-

摘要:

上浆剂对高性能碳纤维(CF)表面的修饰作用及对其复合材料界面性能的调制作用至关重要。以湿法制备的宇航级T800碳纤维为研究对象,分析上浆前后纤维表面微结构、化学组成和化学反应特性的变化规律,并对其复合材料的宏微观界面性能进行表征评价。采用X射线光电子能谱(XPS)、差式扫描量热法(DSC)、傅里叶变换红外光谱(FTIR)等表征方法,分析上浆剂的反应性及其与环氧树脂(EP)、双马来酰亚胺树脂(BMI)的化学反应行为。结果表明:在树脂固化温度条件下上浆剂与纤维表面基团发生化学反应,使得纤维上浆剂提取量及纤维表面活性碳元素含量降低,并且上浆剂与EP、BMI工艺具有良好的化学反应性。经过高温处理后CF表面的上浆剂失活,CF/EP的界面剪切强度发生一定变化,CF/BMI的界面剪切强度下降13%。综上可见:具有化学活性的环氧类上浆剂可明显改善CF表面特性,进而对复合材料的界面性能产生影响,其中上浆剂与树脂体系的反应性对界面亦有影响。

Abstract:The effect of the sizing agent on the surface modification of high-performance carbon fiber (CF) and the modulation effect on the interface performance of its composite is very important. In this paper, the aerospace-grade T800 carbon fibers prepared by the wet method are used, and the changes in the surface microstructure, chemical composition, and chemical reaction characteristics of the fiber before and after sizing are analyzed, and the macro and micro interface properties of the composites are characterized. In addition, the reactivity of the sizing agent and its chemical reaction behavior with epoxy resin (EP) and bismaleimide resin (BMI) were examined using X-ray photoelectron spectroscopy (XPS), differential scanning calorimetry (DSC), Fourier transform infrared spectroscopy (FTIR), and other characterization techniques. The results show that the sizing agent reacts chemically with the groups on the fiber surface under the curing temperature of the resin so that the extraction amount of the sizing agent and the content of active carbon atoms on the fiber surface is reduced. The sizing agent has good chemical reaction characteristics with EP and BMI. The surface of CF sizing agent is rendered inactive after the high-temperature treatment, which also results in a little change in the interface shear strength between CF and EP but a 13% reduction between CF and BMI. In conclusion, the epoxy sizing agent with chemical activity can significantly improve the surface properties of carbon fiber, and then affect the interface properties of composites, in which the reactivity between the sizing agent and resin also affects the interface performance.

-

Key words:

- sizing agent /

- carbon fiber /

- chemical reaction /

- interface adjustment /

- composite material

-

高强型聚丙烯腈基碳纤维(carbon fiber,CF)是由石墨微晶组成的多晶多相材料,其表面呈现出明显的化学惰性,不利于纤维与树脂间的应力传递[1-2]。为使界面性能得到改善,普遍的做法是通过CF表面改性提高纤维表面极性及与树脂的亲和性[3-4]。目前工程中采用的主要方法是对CF表面进行电解氧化处理[5]和上浆[3]。上浆的目的是防止生产过程中各种机械摩擦和拉伸对纤维造成起毛断丝等损伤,提高纤维的可加工适应性,以保持纤维本征的高强、高模特性[6]。另一方面,上浆剂可以与CF表面氧化处理的活泼官能团相互作用,起到保护纤维表面活性、免受污染的作用,好的上浆剂还能提高纤维表面极性,提升CF与树脂体系的相似相容特性,保证工艺过程中树脂对纤维的充分浸润[7]。

上浆剂含量一般是CF质量的0.5%~1.5%[3],是一种以树脂为主体,配以一定量的乳化剂,少量或没有交联剂,以及其他助剂而制成的乳液。上浆剂的主体主要有:环氧树脂(epoxyresin,EP)、酚醛树脂、醋酸乙烯树脂、丙烯酸树脂、聚氨酯、聚酰胺、聚酰亚胺等[8-12]。当CF与树脂复合成型过程中,上浆剂作为媒介,可分别与纤维和树脂相互作用,从而影响其复合材料的界面性能。Gu等[7]使用双酚A型环氧上浆剂改性CF,发现上浆剂可以提高纤维与树脂界面剪切强度(interfacial shear strength,IFSS),同时使界面层模量增加、断裂韧性降低。Ren等[13]使用E51和E20的EP对CF进行上浆,发现环氧上浆剂可以起到催化剂的作用,氰酸酯树脂的固化温度降低了30 ℃,进而消除界面处的残余热应力和缺陷,层间剪切强度(interlaminar shear strength,ILSS)提高了13%。Yang等[14]研究发现,未改性环氧上浆剂和SiO2改性的环氧上浆剂使CF环氧复合材料的ILSS分别提高了9%和14%,同时环氧/ SiO2 混合上浆剂提高了复合材料的ILSS和冲击强度[15]。Zhang等[16]研究发现,环氧上浆剂可以提升高模量CF的表面活性,改善纤维与树脂的浸润性,使用针对性研制的固化剂改性上浆剂,可使复合材料的ILSS提高8.6%。Yuan等[17]使用有机无溶剂聚酰胺酸纳米乳液对CF进行上浆,上浆后纤维表面张力能从42.91 mN/m增加到54.55 mN/m,CF/聚醚砜复合材料IFSS从33.6 MPa增加到49.7 MPa。Chen等[18]使用E51/环氧化聚丁二烯等组成上浆剂对CF进行上浆,提高了纤维的工艺性,降低了纤维表面粗糙度和缺陷,使其CF环氧复合材料的ILSS提高了16.9%。Li等[19]发现丙烯酸上浆剂可以降低CF的表面能和纤维/树脂接触角,苯酚、间苯二胺、丙烯酸3种上浆剂均可以提高CF酚醛复合材料的ILSS。Liu等[20]发现使用聚醚醚酮(poly ether-ether-ketone,PEEK)上浆后CF热稳定性和表面能均提高,纤维与树脂浸润性、CF/PEEK的IFSS提高。上述大部分研究表明,上浆剂可提高复合材料的界面性能,而上浆剂和树脂的相容性是决定复合材料界面性能的决定性因素[3, 21]。

笔者前期研究发现,大部分上浆剂主组分为分子量为几千的预聚物,并且其中含有一定量的活性官能团[8, 22]。在复合材料的固化过程中,上浆剂会发生一定程度的固化反应,在界面层形成共价键。另外,在固化过程中,树脂中的固化剂也必然会扩散到约30~100 nm厚的上浆剂层中,扩散到上浆剂层中的固化剂与上浆剂自身含有的活性官能团均可与树脂基体中的官能团发生反应,其反应程度必然会影响复合材料的界面性能[22-24]。

对于特定的纤维/树脂体系,研制新型上浆剂作为偶联剂提高其界面性能仍在不断发展[10, 18]。近年来,采用纳米颗粒或纳米添加剂改性上浆剂进而提高界面力学性能、热稳定性等受到广泛关注,其中碳纳米管(carbon nanotube,CNT)以其超常的强度、模量、韧性及优异的电、热功能特性而备受青睐[25-30]。Liu等[25]将CNT分散在水性聚碳酸酯和水性聚氨酯上浆剂中,提高了CF与聚碳酸酯的界面结合力。Wu等[28]将氨基化CNT加入到上浆剂中,改善CF增强不饱和聚酯复合材料的性能,其ILSS和冲击韧性分别提高了32.3%和55.2%。但是针对航空航天用的新型高性能CF,面向主结构应用提出的高强度、高韧性苛刻需求,其纤维表面处理与上浆对复合材料界面和耐久性的影响尤为重要[31-32]。

本文针对湿法纺丝T800级CF,分析上浆对其表面微观形貌和化学组成的调制作用。在此基础上,研究了不同上浆体系下T800级CF与 EP和双马来酰亚胺树脂(bismale-imiedresin, BMI)的宏微观界面性能的差异性。分析了不同固化温度下CF表面上浆剂的化学反应程度 。采用X射线光电子能谱(X-ray photoelectron spectroscopy,XPS)、傅里叶变换红外光谱(Fourier transform infra-red,FTIR)、差示扫描量热法(differential scanning calorimetry, DSC),表征分析了上浆剂与纤维表面的化学特性,以及上浆剂、树脂在固化过程中的反应放热和官能团变化,进而对CF与树脂微观界面的影响。研究结果对上浆剂的研制及其与纤维、树脂的匹配研究提供指导与借鉴。

1. 实验材料及方法

1.1 实验材料

本文使用了4种具有不同表面处理状态和上浆剂的国产宇航级T800级CF,分别记为F1~F4,每种上浆纤维各有未上浆的裸丝纤维与之对应,分别记为F1-US、F2-US、F3-US和F4-US,其中F2-US使用了氨基化表面处理,F1-US、F3-US和F4-US 的表面处理工艺相同且纤维表面氧含量更高。F2与F4使用同类型的多官能度环氧上浆剂,F1和F3则为双官能度环氧上浆剂,但F3上浆剂环氧值要低于F1,其分子量更大,各种纤维均由威海拓展纤维有限公司提供。

本文所用的2种树脂体系,一种是高温固化的多官能度EP体系,其固化工艺制度为180 ℃、3 h;另一种是高韧性BMI体系,其固化工艺制度为180 ℃、2 h和200 ℃、6 h,2种树脂均为自制体系。为了考察在复合材料固化工艺过程中上浆剂失活对界面的影响作用,采用以上2种树脂的固化温度制度分别对CF进行热处理,对应标记为EP工艺和BMI工艺。

1.2 性能表征

使用日本电子株式会社的JEOL-JSM 7500F场发射扫描电子显微镜(scanning electron microscope,SEM)和德国布鲁克公司的Multimode8原子力显微镜(atomic force microscope ,AFM)表征CF的表面形貌,AFM观察区域为3 μm×3 μm,表面粗糙度由NanoScope Analysis软件处理得到。使用美国Thermo Scientific公司的ESCALAB 250XI型XPS表征CF表面元素含量及结合能特性,测试时采用单丝Al Kα射线源,真空室真空度约为8×10−10 Pa,以能量为284.6 eV处的峰为参考峰,对碳C1s谱进行了七参数曲线拟合考察碳元素结合能情况。使用美国尼高力仪器公司的Nicolet Nexus470的FTIR表征上浆剂及树脂所含官能团情况,扫描范围为400~4000 cm−1。采用Mettler Toledo公司的DSC-1对树脂、上浆剂和质量比例为1∶1混合物进行固化反应分析,升温速率为5 ℃/min,扫描温度范围为25~350 ℃。采用原位红外的方法分析官能团在固化工艺过程中的变化情况,其中树脂与上浆剂质量比例为1∶1,扫描范围为400~4000 cm−1,分辨率为4 cm−1,扫描次数为32。CF表面上浆剂含量参照GB/T 26752-2020[33]进行测试。

使用日本东荣株式会社的HM410复合材料界面测试装置进行微脱黏测试,对不同CF和2种树脂体系的IFSS进行表征,IFSS计算如下:

τIFSS=Fπdl (1) 式中:τIFSS为界面剪切强度, MPa;F为最大脱黏力, mN;d为碳纤维单丝直径,μm;l为碳纤维在树脂珠中的包埋长度,mm。每组试样测试15个有效数据计算均值、标准差和变异系数(coefficient of variation,CV)值。

2. 结果与讨论

2.1 上浆剂对高性能碳纤维表面的修饰作用

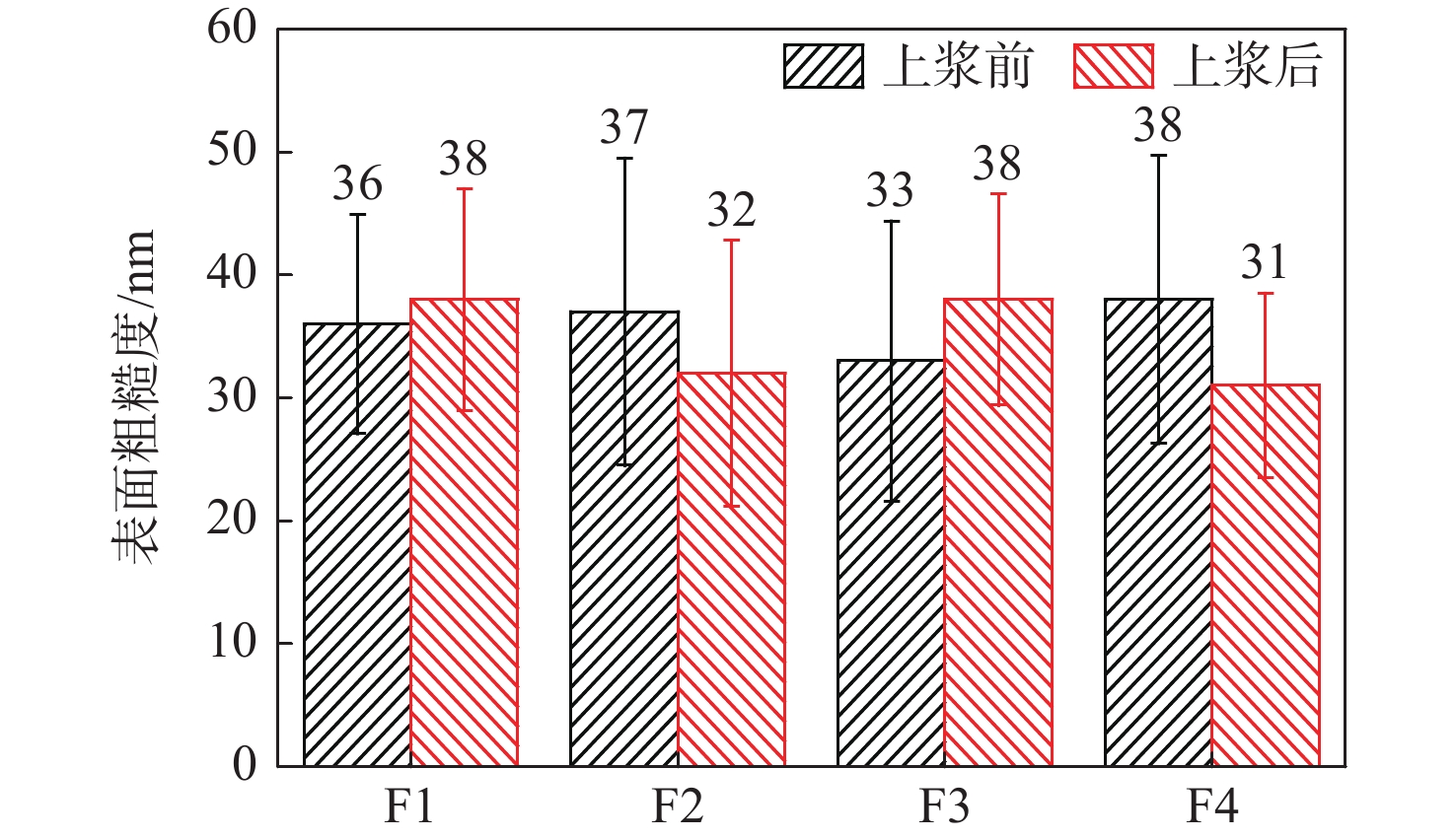

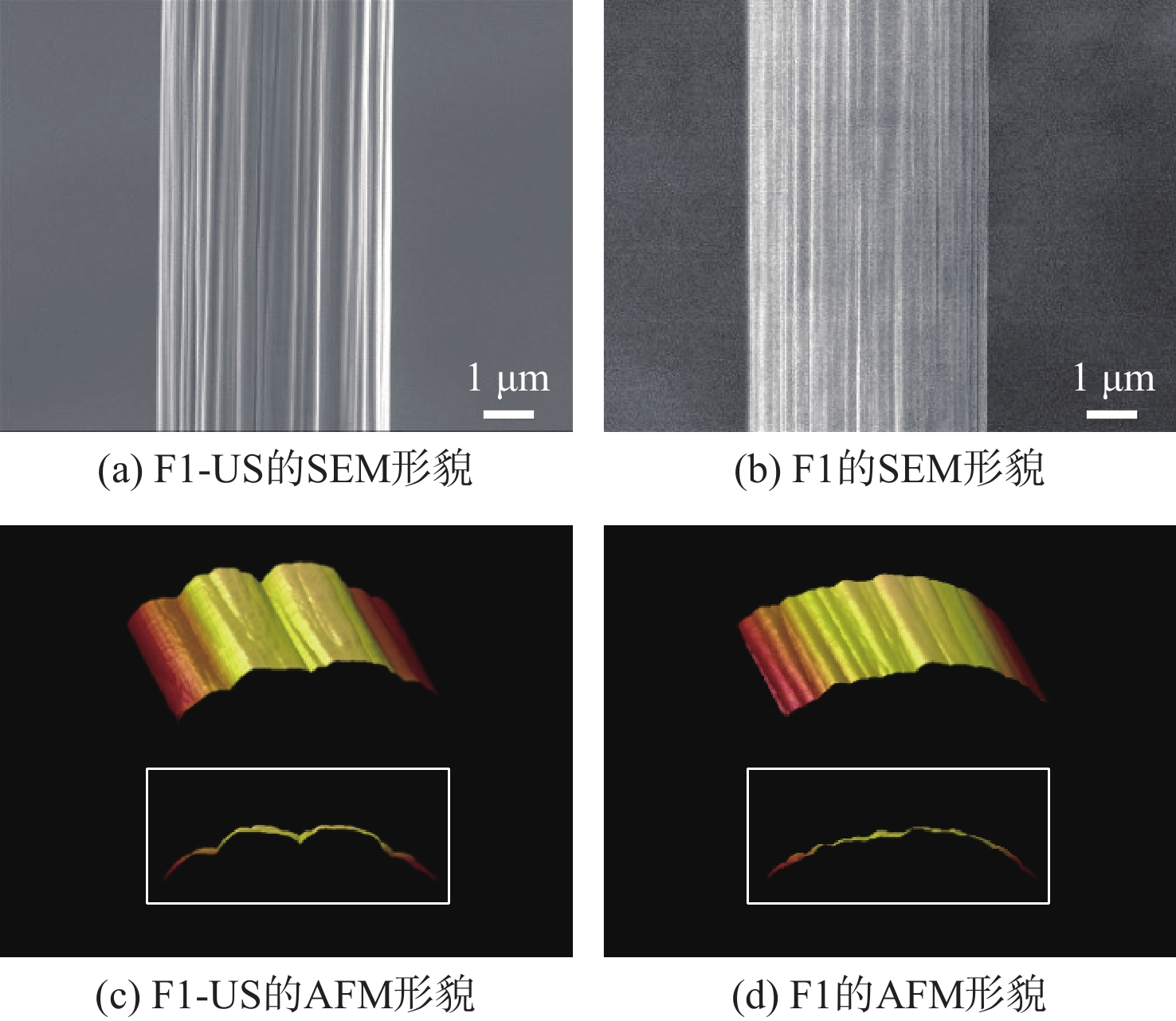

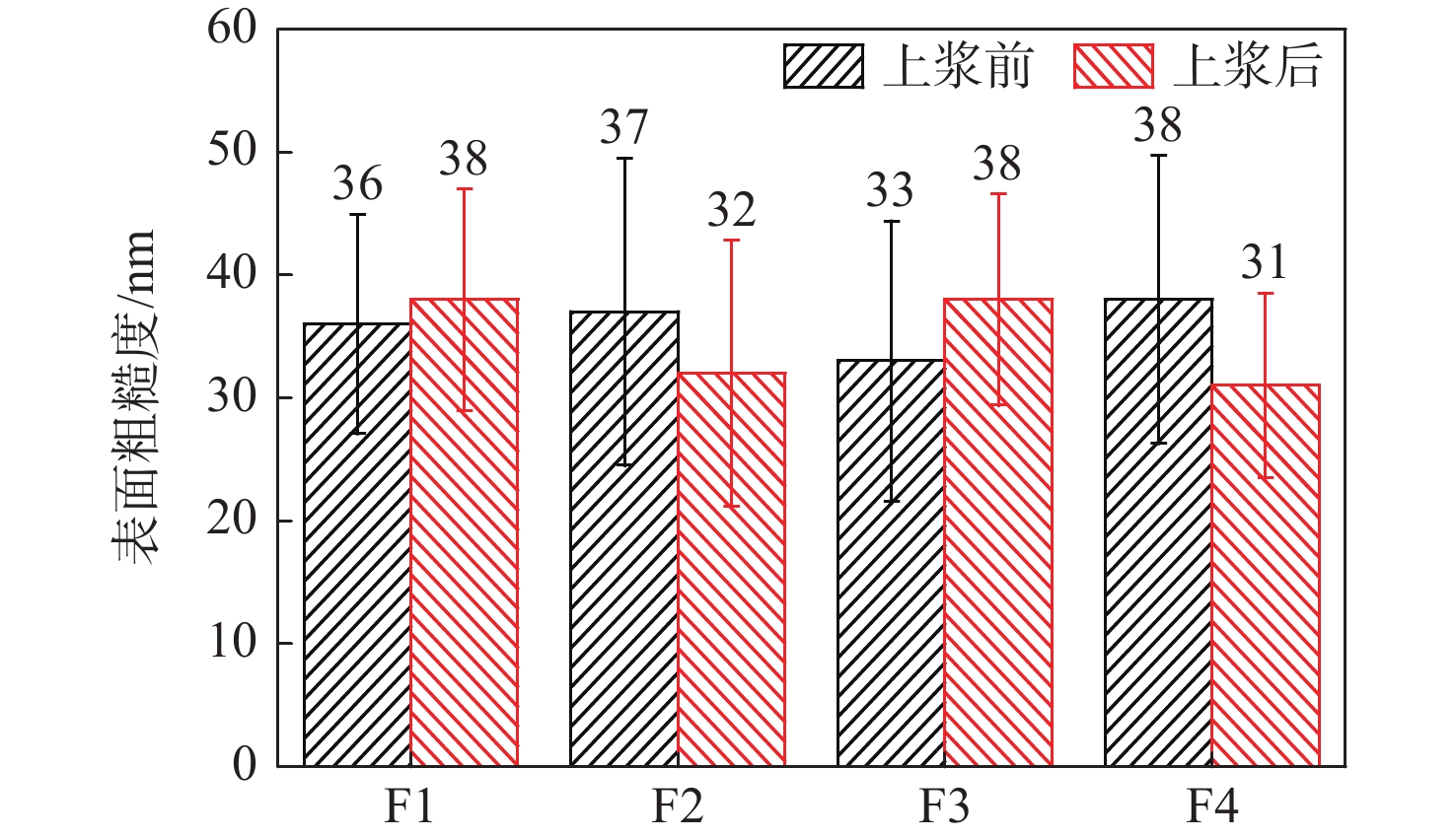

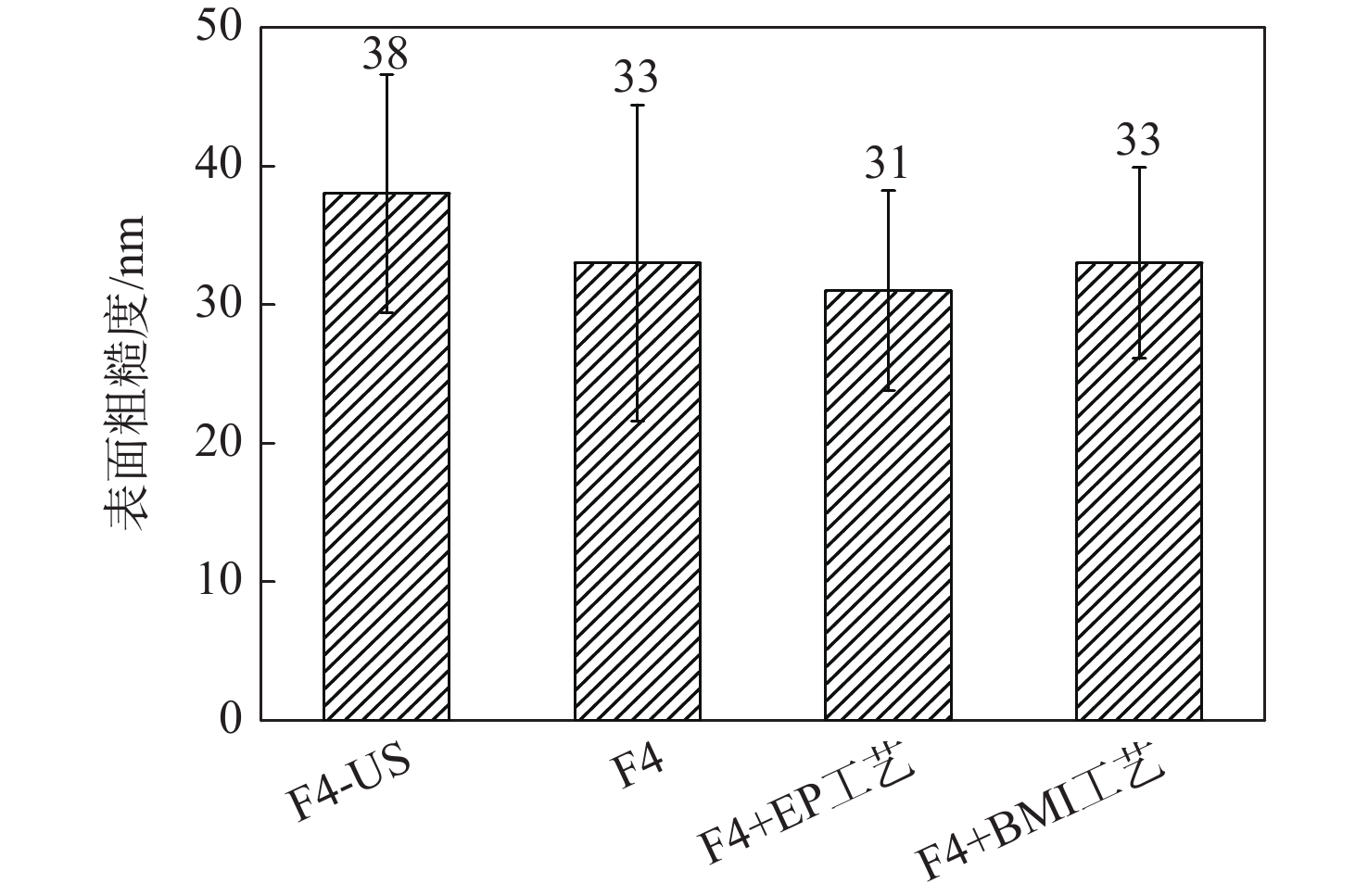

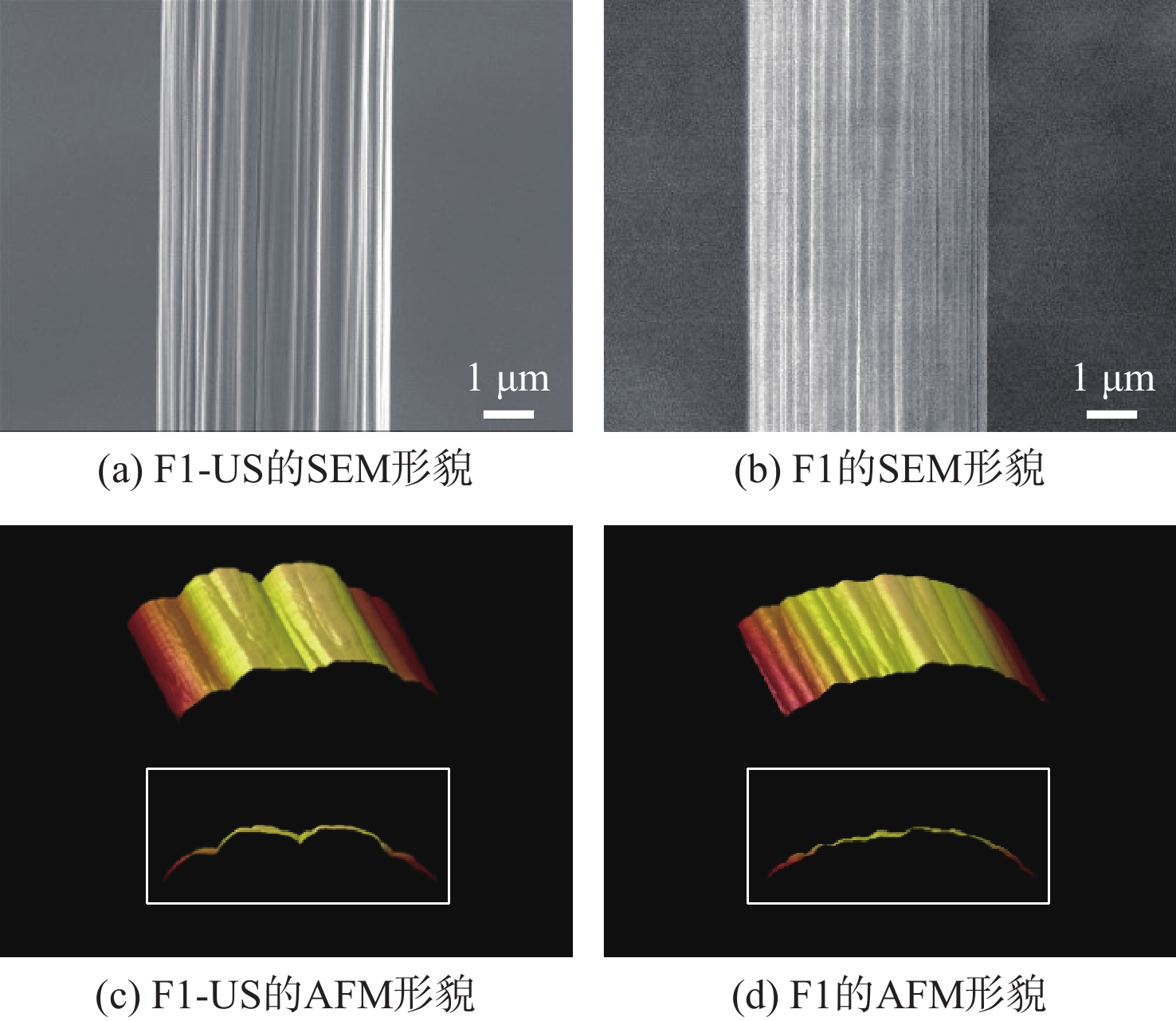

图1给出了F4纤维上浆前后表观形貌,其中,采用湿法纺丝技术制备的T800级CF表面具有明显规则的沟槽结构。未上浆裸纤维表面沟槽较为显著,上浆后CF表面的沟槽结构被部分填充。通过AFM对纤维表面形貌变化进行定量表征,得到各纤维表面粗糙度数值如图2所示。F1~F4这4种CF在上浆前后的表面粗糙度平均值均介于30~40 nm之间。说明上浆剂的使用对纤维表面粗糙度影响不大,因而也不会对界面相互作用中的机械啮合产生明显影响。其中F1和F3这2种纤维上浆后粗糙度略有增加,F2和F4这2种纤维上浆后的表面粗糙度路有下降,这可能与上浆剂的分子量大小有关,低分子量上浆剂容易填充到沟槽内部,形成较致密的表面涂层。综上所述,本文基本可以忽略表面粗糙度差异变化对界面性能的影响,从而更好地明晰上浆剂与CF表面和树脂的化学反应特性对界面性能的影响情况。

通过XPS分析了几种CF表面的元素组成。全谱分析结果中,各CF表面主要有C、O、N、Si元素,部分上浆碳纤维表面含有微量S或Na元素,如表1所示。对比上浆前后纤维表面成分的变化可知,带浆纤维表面的C含量均有所减小,Si含量均有所增加,O含量和N含量的变化规律不一。以表征纤维表面活性参量的氧碳比(O/C)为例,4种纤维中的F2纤维上浆后O/C比增加非常显著,其他3种纤维的表面O/C比在上浆前后变化较小。并且,F2-US的表面N元素含量较高而O元素含量较低,应该与其氨基化表面处理条件密切相关,上浆后F2纤维表面的O含量增长最为显著。

表 1 不同T800级CF上浆前后的表面元素Table 1. Surface element content of different T800 grade CF before and after sizing纤维类型 C/% O/% N/% Si/% S/% Na/% O/C F1 74.12 16.83 2.2 6.01 0.84 0 0.23 F1-US 78.72 16.24 2.43 2.62 0 0 0.21 F2 74.35 19.4 1.73 4.52 0 0 0.26 F2-US 79.74 14.05 2.99 3.22 0 0 0.18 F3 76.32 16.39 2.98 3.39 0.73 0.2 0.21 F3-US 78.16 17.12 2.28 2.44 0 0 0.22 F4 76.1 16.99 2.28 3.71 0.91 0 0.22 F4-US 77.58 16.85 2.36 3.21 0 0 0.22 对谱图的C1s进行分峰拟合以分析不同结合状态的碳元素含量,结果如表2所示,其中,Peak1~Peak6为不同能量分峰情况,分峰Peak3~Peak6中的碳元素为活性碳元素。除F2-US外,其余未上浆纤维表面活性碳元素含量均低于20%。而上浆后4种纤维活性碳元素含量均有所提升,纤维表面化学活性得到增强,其中F2和F4的活性碳元素含量达到50%以上。各纤维活性碳元素含量的提升主要归因于羟基/氨基(Peak3下)含量和环氧基团(Peak4下)含量的增加,且各纤维的环氧基团均有一倍以上的提升。上浆后纤维表面含有大量活性基团如氨基、羟基和环氧基团,有助于形成更多的纤维/树脂的界面化学键合。

表 2 不同CF XPS的C1s分峰拟合结果Table 2. XPS C1s peak fitting results of different CF% 纤维类型 参比基团含量 −C−C−;

−C−H−含量−C−OH−C−O−;

−C−NH2含量C−O−C=O;

环氧基团含量−C=O−

C=N含量−O−C=OHO−

C=O含量活性碳元素含量 (Peak1,

能量284.8 eV)(Peak2,

能量285.0 eV)(Peak3,

能量286.1 eV)(Peak4,

能量286.6 eV)(Peak5,

能量287.7 eV)(Peak6,

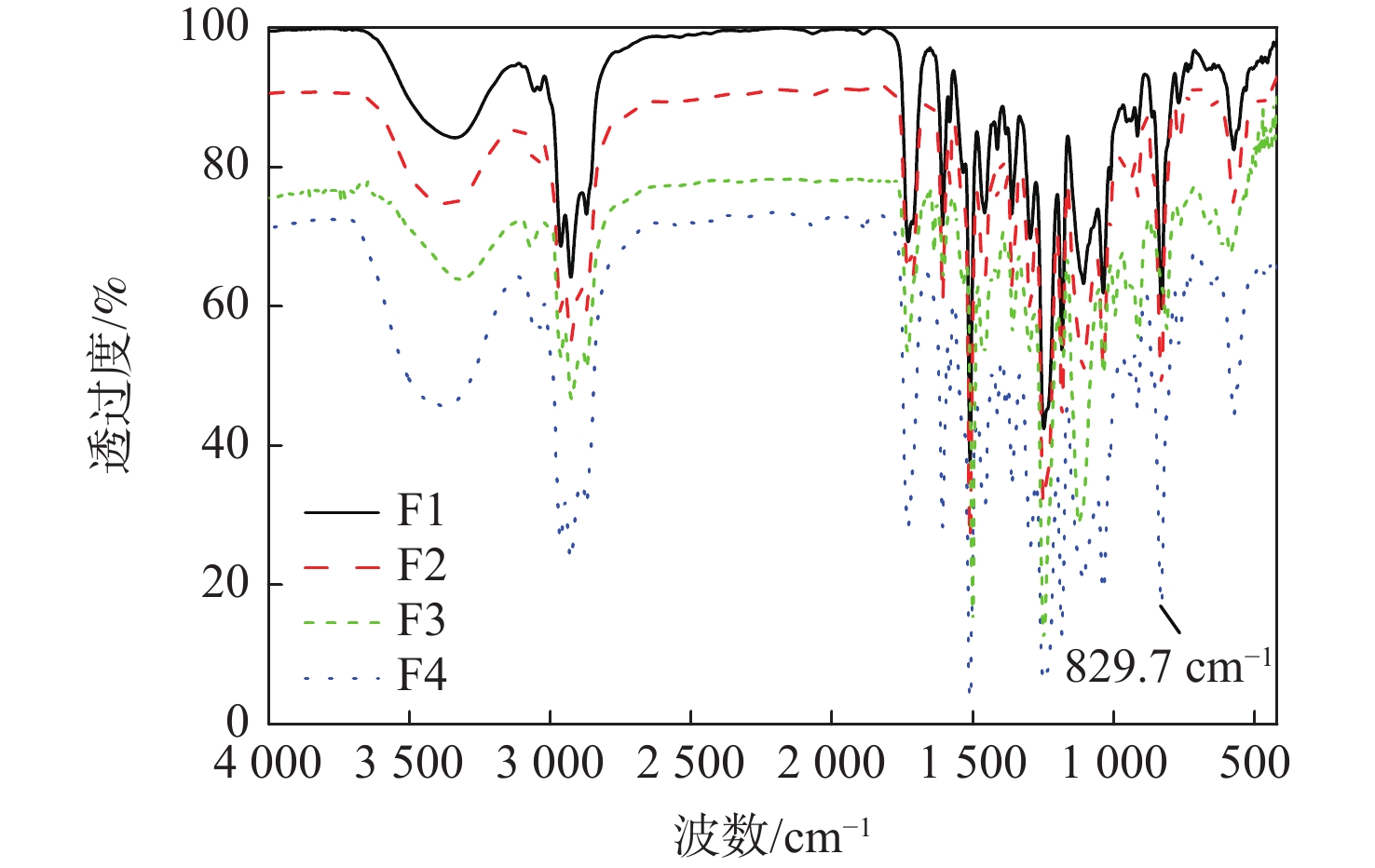

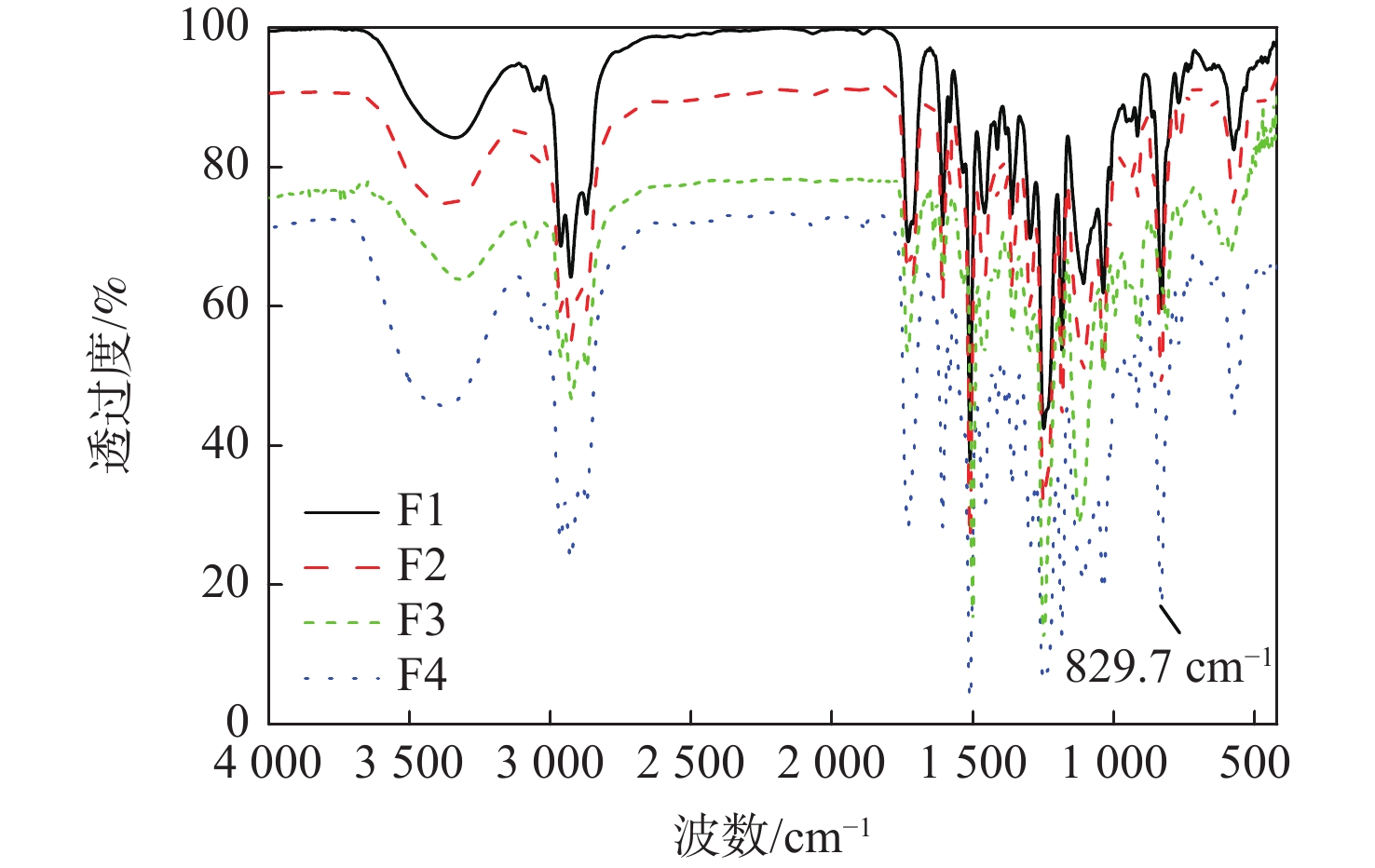

能量289.4 eV)F1 38.54 26.05 10.92 16.35 6.45 1.69 35.41 F1- US 70.22 11.65 0.00 6.02 7.15 4.96 18.13 F2 36.67 12.59 20.59 17.49 3.31 9.35 50.74 F2- US 37.09 18.02 24.05 0.00 11.35 9.49 44.89 F3 44.20 13.92 16.36 12.29 6.40 6.85 41.90 F3- US 59.81 20.80 1.53 3.75 6.79 7.31 19.38 F4 24.61 13.73 27.97 22.03 4.90 6.77 61.67 F4- US 73.21 7.38 2.84 4.43 6.66 5.49 19.42 通过FTIR对几种纤维上浆剂的官能团组成进行分析,结果如图3所示。4种纤维的上浆剂主组分均为含芳环的EP,主要含有羟基、氨基、酯基、苯环、醚键、长链烷基及环氧基团。对比几种上浆剂,F2和F4纤维上浆剂红外光谱基本相同,在波数为829.7 cm−1处的环氧峰表明环氧基团含量较高。相对而言F3纤维上浆剂的环氧峰强度较低,这与F3较低的环氧值和表2中F3纤维分峰拟合的Peak4对应的环氧类活性碳元素含量为各纤维中最低相印证。这些结果均表明不同上浆剂对CF表面官能团组成有调制作用。

2.2 上浆剂的化学反应活性

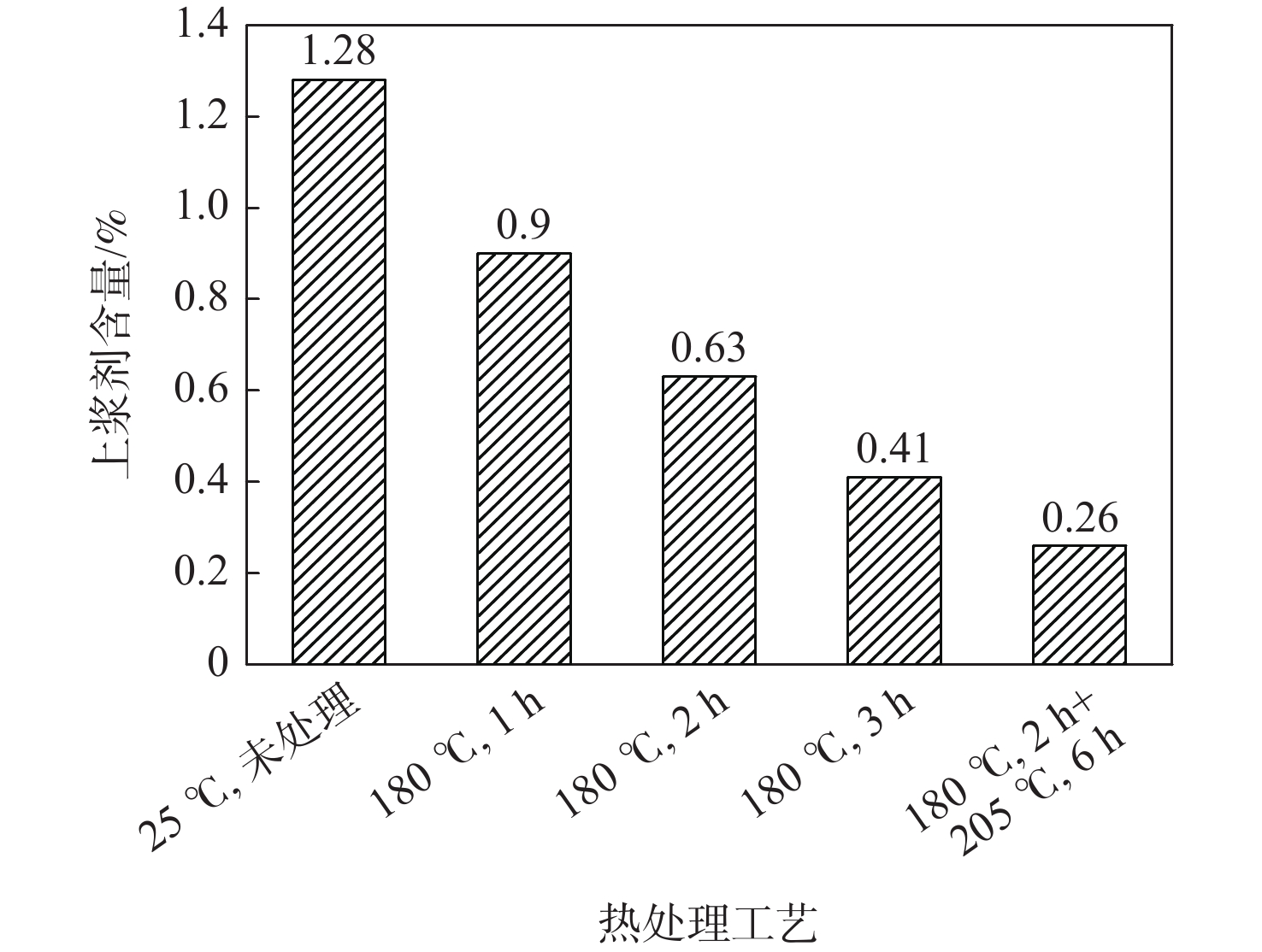

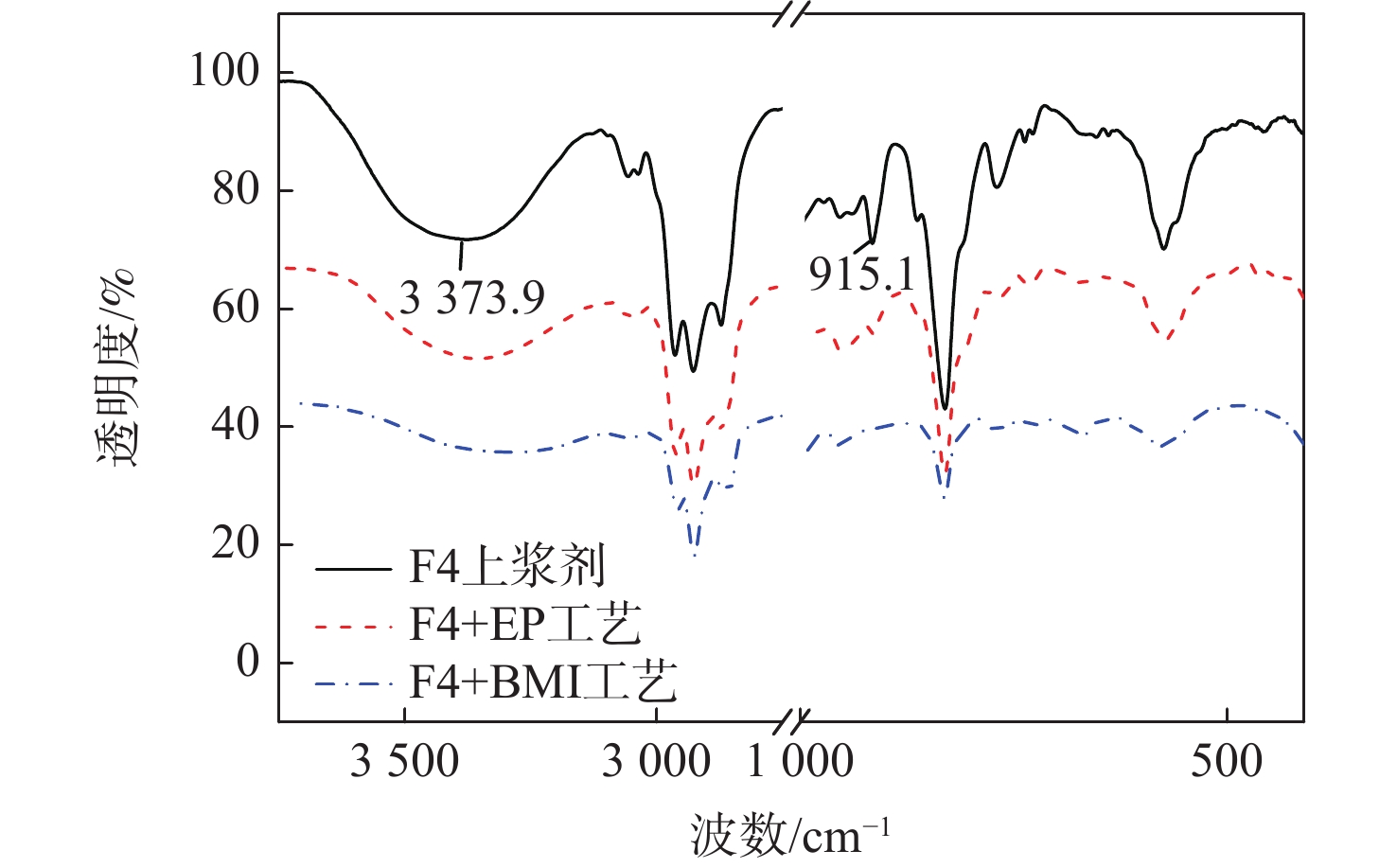

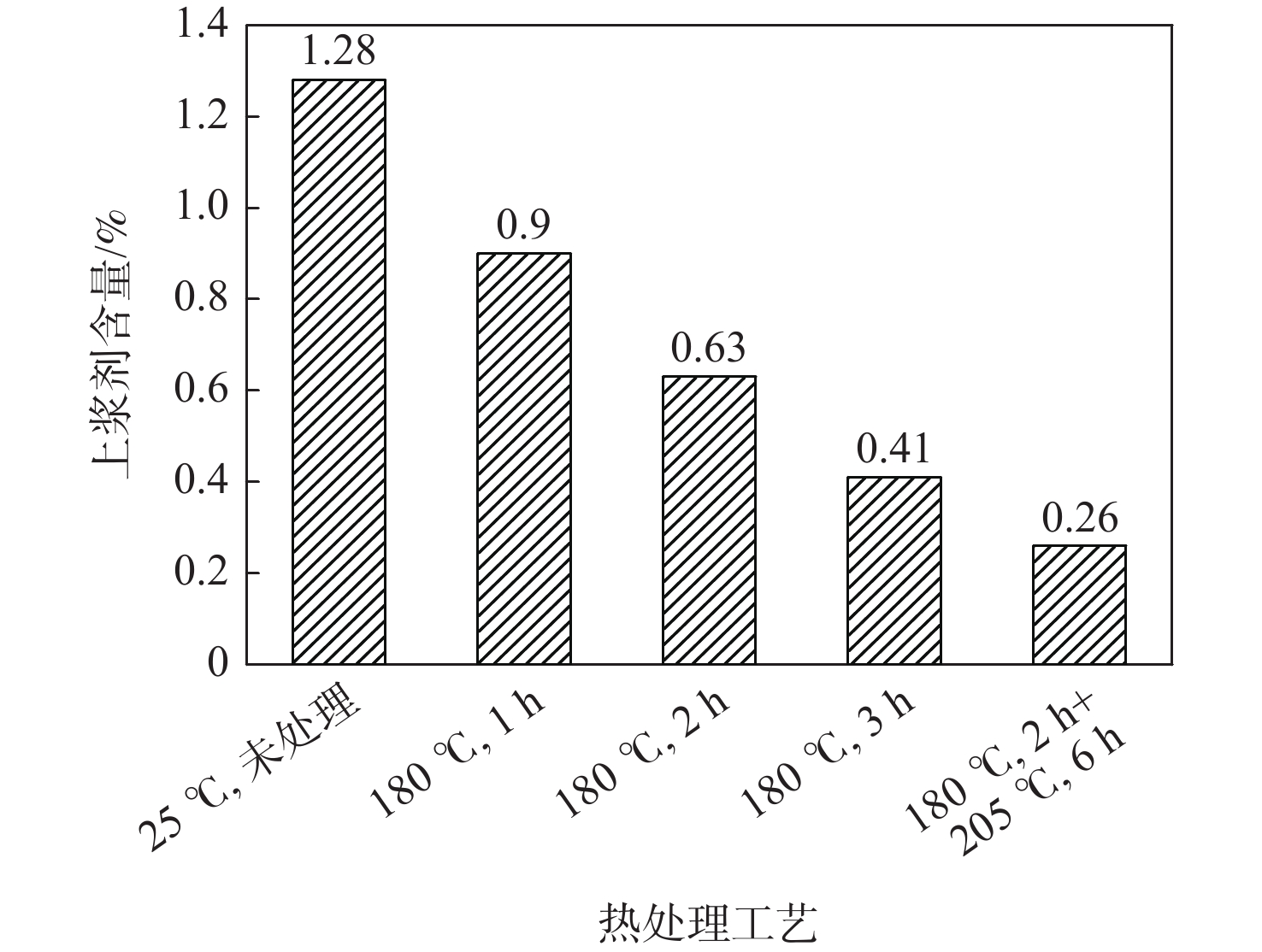

为深入探究上浆剂与纤维的反应特性,以纤维表面活性碳元素较多的F4纤维为对象,参照树脂固化工艺对带浆纤维进行热处理,热处理后的F4纤维表面上浆剂通过丙酮回流抽提,其洗提量如图4所示。经过180 ℃热处理1 h后,纤维表面的上浆剂发生反应,生成了不溶于丙酮的固化物,其上浆剂的提取量显著下降,并随着180 ℃热处理时间延长由0.90%继续减少至0.41%。与180 ℃的EP工艺相比,(180 ℃,2 h)+(205 ℃,6 h)的BMI工艺处理使CF表面的上浆剂发生了更完全的固化反应,其上浆剂提取量仅为0.26%,此时可溶解的主要是上浆剂中的助剂成分。

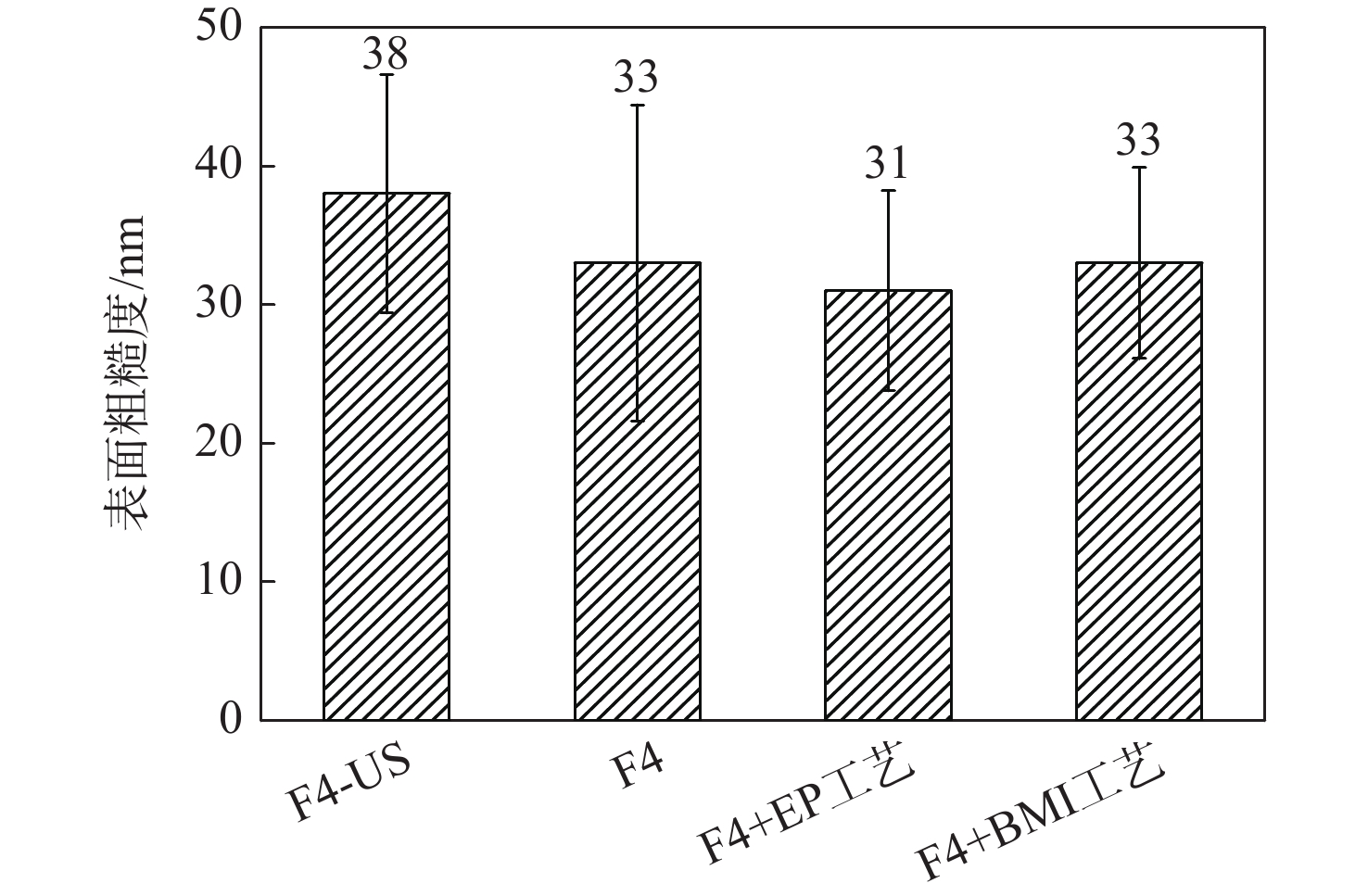

使用AFM分析2种工艺热处理并提取上浆剂后的F4纤维的表面粗糙度,结果如图5所示。可知,经热处理后F4纤维表面粗糙度变化不明显,F4及经2种树脂的热固化工艺条件分别处理后3种状态的纤维表面粗糙度均小于初始未上浆的F4-US纤维。这说明上浆过程中F4纤维本体表面的沟槽结构被上浆剂覆盖,经热处理后,上浆剂中的环氧主组分已发生化学反应,并固结在CF表面,只有很少部分未固化组分和小分子助剂可被溶剂溶解。

对于2种条件热处理后的F4纤维,经提取上浆剂后,通过XPS进一步分析其表面元素含量发生的变化。如表3所示,经EP固化条件热处理后,纤维表面Si、S元素消失,可能与对应的化学成分溶于丙酮有关,O、N含量略下降,O/C比出现一定下降,说明此处理工艺下上浆剂已经与纤维发生一定程度的化学反应。而BMI固化条件热处理后,纤维表面C含量进一步提高,O含量进一步降低,O/C比大幅降低至0.11,说明在更高的热处理温度条件下纤维表面上浆剂化学反应程度更高。对C1s进行分峰拟合得到不同纤维表面活性碳元素含量,如表4所示。EP固化条件热处理后,活性碳元素含量降低了33.4%,主要表现为氨基/羟基(Peak3)少量减少和环氧基团(Peak4)的大幅减少,以及羰基/亚胺基(Peak5)和羧基(Peak6)的消失,表明EP固化条件热处理时发生了环氧的开环反应。而经过BMI固化条件热处理并提取上浆剂后,纤维表面活性碳元素含量进一步降低至14.47%,氨基/羟基(Peak3)和环氧基团(Peak4)含量也均进一步降低,上浆剂中的活性基团与纤维表面反应更加充分。

表 3 不同工艺制度处理后F4纤维表面元素Table 3. Surface element content of F4 fiber after different heat treatment processes纤维类型 C/% O/% N/% Si/% S/% O/C F4 76.1 16.99 2.28 3.71 0.91 0.22 F4+EP工艺 82.03 15.93 2.04 0 0 0.19 F4+BMI 工艺 89.98 10.02 0 0 0 0.11 表 4 不同工艺处理后F4纤维XPS的C1s分峰拟合结果Table 4. XPS C1s peak fitting results of F4 fiber after different heat treatment processes% 纤维类型 参比基团含量 −C−C−;

−C−H−含量−C−OH−C−O−;

−C−NH2含量C−O−C=O;

环氧基团含量−C=O−

C=N含量−O−C=OHO−

C=O含量活性碳元素含量 (Peak1,

能量284.8 eV)(Peak2,

能量285.0 eV)(Peak3,

能量286.1 eV)(Peak4,

能量286.6 eV)(Peak5,

能量287.7 eV)(Peak6,

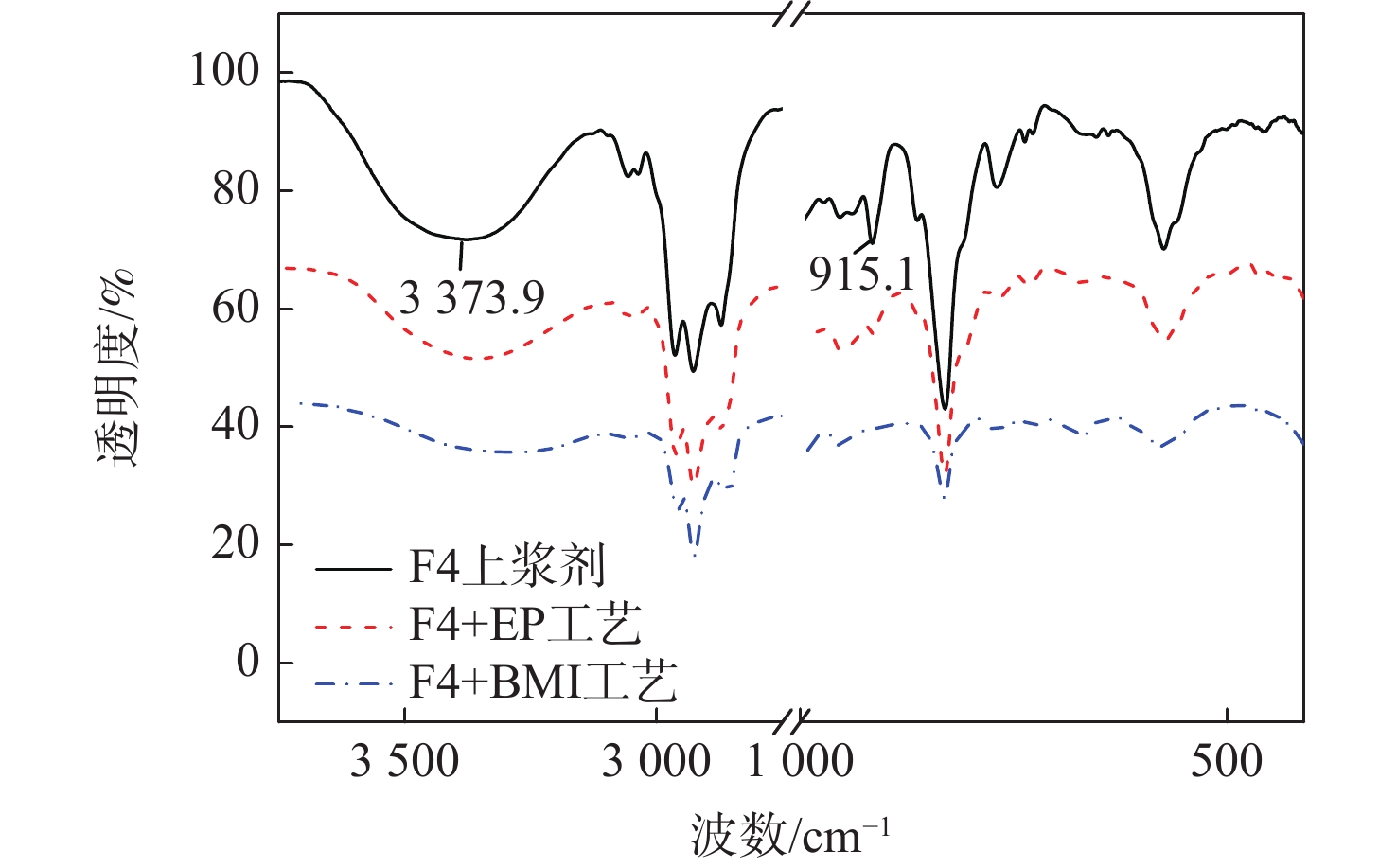

能量289.4 eV)F4 24.61 13.73 27.97 22.03 4.90 6.77 61.67 F4+EP工艺 45.05 26.66 20.52 7.76 0 0 28.28 F4+BMI工艺 37.24 48.29 11.38 3.09 0 0 14.47 对F4纤维2种条件热处理后的F4纤维提取上浆剂并进行红外光谱测试,其结果如图6所示。对比发现,红外光谱中主要发生变化的是波数为3 373.9 cm−1处的羟基振动收缩峰及波数为915.1 cm−1处的环氧特征峰,经过树脂固化条件热处理后,上浆剂与纤维表面基团发生了环氧的开环反应。羟基特征峰在进行热处理后向低波数方向偏移,在EP固化条件热处理后峰面积减小,而BMI固化条件热处理后峰面积进一步减小。环氧特征峰的变化更加明显,峰强在较低温度的EP固化条件热处理后有一定程度的下降,在较高温度的BMI固化条件热处理后则基本消失,这也与表4中XPS的测试结果相照应。

本节研究结果表明,在树脂体系的标准固化制度条件下,F4纤维表面的上浆剂与纤维表面具有良好的化学反应性。因此,在复合材料成型过程中,上浆剂与纤维表面产生化学反应,形成良好的纤维/上浆剂结合界面,有利于CF/树脂界面键合作用的形成与强化。对比2种热处理条件,在经历更高温度的BMI固化工艺过程中,更高含量的上浆剂与纤维表面发生了更高程度的化学反应,形成稳定化学结构并牢固结合在纤维表面。由此可知,较高的固化温度和较长的固化时间更利于CF本体表面与上浆剂中的活性组分发生化学反应,将有利于提高树脂基体与CF的界面结合作用能。

2.3 上浆剂对CF复合材料微观界面的影响

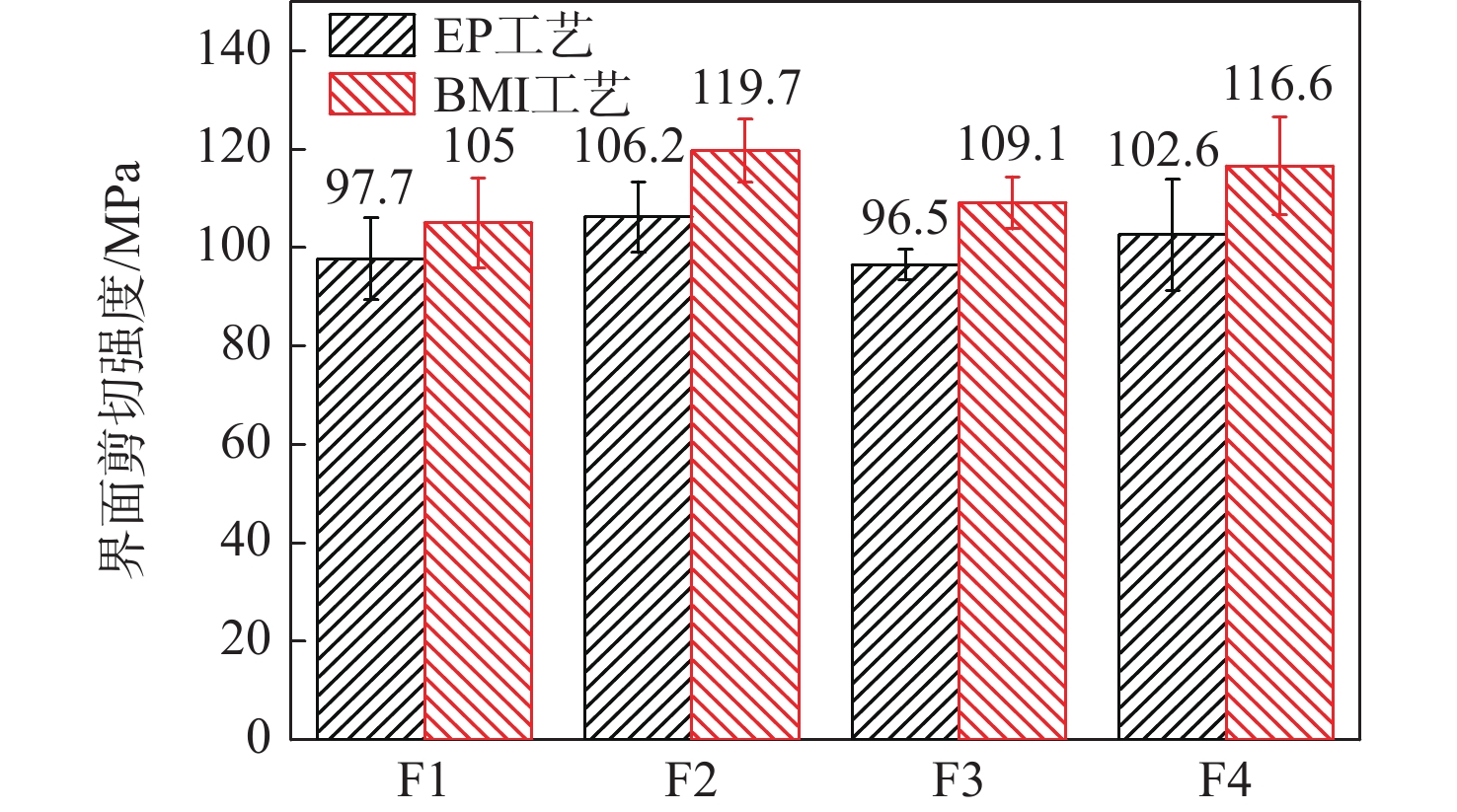

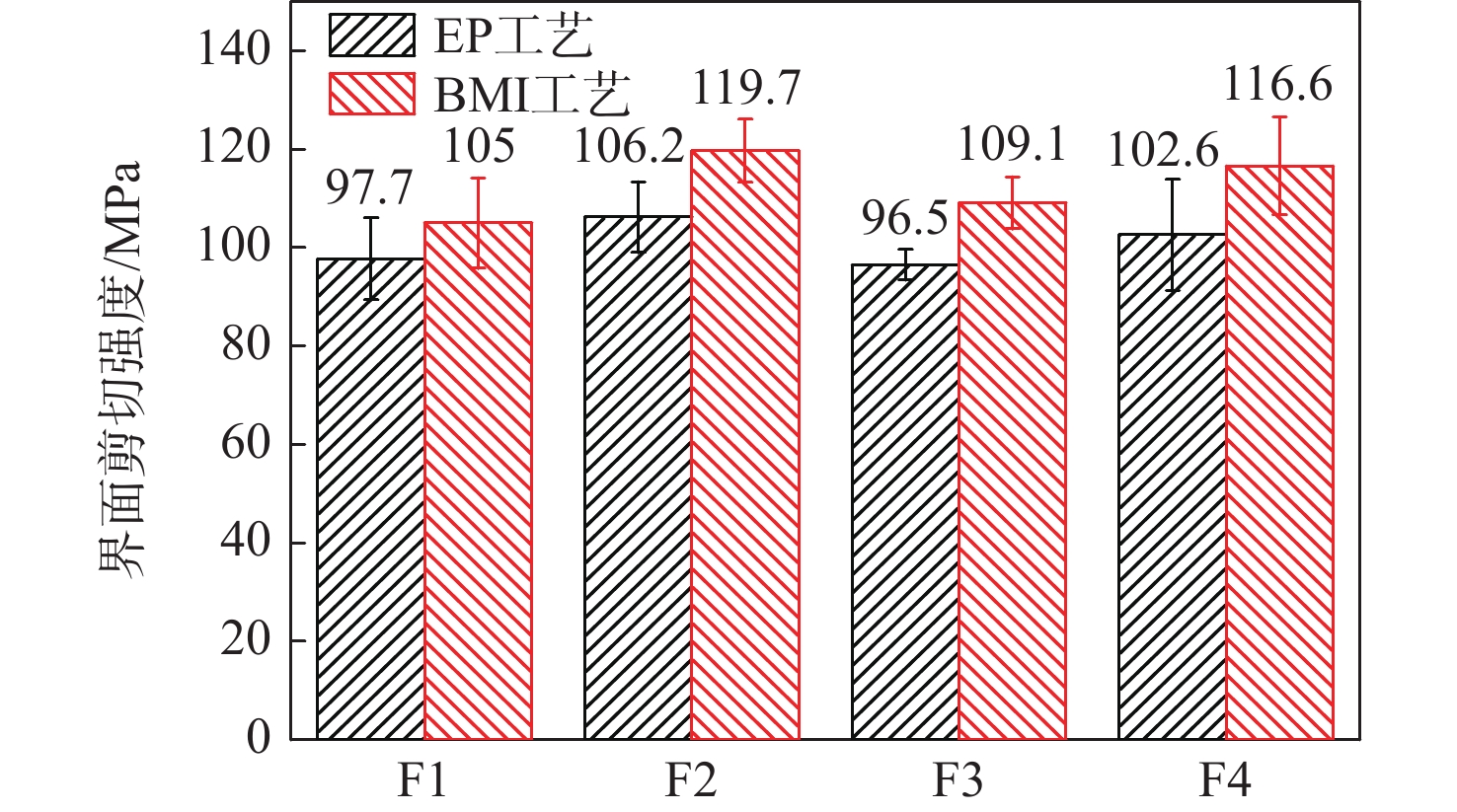

2.2节研究表明,上浆剂不会显著改变CF表面的粗糙度,即对CF/树脂界面的机械啮合作用影响很小,但不同上浆剂造成了CF表面化学组成的变化,可能会对其纤维/树脂的界面性能产生较大影响。为定量表征界面性能的变化,实验测试了不同带浆纤维与EP、BMI这2种工艺的界面剪切强度,结果如图7所示。4种纤维与BMI的IFSS均高于EP,说明BMI与各种纤维的界面结合作用更强,这可能与其更高的内聚能有关。不同纤维之间比较,F2、F4纤维与2种树脂的界面剪切强度均较高,推测与表2所示2种纤维表面较高的活性碳元素含量有关。F1和F3纤维的表面活性碳元素含量基本一致,两者与EP、BMI的IFSS也基本相当,均略低于F2和F4纤维及其复合体系。这一规律说明上浆剂所引入的活性碳元素可以调制CF与树脂的界面结合作用,不同上浆剂与树脂体系产生了不同的界面反应。相较于EP,BMI表现出与T800级CF更高的界面剪切强度,而上浆剂作为纤维/树脂界面形成的中间桥梁,深入明确其与纤维表面和树脂的相容性显得尤为重要。

2.4 上浆剂与EP、BMI的反应性

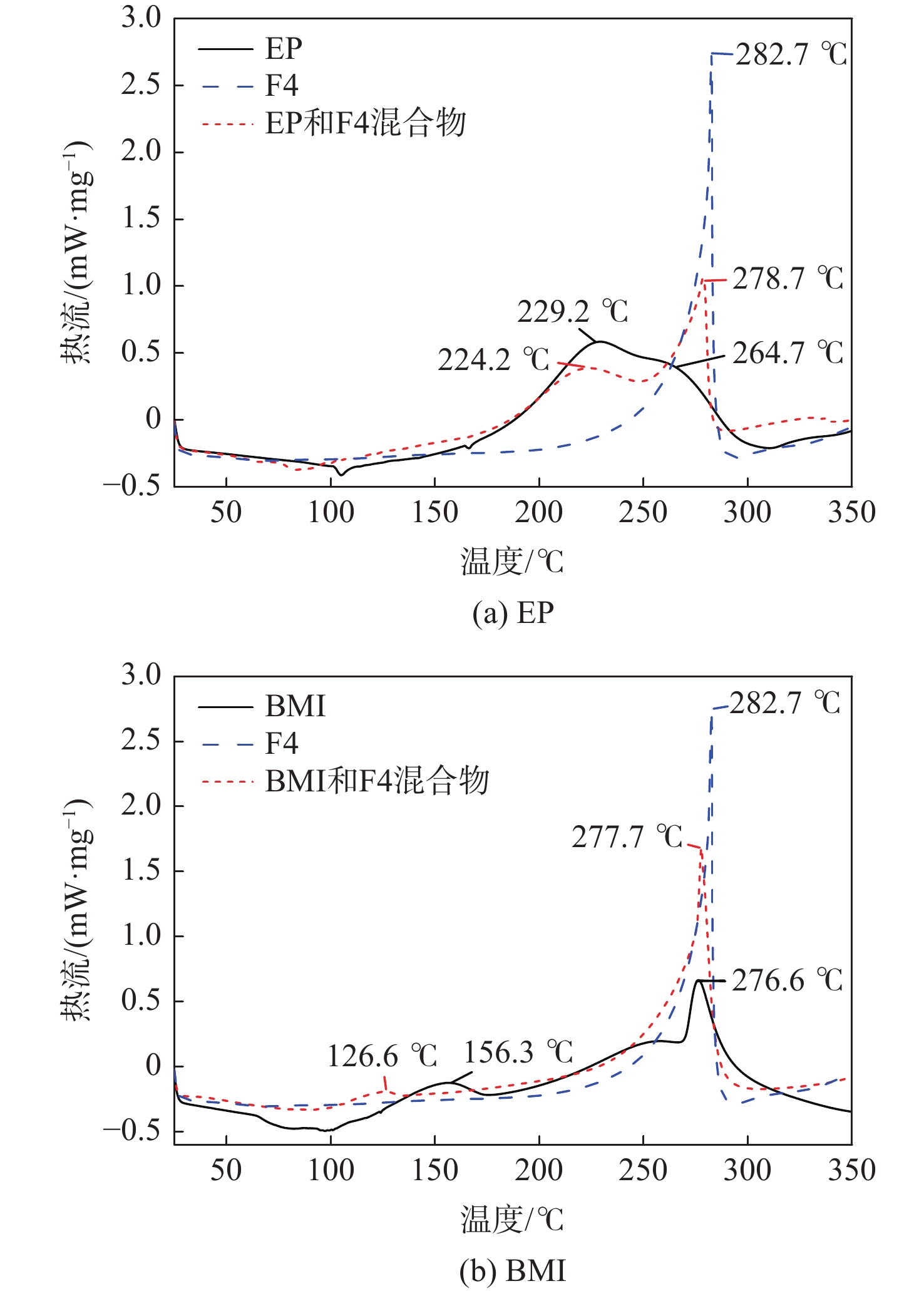

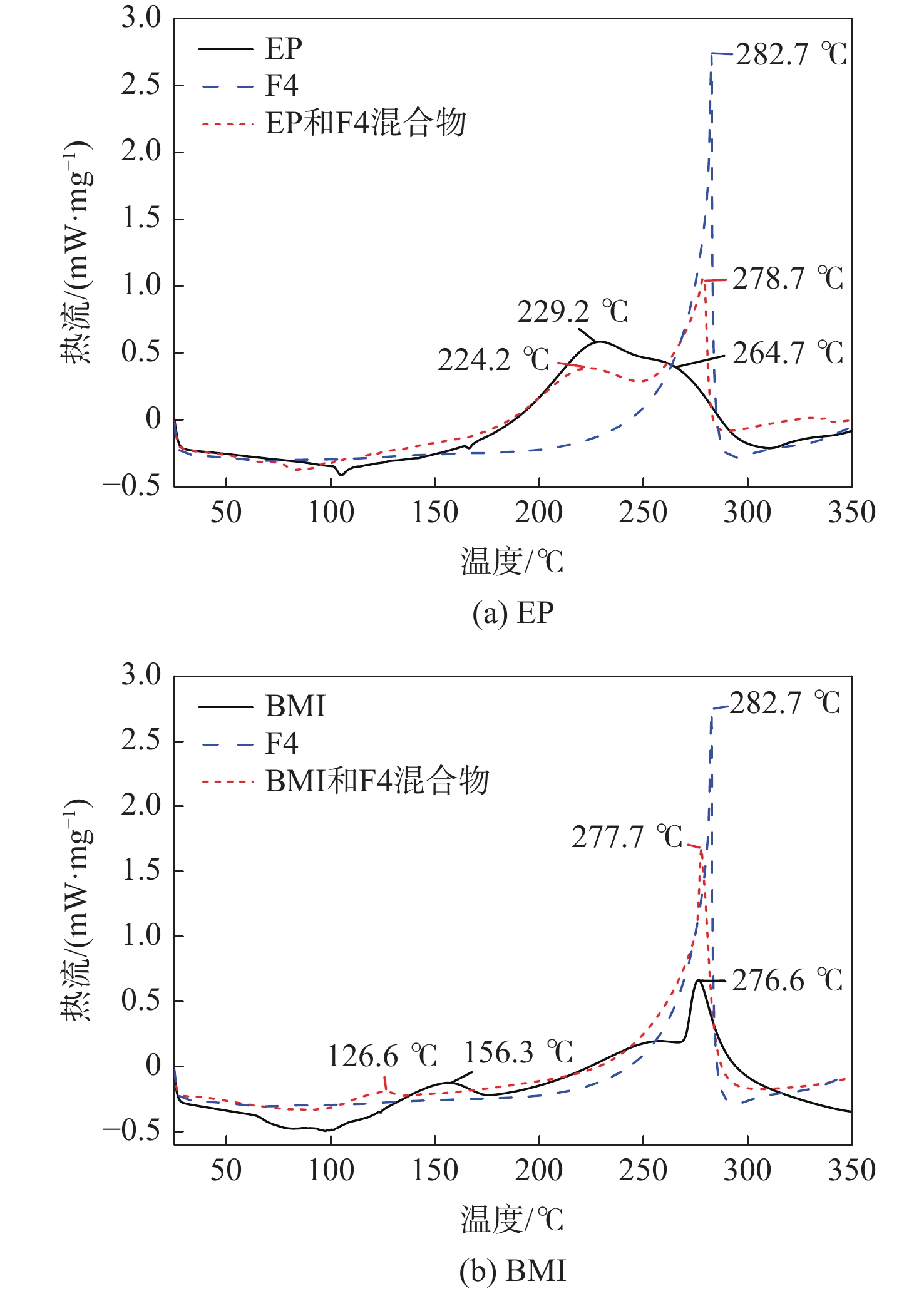

2.3节分析结果证明上浆剂与纤维表面具有良好的化学反应性,作为纤维/树脂界面的中间媒介,上浆剂与树脂的反应性也至关重要。为表征F4纤维上浆剂与2种树脂的反应特性,对纯树脂、上浆剂及F4上浆剂/树脂混合物进行DSC测试,得到其固化放热曲线如图8所示。将图中的反应峰温度及放热量等数据列出,如表5所示。由DSC曲线可知,树脂与F4上浆剂混合后,第1个放热峰均有所前移,F4上浆剂加入使树脂放热反应提前。而第2放热峰与F4上浆剂放热峰合并在一起,较F4上浆剂的反应峰稍有前移且峰宽变宽。BMI的放热峰与F4上浆剂更为接近,因此,更利于F4上浆剂与树脂在BMI固化工艺制度下的化学反应。从放热量来看,EP/F4混合物的放热量为360.4 J/g,较EP和F4各自的放热量加和的平均值增加26.3 J/g;而BMI/F4混合物放热量较2种纯组分的放热量加和的平均值减少48.7 J/g。放热量和放热峰位置的变化是树脂与F4上浆剂发生化学反应所致。

表 5 不同树脂/上浆剂的DSC峰值温度与放热Table 5. DSC peak temperature and heat of different resins/sizing agents树脂/上浆剂 第1峰值

温度/℃第2峰值

温度/℃第3峰值

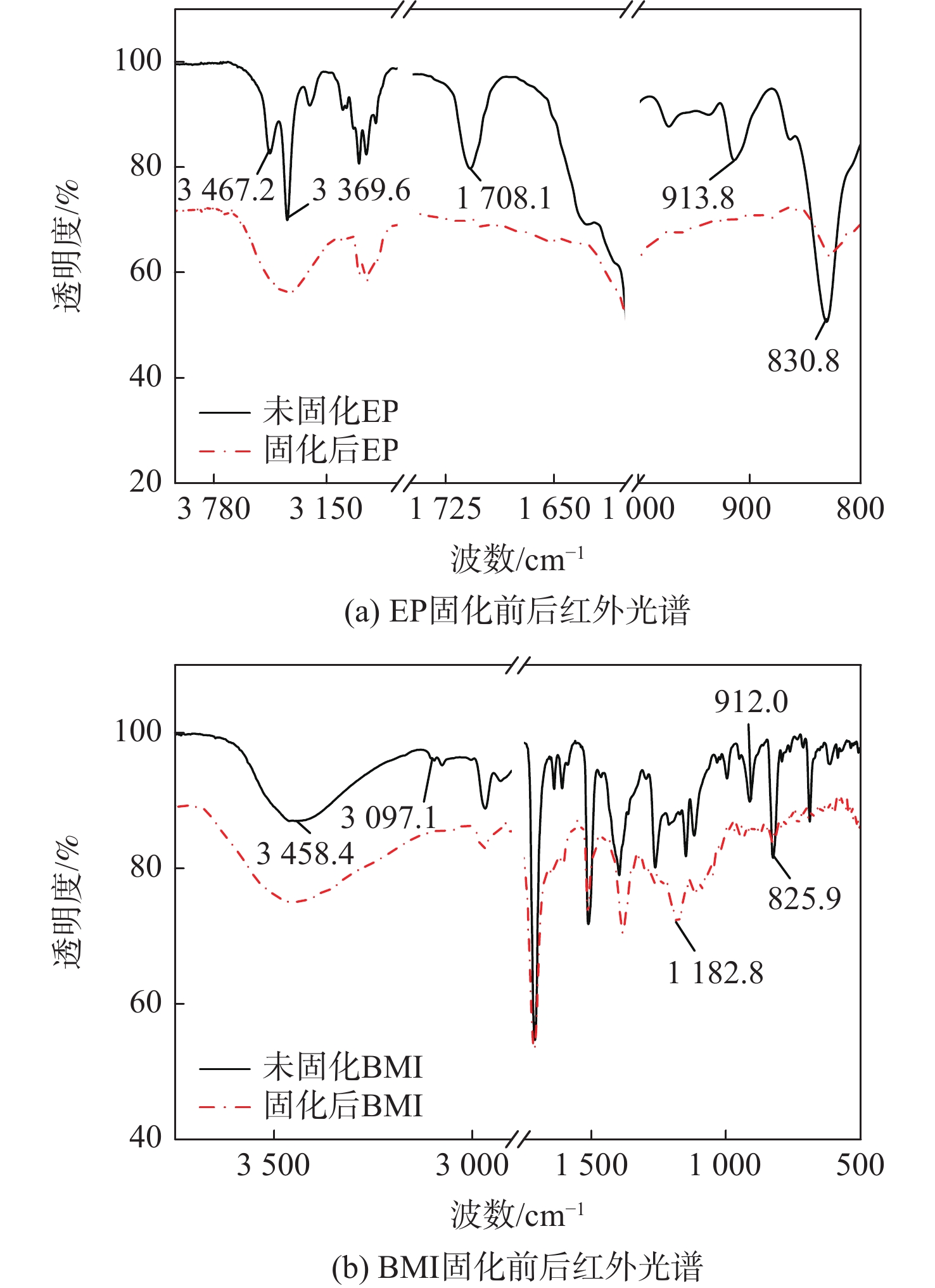

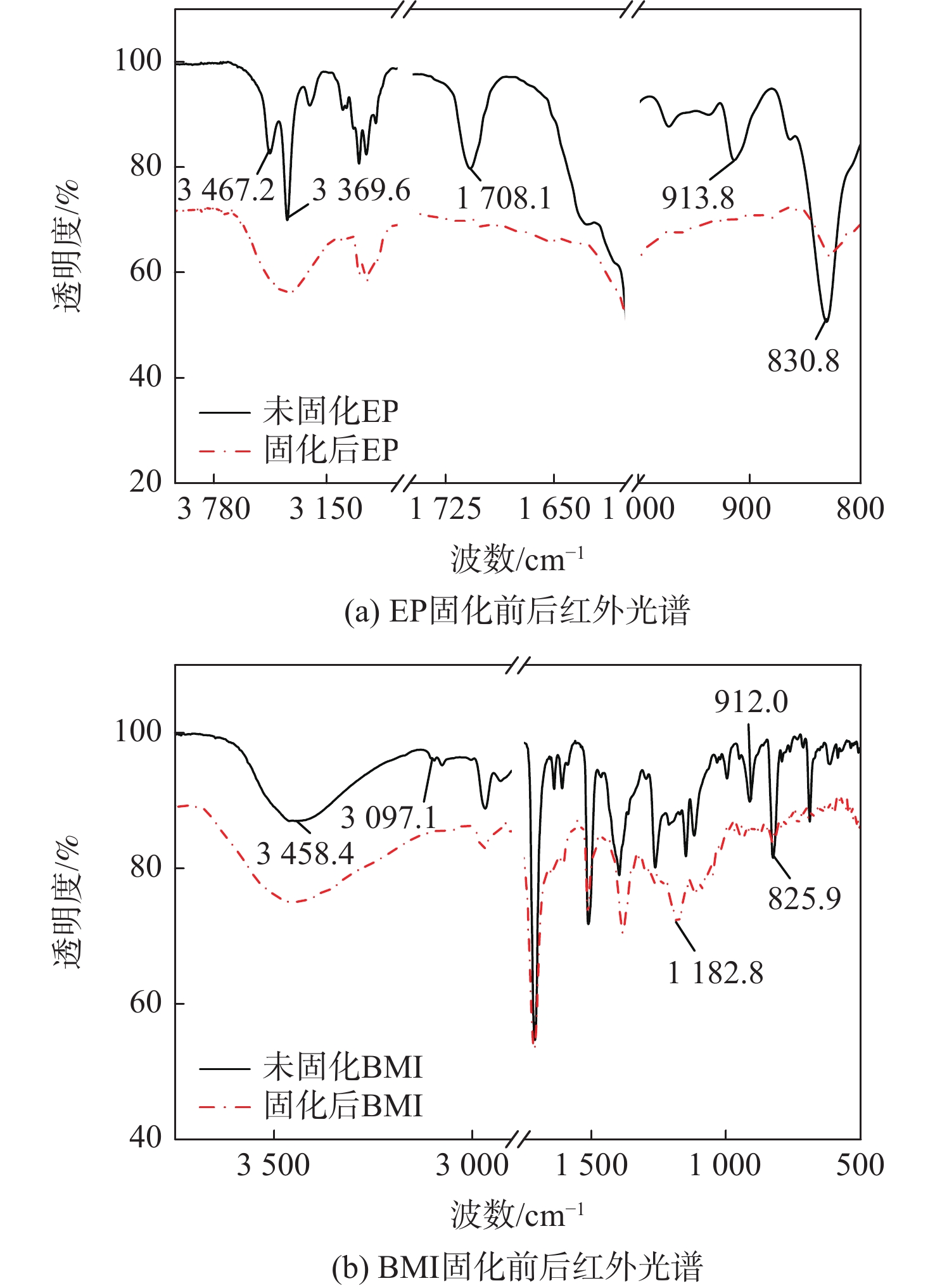

温度/℃放热/(J·g−1) EP 229.2 264.7 421.5 F4 282.7 246.8 EP和F4 224.2 282.7 360.4 BMI 156.3 258.1 176.6 482.8 F4 282.7 246.8 BMI和F4 126.6 277.7 316.1 为了进一步明确树脂的固化反应情况,对树脂体系固化前后进行红外光谱表征。图9为EP和BMI固化前后的红外光谱,图9(a)中,未固化EP图谱中主要含有波数为3 467.2 cm−1处的羟基伸缩峰,波数为3 369.6 cm−1处的氨基反对称伸缩峰,波数为1 708.1 cm−1处的脂肪酮或芳香醛羰基伸缩峰,苯环骨架特征峰,醚键弯曲伸缩振动峰及波数为913.8 cm−1和830.8 cm−1处的环氧特征峰。在固化后氨基峰强度降低,羟基峰宽变宽,饱和脂肪酮的羰基和波数为913.8 cm−1处环氧特征峰强度基本消失,推测EP固化主要发生环氧开环反应。图9(b)中未固化BMI图谱中主要含有波数为3 458.4 cm−1处的羟基伸缩峰,波数为3 097.1 cm−1处=CH2吸收峰,亚胺环上的羰基伸缩峰,苯环骨架特征峰,亚胺环上O=C−N键吸收峰,波数为912.0 cm−1处的环氧特征峰及波数为825.9 cm−1处的碳碳双键变形振动吸收峰。在固化后=CH2、碳碳双键峰强度大幅降低,波数为912.0 cm−1处的环氧特征峰甚至基本消失,羟基峰宽稍有变宽,波数为1 182.8 cm−1处的亚胺环上C−N−C键吸收峰强度增大,推测BMI固化可能发生了环氧开环反应及亚胺环C=C双键打开后的交联反应。

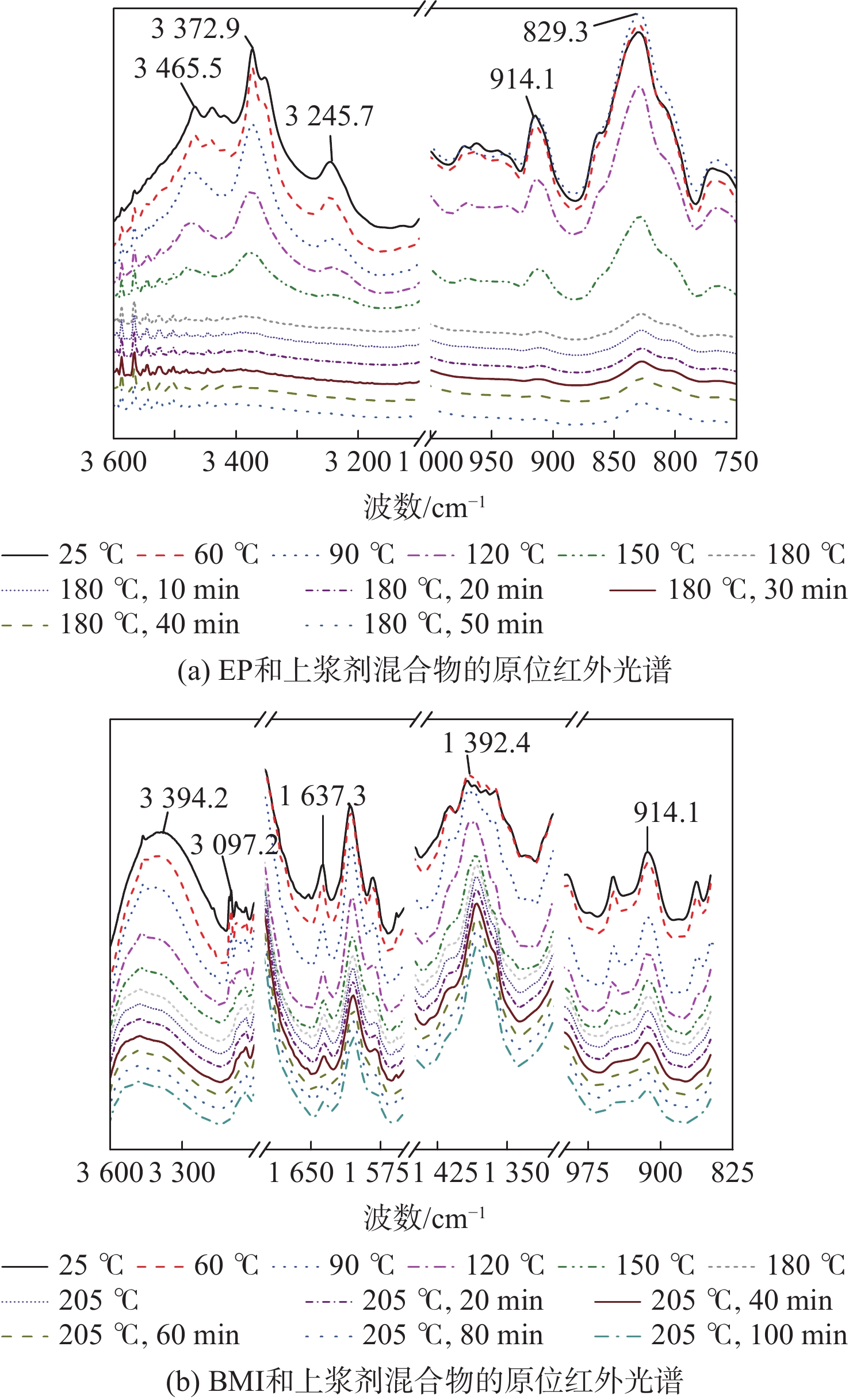

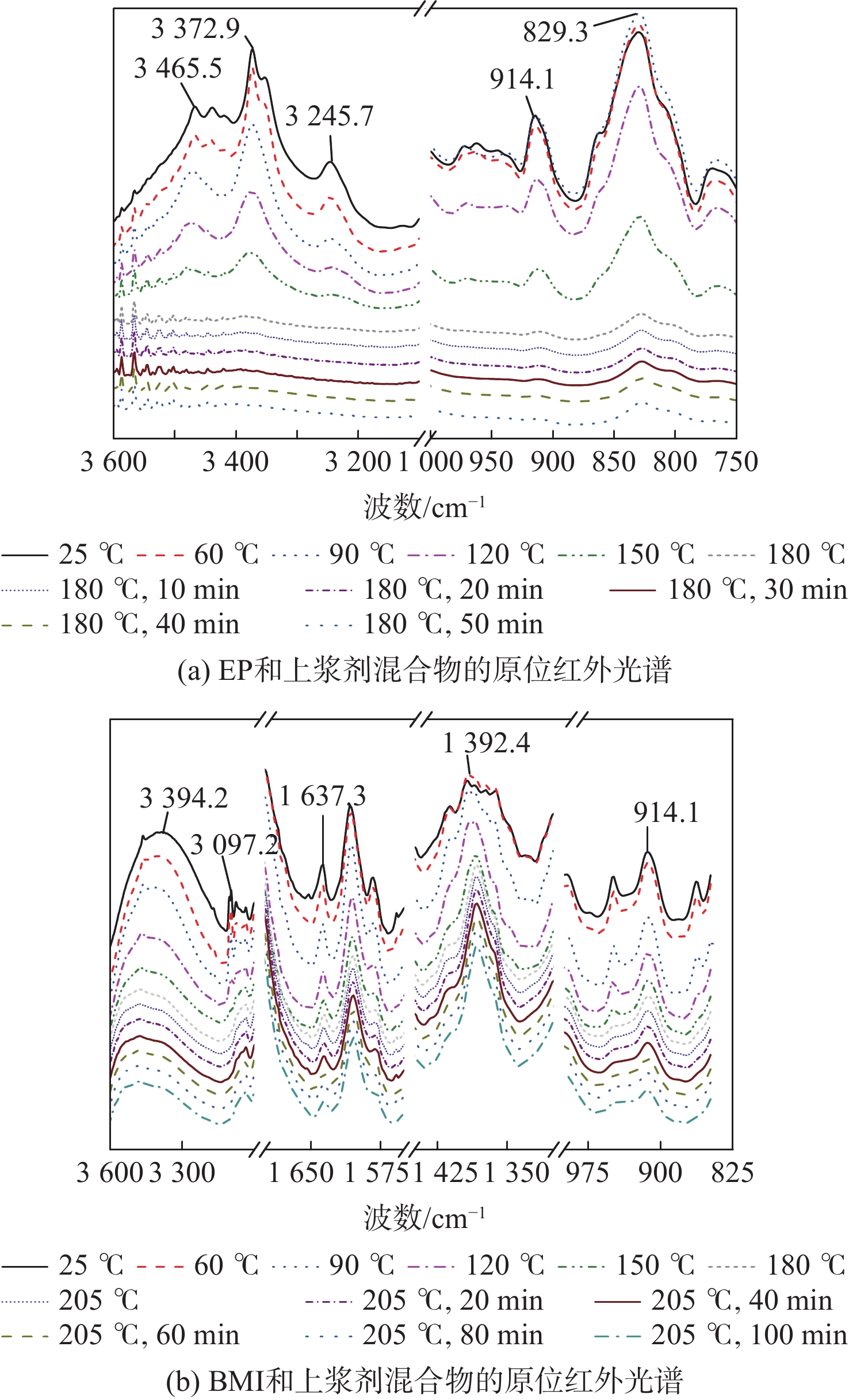

为深入研究上浆剂/树脂混合物的实时反应情况,观察上浆剂/树脂混合体系反应过程中官能团变化,对树脂和上浆剂的混合物进行固化工艺条件下的原位傅里叶红外光谱测试。图10为树脂与上浆剂混合物的原位红外光谱,图10(a)中,升温阶段EP/上浆剂混合体系在波数为3372.9 cm−1处的氨基峰高略有降低,其余变化不大,当温度升至180℃时,波数为914.1 cm−1和829.3 cm−1处的环氧基团及波数为3 465.5 cm−1处的羟基基团含量迅速降低,说明此时发生了环氧开环反应。恒温阶段环氧基团持续减少,30 min后其峰高基本不再发生变化。图6中热处理后提取上浆剂的FTIR和图9(a)中EP固化后的FTIR均显示有一定量的羟基/氨基官能团,然而图10(a)中完全反应的树脂/上浆剂混合物并未发现明显的羟基峰和氨基峰。这说明在受热条件下,EP与上浆剂各自的羟基和氨基相互反应而基本消失,同时其环氧基团也参与了反应,说明EP与上浆剂有良好的化学反应性。图10(b)中,BMI/上浆剂混合体系在升温过程中波数为3 097.2 cm−1处的=CH2吸收峰强度减弱,可能发生了扩链反应。当温度超过180℃~205℃保温阶段,谱图显示波数为3 394.2 cm−1处的羟基收缩振动峰略有减低并蓝移,波数为914.1 cm−1处的环氧基团强度大幅度降低,波数为1 637.31 cm−1处的碳碳双键强度也明显降低,表明BMI与上浆剂的混合物中发生了开环反应和碳碳双键的加成反应。此外,原位红外结果显示随着混合物反应的进行,波数为3 394.2 cm−1处的羟基峰蓝移明显,而图9(b)纯树脂固化前后羟基峰并未出现明显蓝移,图6中纯上浆剂热处理反应后羟基峰甚至出现少量红移,这表明上浆剂与树脂的反应使得与羟基连接的碳链上电子云密度出现明显变化,有新的化学结构形成,从而导致了羟基峰的蓝移。综上所述,F4纤维的上浆剂表现出了与EP、BMI良好的反应活性,不同官能团的变化也说明上浆剂与环、BMI产生的化学反应类型明显不同,EP可能对2种树脂与CF的界面结合作用能形成差异。

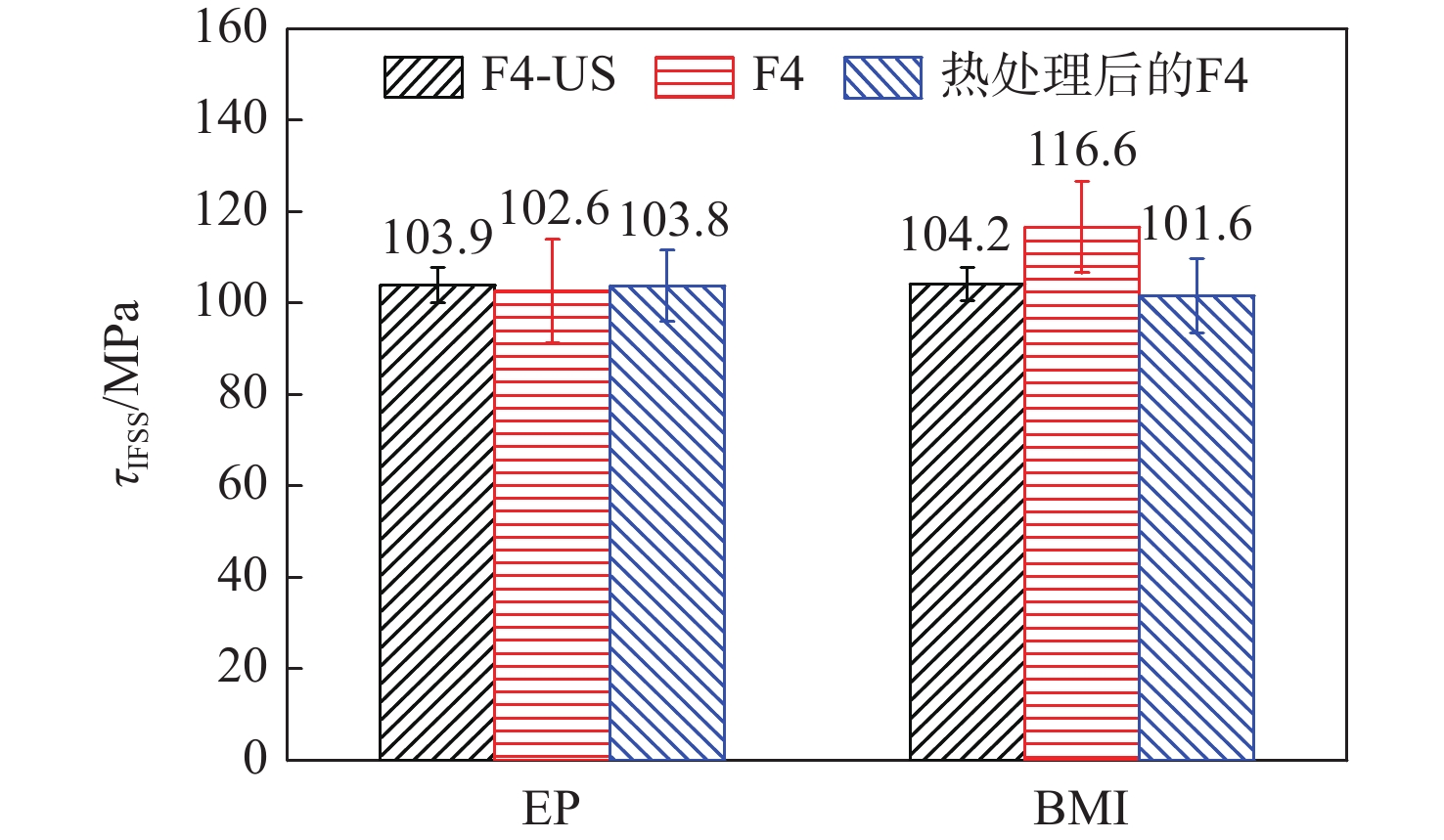

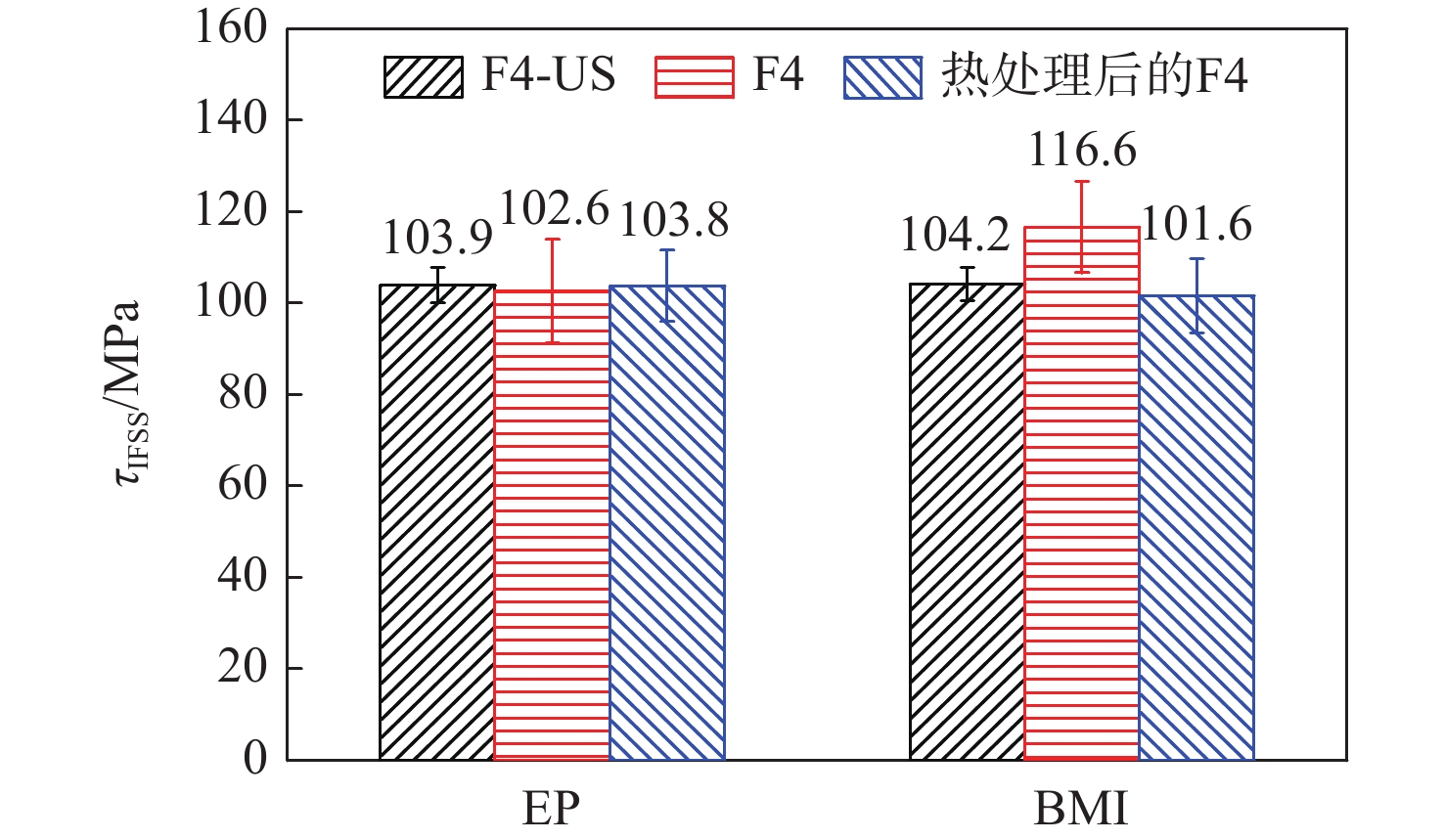

为进一步明确上浆剂反应性对CF/树脂界面性能的影响,考察了未上浆F4-US、上浆F4纤维及热处理后F4纤维分别与EP、BMI的IFSS,结果如图11所示。由于F4纤维上浆剂与纤维表面及树脂都具有良好的化学反应,上浆纤维与EP的IFSS高于100 MPa,显著高于文献报道的T800/环氧TDE-85的79.5 MPa的IFSS[34]。F4上浆纤维与BMI的IFSS也达到了116.6MPa,与国内现有的研究相当[35]。3种表面状态的F4纤维与EP界面剪切强度在103 MPa左右,无明显差异。然而,未上浆的F4裸纤维和经过固化工艺热处理后的F4纤维与BMI树脂的界面剪切强度均显著低于上浆F4纤维/BMI体系,其IFSS分别下降了11%和13%。这说明上浆剂与BMI的化学反应对提高其界面作用影响显著,热处理后失去化学活性的F4纤维表面上浆剂与BMI的反应受阻,因而界面剪切强度明显降低。此外,带浆F4纤维与BMI的IFSS达到116.6 MPa,较F4/EP工艺高14%。一方面是由于上浆剂在经历BMI树脂固化条件时,上浆剂中的活性组分与CF表面进行了更完全的化学反应,相对而言,在EP的固化温度条件下,上浆剂的反应程度略低。另一方面由于上浆剂放热峰与BMI的放热峰较为接近,说明在BMI的固化温度条件下2类物质的化学反应同步性更佳。此外,上浆剂与不同树脂反应产生不同的界面化学结构,也会对其界面强度产生影响。

3. 结 论

1) 上浆对湿法纺丝CF表面粗糙程度影响不大,上浆剂主要通过引入羟基、氨基及环氧基等活性官能团,这些活性基团可以与基体树脂体系发生化学反应,因此,纤维表面更高的活性基团含量有利于提高CF与树脂间的界面性能。

2) CF经树脂固化工艺条件热处理后,其表面上浆剂分子发生反应,溶解性下降,纤维表面的环氧基团及氨基/羟基含量均下降,表明在固化工艺过程中上浆剂的化学反应活性可以被激发,有利于提高纤维与树脂的化学键合作用。

3) 上浆剂与EP、BMI的混合体系可发生固化反应,共混物的DSC放热峰位置及放热量均明显不同于其单独组分,同时固化后的红外特征峰与上浆剂、纯树脂分别固化后的基团有较大差异,证明上浆剂与2种树脂体系均具有良好的化学反应性。

4) 上浆剂与树脂的化学反应对提高其界面作用影响显著。带浆T800级CF经热处理后,其与BMI的界面剪切强度下降13%,纤维与环氧的界面剪切强度变化不大。由原位红外分析发现,较高固化温度和较长固化时间更利于碳纤维上浆剂中的活性组分与树脂体系发生充分的化学反应。

-

表 1 不同T800级CF上浆前后的表面元素

Table 1. Surface element content of different T800 grade CF before and after sizing

纤维类型 C/% O/% N/% Si/% S/% Na/% O/C F1 74.12 16.83 2.2 6.01 0.84 0 0.23 F1-US 78.72 16.24 2.43 2.62 0 0 0.21 F2 74.35 19.4 1.73 4.52 0 0 0.26 F2-US 79.74 14.05 2.99 3.22 0 0 0.18 F3 76.32 16.39 2.98 3.39 0.73 0.2 0.21 F3-US 78.16 17.12 2.28 2.44 0 0 0.22 F4 76.1 16.99 2.28 3.71 0.91 0 0.22 F4-US 77.58 16.85 2.36 3.21 0 0 0.22 表 2 不同CF XPS的C1s分峰拟合结果

Table 2. XPS C1s peak fitting results of different CF

% 纤维类型 参比基团含量 −C−C−;

−C−H−含量−C−OH−C−O−;

−C−NH2含量C−O−C=O;

环氧基团含量−C=O−

C=N含量−O−C=OHO−

C=O含量活性碳元素含量 (Peak1,

能量284.8 eV)(Peak2,

能量285.0 eV)(Peak3,

能量286.1 eV)(Peak4,

能量286.6 eV)(Peak5,

能量287.7 eV)(Peak6,

能量289.4 eV)F1 38.54 26.05 10.92 16.35 6.45 1.69 35.41 F1- US 70.22 11.65 0.00 6.02 7.15 4.96 18.13 F2 36.67 12.59 20.59 17.49 3.31 9.35 50.74 F2- US 37.09 18.02 24.05 0.00 11.35 9.49 44.89 F3 44.20 13.92 16.36 12.29 6.40 6.85 41.90 F3- US 59.81 20.80 1.53 3.75 6.79 7.31 19.38 F4 24.61 13.73 27.97 22.03 4.90 6.77 61.67 F4- US 73.21 7.38 2.84 4.43 6.66 5.49 19.42 表 3 不同工艺制度处理后F4纤维表面元素

Table 3. Surface element content of F4 fiber after different heat treatment processes

纤维类型 C/% O/% N/% Si/% S/% O/C F4 76.1 16.99 2.28 3.71 0.91 0.22 F4+EP工艺 82.03 15.93 2.04 0 0 0.19 F4+BMI 工艺 89.98 10.02 0 0 0 0.11 表 4 不同工艺处理后F4纤维XPS的C1s分峰拟合结果

Table 4. XPS C1s peak fitting results of F4 fiber after different heat treatment processes

% 纤维类型 参比基团含量 −C−C−;

−C−H−含量−C−OH−C−O−;

−C−NH2含量C−O−C=O;

环氧基团含量−C=O−

C=N含量−O−C=OHO−

C=O含量活性碳元素含量 (Peak1,

能量284.8 eV)(Peak2,

能量285.0 eV)(Peak3,

能量286.1 eV)(Peak4,

能量286.6 eV)(Peak5,

能量287.7 eV)(Peak6,

能量289.4 eV)F4 24.61 13.73 27.97 22.03 4.90 6.77 61.67 F4+EP工艺 45.05 26.66 20.52 7.76 0 0 28.28 F4+BMI工艺 37.24 48.29 11.38 3.09 0 0 14.47 表 5 不同树脂/上浆剂的DSC峰值温度与放热

Table 5. DSC peak temperature and heat of different resins/sizing agents

树脂/上浆剂 第1峰值

温度/℃第2峰值

温度/℃第3峰值

温度/℃放热/(J·g−1) EP 229.2 264.7 421.5 F4 282.7 246.8 EP和F4 224.2 282.7 360.4 BMI 156.3 258.1 176.6 482.8 F4 282.7 246.8 BMI和F4 126.6 277.7 316.1 -

[1] CONNELL M E, CROSS W M, SNYDER T G, et al. Direct monitoring of silane/epoxy interphase chemistry[J]. Composites Part A Applied Science and Manufacturing, 1998, 29(5): 495-502. [2] 高爱君. PAN基碳纤维成分、结构及性能的高温演变机理[D]. 北京: 北京化工大学, 2012.GAO A J. Evolution mechanism of composition, structure and mechanical properties of carbon fiber during high temperature heat treatment[D]. Beijing: Beijing University of Chemical Technology, 2012 (in Chinese). [3] SHARMA M, GAO S L, MÄDER E, et al. Carbon fiber surfaces and composite interphases[J]. Composites Science and Technology, 2014, 102(6): 35-50. [4] PARK S J, KIM B J. Roles of acidic functional groups of carbon fiber surfaces in enhancing interfacial adhesion behavior[J]. Materials Science and Engineering:A, 2005, 408(1-2): 269-273. doi: 10.1016/j.msea.2005.08.129 [5] KING T R, ADAMS D F, BUTTRY D A. Anodic oxidation of pitch-precursor carbon fibers in ammonium sulfate solutions: Batch screening treatment results[J]. Composites Science and Technology, 1992, 44(4): 351-359. doi: 10.1016/0266-3538(92)90071-A [6] VARELIDIS P C, MCCULLOUGH R L, PAPASPYRIDES C D. The effect on the mechanical properties of carbon/epoxy composites of polyamide coatings on the fibers[J]. Composites Science and Technology, 1999, 59(12): 1813-1823. doi: 10.1016/S0266-3538(99)00039-1 [7] GU Y Z, LI M, WANG J, et al. Characterization of the interphase in carbon fiber/polymer composites using a nanoscale dynamic mechanical imaging technique[J]. Carbon, 2010, 48(11): 3229-3235. doi: 10.1016/j.carbon.2010.05.008 [8] DAI Z S, SHI F H, ZHANG B Y, et al. Effect of sizing on carbon fiber surface properties and fibers/epoxy interfacial adhesion[J]. Applied Surface Science, 2011, 257(15): 6980-6985. doi: 10.1016/j.apsusc.2011.03.047 [9] BOWMAN S, JIANG Q R, MEMON H, et al. Effects of styrene-acrylic sizing on the mechanical properties of carbon fiber thermoplastic towpregs and their composites[J]. Molecules, 2018, 23(3): 547. doi: 10.3390/molecules23030547 [10] LIU J Y, GE H Y, CHEN J A, et al. The preparation of emulsion type sizing agent for carbon fiber and the properties of carbon fiber/vinyl ester resin composites[J]. Journal of Applied Polymer Science, 2012, 124(1): 864-872. doi: 10.1002/app.35126 [11] DILSIZ N, WIGHTMAN J P. Surface analysis of unsized and sized carbon fibers[J]. Carbon, 1999, 37(7): 1105-1114. doi: 10.1016/S0008-6223(98)00300-5 [12] LUO Y F, ZHAO Y, DUAN Y X, et al. Surface and wettability property analysis of CCF300 carbon fibers with different sizing or without sizing[J]. Materials & Design, 2011, 32(2): 941-946. [13] REN P G, LIANG G Z, ZHANG Z P. Influence of epoxy sizing of carbon-fiber on the properties of carbon fiber/cyanate ester composites[J]. Polymer Composites, 2006, 27(5): 591-598. doi: 10.1002/pc.20230 [14] YANG Y, LU C X, SU X L, et al. Effect of nano-SiO2 modified emulsion sizing on the interfacial adhesion of carbon fibers reinforced composites[J]. Materials Letters, 2007, 61(17): 3601-3604. doi: 10.1016/j.matlet.2006.11.121 [15] ZHANG C H, ZHANG Z Q, CAO H L. Effects of epoxy/SiO2 hybrid sizing on the mechanical properties of carbon fiber composites[J]. Solid State Phenomena, 2007, 121: 1253-1256. [16] ZHANG X J, KANG S M, LIU Z Q. Synthesis of latent curing agent for epoxy resin[J]. Advanced Materials Research, 2010, 150-151: 988-991. doi: 10.4028/www.scientific.net/AMR.150-151.988 [17] YUAN H J, ZHANG S C, LU C X, et al. Improved interfacial adhesion in carbon fiber/polyether sulfone composites through an organic solvent-free polyamic acid sizing[J]. Applied Surface Science, 2013, 279: 279-284. doi: 10.1016/j.apsusc.2013.04.085 [18] CHEN J A, LIU J Y, WANG D Z. Effect of emulsion type sizing agents on the properties of carbon fiber and carbon fiber reinforced polymer matrix composite[J]. Advanced Materials Research, 2011, 236-238: 2295-2298. doi: 10.4028/www.scientific.net/AMR.236-238.2295 [19] LI J, FAN Q, CHEN Z H, et al. Effect of electropolymer sizing of carbon fiber on mechanical properties of phenolic resin composites[J]. Transactions of Nonferrous Metals Society of China, 2006, 16(s2): s457-s461. [20] LIU W B, ZHANG S, HAO L F, et al. Properties of carbon fiber sized with poly(phthalazinone ether ketone) resin[J]. Journal of Applied Polymer Science, 2013, 128(6): 3702-3709. doi: 10.1002/app.38605 [21] CHENG T H, ZHANG J, YUMITORI S, et al. Sizing resin structure and interphase formation in carbon fibre composites[J]. Composites, 1994, 25(7): 661-670. doi: 10.1016/0010-4361(94)90199-6 [22] DAI Z S, ZHANG B Y, SHI F H, et al. Effect of heat treatment on carbon fiber surface properties and fibers/epoxy interfacial adhesion[J]. Applied Surface Science, 2011, 257(20): 8457-8461. doi: 10.1016/j.apsusc.2011.04.129 [23] WU Q, LI M, GU Y Z, et al. Imaging the interphase of carbon fiber composites using transmission electron microscopy: Preparations by focused ion beam, ion beam etching, and ultramicrotomy[J]. Chinese Journal of Aeronautics, 2015, 28(5): 1529-1538. doi: 10.1016/j.cja.2015.05.005 [24] WU Q, LI M, GU Y Z, et al. Nano-analysis on the structure and chemical composition of the interphase region in carbon fiber composite[J]. Composites Part A:Applied Science and Manufacturing, 2014, 56: 143-149. doi: 10.1016/j.compositesa.2013.10.003 [25] LIU Y T, LI L, WANG J P, et al. Effect of carbon nanotube addition in two sizing agents on interfacial properties of carbon fiber/polycarbonate composites[J]. New Carbon Materials, 2021, 36(3): 639-648. doi: 10.1016/S1872-5805(21)60035-5 [26] LIU H S, ZHAO Y, CHEN F, et al. Effects of polyetherimide sizing involving carbon nanotubes on interfacial performance of carbon fiber/polyetheretherketone composites[J]. Polymers for Advanced Technologies, 2021, 32(9): 3689-3700. doi: 10.1002/pat.5389 [27] WU G S, MA L C, LIU L, et al. Interfacial improvement of carbon fiber-reinforced methylphenylsilicone resin composites with sizing agent containing functionalized carbon nanotubes[J]. Journal of Adhesion Science and Technology, 2015, 29(21): 2295-2310. doi: 10.1080/01694243.2015.1064509 [28] WU Z J, CUI H Y, CHEN L, et al. Interfacially reinforced unsaturated polyester carbon fiber composites with a vinyl ester-carbon nanotubes sizing agent[J]. Composites Science and Technology, 2018, 164: 195-203. doi: 10.1016/j.compscitech.2018.05.051 [29] 秦建杰. 碳纤维表面连续生长碳纳米管及其增强复合材料的研究[D]. 济南: 山东大学, 2021.QIN J J. Study on the continuous growth of carbon nanotubes on carbon fiber surfaces and their reinforced composites[D]. Jinan: Shandong University, 2021 (in Chinese). [30] YAO Z Q, WANG C G, QIN J J, et al. Interfacial improvement of carbon fiber/epoxy composites using one-step method for grafting carbon nanotubes on the fibers at ultra-low temperatures[J]. Carbon, 2020, 164: 133-142. doi: 10.1016/j.carbon.2020.03.060 [31] 包建文, 钟翔屿, 张代军, 等. 国产高强中模碳纤维及其增强高韧性树脂基复合材料研究进展[J]. 材料工程, 2020, 48(8): 33-48. doi: 10.11868/j.issn.1001-4381.2020.000208BAO J W, ZHONG X Y, ZHANG D J, et al. Progress in high strength intermediate modulus carbon fiber and its high toughness resin matrix composites in China[J]. Journal of Materials Engineering, 2020, 48(8): 33-48(in Chinese). doi: 10.11868/j.issn.1001-4381.2020.000208 [32] 于广, 魏化震, 李大勇, 等. 碳纤维上浆剂及其对复合材料界面性能的影响研究进展[J]. 工程塑料应用, 2019, 47(2): 143-147. doi: 10.3969/j.issn.1001-3539.2019.02.026YU G, WEI H Z, LI D Y, et al. Research progress of carbon fiber sizing agent and its effects on interface properties of composites[J]. Engineering Plastics Application, 2019, 47(2): 143-147(in Chinese). doi: 10.3969/j.issn.1001-3539.2019.02.026 [33] 国家市场监督管理总局, 国家标准化管理委员会. 聚丙烯腈基碳纤维: GB/T 26752—2020[S]. 北京: 中国标准出版社, 2020.State Administration for Market Regulation, Standardization Administration. PAN-based carbon fiber: GB/T 26752—2020[S]. Beijing: Standards Press of China, 2020 (in Chinese). [34] 张琳, 郑莉, 迟波. 碳纤维/TDE85环氧树脂复合材料界面性能的研究[J]. 玻璃钢/复合材料, 2013, 3: 58-61.ZHANG L, ZHENG L, CHI B. Study of interfacial performance of T800/TDE85 composite[J]. Fiber Reinforced Plastics/Composites, 2013, 3: 58-61(in Chinese). [35] 王新庆, 柳肇博, 刘寒松, 等. 上浆剂对国产T800级碳纤维增强热固性复合材料界面性能的影响[J]. 复合材料学报, 2022, 39(9): 4393-4405. doi: 10.13801/j.cnki.fhclxb.20220104.001WANG X Q, LIU Z B, LIU H S, et al. Effect of sizing agent on interfacial properties of domestic T800 grade carbon fiber reinforced thermosetting composites[J]. Acta Materiae Compositae Sinica, 2022, 39(9): 4393-4405(in Chinese). doi: 10.13801/j.cnki.fhclxb.20220104.001 -

下载:

下载:

下载:

下载: