-

摘要:

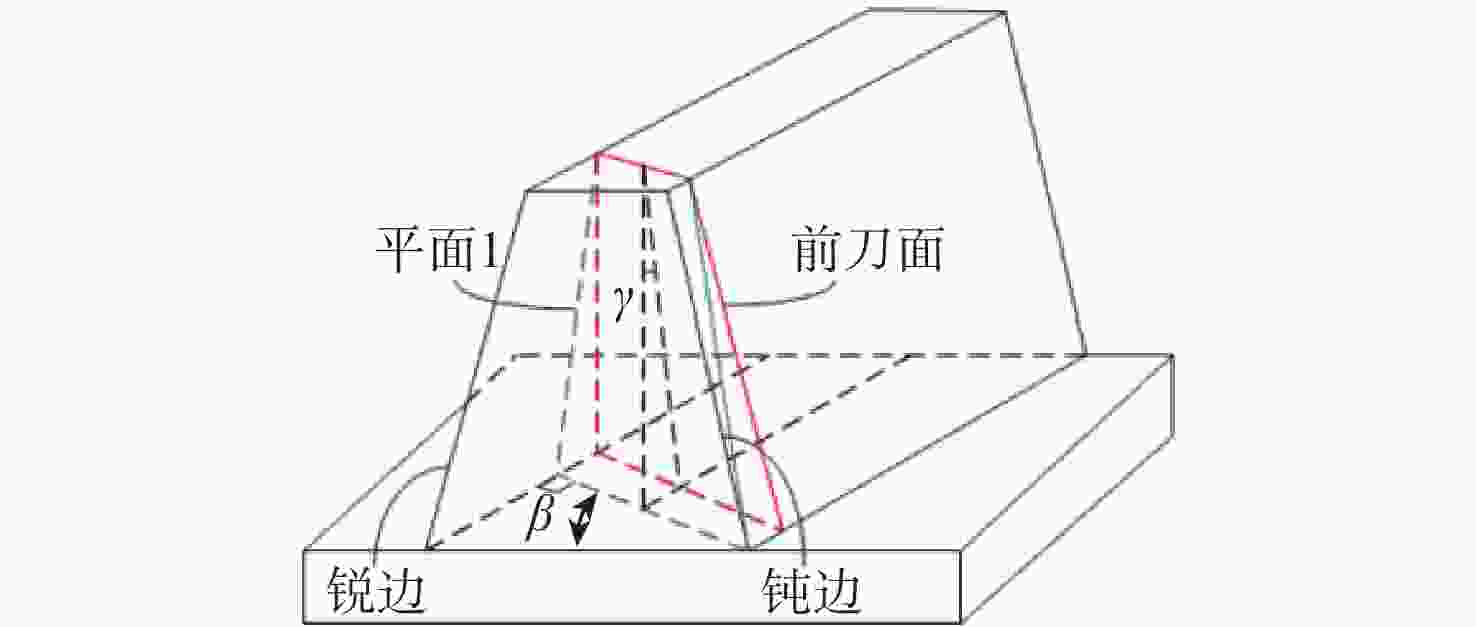

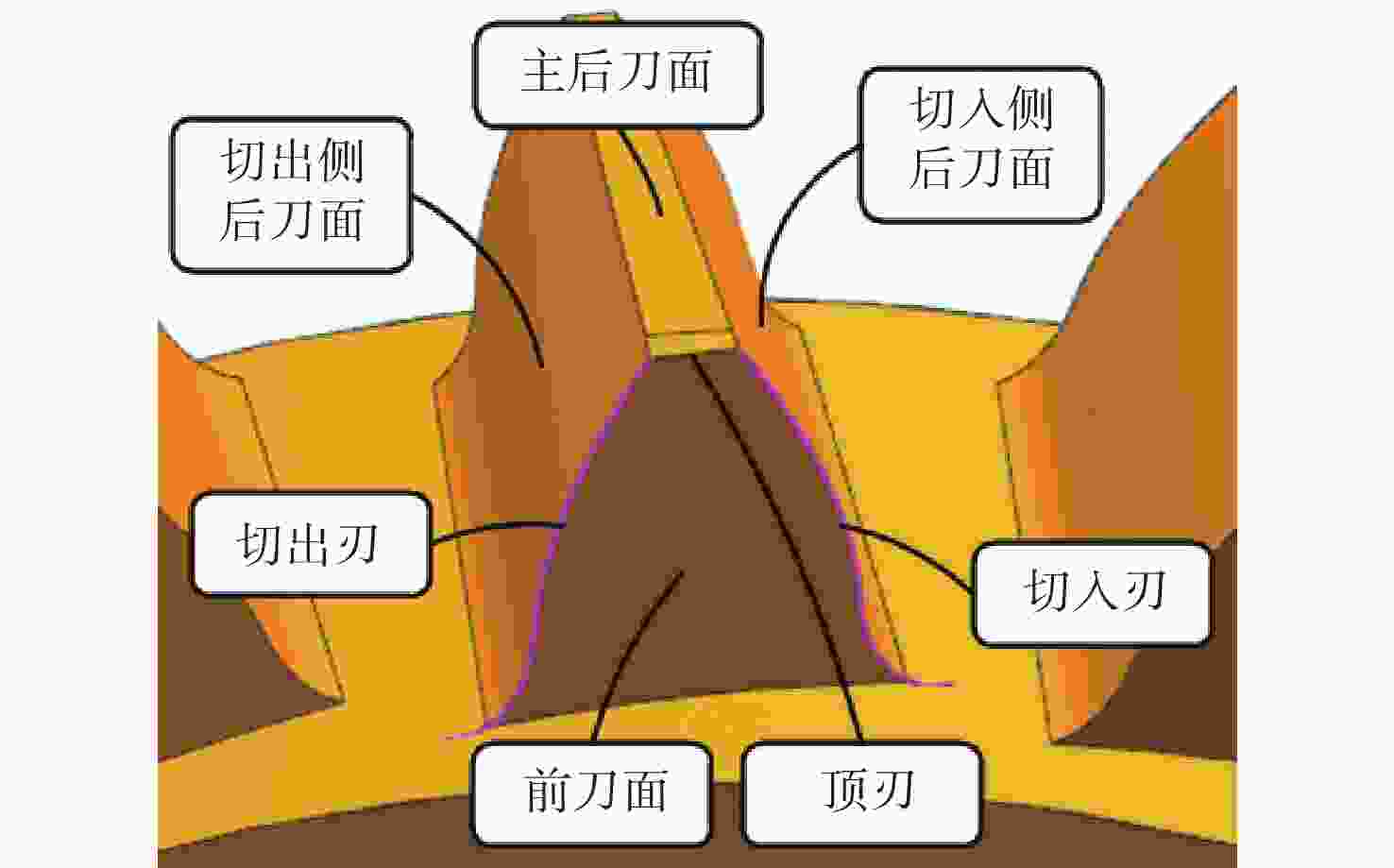

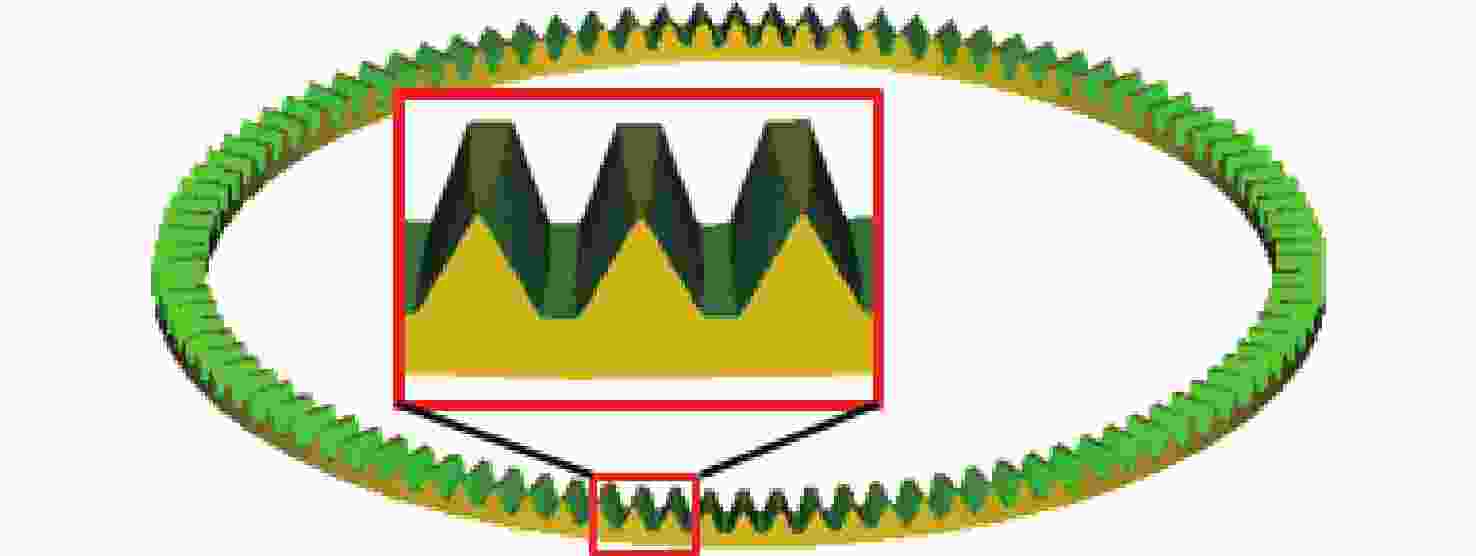

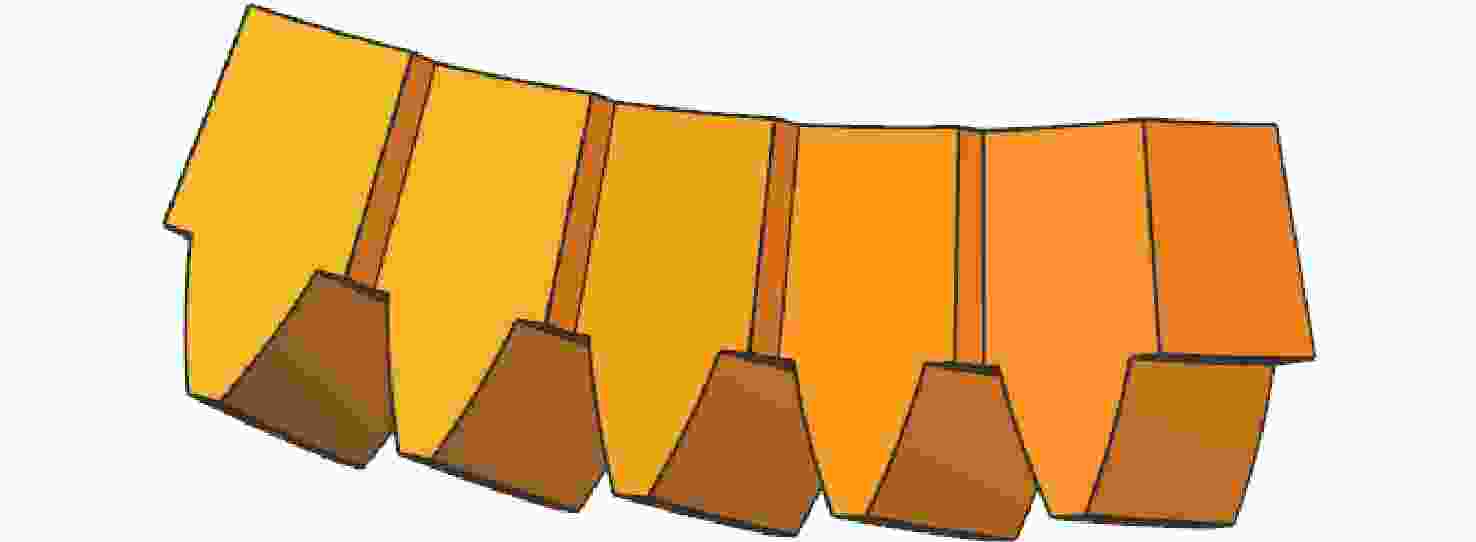

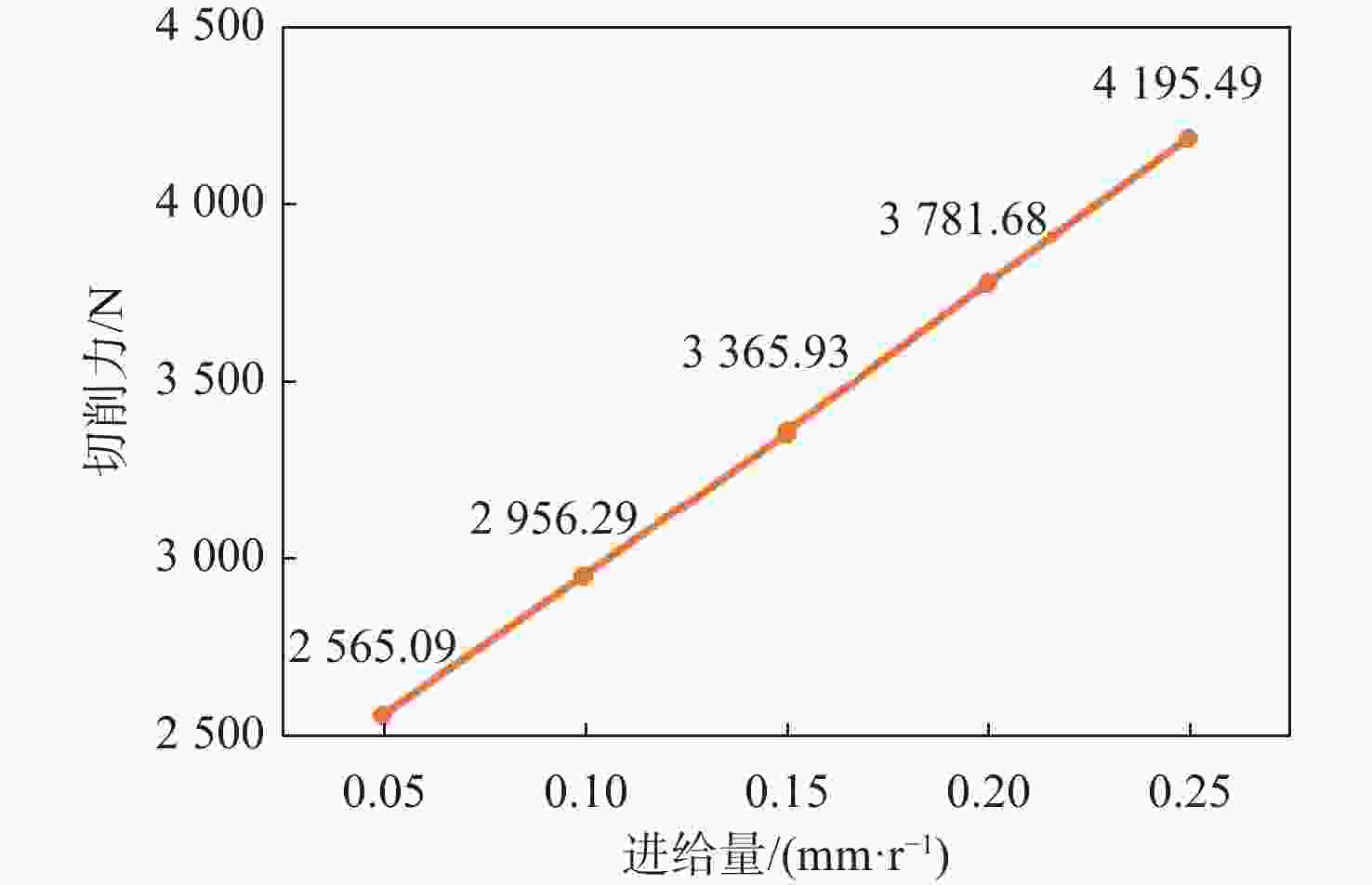

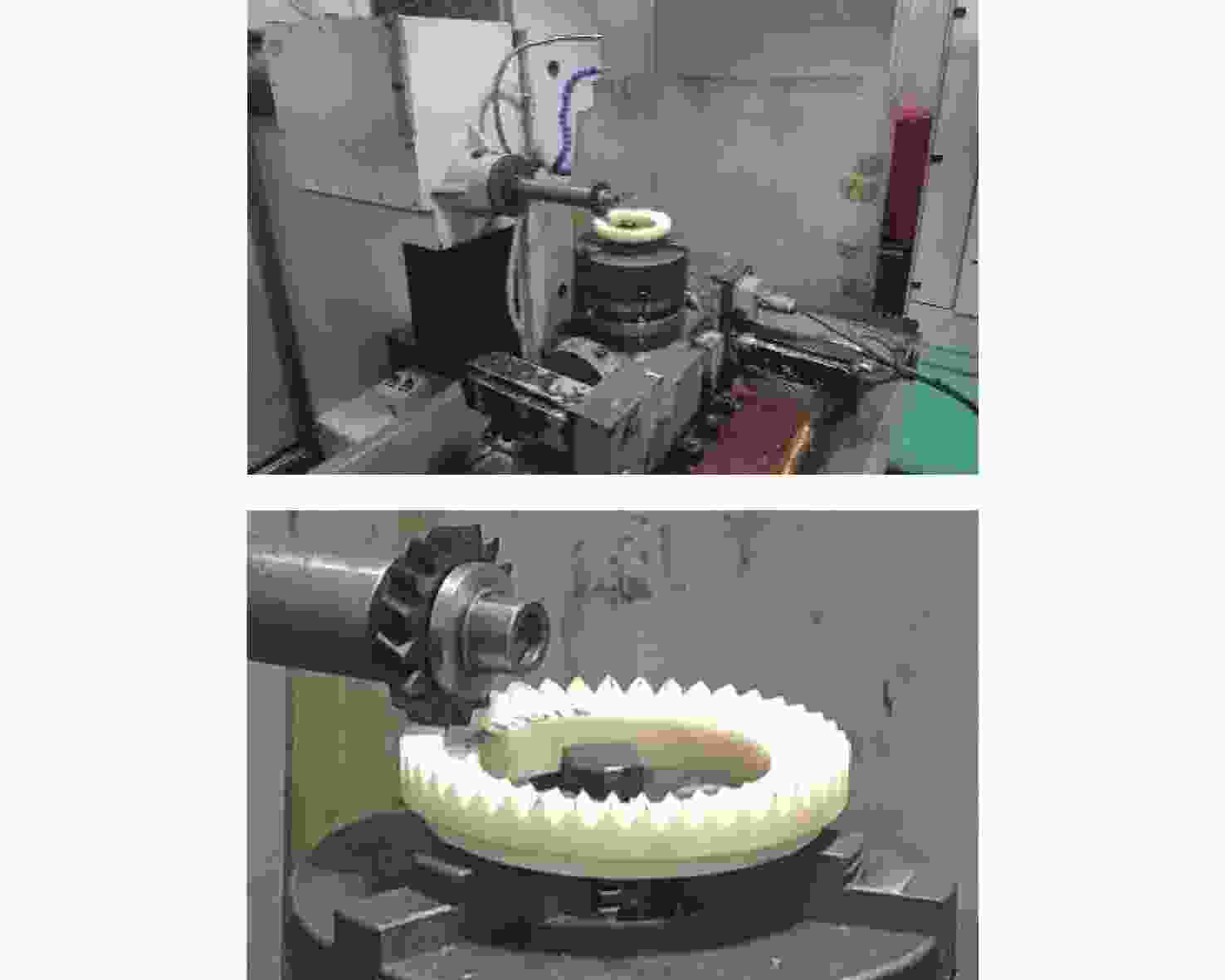

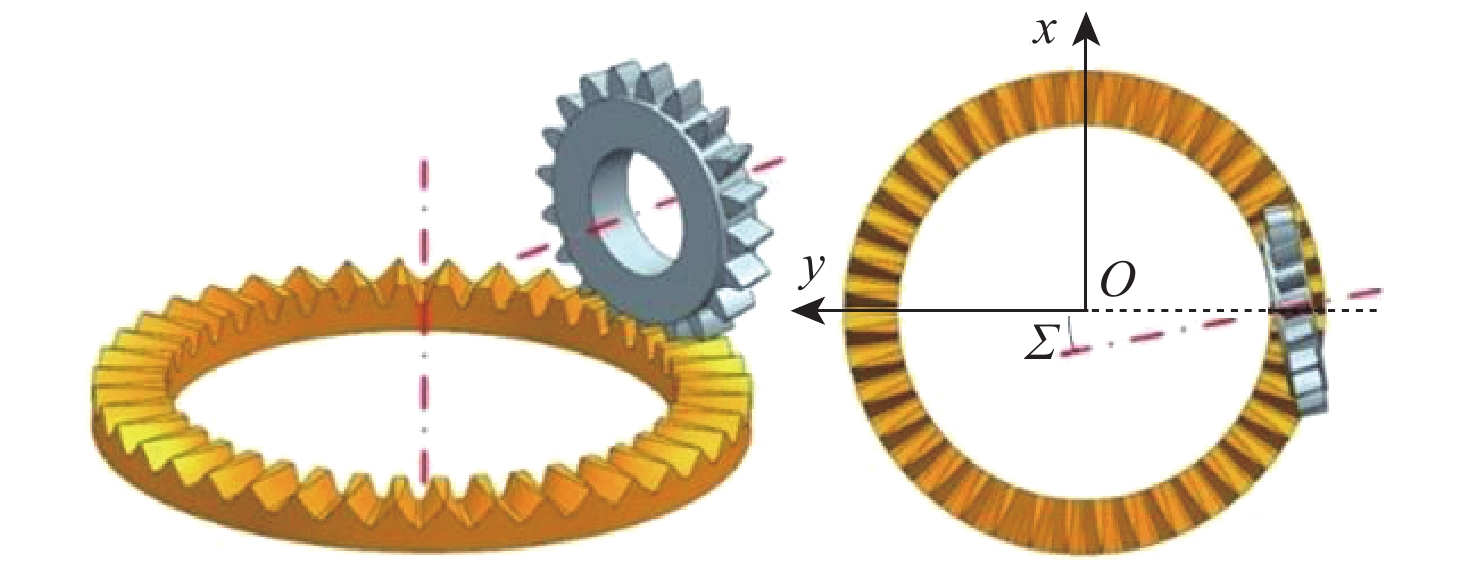

为了提高面齿轮的加工效率,结合车齿加工圆柱齿轮的方法,提出了一种利用车齿刀加工面齿轮的加工方法。分析了车齿加工的工作原理,建立了加工运动关系模型及车齿加工坐标系,推导了车齿刀切削刃上切削点的切削速度。对车齿刀前后刀面进行设计,建立了切削角度数学模型,分析了刀具切削角度在加工过程中的变化规律。利用VERICUT和DEFORM仿真分析软件对车齿过程进行验证,获得了加工后误差及加工参数对切削力的影响规律。

Abstract:Combining a method for skiving cylindrical gear with one for machining face gear is suggested in order to increase the processing effectiveness of face gears. First, the principle of the skiving machining is analyzed, and the machining motion model and the skiving coordinate system are established. The cutting speed of the cutting point on the cutting edge of the skiving tool is derived. Secondly, the rack face and the flank face of the skiving tool are designed, the mathematical model of the cutting angle is established, and the change rule of the cutting angle of the tool during the machining process is analyzed. Finally, using VERICUT and DEFORM simulation analysis software to verify the skiving process, the post-processing errors and the influence of processing parameters on the cutting force are obtained.

-

Key words:

- face gear /

- skiving /

- cutting angle /

- cutting force /

- machining model

-

表 1 车齿基本参数

Table 1. Basic parameters of gear

参数 数值 模数m 5 压力角$ \alpha $/(°) 20 螺旋角$ \beta $/(°) 23 安装夹角$\varSigma$/(°) 23 面齿轮齿数${Z}_{2}$ 100 车齿刀齿数${Z}_{\mathrm{s} }$ 70 面齿轮根切内半径$ {R}_{\mathrm{u}} $/mm 48.7 面齿轮变尖外半径$ {R}_{\mathrm{p}} $/mm 54.65 表 2 车齿仿真加工参数

Table 2. Gear simulation machining parameters

仿真 刀具转速/(r·s−1) 进给量/(mm·r−1) 1 10 0.05,0.1,0.15,0.2,0.25 2 10,11,12,13,14 0.05 -

[1] LITVIN F, FUENTES A. Gear geometry and applied theory[M]. Cambridge: Cambridge University Press, 2004. [2] LITVIN F, WANG J, BOSSLER R, et al. Application of face-gear drives in helicopter transmissions[J]. Journal of Mechanical Design, 1994, 116(3): 672-676. doi: 10.1115/1.2919434 [3] LITVIN F, FUENTES A, GONZALEZ-PEREZ I, et al. Face gear drive with helical involute pinion: Geometry, generation by a shaper and a worm, avoidance of singularities and stress analysis: NASA/CR-213443[R]. Washington, D. C. : NASA, 2005. [4] 南耀仕, 张满栋, 吕明, 等. 面齿轮插齿仿真加工及分析[J]. 工具技术, 2018, 52(3): 77-80. doi: 10.3969/j.issn.1000-7008.2018.03.017NAN Y S, ZHANG M D, LV M, et al. Simulation and analysis of face gear shaping process[J]. Tool Engineering, 2018, 52(3): 77-80(in Chinese). doi: 10.3969/j.issn.1000-7008.2018.03.017 [5] 李政民卿, 朱如鹏. 面齿轮插齿加工中过程包络面和理论齿廓的干涉[J]. 重庆大学学报(自然科学版), 2007, 30(5): 55-58.LI Z M Q, ZHU R P. Process method of face-gear drive with spur involute pinion with the shaping machine[J]. Journal of Chongqing University (Natural Science Edition), 2007, 30(5): 55-58(in Chinese). [6] YANG X, TANG J. Research on manufacturing method of CNC plunge milling for spur face-gear[J]. Journal of Materials Processing Technology, 2014, 214(12): 3013-3019. doi: 10.1016/j.jmatprotec.2014.07.010 [7] 唐进元, 杨晓宇. 面齿轮数控插铣加工方法研究[J]. 机械传动, 2015, 39(6): 5-8. doi: 10.16578/j.issn.1004.2539.2015.06.004TANG J Y, YANG X Y. Research of the plunge milling for face gear[J]. Journal of Mechanical Transmission, 2015, 39(6): 5-8(in Chinese). doi: 10.16578/j.issn.1004.2539.2015.06.004 [8] YOUSHINO H, SHAO M, ISHIBASHI A. Design and manufacture of pinion cutters for finishing gears with an arbitrary profile[J]. JSME International Journal, 1992, 35(2): 313-319. [9] CHEN X C, LI J, LOU B C. A study on the design of error-free spur slice cutter[J]. International Journal of Advanced Manufacturing Technology, 2013, 68(1-4): 727-738. doi: 10.1007/s00170-013-4794-3 [10] 贾康, 郑帅, 郭俊康, 等. 一种刮削加工切削齿刃形计算与加工运动仿真方法[J]. 机械工程学报, 2019, 55(1): 216-224. doi: 10.3901/JME.2019.01.216JIA K, ZHENG S, GUO J K, et al. A method of cutter profile identification and machining motion simulation for skiving[J]. Journal of Mechanical Engineering, 2019, 55(1): 216-224(in Chinese). doi: 10.3901/JME.2019.01.216 [11] SPATH D, HÜHSAM A. Skiving forhigh-performance machining of periodic structures[J]. CIRP Annals-Manufacturing Technology, 2002, 51(1): 91-94. doi: 10.1016/S0007-8506(07)61473-5 [12] GUO Z, MAO S M, LIANG H Y, et al. Research and improvement of the cutting performance of skiving tool[J]. Mechanism and Machine Theory, 2018, 120: 302-313. doi: 10.1016/j.mechmachtheory.2017.08.004 [13] GUO E K, HONG R, HUANG X, et al. Research on the design of skiving tool for machining involute gears[J]. Journal of Mechanical Science and Technology, 2014, 28: 5107-5115. doi: 10.1007/s12206-014-1133-z [14] VARGAS B, ZAPF M, KLOSE J, et al. Numerical modelling of cutting forces in gear skiving[J]. Procedia CIRP, 2019, 82: 455-460. doi: 10.1016/j.procir.2019.04.039 [15] WANG Y Z, SU G Y, CHU X M, et al. A finishing method for the continuous generation of spur face gears with shaving cutters[J]. International Journal of Mechanical Sciences, 2021, 190: 106020. doi: 10.1016/j.ijmecsci.2020.106020 -

下载:

下载: