-

摘要:

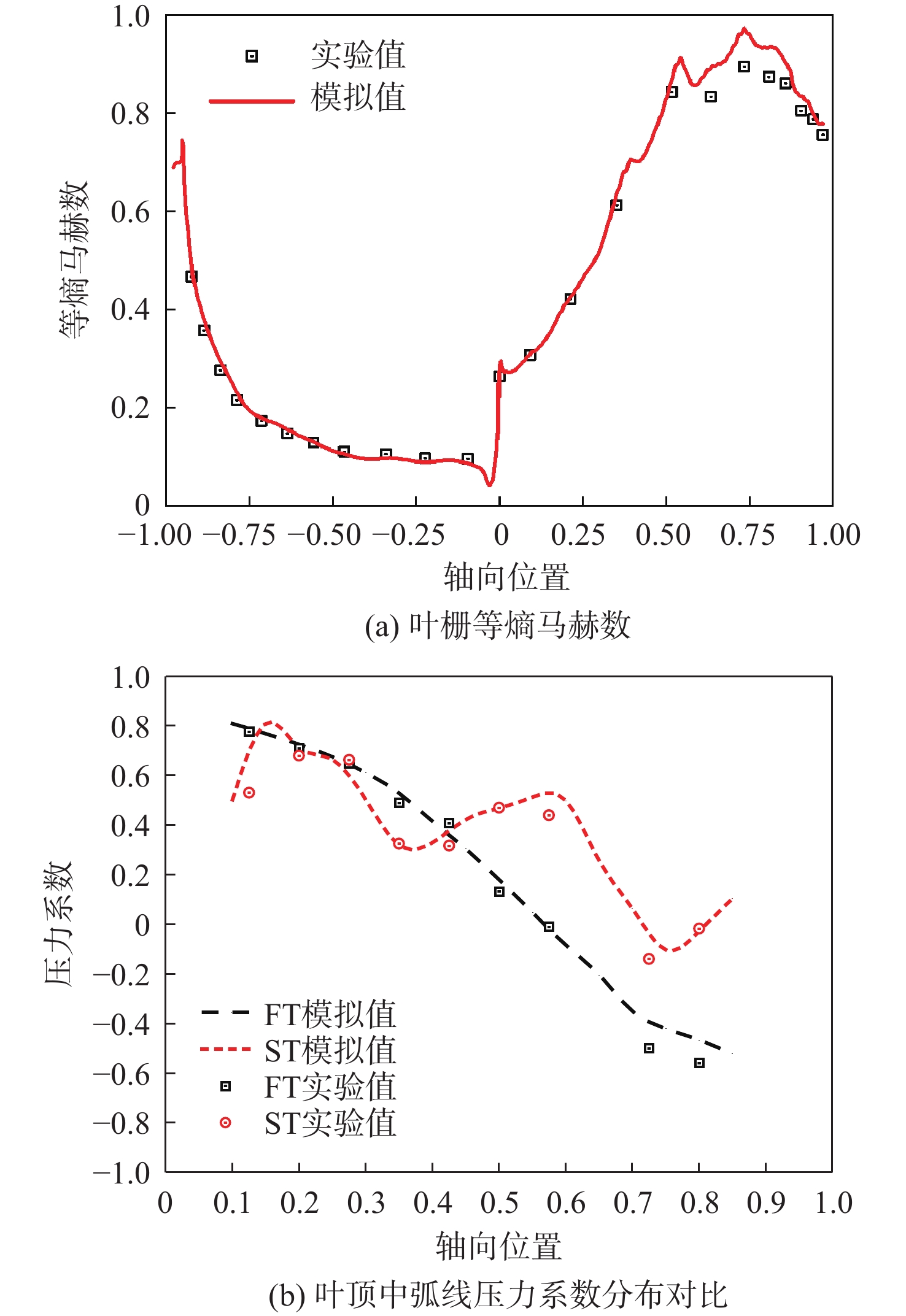

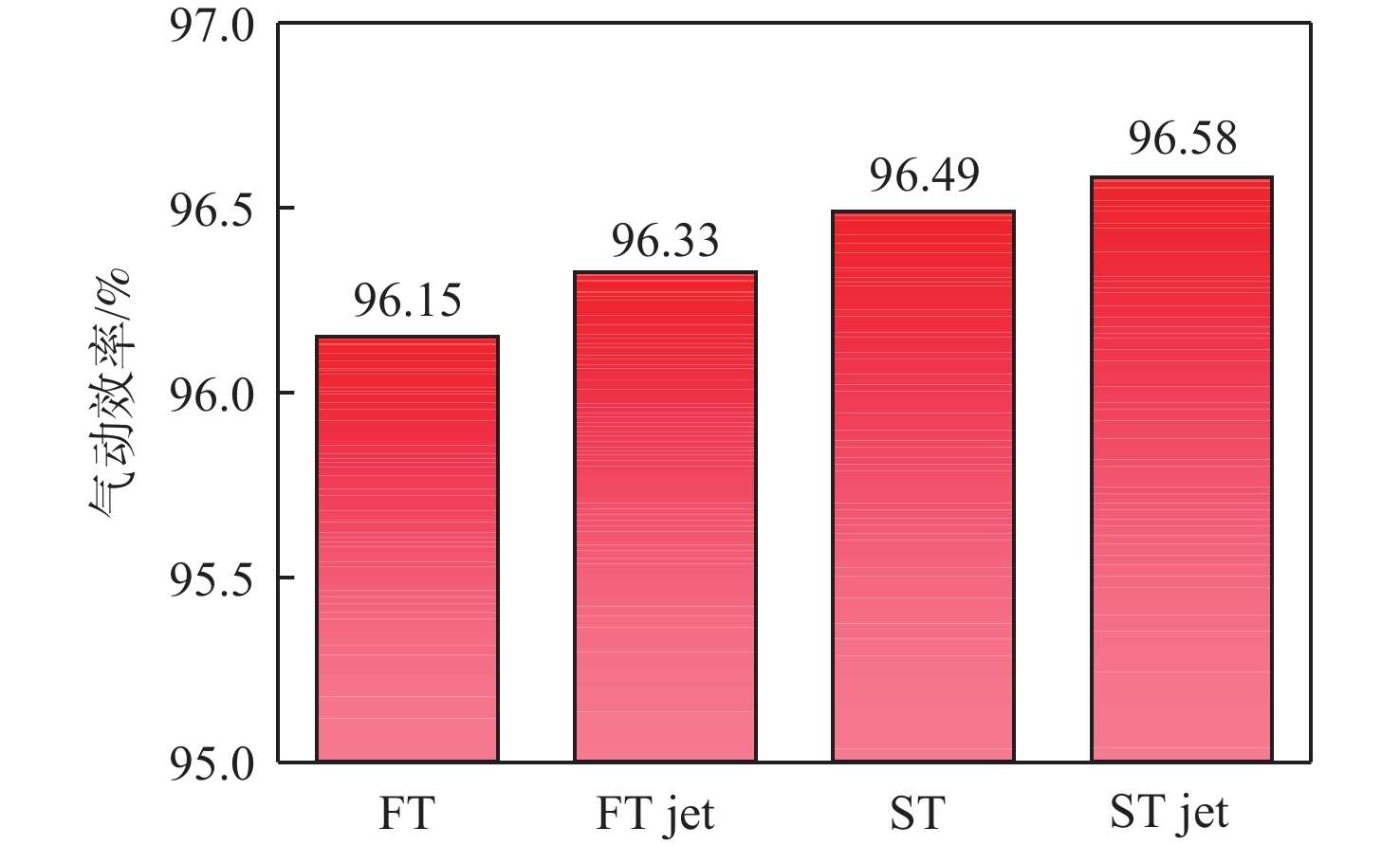

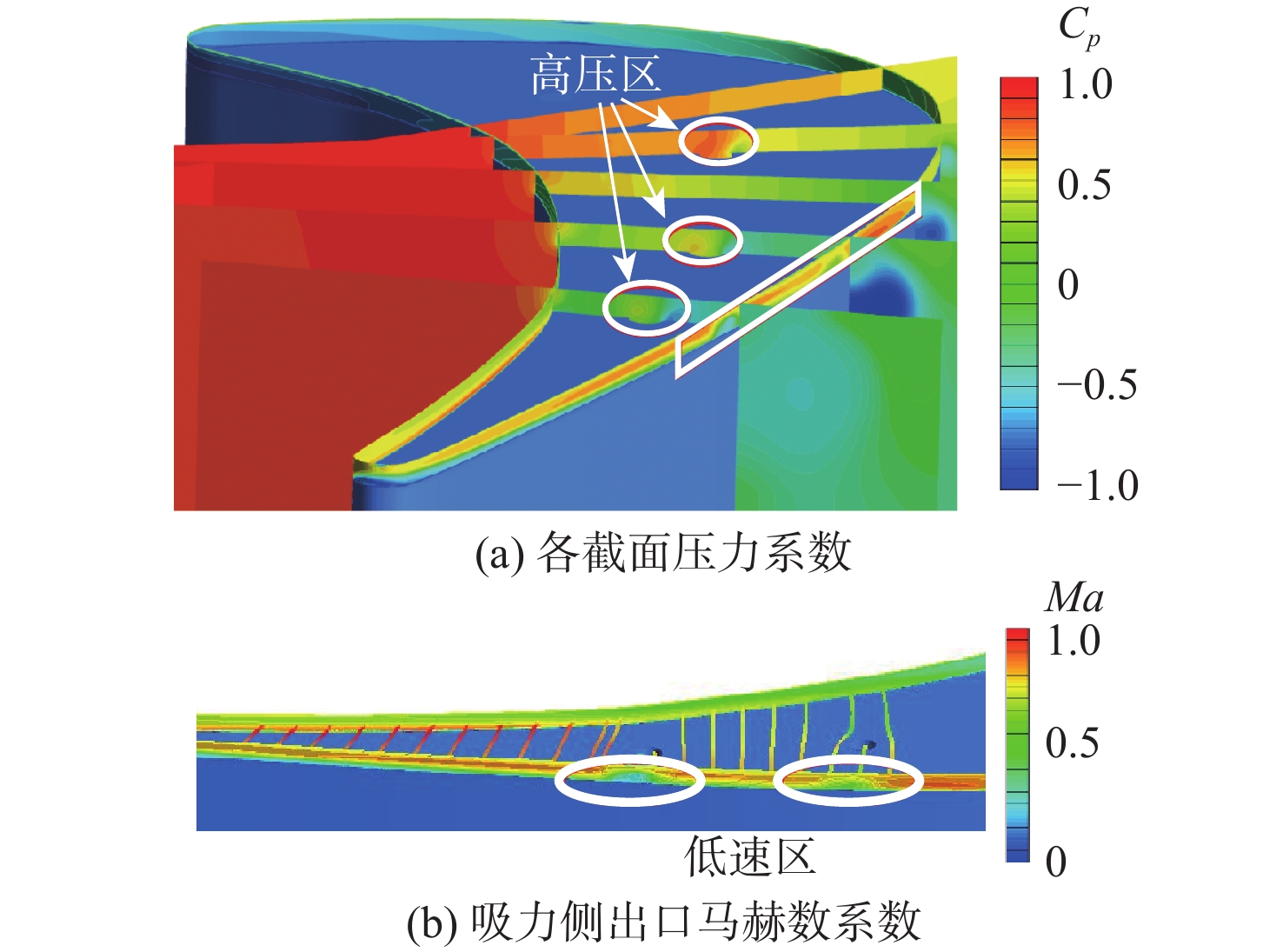

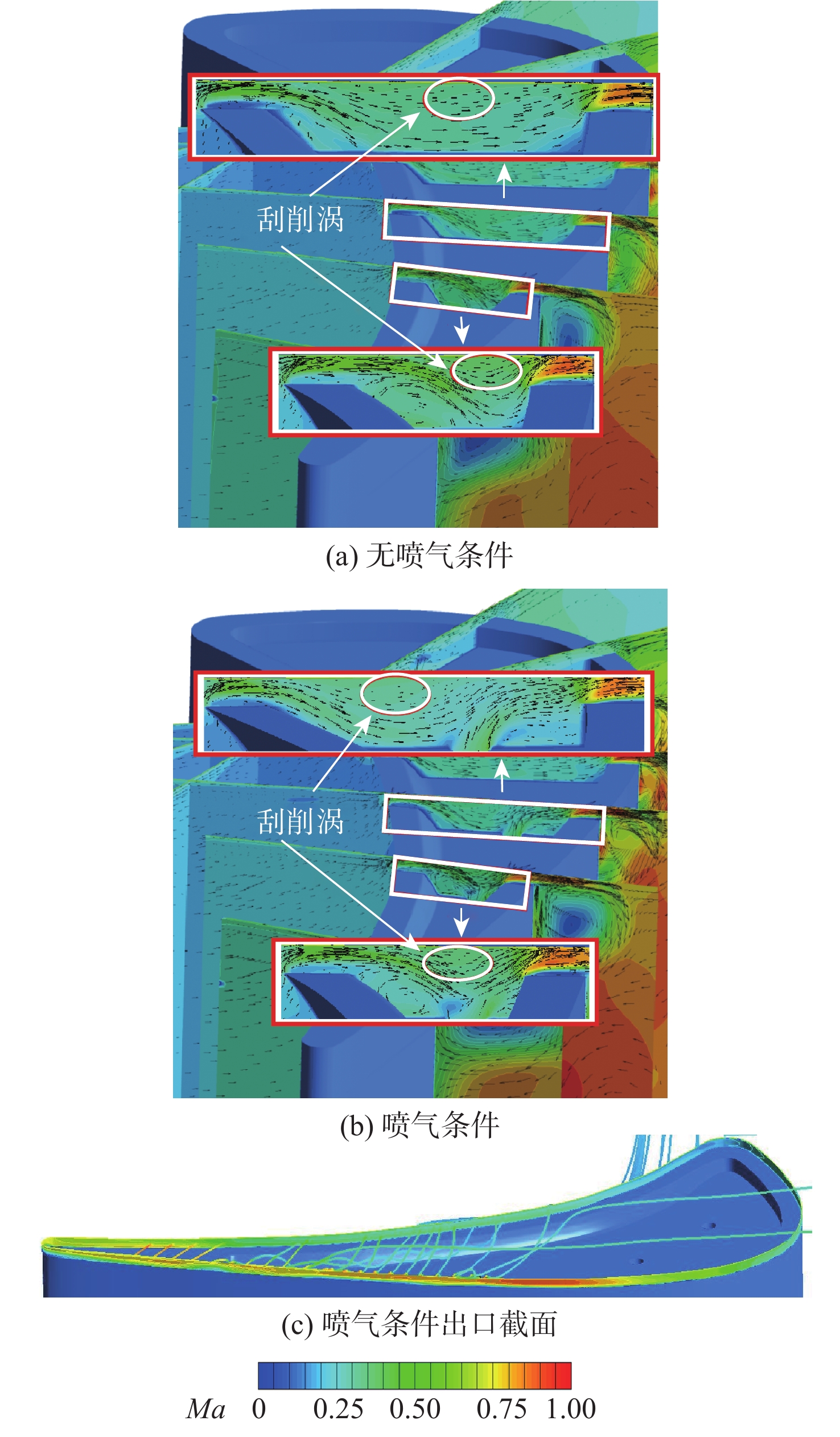

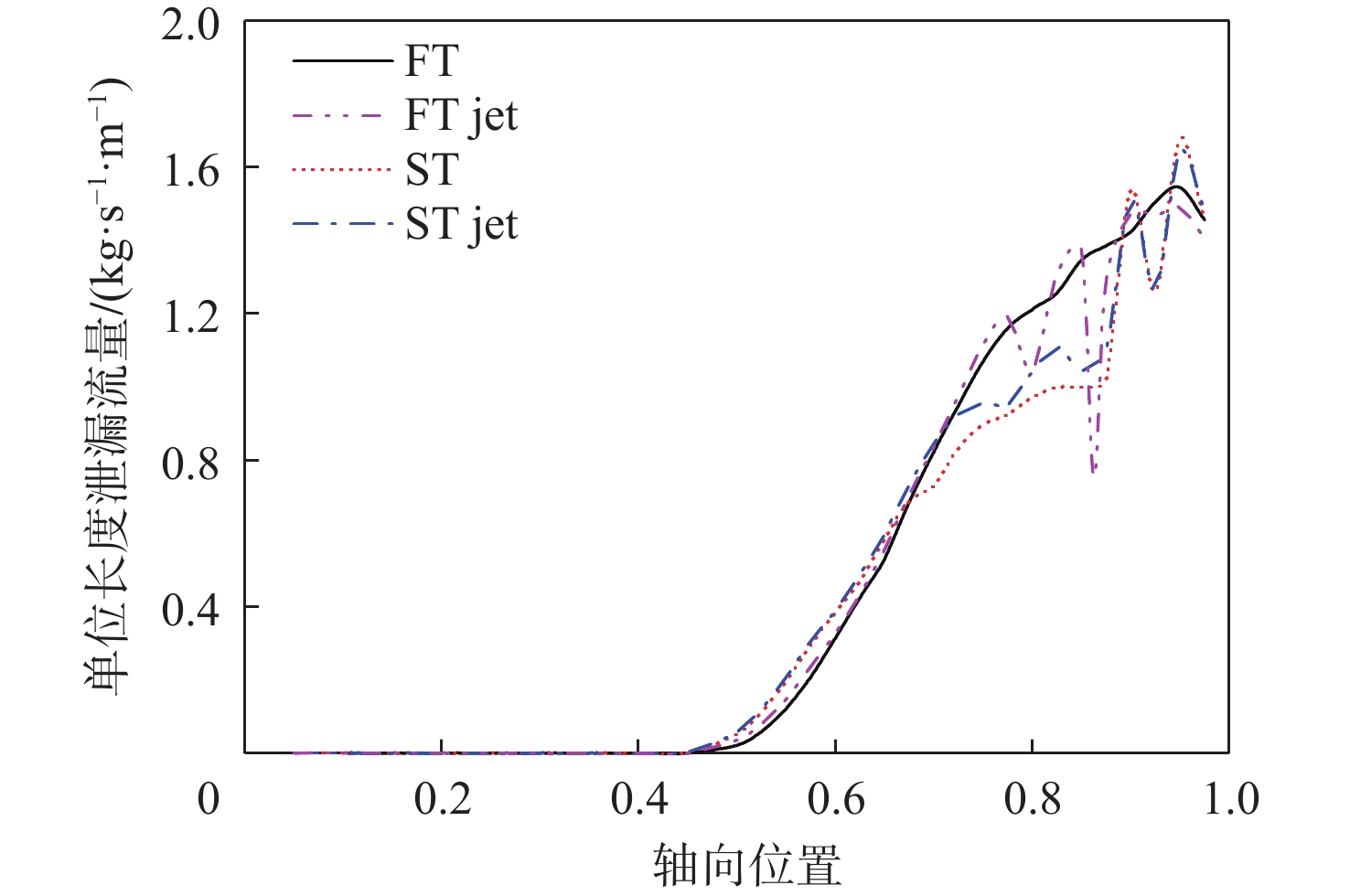

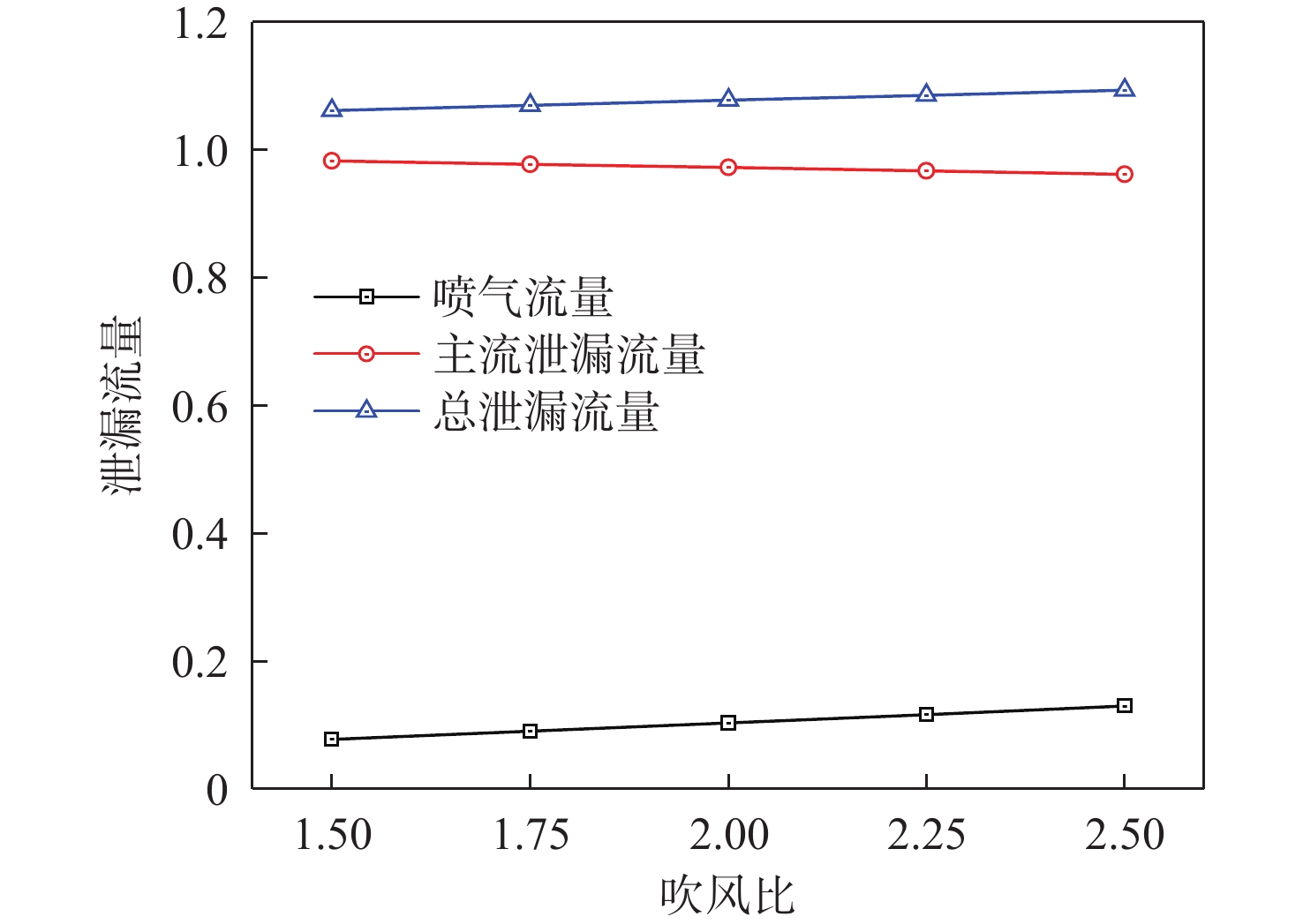

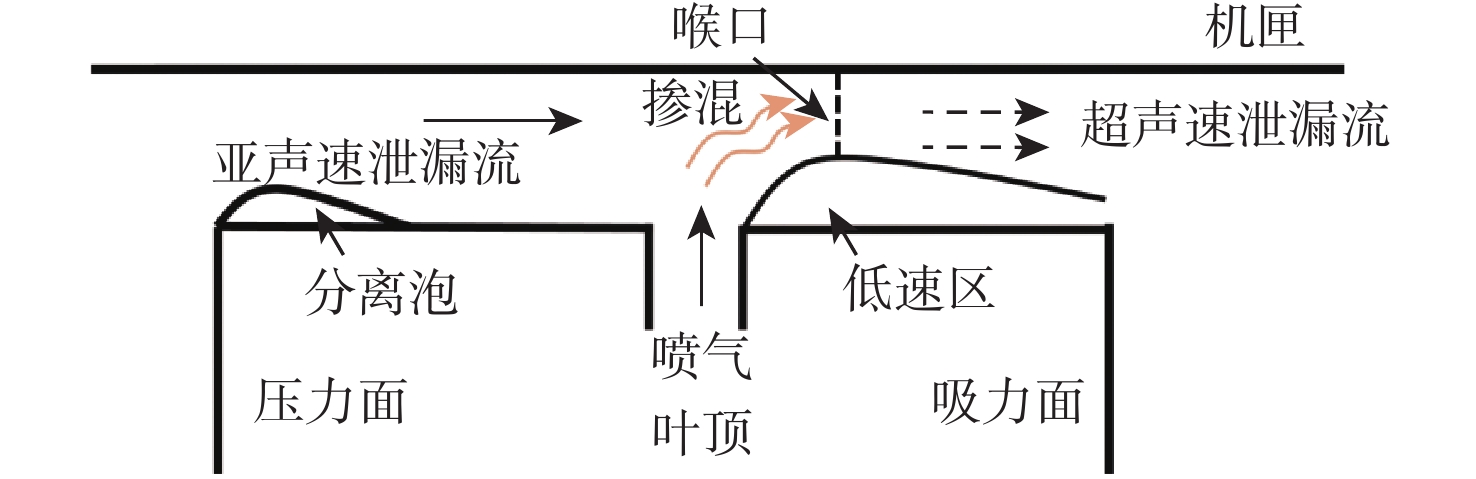

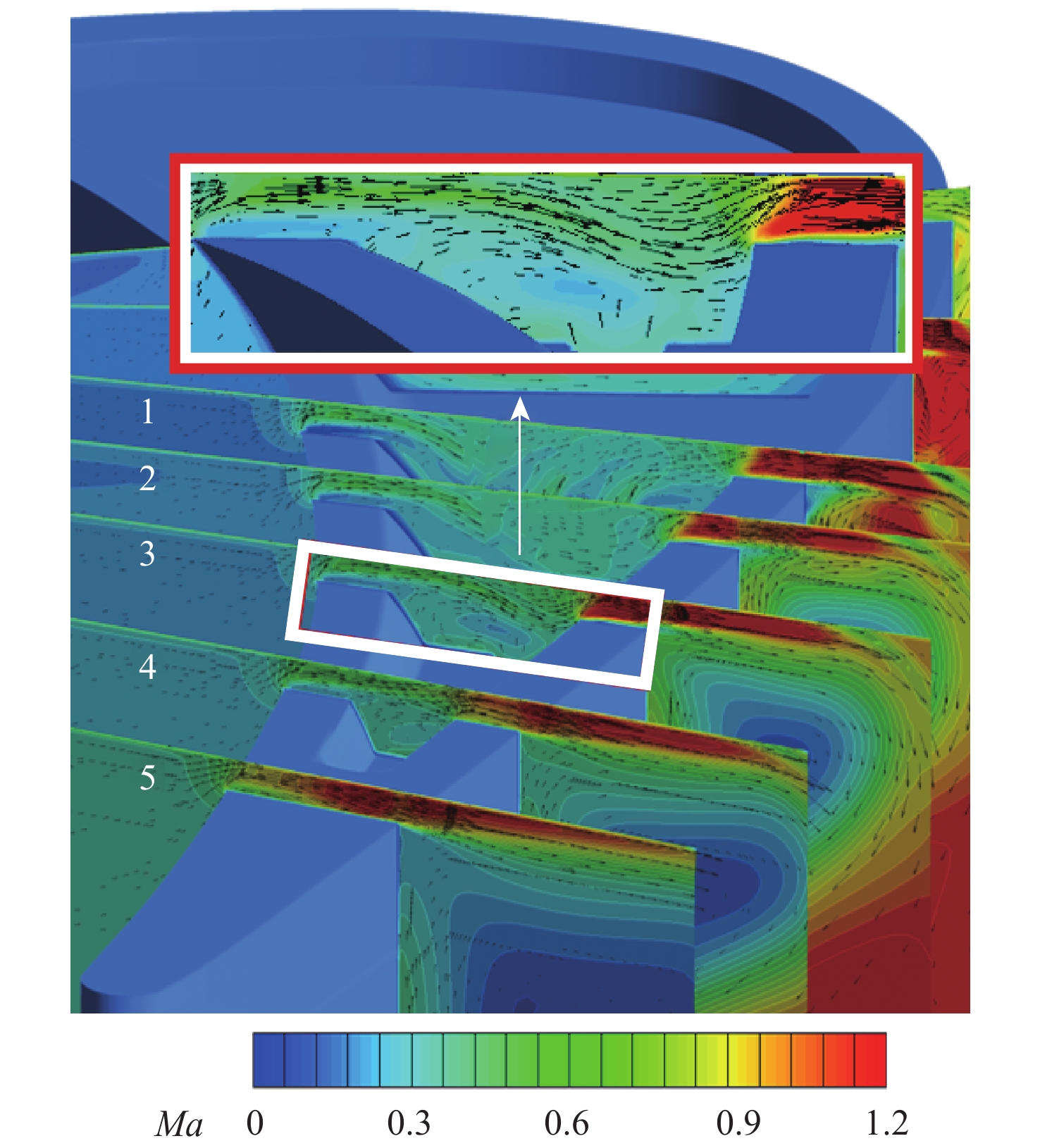

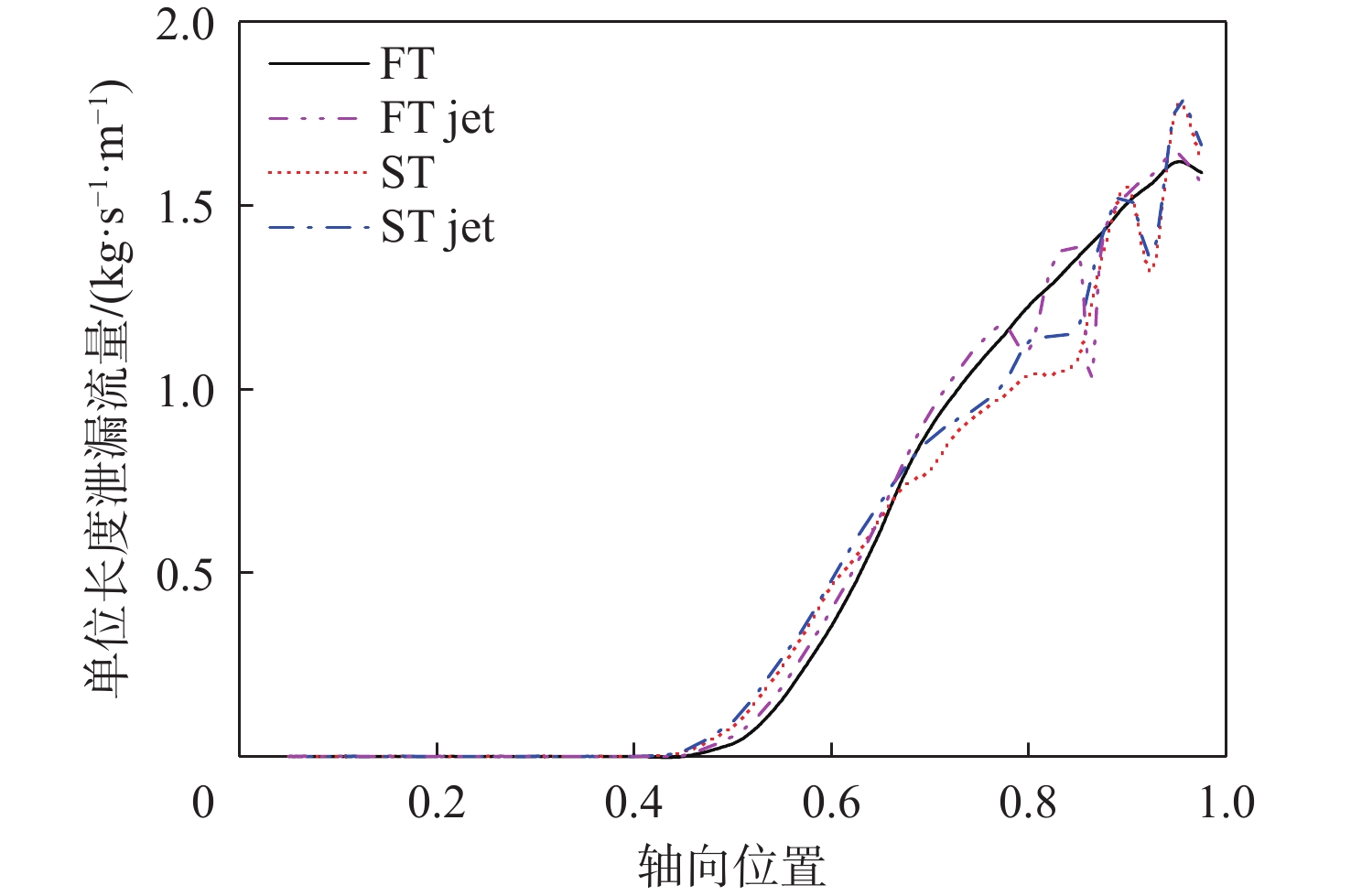

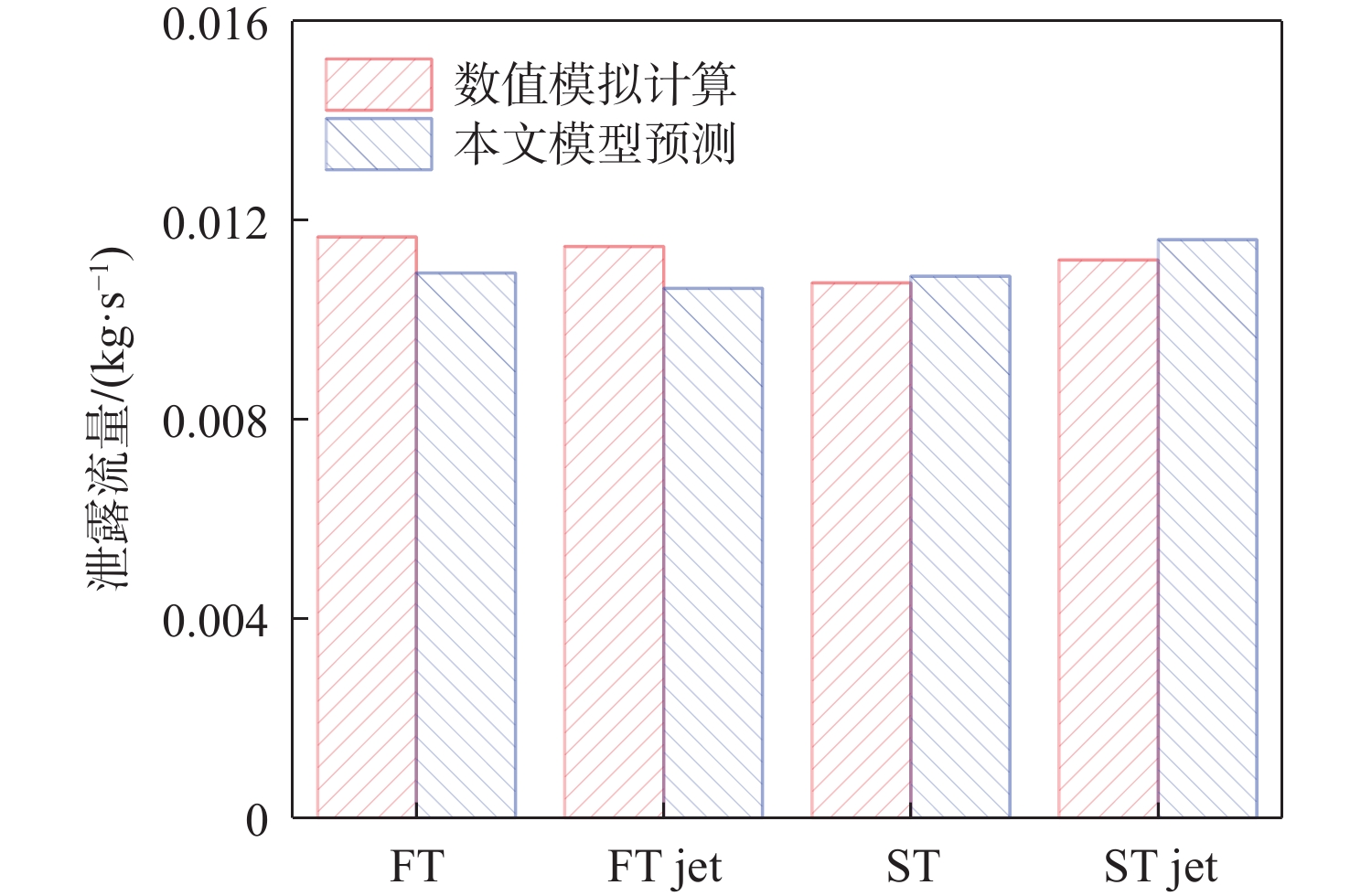

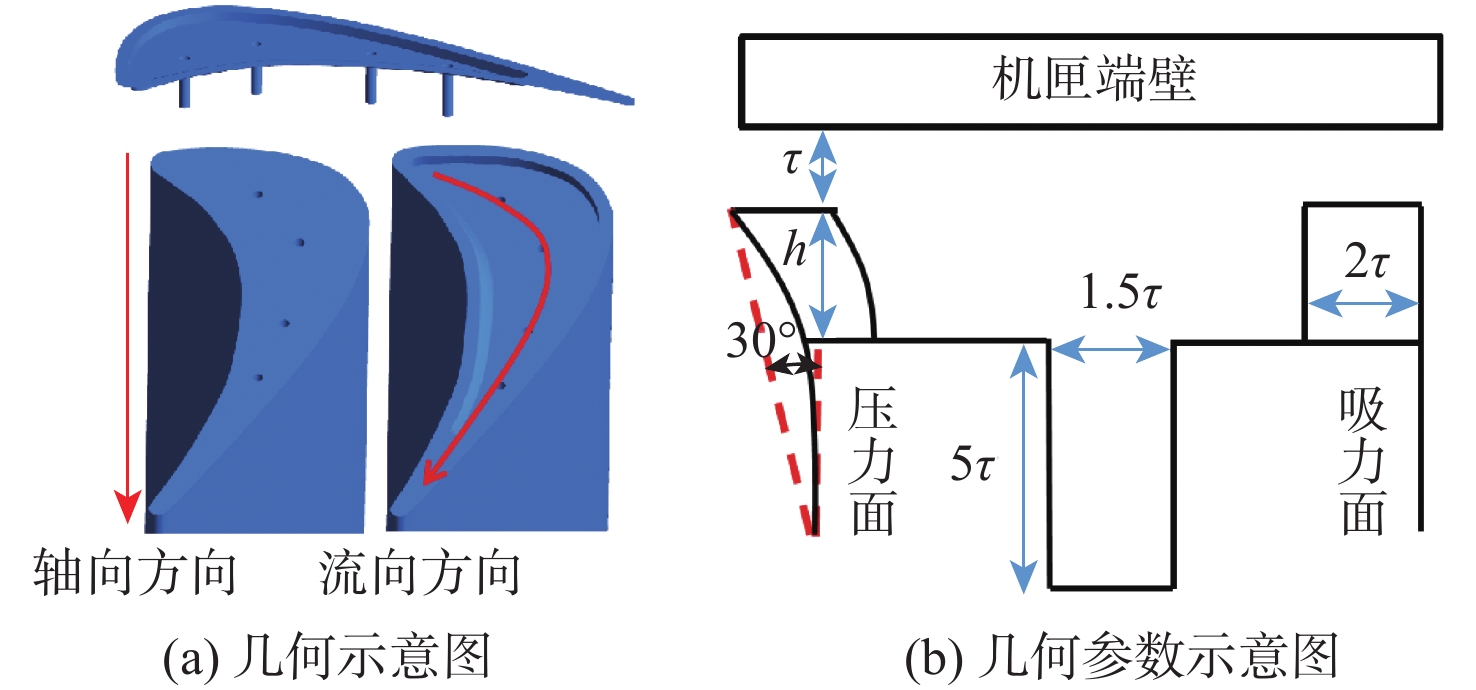

为明确跨音涡轮叶尖泄漏流动机理,进一步提升涡轮效率,对跨音条件下叶顶喷气对平叶尖及凹槽叶尖性能的影响进行研究,并探讨跨音条件下平叶尖及凹槽叶尖间隙内部的流动状态。结果表明:跨音条件下,叶顶喷气可以增加平叶尖叶栅的气动效率,而刮削涡仍是凹槽内的主控流动结构;喷气流量的增加对平叶尖的总泄漏流量影响有限,但会增加凹槽叶尖的总泄漏流量。在更高负荷情况下,平叶尖间隙内呈跨音速流动特征,具体状态与叶片负荷、叶片厚度有关;凹槽叶尖条件下,泄漏流动在吸力侧肋条上方快速膨胀至超声速状态。基于此,建立可用于跨音条件下的泄漏流量预测模型。

Abstract:In order to clarify the mechanism of the tip leakage flow in transonic turbines and further improve turbine efficiency, the effect of tip injection on the performance of a flat tip and a squealer tip is studied under the transonic condition, and the flow state in the clearance between a flat tip and squealer tip is discussed. The results show that under transonic conditions, tip jet can increase the aerodynamic efficiency of the flat tip cascade, and that the scraping vortex is still the dominant flow structure in the cavity of the squealer tip. The increase of jet flow has limited effect on the total leakage flow of the flat tip, but will increase the total leakage flow of the squealer tip. With higher load, the transonic flow in the flat tip clearance is related to the blade load and thickness. For squealer tips, the leakage flow expands rapidly to the supersonic state above the suction side squealer. Finally, a leakage flow prediction model for transonic conditions is established.

-

Key words:

- transonic turbine /

- leakage flow /

- tip clearance /

- tip injection /

- flow model

-

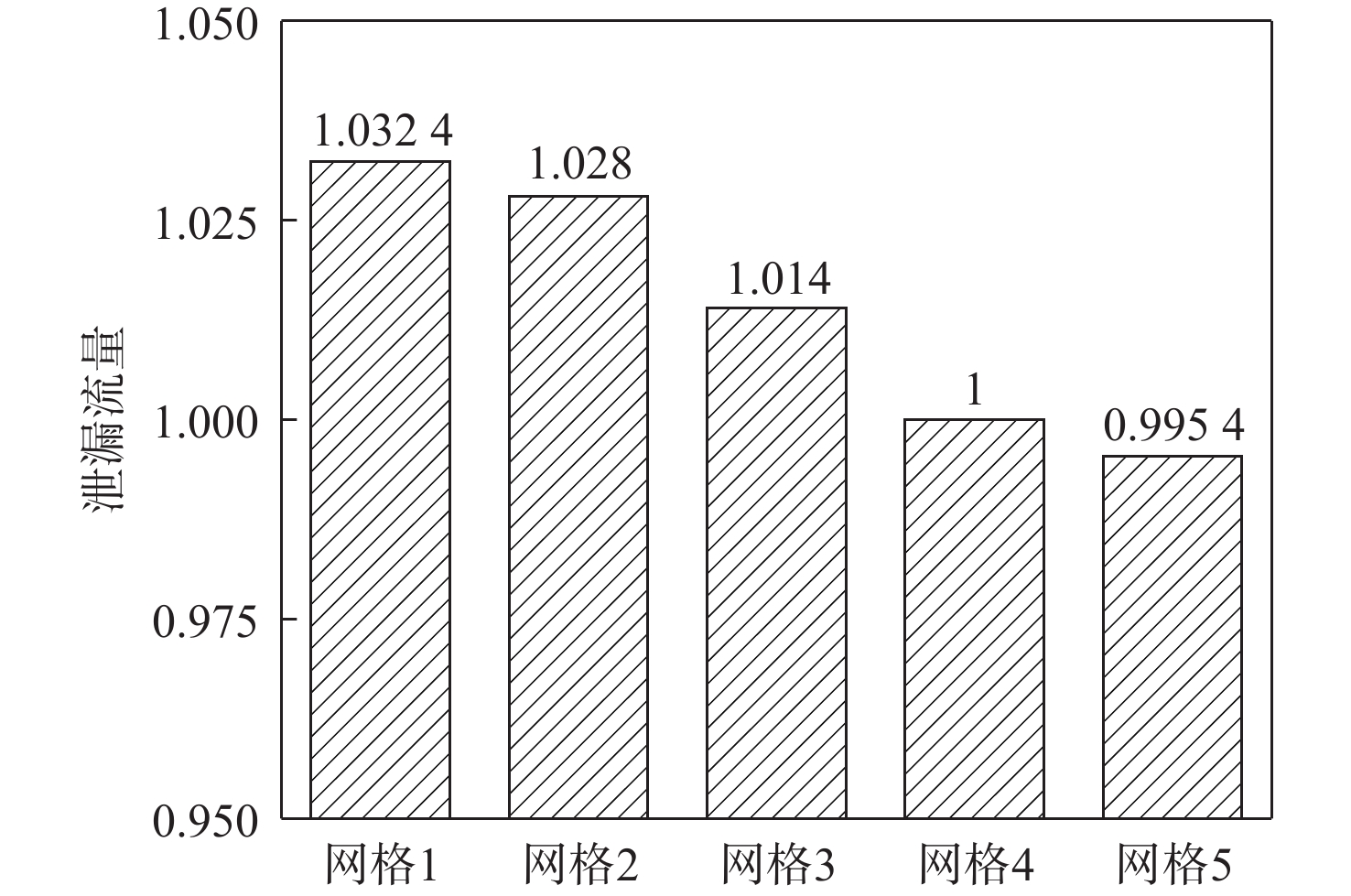

表 1 网格参数

Table 1. Grid parameters

网格编号 间隙径向网格数量 网格总数/106 网格1 9 2.51 网格2 15 2.67 网格3 21 2.84 网格4 26 2.98 网格5 31 3.14 -

[1] DENTON J D. The 1993 IGTI scholar lecture: Loss mechanisms in turbomachines[J]. Journal of Turbomachinery, 1993, 115(4): 621-656. doi: 10.1115/1.2929299 [2] HAN J C. Fundamental gas turbine heat transfer[J]. Journal of Thermal Science and Engineering Applications, 2013, 5(2): 021007. doi: 10.1115/1.4023826 [3] ZOU Z P, WANG S T, LIU H X, et al. Axial turbine aerodynamics for aero-engines[M]. Berlin: Springer, 2018. [4] RAINS D A. Tip clearance flows in axial flow compressors and pumps[D]. Pasadena: California Institute of Technology, 1954. [5] BINDON J P. The measurement and formation of tip clearance loss[J]. Journal of Turbomachinery, 1989, 111(3): 257-263. doi: 10.1115/1.3262264 [6] YARAS M I, SJOLANDER S A. Prediction of tip-leakage losses in axial turbines[C]//Proceedings of ASME 1990 International Gas Turbine and Aeroengine Congress and Exposition. Brussels: International Gas Turbine Institute , 2015. [7] GAO J, ZHENG Q, XU T B, et al. Inlet conditions effect on tip leakage vortex breakdown in unshrouded axial turbines[J]. Energy, 2015, 91: 255-263. doi: 10.1016/j.energy.2015.08.065 [8] HUANG A. Loss mechanisms in turbine tip clearance[D]. Cambridge : Massachusetts Institute of Technology, 2011. [9] VIRDI A S, ZHANG Q, HE L, et al. Aerothermal performance of shroudless turbine blade tips with relative casing movement effects[J]. Journal of Propulsion and Power, 2015, 31(2): 527-536. doi: 10.2514/1.B35331 [10] BUNKER R S. Axial turbine blade tips: Function, design, and durability[J]. Journal of Propulsion and Power, 2006, 22(2): 271-285. doi: 10.2514/1.11818 [11] 邹正平, 姚李超, 轩笠铭, 等. 涡轮转子凹槽叶尖泄漏流动气动热力特征[J]. 推进技术, 2020, 41(9): 1975-1987.ZOU Z P, YAO L C, XUAN L M, et al. Aero-thermodynamic characteristics of tip leakage flow in turbine rotor with squealer tip[J]. Journal of Propulsion Technology, 2020, 41(9): 1975-1987(in Chinese). [12] ZOU Z P, SHAO F, LI Y R, et al. Dominant flow structure in the squealer tip gap and its impact on turbine aerodynamic performance[J]. Energy, 2017, 138: 167-184. doi: 10.1016/j.energy.2017.07.047 [13] 杜金霖, 邹正平, 黄霖, 等. 计及机匣相对运动的涡轮叶片叶顶凹槽流动研究[J]. 实验流体力学, 2021, 35(2): 22-35. doi: 10.11729/syltlx20200073DU J L, ZOU Z P, HUANG L, et al. Experimental and numerical study of squealer tip flow field considering relative casing motion[J]. Journal of Experiments in Fluid Mechanics, 2021, 35(2): 22-35(in Chinese). doi: 10.11729/syltlx20200073 [14] KRISHNABABU S K, NEWTON P J, DAWES W N, et al. Aerothermal investigations of tip leakage flow in axial flow turbines—part I: Effect of tip geometry and tip clearance gap[J]. Journal of Turbomachinery, 2009, 131(1): 011006. doi: 10.1115/1.2950068 [15] KEGALJ M, SCHMID G, WARTZEK F, et al. Experimental and numerical investigation of tip leakage flow in a 1 1/2 stage turbine rig comparing flat and cavity-squealer tip geometries[C]//Proceedings of ASME Turbo Expo 2012: Turbine Technical Conference and Exposition. Copenhagen: International Gas Turbine Institute, 2012. [16] MOORE J, MOORE J G, HENRY G S, et al. Flow and heat transfer in turbine tip gaps[J]. Journal of Turbomachinery, 1989, 111(3): 301-309. doi: 10.1115/1.3262269 [17] JIANG S J, LI Z G, LI J, et al. Numerical investigations on the heat transfer performance of transonic squealer tip with different film cooling layouts[C]//Proceedings of ASME Turbo Expo 2020: Turbomachinery Technical Conference and Exposition. [S. l. ] : International Gas Turbine Institute , 2021. [18] WANG T Y, XUAN Y M, HAN X S. The effects of tip gap variation on transonic turbine blade tip leakage flow based on VLES approach[J]. Aerospace Science and Technology, 2021, 111: 106542. doi: 10.1016/j.ast.2021.106542 [19] WHEELER A P S, ATKINS N R, HE L. Turbine blade tip heat transfer in low speed and high speed flows[J]. Journal of Turbomachinery, 2011, 133(4): 041025. doi: 10.1115/1.4002424 [20] MOORE J, ELWARD K M. Shock formation in overexpanded tip leakage flow[J]. Journal of Turbomachinery, 1993, 115(3): 392-399. doi: 10.1115/1.2929266 [21] ARISI A, XUE S, NG W F, et al. Numerical investigation of aerothermal characteristics of the blade tip and near-tip regions of a transonic turbine blade[C]//Proceedings of ASME Turbo Expo 2014: Turbine Technical Conference and Exposition. Düsseldorf : International Gas Turbine Institute , 2014. [22] WHEELER A P S, SALEH Z. Effect of cooling injection on transonic tip flows[J]. Journal of Propulsion and Power, 2013, 29(6): 1374-1381. doi: 10.2514/1.B34657 [23] DUAN P H, HE L. Optimization of turbine cascade squealer tip cooling design by combining shaping and flow injection[J]. Journal of Turbomachinery, 2021, 143(11): 111007. doi: 10.1115/1.4051204 [24] MA H, ZHANG Q, HE L, et al. Cooling injection effect on a transonic squealer tip—part II: Analysis of aerothermal interaction physics[J]. Journal of Engineering for Gas Turbines and Power, 2017, 139(5): 052507. doi: 10.1115/1.4035200 [25] WANG Y B, SONG Y P, YU J Y, et al. Effect of cooling injection on the leakage flow of a turbine cascade with honeycomb tip[J]. Applied Thermal Engineering, 2018, 133: 690-703. doi: 10.1016/j.applthermaleng.2018.01.090 [26] ZHOU Z H, CHEN S W, LI W H, et al. Thermal performance of blade tip and casing coolant injection on a turbine blade with cavity and winglet-cavity tip[J]. International Journal of Heat and Mass Transfer, 2019, 130: 585-602. doi: 10.1016/j.ijheatmasstransfer.2018.10.130 [27] 胡建军, 张铎, 张香兰, 等. 一种复合方法抑制叶尖泄漏的试验及模拟研究[J]. 北京航空航天大学学报, 2018, 44(11): 2283-2291.HU J J, ZHANG D, ZHANG X L, et al. Experiment and simulation study on tip leakage suppression by a compound method[J]. Journal of Beijing University of Aeronautics and Astronautics, 2018, 44(11): 2283-2291(in Chinese). [28] 王维杰, 卢少鹏, 马海腾, 等. 高压涡轮尾切凹槽叶尖冷却换热特性[J]. 航空动力学报, 2019, 34(10): 2131-2139.WANG W J, LU S P, MA H T, et al. Cooling and heat transfer characteristics of high-pressure turbine blade with cutback squealer tip[J]. Journal of Aerospace Power, 2019, 34(10): 2131-2139(in Chinese). [29] 杨蓓洁, 谭晓茗, 单勇, 等. 肋条结构对气膜冷却凹槽叶尖流动换热的影响[J]. 航空动力学报, 2021, 36(7): 1462-1471.YANG B J, TAN X M, SHAN Y, et al. Effects of rib structure on flow and heat transfer characteristics of film cooling rotor blade with squealer tip[J]. Journal of Aerospace Power, 2021, 36(7): 1462-1471(in Chinese). [30] GAO J, ZHENG Q, ZHANG Z Y, et al. Aero-thermal performance improvements of unshrouded turbines through management of tip leakage and injection flows[J]. Energy, 2014, 69: 648-660. doi: 10.1016/j.energy.2014.03.060 [31] ZHOU C, HODSON H. The tip leakage flow of an unshrouded high pressure turbine blade with tip cooling[J]. Journal of Turbomachinery, 2011, 133(4): 041028. doi: 10.1115/1.4001174 [32] NICHOLSON J H, FOREST A E, OLDFIELD M L G, et al. Heat transfer optimised turbine rotor blades: An experimental study using transient techniques[C]//Proceedings of ASME 1982 International Gas Turbine Conference and Exhibit. London: International Gas Turbine Institute, 2015. [33] ZENG F, DU J L, HUANG L, et al. An experimental method for squealer tip flow field considering relative casing motion[J]. Chinese Journal of Aeronautics, 2020, 33(7): 1942-1952. doi: 10.1016/j.cja.2020.03.002 [34] YOUNG J B, HORLOCK J H. Defining the efficiency of a cooled turbine[J]. Journal of Turbomachinery, 2006, 128(4): 658-667. doi: 10.1115/1.2218890 [35] SCHLICHTING H. Boundary-layer theory[M]. 7th ed. New York: McGraw-Hill, 1979. [36] MUNSON B R, YOUNG D F, OKIISHI T H. Fundamentals of fluid mechanics[M]. New York: Wiley, 1990. -

下载:

下载: