of low-resistivity ceramic-based PTC material

-

摘要:

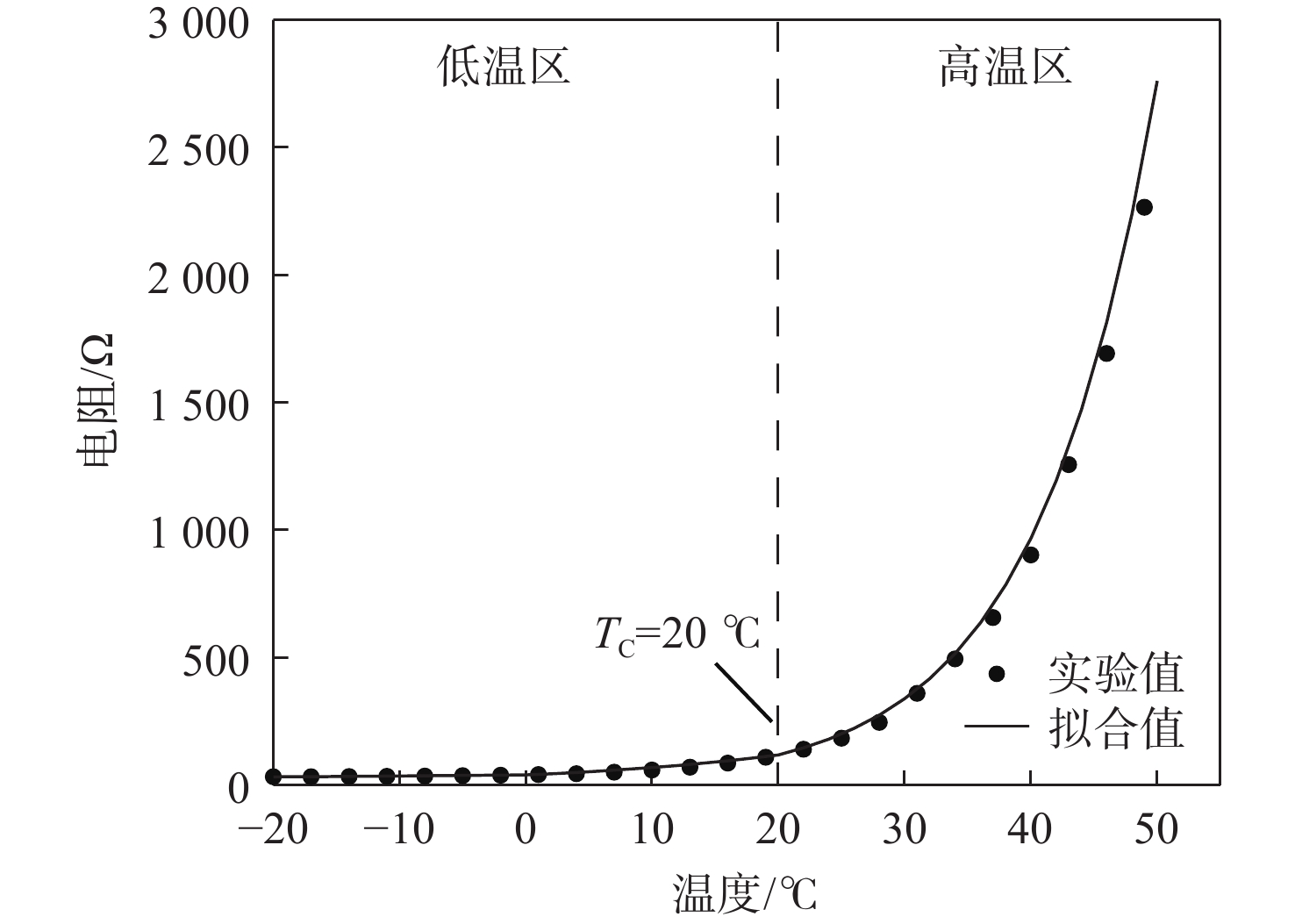

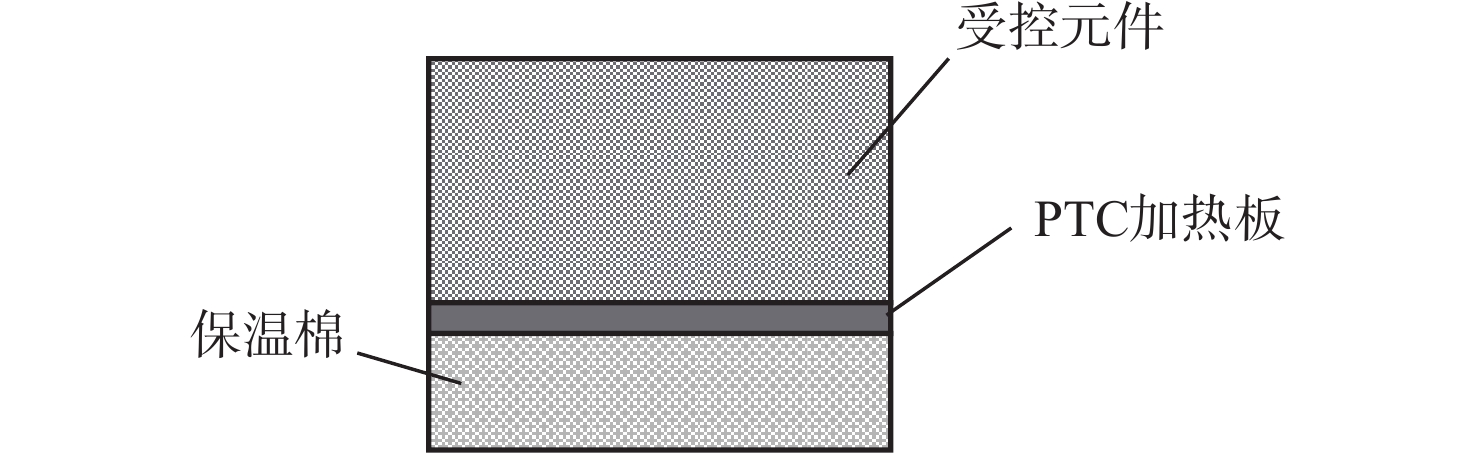

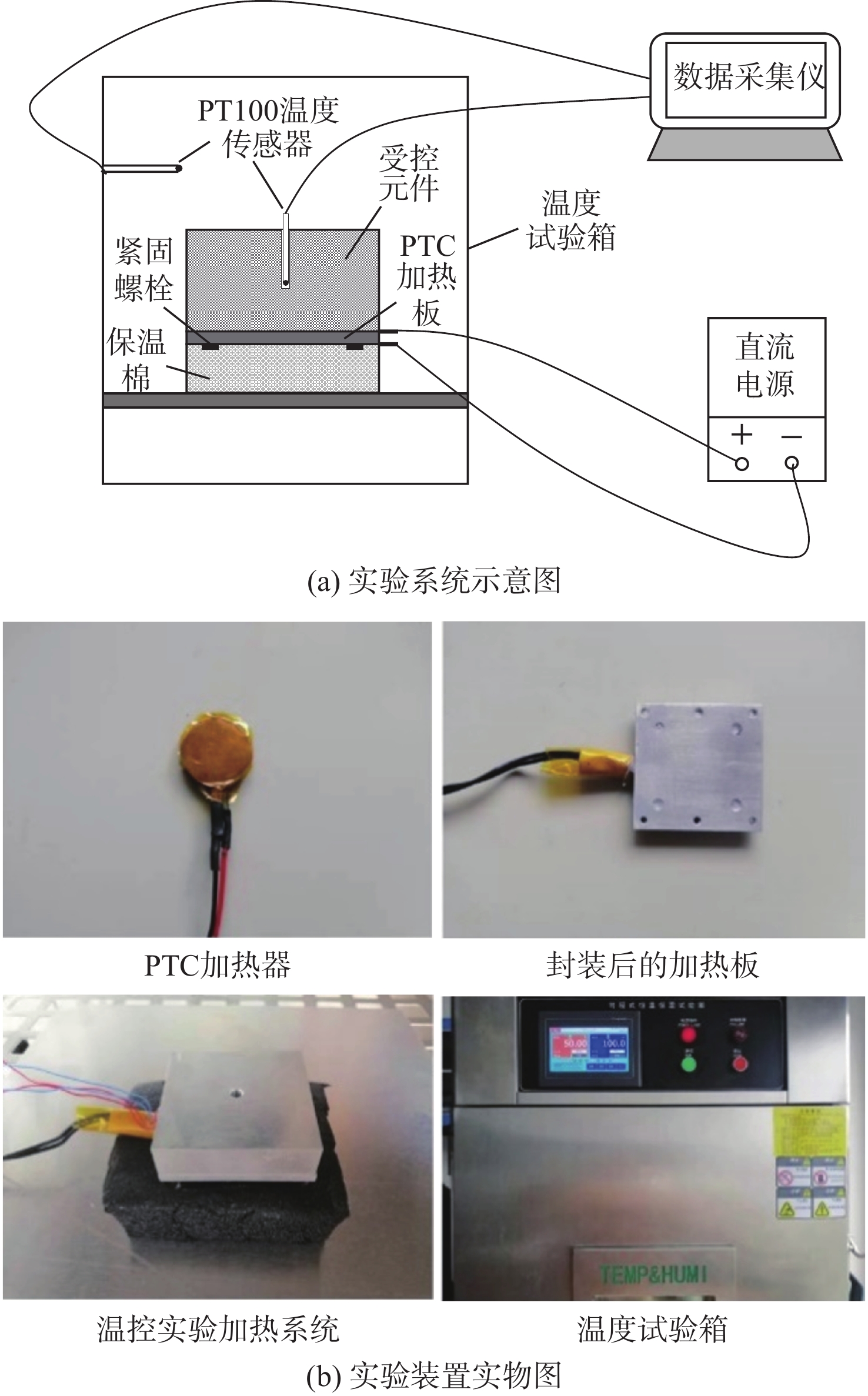

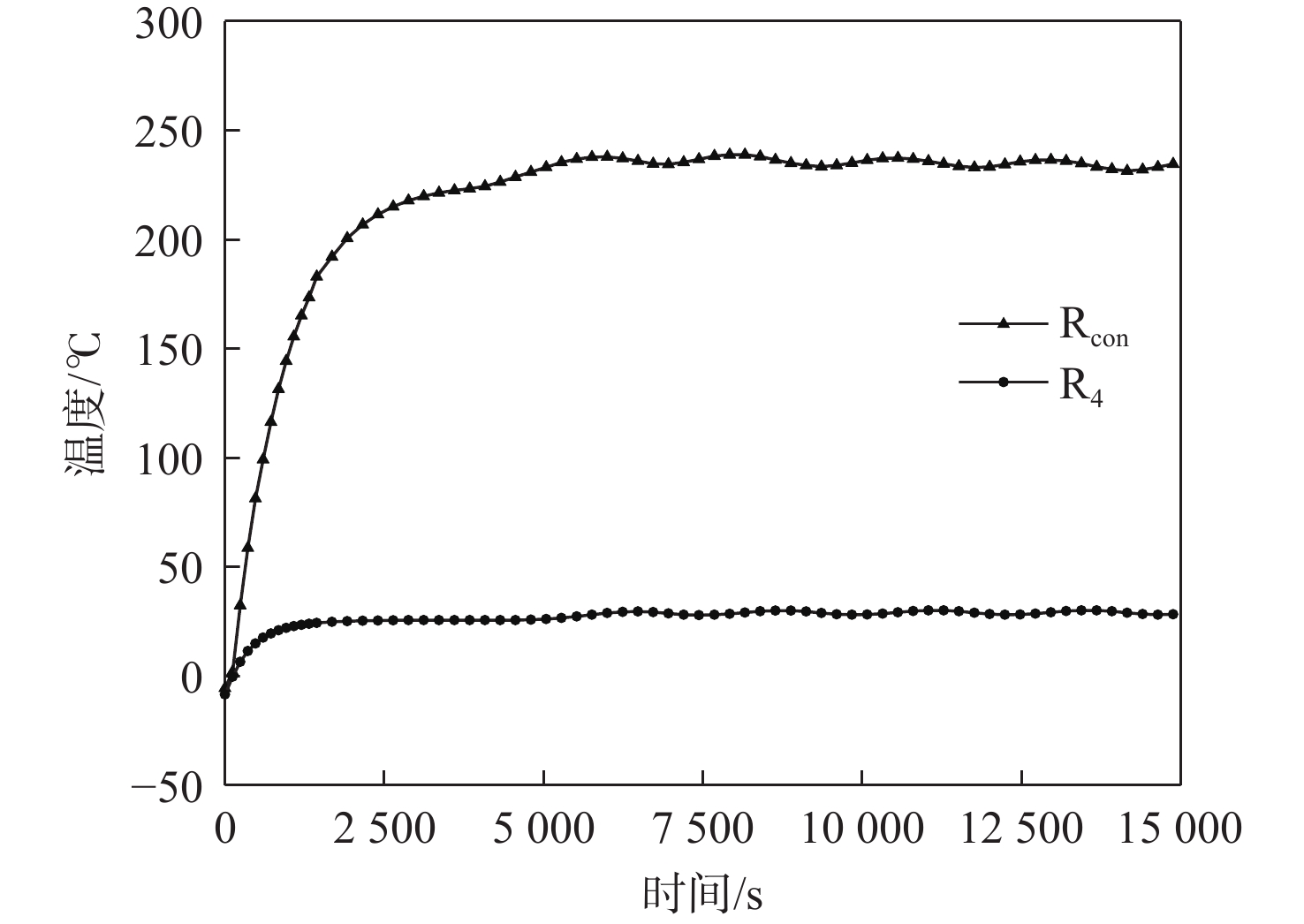

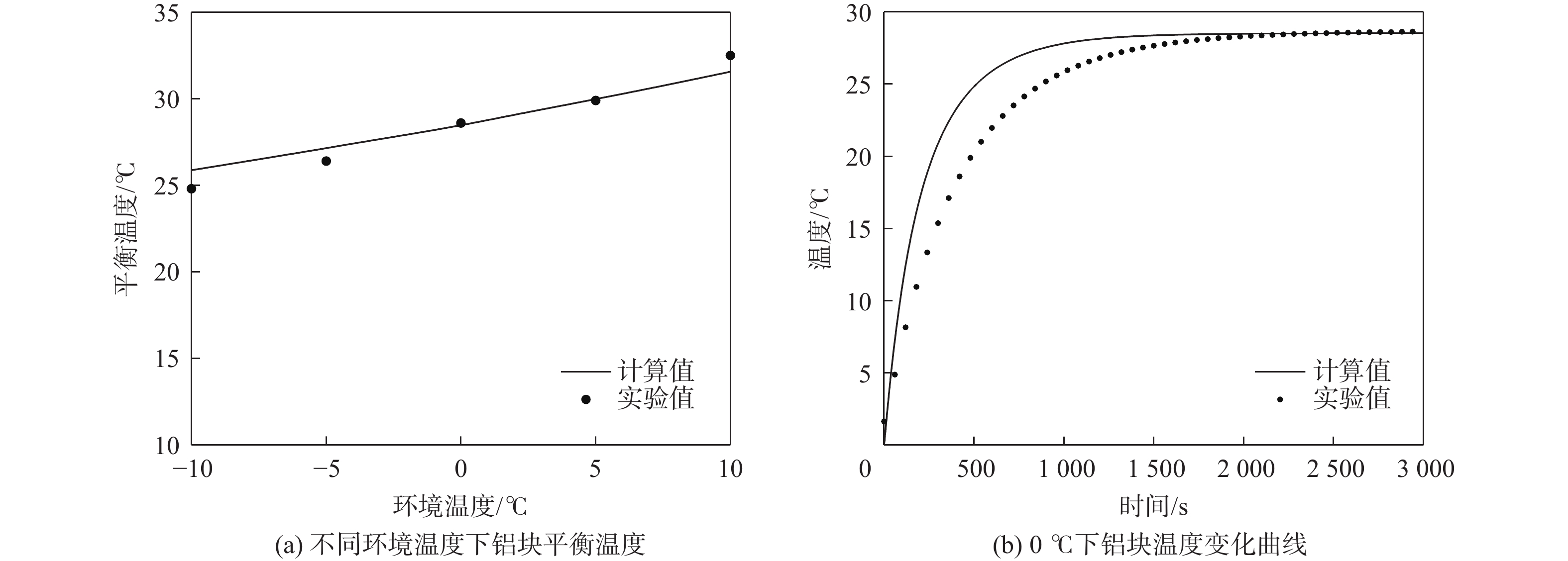

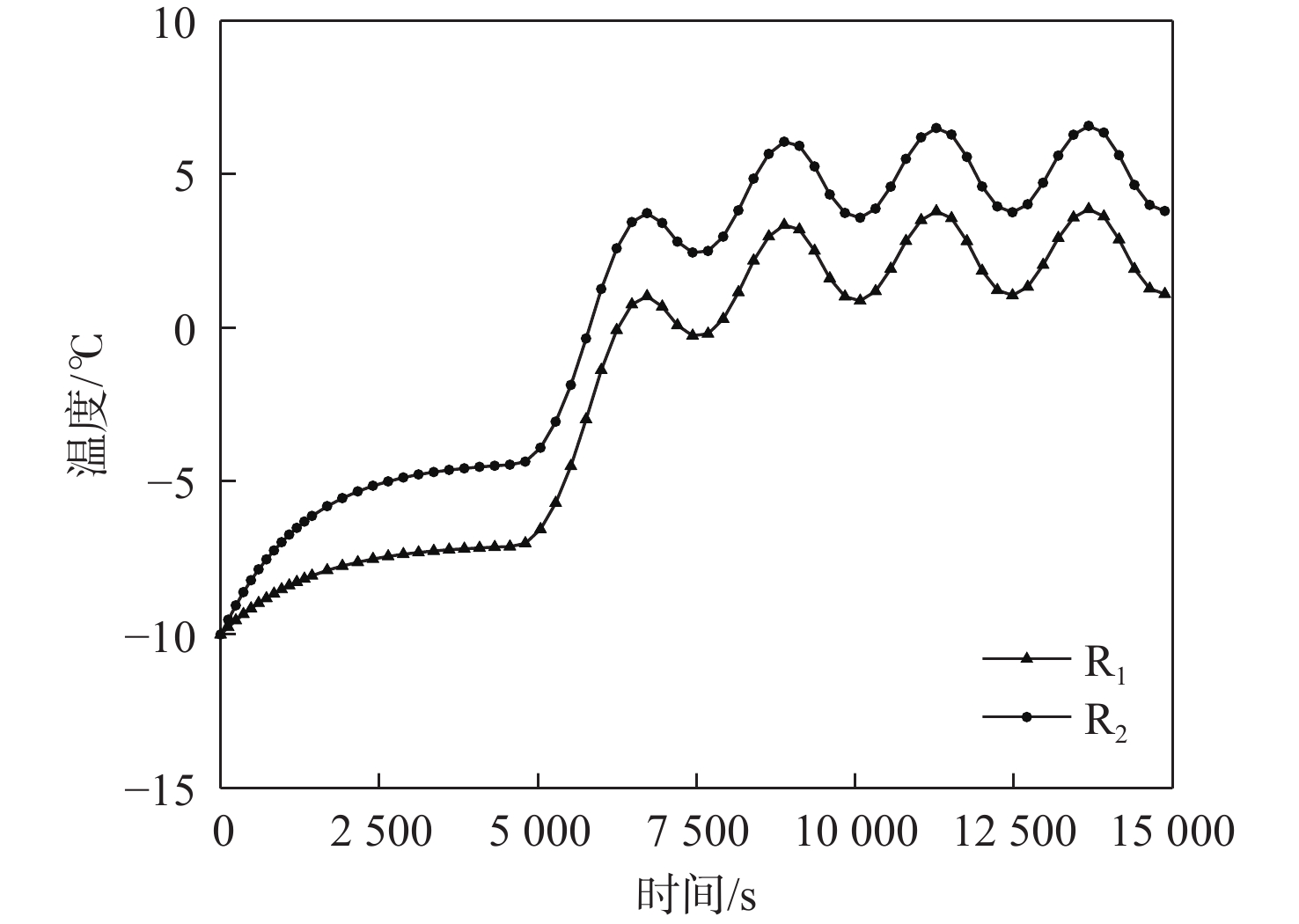

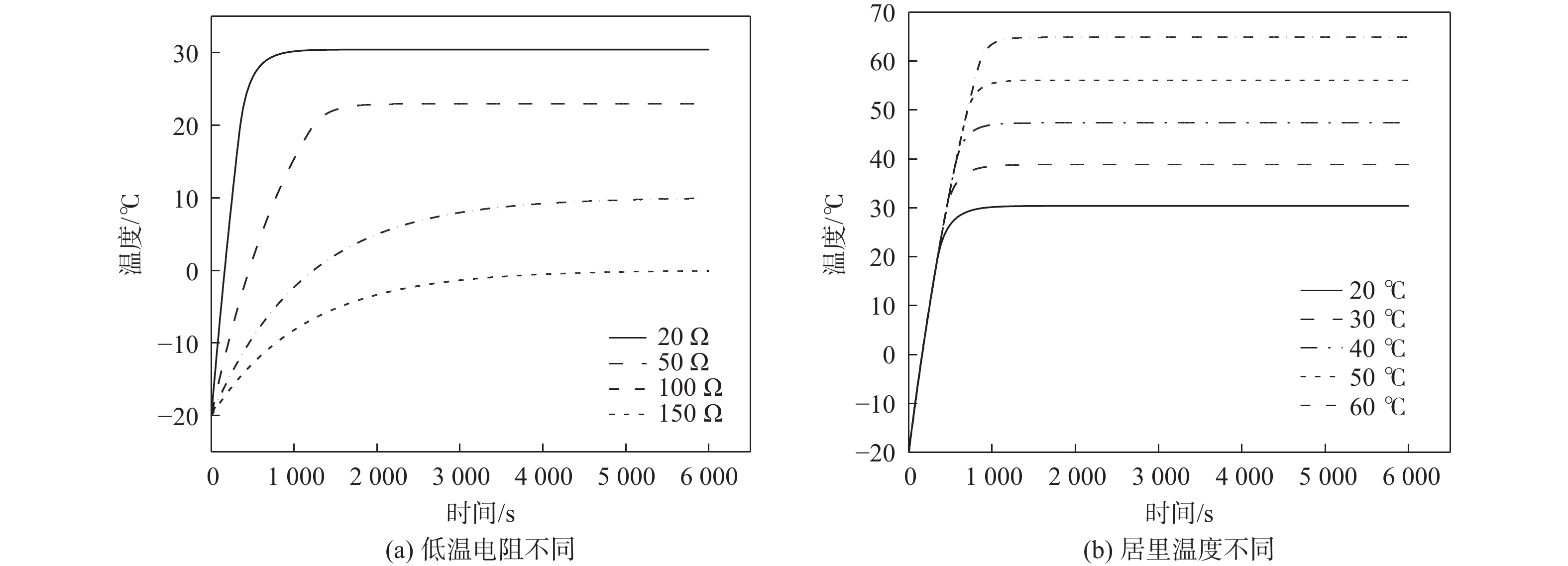

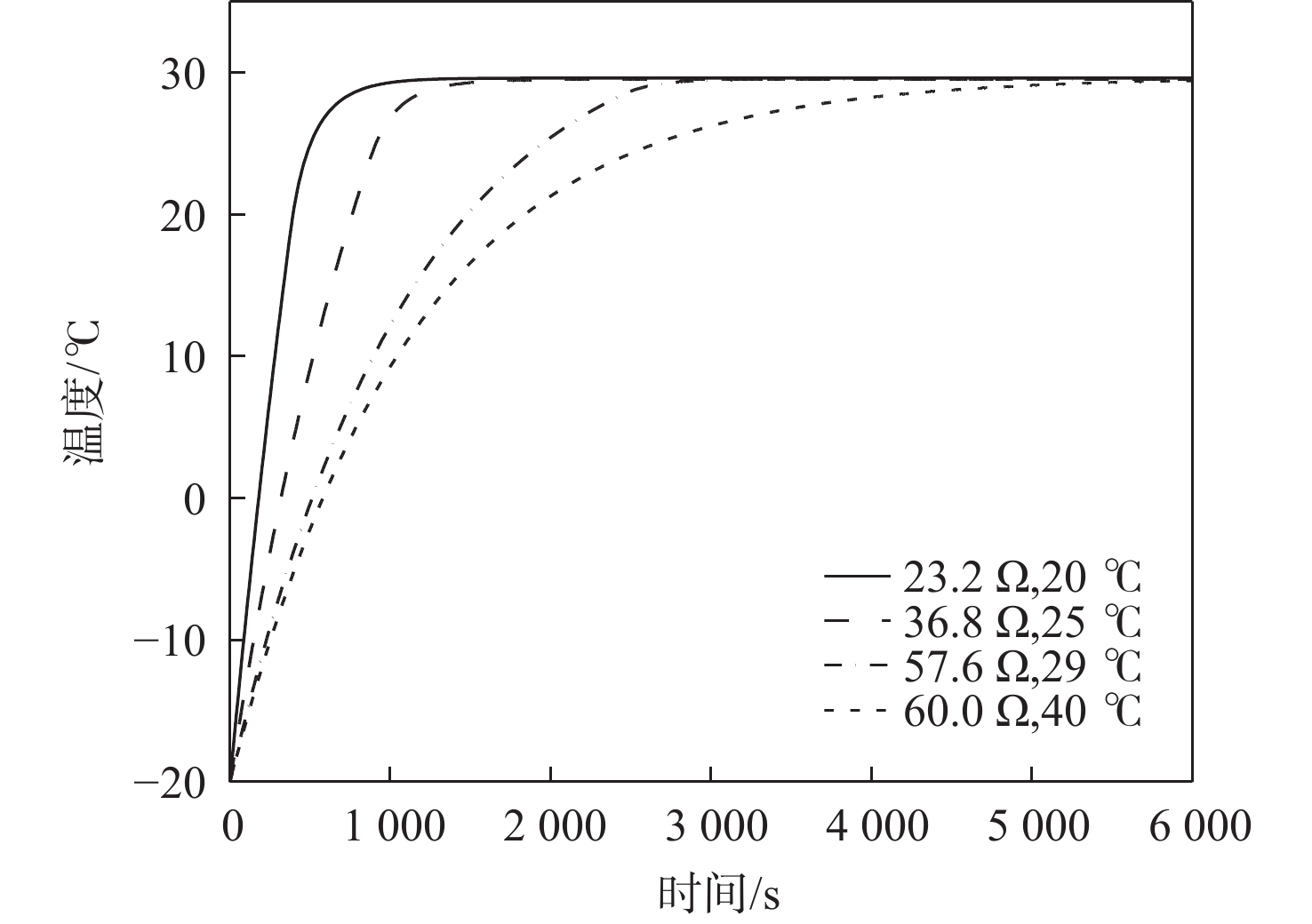

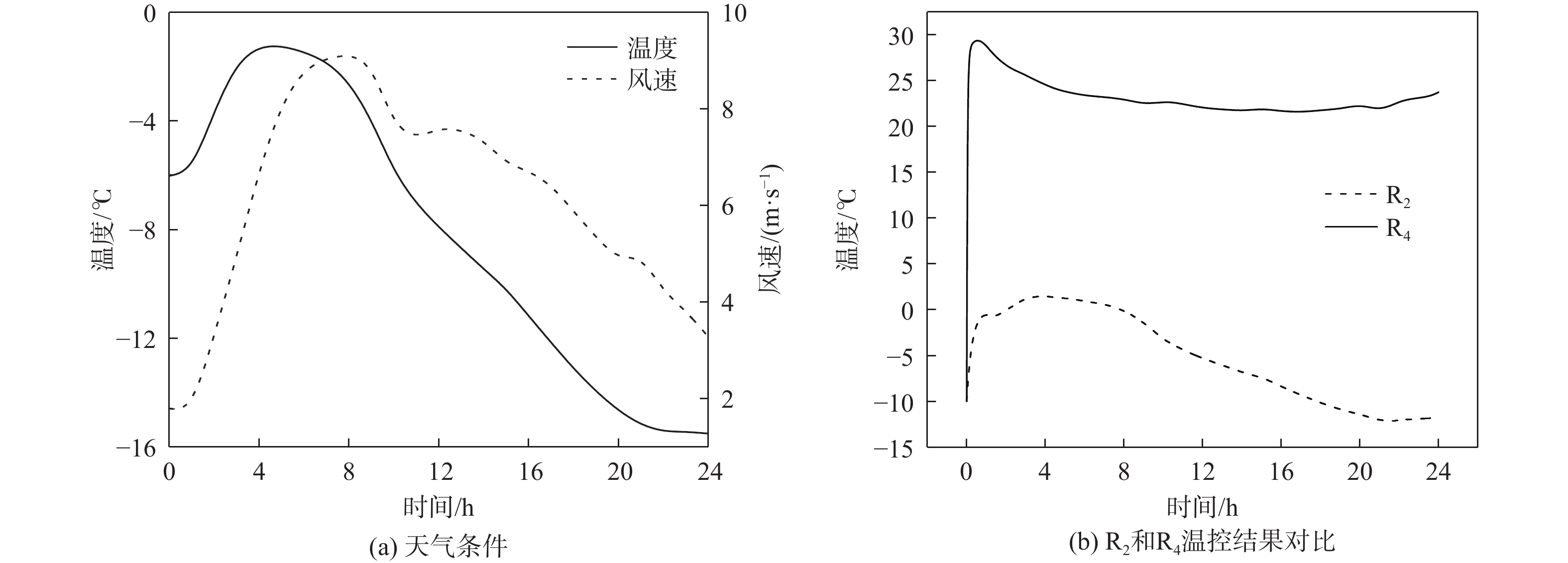

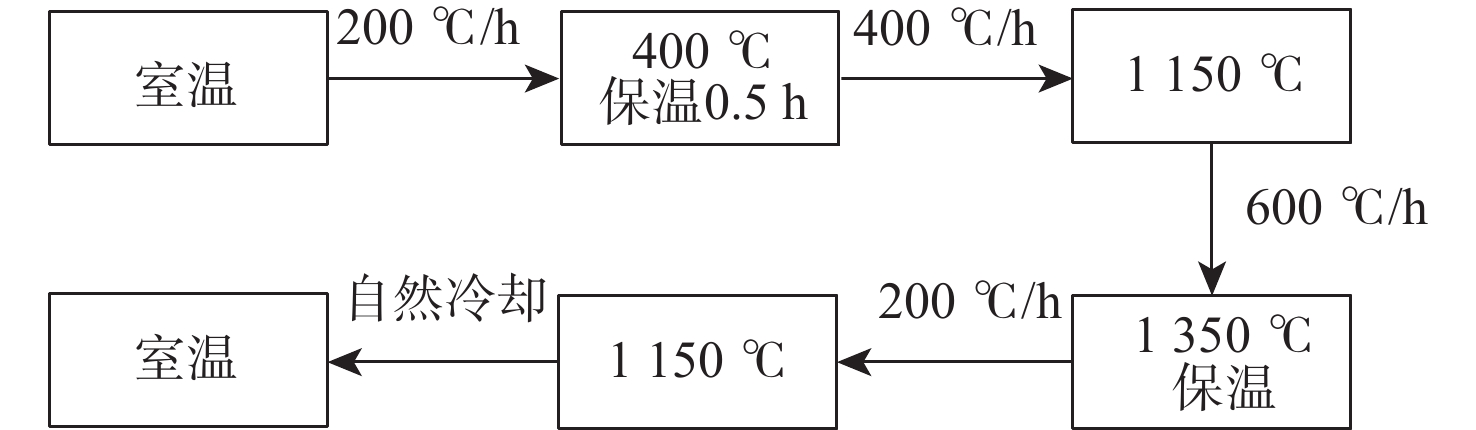

常温居里点陶瓷基正温度系数材料在常温段热控领域具有广阔应用前景,但其存在低温区电阻率过大的问题。基于此,以Ba0.64Sr0.36TiO3为基体并采用固相烧结工艺,研制出低温区电阻率为800 Ω·cm的常温居里点PTC材料,分别利用实验和仿真手段对其温控性能进行研究。结果表明:在低温、低电压工况下,该材料可将受控体温度迅速维持在25.6 ℃附近,而其他加热元件控制温度均偏离常温。该材料热控响应时间少于其他加热元件的50%。在−5~5 ℃的周期性变化环境中,该材料控温波动幅度最小,只有2.1 ℃。在真实低温环境下,该材料能将受控体温度快速升至约22.3 ℃,在12 h内温度波动不到2 ℃,有效抑制了外界环境对热控过程的干扰。

Abstract:The room temperature Curie point ceramic-based positive temperature coefficient material has broad application prospects in the field of thermal control at room temperature, but it currently has the problem of large resistivity in the low-temperature region. Based on this, by using Ba0.64Sr0.36TiO3 as the matrix and adopting a suitable sintering process, a room-temperature Curie point PTC material with a resistivity of 800 Ω·cm in the low-temperature region was developed. Then, the thermal control performance is studied by experiment and simulation respectively. The results show that under low temperature and low voltage conditions, the prepared material can quickly maintain the temperature of the controlled body near 25.6℃, while the control temperature of other heating elements deviates from normal temperature. Additionally, compared to conventional heating elements, the material’s thermal control response time is less than half as fast. In the periodic environment of −5~5 ℃, the fluctuation range of thermal control is the smallest, only 2.1 ℃. In the actual low-temperature environment, the material can still quickly raise the body’s temperature to roughly 22.3 °C, and the variation is less than 2 °C over the course of 12 hours, effectively suppressing the influence of the external environment with the thermal management process.

-

-

[1] 刘荻帆, 钟少龙, 党智敏. 正温度系数聚合物复合材料的制备及限流特性的仿真研究[J]. 绝缘材料, 2021, 54(3): 24-28.LIU D F, ZHONG S L, DANG Z M. Preparation of polymer composites with positive temperature coefficient and simulation study on its current limiting characteristics[J]. Insulating Materials, 2021, 54(3): 24-28(in Chinese). [2] 张安迪, 张艳荣, 李涛. 论域可变的模糊PID控制在半导体激光器温度控制系统中的应用[J]. 光学学报, 2021, 41(12): 153-161.ZHANG A D, ZHANG Y R, LI T. Application of variable domain fuzzy PID control in semiconductor laser temperature control system[J]. Acta Optica Sinica, 2021, 41(12): 153-161(in Chinese). [3] 李运泽, 魏传锋, 袁领双, 等. 应用PTC电加热器的卫星局部温度控制系统仿真[J]. 系统仿真学报, 2005, 17(6): 1494-1496. doi: 10.3969/j.issn.1004-731X.2005.06.059LI Y Z, WEI C F, YUAN L S, et al. Simulation study of satellite partial temperature control system using PTC heater[J]. Acta Simulata Systematica Sinica, 2005, 17(6): 1494-1496(in Chinese). doi: 10.3969/j.issn.1004-731X.2005.06.059 [4] 何浩, 潘俊安, 雷维新, 等. 聚合物基PTC导电材料的制备及其在锂离子电池中的应用[J]. 储能科学与技术, 2019, 8(4): 718-724. doi: 10.12028/j.issn.2095-4239.2019.0009HE H, PAN J A, LEI W X, et al. Preparation of conductive fire retardant and its application in Li-ion battery[J]. Energy Storage Science and Technology, 2019, 8(4): 718-724(in Chinese). doi: 10.12028/j.issn.2095-4239.2019.0009 [5] SONG J L, CHENG W L, XU Z M, et al. Study on PID temperature control performance of a novel PTC material with room temperature Curie point[J]. International Journal of Heat and Mass Transfer, 2016, 95: 1038-1046. doi: 10.1016/j.ijheatmasstransfer.2015.12.057 [6] CHENG W L, SONG J L, LIU Y, et al. Theoretical and experimental studies on thermal control by using a novel PTC material with room temperature Curie point[J]. International Journal of Heat and Mass Transfer, 2014, 74: 441-447. [7] WANG R J, PAN Y H, NIAN Y L, et al. Study on dynamic thermal control performance of positive temperature coefficient (PTC) material based on a novel heat transfer model considering internal heat transfer[J]. Applied Thermal Engineering, 2020, 165: 114452. doi: 10.1016/j.applthermaleng.2019.114452 [8] 华尔天, 张人杰, 方吉庆. 空调PTC加热器热分析与工艺参数优化[J]. 浙江工业大学学报, 2019, 47(4): 361-367. doi: 10.3969/j.issn.1006-4303.2019.04.002HUA E T, ZHANG R J, FANG J Q. Thermal analysis of PTC heater and optimization of process parameters in air-conditioning[J]. Journal of Zhejiang University of Technology, 2019, 47(4): 361-367(in Chinese). doi: 10.3969/j.issn.1006-4303.2019.04.002 [9] 朱波, 杜如海, 姚明尧, 等. 基于相变材料的纯电动汽车电池热管理研究[J]. 电源技术, 2020, 44(11): 1666-1670. doi: 10.3969/j.issn.1002-087X.2020.11.027ZHU B, DU R H, YAO M Y, et al. Research on thermal management of pure electric vehicle battery based on phase change material[J]. Chinese Journal of Power Sources, 2020, 44(11): 1666-1670(in Chinese). doi: 10.3969/j.issn.1002-087X.2020.11.027 [10] 曹勇. 电动汽车动力电源系统低温加热策略研究[J]. 电源技术, 2017, 41(5): 765-769. doi: 10.3969/j.issn.1002-087X.2017.05.032CAO Y. Low temperature heating strategy research of electric vehicle power supply system[J]. Chinese Journal of Power Sources, 2017, 41(5): 765-769(in Chinese). doi: 10.3969/j.issn.1002-087X.2017.05.032 [11] 郭坚, 陈燕, 邵兴国. 航天器热控自主管理中的智能控制技术[J]. 航天器工程, 2012, 21(6): 49-53.GUO J, CHEN Y, SHAO X G. Intelligent control technology for spacecraft thermal autonomous management[J]. Spacecraft Engineering, 2012, 21(6): 49-53(in Chinese). [12] 杨昌鹏, 赵欣, 辛强. 倾斜轨道星敏感器热控设计及在轨分析[J]. 航天器工程, 2013, 22(6): 59-64.YANG C P, ZHAO X, XIN Q. Thermal design and on-orbit thermal analysis on star sensor of inclined-orbit satellite[J]. Spacecraft Engineering, 2013, 22(6): 59-64(in Chinese). [13] 刘海波, 谭吉春, 郝云彩, 等. 环境温度对星敏感器测量精度的影响[J]. 光电工程, 2008, 35(12): 40-44.LIU H B, TAN J C, HAO Y C, et al. Effect of ambient temperature on star sensor measurement accuracy[J]. Opto-Electronic Engineering, 2008, 35(12): 40-44(in Chinese). [14] 刘红, 张晓峰, 冯建朝, 等. 精密热控技术在太极一号卫星上的应用[J]. 空间科学学报, 2021, 41(2): 337-341. doi: 10.11728/cjss2021.02.337LIU H, ZHANG X F, FENG J C, et al. Application of precision thermal control techniques in Taiji-1 satellite[J]. Chinese Journal of Space Science, 2021, 41(2): 337-341(in Chinese). doi: 10.11728/cjss2021.02.337 [15] CHENG W L, WU W F, SONG J L, et al. A new kind of shape-stabilized PCMs with positive temperature coefficient (PTC) effect[J]. Energy Conversion and Management, 2014, 79: 470-476. doi: 10.1016/j.enconman.2013.12.053 [16] CHENG W L, YUAN S, SONG J L. Studies on preparation and adaptive thermal control performance of novel PTC (positive temperature coefficient) materials with controllable Curie temperatures[J]. Energy, 2014, 74: 447-454. doi: 10.1016/j.energy.2014.07.009 [17] 常畅. 低居里温度点正温度系数层状电热材料的制备与应用研究[D]. 广州: 华南理工大学, 2020.CHANG C. Preparation and application of positive temperature coefficient laminated electric heating materials with low Curie temperature[D]. Guangzhou: South China University of Technology, 2020(in Chinese). [18] CHEN T T, FU M S, JIA B W, et al. Dielectric and ferroelectric properties of Ba1−xSrxTiO3 ceramics: Effects of grain size and ferroelectric domain[J]. Advances in Applied Ceramics, 2013, 112(5): 270-276. doi: 10.1179/1743676112Y.0000000070 [19] YU A M, LI Q, FAN D S, et al. Study on positive temperature coefficient of resistivity of co-doped BaTiO3 with Curie temperature in room temperature region[J]. Science China Technological Sciences, 2019, 62(5): 811-819. doi: 10.1007/s11431-018-9435-7 [20] YU A M, LI Q. Temperature-dependent resistivity performance of Mn/Y-doped Ba1−xSrxTiO3 compositions with potential thermal control applications[J]. Ceramics International, 2020, 46(7): 8796-8805. doi: 10.1016/j.ceramint.2019.12.119 [21] 宋嘉梁. 常温PTC热控材料及其热控方法研究[D]. 合肥: 中国科学技术大学, 2016.SONG J L. Study on PTC thermal control material at room temperature and its thermal control method[D]. Hefei: University of Science and Technology of China, 2016(in Chinese). -

下载:

下载: