Collapse modes and energy absorption performance of conventional and re-entrant hexagonal tubes under lateral compression

-

摘要:

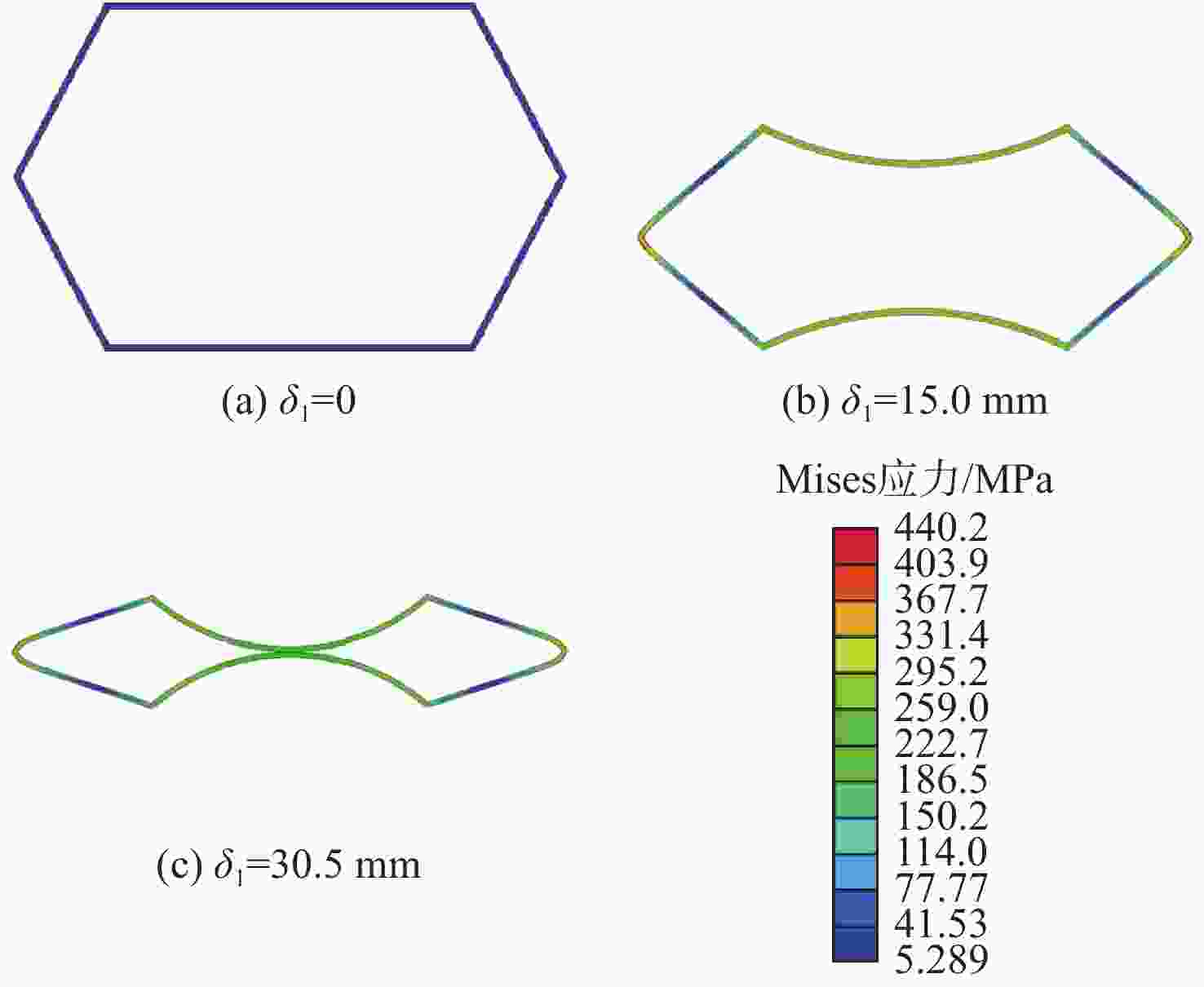

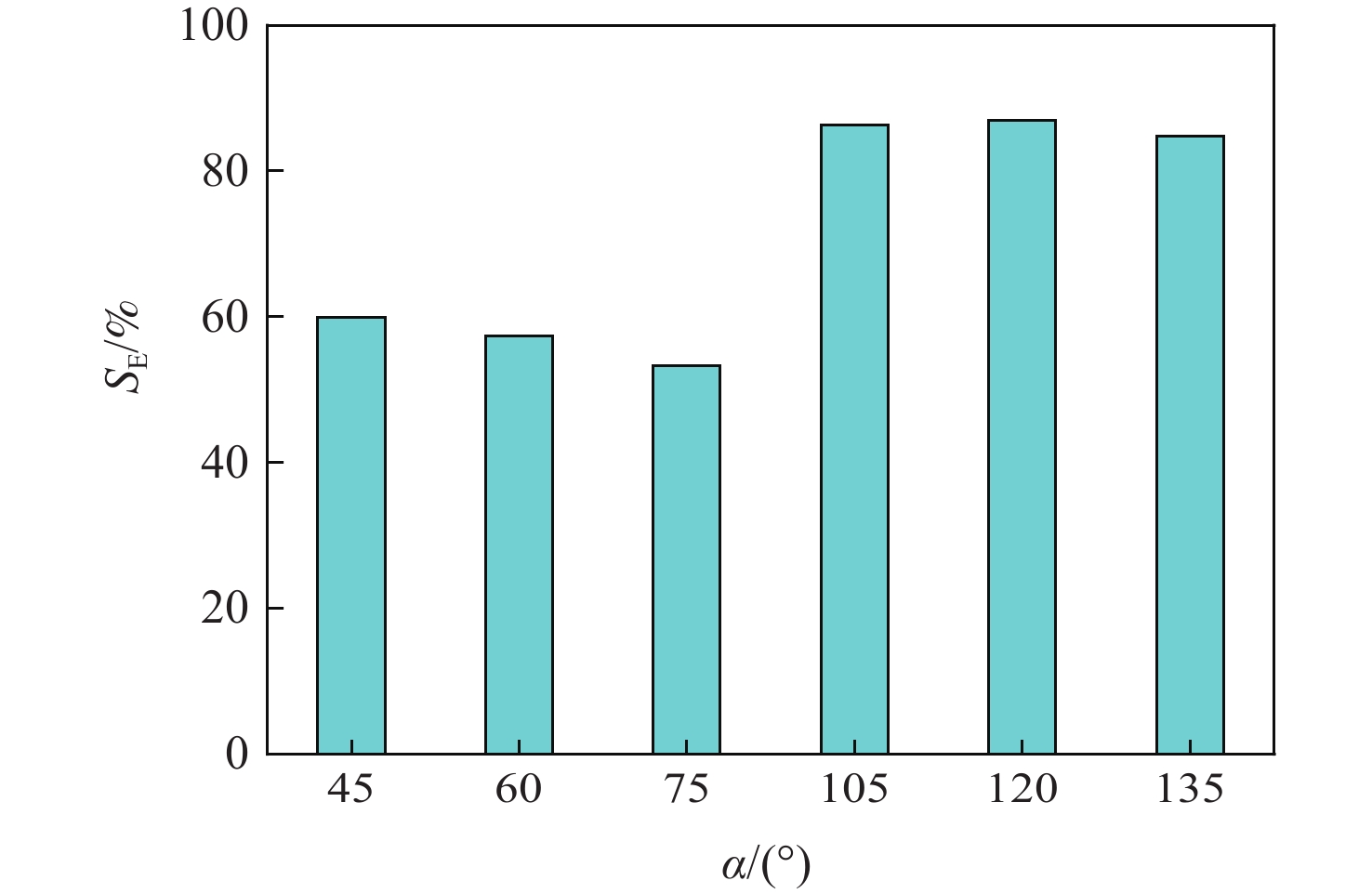

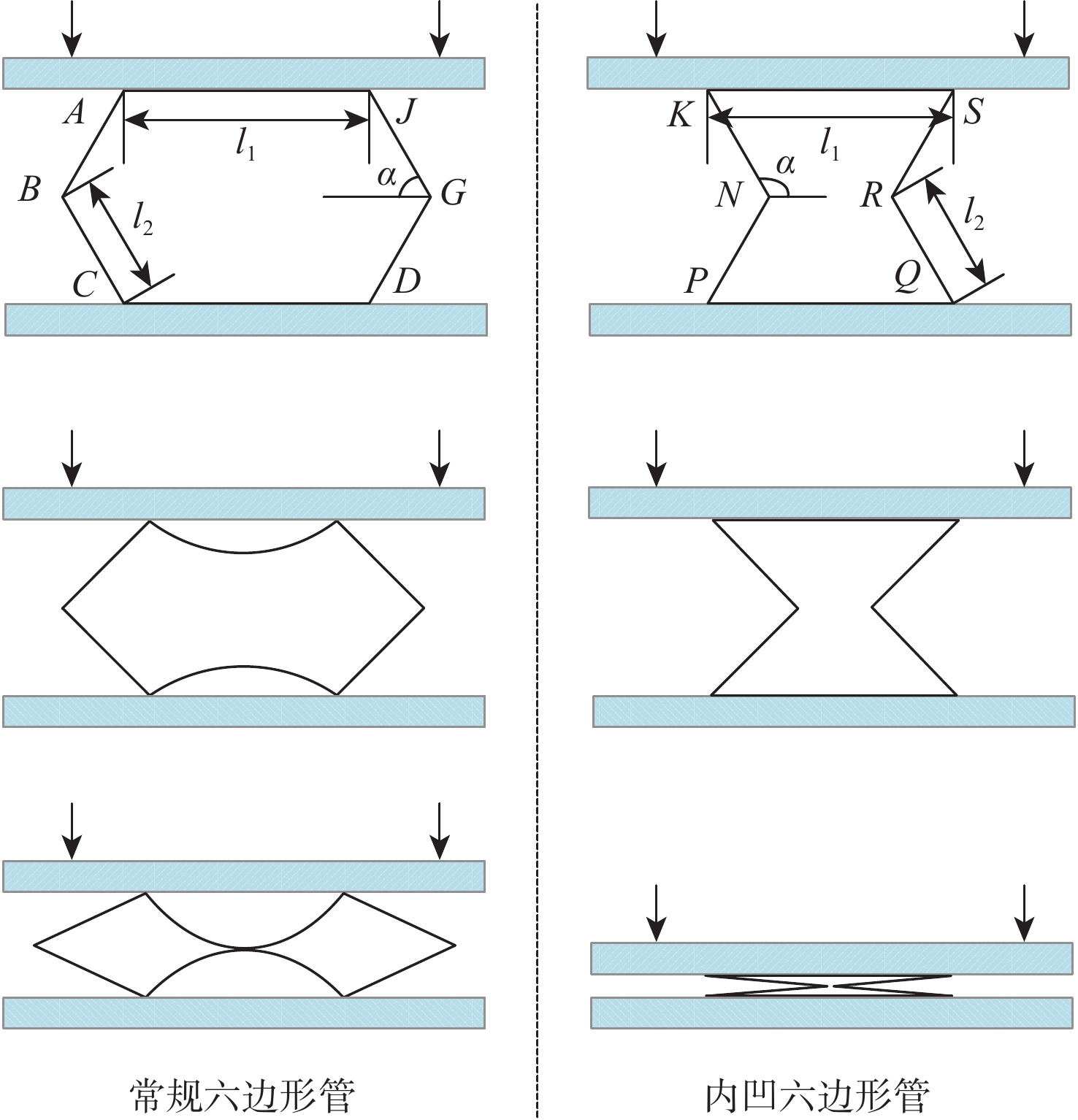

六边形薄壁结构被广泛应用于吸能防护领域。为提升六边形薄壁管的吸能性能,对常规六边形薄壁管和内凹六边形薄壁管在横向压缩载荷作用下的变形模式和吸能性能进行对比研究。针对这2种六边形管分别建立考虑应变强化效应的理论模型,运用商业软件ABAQUS进行有限元分析。对比理论模型和有限元分析得到的六边形管变形模式及载荷-位移关系,理论结果和有限元结果具有良好的一致性。针对2种六边形管,分别设置不同的侧边倾斜角,探究不同六边形管在横向压缩载荷作用下的塑性变形行为和吸能性能。结果表明:内凹六边形管相比于对应的常规六边形管具备更优的吸能性能,内凹六边形管的冲程效率和总吸能分别为对应的常规六边形管的1.41~1.62倍和1.79~1.83倍。另外,内凹六边形管所需的横向安装空间更小。

Abstract:Hexagonal thin-walled structures are widely used in the field of energy absorption and protection. To improve the energy absorption performance of hexagonal thin-walled tubes, in this study, a comparative study on the collapse modes and energy absorption performance of the conventional and re-entrant hexagonal tubes under lateral compression was performed. The theoretical models of these two kinds of hexagonal tubes were established and the effect of strain-hardening was taken into account. Then the finite element analyses were conducted by using the commercial software ABAQUS. The deformation modes and force-displacement relations obtained from the finite element analyses were compared with those predicted by the theoretical models. The results of the finite element and theory show a good degree of concordance. The plastic deformation behavior and energy absorption performance of the conventional and re-entrant hexagonal tubes with different inclination angles under lateral compression were explored. It is found that, compared with the conventional hexagonal tubes, the energy absorption performance of the re-entrant hexagonal tubes is better. The stroke efficiency and energy absorption of the re-entrant hexagonal tubes are respectively 1.41~1.62 times and 1.79~1.83 times those of the corresponding conventional hexagonal tubes. In addition, the re-entrant hexagonal tubes requires less installation space.

-

Key words:

- hexagonal tube /

- re-entrant structure /

- lateral compression /

- plastic deformation /

- energy absorption

-

-

[1] BAROUTAJI A, SAJJIA M, OLABI A G. On the crashworthiness performance of thin-walled energy absorbers: Recent advances and future developments[J]. Thin-Walled Structures, 2017, 118: 137-163. doi: 10.1016/j.tws.2017.05.018 [2] LU G, YU T X. Energy absorption of structures and materials[M]. Cambridge: Woodhead Publishing Ltd, 2003. [3] HA N S, PHAM T M, HAO H, et al. Energy absorption characteristics of bio-inspired hierarchical multi-cell square tubes under axial crushing[J]. International Journal of Mechanical Sciences, 2021, 201: 106464. doi: 10.1016/j.ijmecsci.2021.106464 [4] TIAN K, ZHANG Y, YANG F, et al. Enhancing energy absorption of circular tubes under oblique loads through introducing grooves of non-uniform depths[J]. International Journal of Mechanical Sciences, 2020, 166: 105239. doi: 10.1016/j.ijmecsci.2019.105239 [5] WANG Z G, ZHANG J, LI Z D, et al. On the crashworthiness of bio-inspired hexagonal prismatic tubes under axial compression[J]. International Journal of Mechanical Sciences, 2020, 186: 105893. doi: 10.1016/j.ijmecsci.2020.105893 [6] SAID M R, REDDY T Y. Quasi-static response of laterally simple compressed hexagonal rings[J]. International Journal of Crashworthiness, 2002, 7(3): 345-364. [7] NIKNEJAD A, RAHMANI D M. Experimental and theoretical study of the lateral compression process on the empty and foam-filled hexagonal columns[J]. Materials & Design, 2014, 53: 250-261. [8] ZHOU Z P, LIU F, GAO Y H, et al. Experimental study on the lateral compression energy absorption characteristics of hexagonal steel tube filled with polyurethane foam[J]. Applied Mechanics and Materials, 2014, 692: 210-216. doi: 10.4028/www.scientific.net/AMM.692.210 [9] LIU Y C. Thin-walled curved hexagonal beams in crashes-FEA and design[J]. International Journal of Crashworthiness, 2010, 15(2): 151-159. doi: 10.1080/13588260903094400 [10] 唐治, 付洪源, 王建, 等. 六边薄壁构件在准静态径向压缩下的吸能特性[J]. 地下空间与工程学报, 2018, 14(1): 72-77.TANG Z, FU H Y, WANG J, et al. Energy absorption characteristics of hexagonal thin-walled component under quasi-static radial compression[J]. Chinese Journal of Underground Space and Engineering, 2018, 14(1): 72-77(in Chinese). [11] GOWID S, MAHDI E, ALABTAH F. Modeling and optimization of the crushing behavior and energy absorption of plain weave composite hexagonal quadruple ring systems using artificial neural network[J]. Composite Structures, 2019, 229: 111473. doi: 10.1016/j.compstruct.2019.111473 [12] TRAN T N, BAROUTAJI A, ESTRADA Q, et al. Crashworthiness analysis and optimization of standard and windowed multi-cell hexagonal tubes[J]. Structural and Multidisciplinary Optimization, 2021, 63(5): 2191-2209. doi: 10.1007/s00158-020-02794-y [13] 仝军, 杨晓翔, 韦铁平, 等. 超大轴向冲击载荷下六边形蜂窝铝结构的吸能特性优化研究[J]. 机电工程, 2021, 38(7): 897-901. doi: 10.3969/j.issn.1001-4551.2021.07.014TONG J, YANG X X, WEI T P, et al. Optimization of energy absorption characteristics of hexagonal honeycomb aluminum structure under super large axial impact load[J]. Journal of Mechanical & Electrical Engineering, 2021, 38(7): 897-901(in Chinese). doi: 10.3969/j.issn.1001-4551.2021.07.014 [14] 任鑫, 张相玉, 谢亿民. 负泊松比材料和结构的研究进展[J]. 力学学报, 2019, 51(3): 656-687. doi: 10.6052/0459-1879-18-381REN X, ZHANG X Y, XIE Y M. Research progress in auxetic materials and structures[J]. Chinese Journal of Theoretical and Applied Mechanics, 2019, 51(3): 656-687(in Chinese). doi: 10.6052/0459-1879-18-381 [15] 任毅如, 蒋宏勇, 金其多, 等. 仿生负泊松比拉胀内凹蜂窝结构耐撞性[J]. 航空学报, 2021, 42(3): 223978.REN Y R, JIANG H Y, JIN Q D, et al. Crashworthiness of bio-inspired auxetic reentrant honeycomb with negative Poisson’s ratio[J]. Acta Aeronautica et Astronautica Sinica, 2021, 42(3): 223978(in Chinese). [16] REDWOOD R G. Discussion: “Crushing of a tube between rigid plates” (DeRuntz, jr., john A., and hodge, jr., P. G., 1963, ASME J. appl. mech., 30, pp. 391–395)[J]. Journal of Applied Mechanics, 1964, 31(2): 357-358. doi: 10.1115/1.3629622 [17] 庄茁, 由小川, 廖剑晖, 等. 基于ABAQUS的有限元分析和应用[M]. 北京: 清华大学出版社, 2009: 234.ZHUANG Z, YOU X C, LIAO J H, et al. Finite element analysis and application based on ABAQUS[M]. Beijing: Tsinghua University Press, 2009: 234(in Chinese). [18] LI Q M, MAGKIRIADIS I, HARRIGAN J J. Compressive strain at the onset of densification of cellular solids[J]. Journal of Cellular Plastics, 2006, 42(5): 371-392. doi: 10.1177/0021955X06063519 [19] LU J Y, WANG Y H, ZHAI X M, et al. Impact behavior of a cladding sandwich panel with aluminum foam-filled tubular cores[J]. Thin-Walled Structures, 2021, 169: 108459. doi: 10.1016/j.tws.2021.108459 [20] ZHANG J X, GUO H Y, DU J L, et al. Splitting and curling collapse of metal foam core square sandwich metal tubes: Experimental and theoretical investigations[J]. Thin-Walled Structures, 2021, 169: 108346. doi: 10.1016/j.tws.2021.108346 -

下载:

下载: