-

摘要:

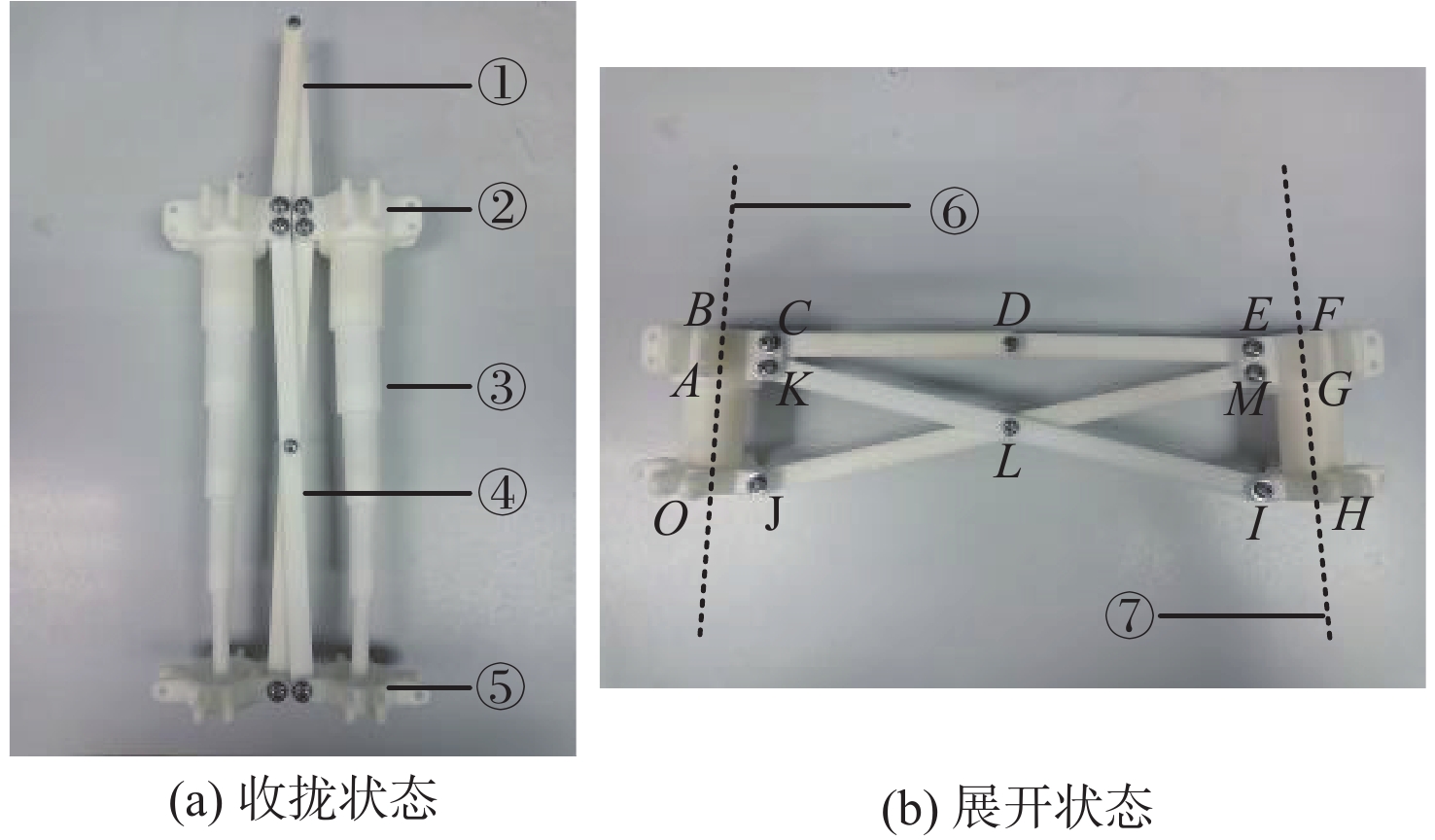

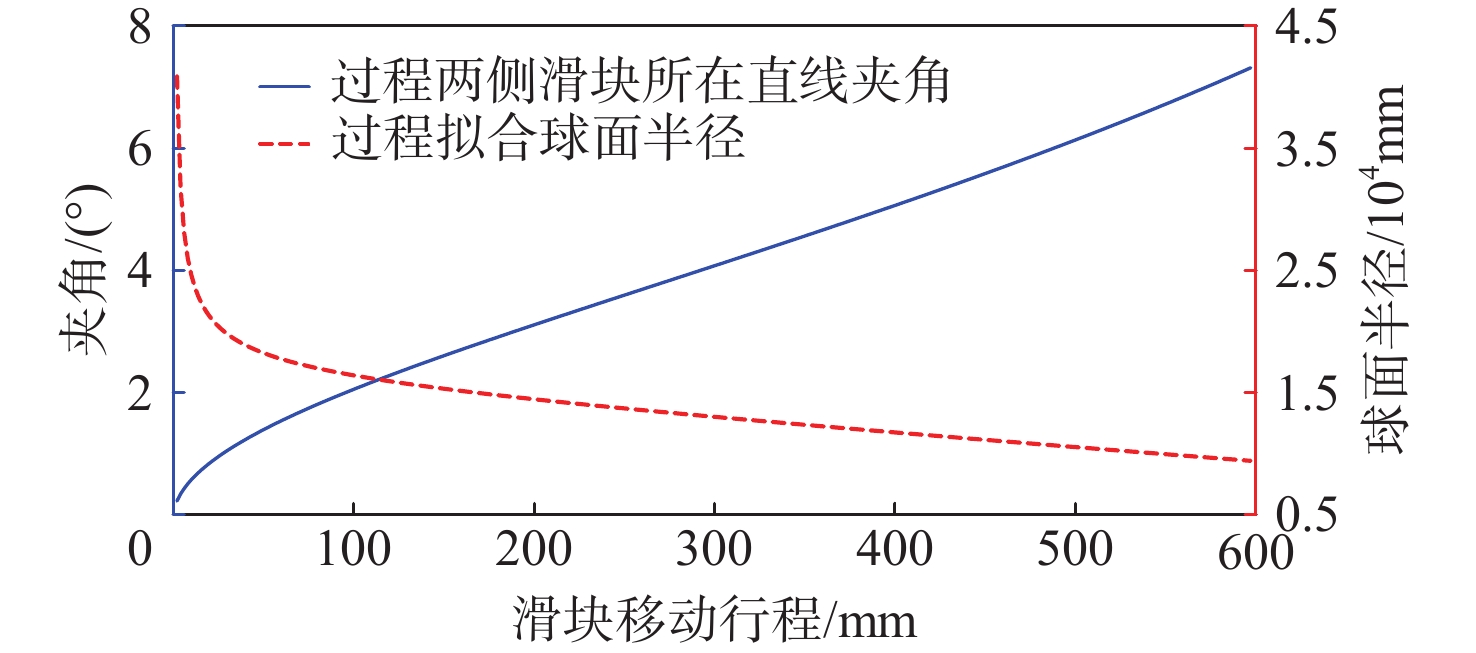

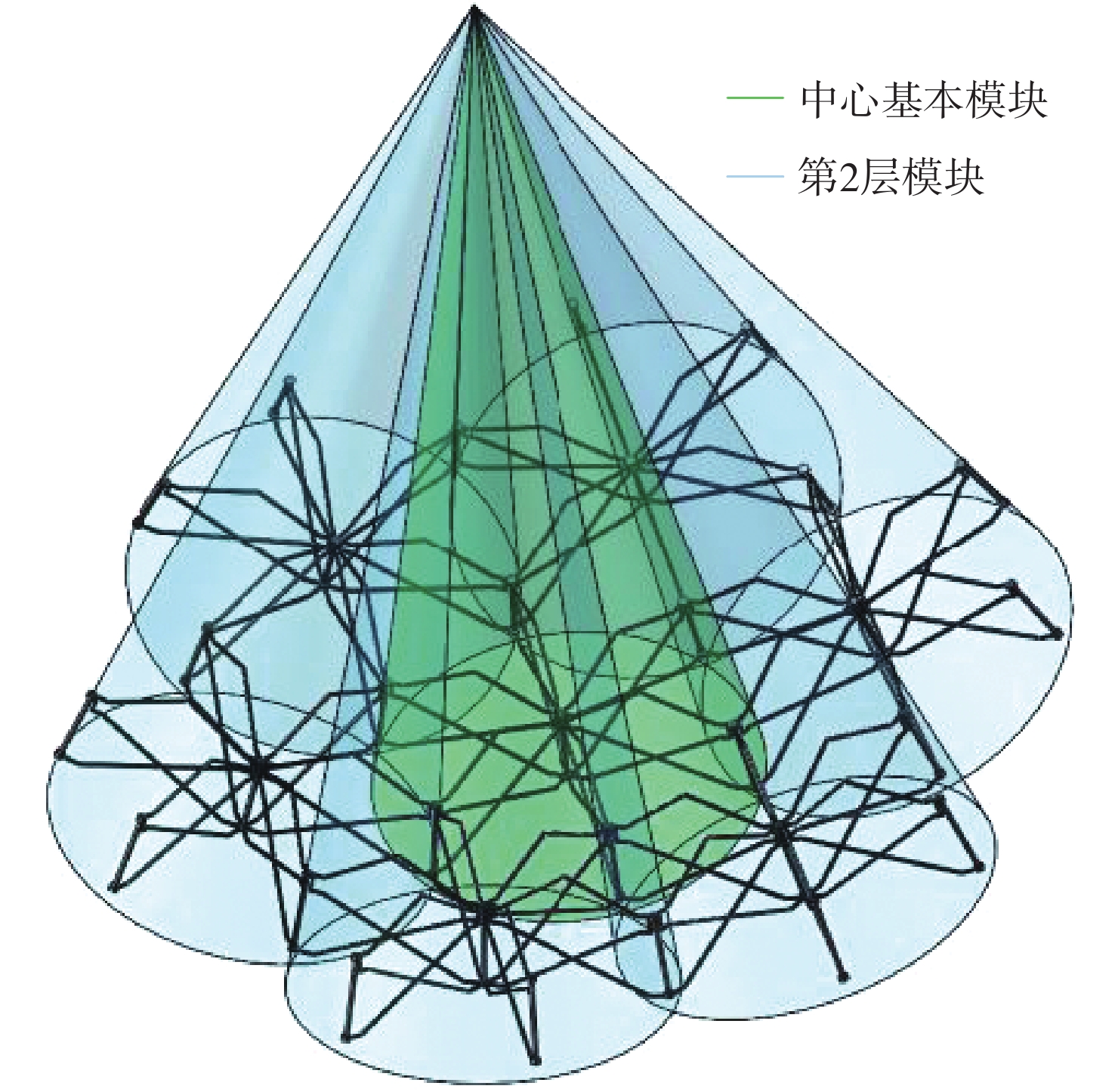

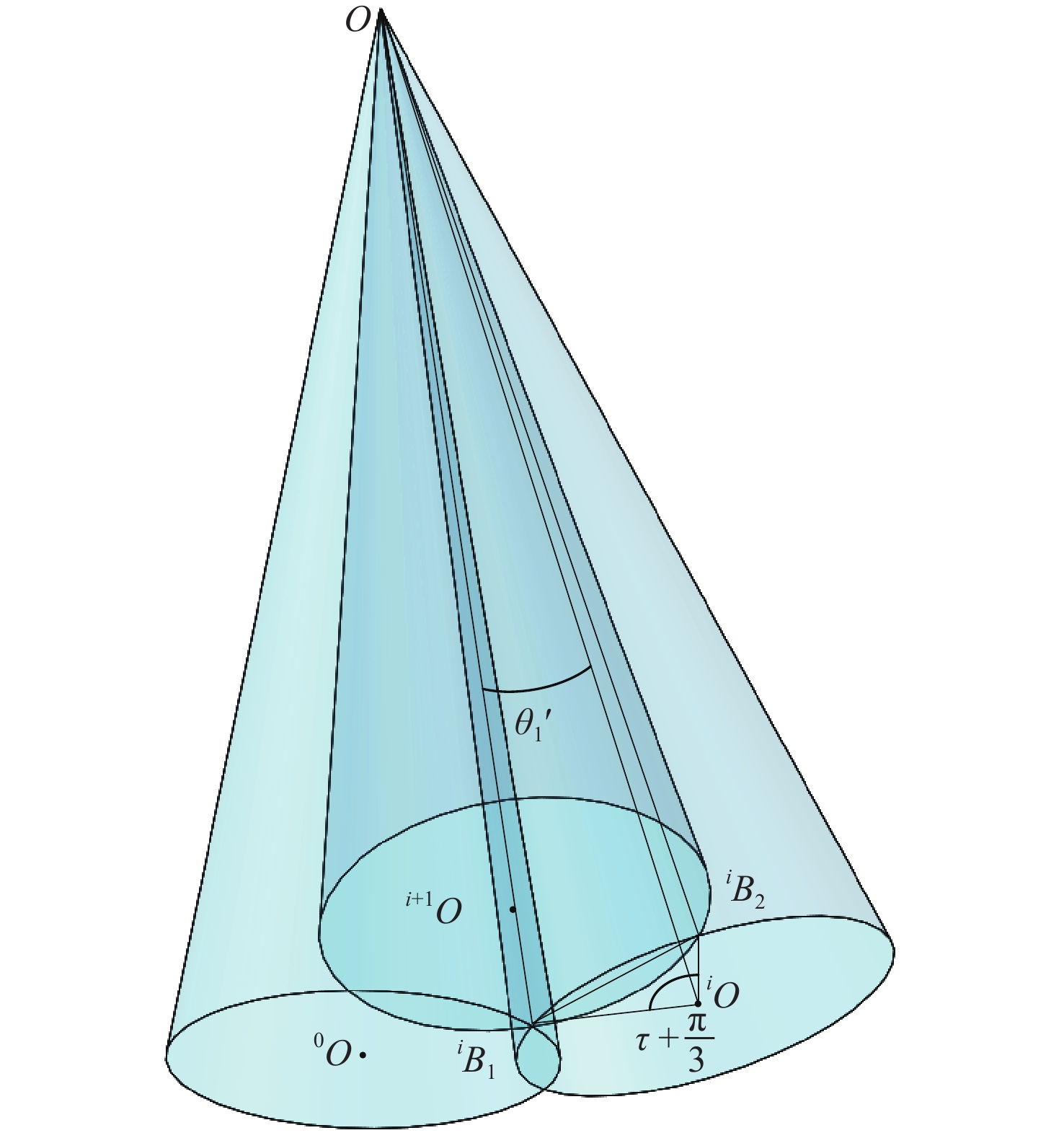

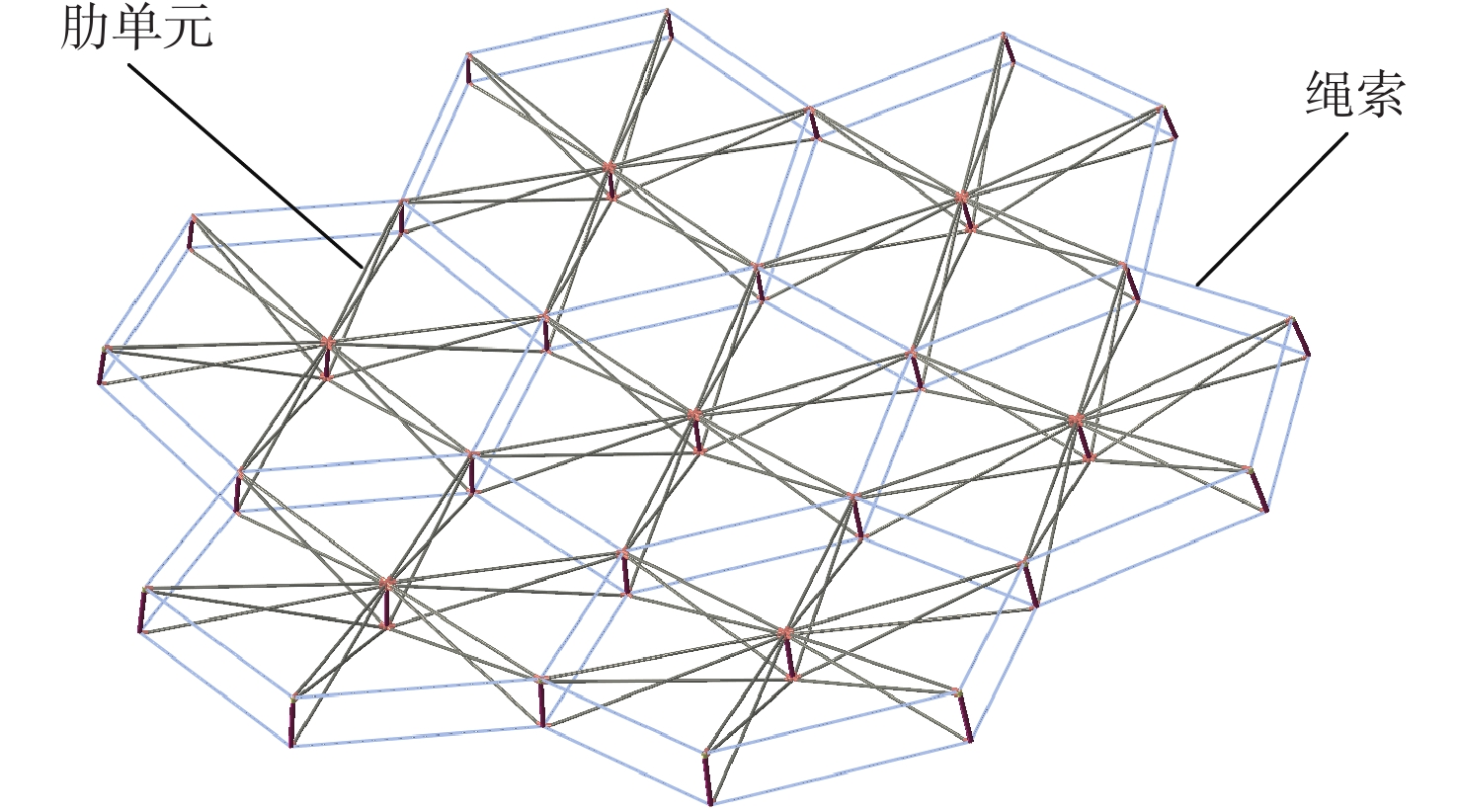

抛物面天线作为卫星上重要的功能组件,是实现遥感测量和无线通信等功能的基础。为了解决模块化抛物面天线折展机构构型设计与刚度匹配困难的问题,提出一种基于剪刀机构的肋单元折展机构的构型方法,并设计了肋单元折展机构。通过运动学分析,验证了该机构通过参数的修改,可以实现同一折展机构展开状态包络不同抛物面拟合球面。给出一种包络锥法实现多模块折展机构展开过程的求解思路,为可转动肋单元的运动副配置提供依据。构建多模块折展机构的有限元模型,以提高固有频率和降低整体质量为优化目标,对肋单元折展机构的构型参数进行优化。采用非劣排序遗传算法完成优化迭代计算,得到具有高刚度、轻量化的折展机构设计参数,在相同条件下优化后调和平均固有频率提高了67.4%,天线整体质量下降了35.2%。

Abstract:As an important functional component of a satellite, a parabolic antenna is a basis for realizing remote sensing measurement and wireless communication. In order to solve the difficulty of configuration design and stiffness matching of modular parabolic antenna deployable mechanism, a configuration method of rib element deployable mechanism based on scissors mechanism is proposed, and the rib element deployable mechanism is designed. Through kinematic analysis, it is verified that the same deployable mechanism can envelope different paraboloid-fitted spheres through the modification of parameters. The configuration of kinematic pairs of rotatable rib parts is based on a concept for solving the unfolding process of the multi-module deployable mechanism by the envelope cone approach.The configuration parameters of the rib element deployable mechanism are improved to increase natural frequency and decrease overall quality, and the finite element model of the multi-module deployable mechanism is built. The non-inferior sorting genetic algorithm is used to complete the optimization iterative calculation, and the design parameters of deployable mechanisms with high structural stiffness and lightweight are obtained. Under the same conditions, the harmonic average natural frequency is increased by 67.4%, and the overall quality of the antenna is reduced by 35.2% after optimization.

-

表 1 杆件与绳索材料参数

Table 1. Material parameters of rods and rope

类型 弹性模量/MPa 密度/(103 kg·m−3) 泊松比 杆件 7×104 2.84 0.3 绳索 1.5×105 7.9 0.3 表 2 杆件与绳索截面参数

Table 2. Section parameters of rods and rope

杆件截

面编号杆件外

圆半径杆件厚

度/mm应用杆件

(见图3)绳索截面

半径/mm绳索截面

张紧压强/MPa1 $ {r_1} $ 1 CD、DE、KI、JM 0.75 113.32 2 $ {r_2} $ 1 OJ、AK、BC、EF、

MG、IH0.75 113.32 3 $ {r_3} $ 12 AB、FG 0.75 113.32 4 $ {r_3} $ 4 OA、GH 0.75 113.32 表 3 固定构型参数

Table 3. Fixed configuration parameters

$ {\theta _1} $/(°) $ R $/mm $ {l}_{C'E'} $/mm $ {r_2} $/mm $ {r_3} $/mm 7.318 9402 20 11 13 表 4 优化数学模型自变量取值范围

Table 4. Range of independent variables of optimization mathematical model

类型 $ {l_{OJ}} $/mm $ {l_{BC}} $/mm $ {l_{AB}} $/mm $ {r_1} $/mm 下界 24 24 20 5 上界 40 40 30 20 表 5 优化数学模型更新后自变量取值范围

Table 5. Range of independent variables after updating the optimization mathematical model

类型 x/mm y/mm lAB/mm r1/mm 下界 0 0 20 5 上界 23.6 1.03 30 20 表 6 优化算法参数

Table 6. Optimization algorithm parameters

种群数 进化代数 交叉概率 交叉指数 变异指数 24 40 0.9 10 20 表 7 优化前后对比

Table 7. Comparison before and after optimization

类型 $ {l_{OJ}} $/mm $ {l_{BC}} $/mm $ {l_{BC}} $/mm $ {l_{BC}} $/mm $ {l_{BC}} $/mm $ {l_{BC}} $/mm 初始值 39 40 25 12.5 1.216 77.565 最优解 39.513 39.782 21.295 7.944 2.036 50.293 -

[1] 陈传志, 董家宇, 陈金宝, 等. 空间大型星载抛物面天线研究进展[J]. 航空学报, 2021, 42(1): 523833.CHEN C Z, DONG J Y, CHEN J B, et al. Large spaceborne parabolic antenna researchp progress[J]. Acta Aeronautica et Astronautica Sinica, 2021, 42(1): 523833(in Chinese). [2] NATORI M C, HIRABAYASHI H, OKUIZUMI N, et al. A structure concept of high precision mesh antenna for space VLBI observation[C]// 43rd AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference. Reston: AIAA, 2002: 1359-1362. [3] YONEZAWA K, HOMMA M. Attitude control on ETS-8 mobile communication satellite with large deployable antennas[C]//21st International Communications Satellite Systems Conference and Exhibit. Reston: AIAA, 2003: 1-5. [4] ONODA J, FU D Y, MINESUGI K. Two-dimensional deployable hexapod truss[J]. Journal of Spacecraft and Rockets, 1996, 33(3): 416-421. doi: 10.2514/3.26776 [5] GUO J W, ZHAO Y S, XU Y D, et al. Design and analysis of truss deployable antenna mechanism based on a novel symmetric hexagonal profile division method[J]. Chinese Journal of Aeronautics, 2021, 34(8): 87-100. doi: 10.1016/j.cja.2020.06.004 [6] XU Y D, CHEN L L, LIU W L, et al. Type synthesis of the deployable mechanisms for the truss antenna using the method of adding constraint chains[J]. Journal of Mechanisms and Robotics, 2018, 10(4): 041002. doi: 10.1115/1.4039341 [7] 刘兆晶. 模块化可展开抛物面天线支撑机构设计与研制[D]. 哈尔滨: 哈尔滨工业大学, 2011: 12-13.LIU Z J. Design and development of modular deployable parabolic antenna support mechanism[D]. Harbin: Harbin Institute of Technology, 2011: 12-13 (in Chinese). [8] 陈向阳, 关富玲. 六棱柱单元可展抛物面天线结构设计[J]. 宇航学报, 2001, 22(1): 75-78.CHEN X Y, GUAN F L. A large deployable hexapod paraboloid antenna[J]. Journal of Astronautics, 2001, 22(1): 75-78(in Chinese). [9] 岳建如, 关富玲, 陈向阳. 大型可展构架式星载抛物面天线结构设计[J]. 浙江大学学报, 2001, 35(3): 238-243.YUE J R, GUAN F L, CHEN X Y. A large deployable hexapod paraboloid antenna[J]. Journal of Zhejiang University, 2001, 35(3): 238-243(in Chinese). [10] HU F, SONG Y P, HUANG Z R, et al. Malleability and optimization of tetrahedral metamorphic element for deployable truss antenna reflector[J]. AIP Advances, 2018, 8(5): 055217. doi: 10.1063/1.5019828 [11] HU F, SONG Y P, XU Y D, et al. Synthesis and optimization of modular deployable truss antenna reflector[J]. Aircraft Engineering and Aerospace Technology, 2018, 90(8): 1288-1294. doi: 10.1108/AEAT-11-2017-0234 [12] 崔吉. 大尺度可展开式抛物面天线机构的设计与展开性能分析[D]. 哈尔滨: 哈尔滨工业大学, 2012: 9-11.CUI J. Design and unfolding performance analysis of largescale deployable parabolic antenna mechanism[D]. Harbin: Harbin Institute of Technology, 2012: 9-11(in Chinese). [13] 余丹敏. 大口径可展抛物面天线支撑桁架结构优化设计及性能研究[D]. 哈尔滨: 哈尔滨工业大学, 2020: 16-24.YU D M. Structural optimization design and performance study of support truss for large-aperture deployable paraboloid antenna[D]. Harbin: Harbin Institute of Technology, 2020: 16-24(in Chinese). [14] 田大可, 郭宏伟, 邓宗全, 等. 多模块构架式空间可展开天线结构参数优化[J]. 华中科技大学学报(自然科学版), 2012, 40(3): 49-53.TIAN D K, GUO H W, DENG Z Q, et al. Optimization of structural parameters for space deployable truss antenna with multi-module[J]. Journal of Huazhong University of Science and Technology (Nature Science), 2012, 40(3): 49-53(in Chinese). [15] 史创. 基于四棱柱可展单元的索杆张拉式天线机构研究[D]. 哈尔滨: 哈尔滨工业大学, 2019: 14-39.SHI C. Research on cable-strut tension antenna mechanism based on quadrangular prism deployable element[D]. Harbin: Harbin Institute of Technology, 2019: 14-39 (in Chinese). [16] 王辉, 何天宇, 都显琛, 等. 单元构架式抛物面天线张紧绳索多层设计方法[J]. 北京航空航天大学学报, 2022, 48(4): 657-664.WANG H, HE T Y, DU X C, et al. Multi-layer design method of tension rope for paraboloid antenna[J]. Journal of Beijing University of Aeronautics and Astronautics, 2022, 48(4): 657-664(in Chinese). [17] 刘荣强, 田大可, 邓宗全, 等. 多模块构架式空间可展开天线背架的模态分析[J]. 北京理工大学学报, 2011, 31(6): 685-690.LIU R Q, TIAN D K, DENG Z Q, et al. Modal analysis of truss structure for deployable truss antenna with multi-module[J]. Transactions of Beijing Institute of Technology, 2011, 31(6): 685-690(in Chinese). [18] MA Z D, KIKUCHI N, CHENG H C. Topological design for vibrating structures[J]. Computer Methods in Applied Mechanics and Engineering, 1995, 121(1-4): 259-280. doi: 10.1016/0045-7825(94)00714-X -

下载:

下载: