-

摘要:

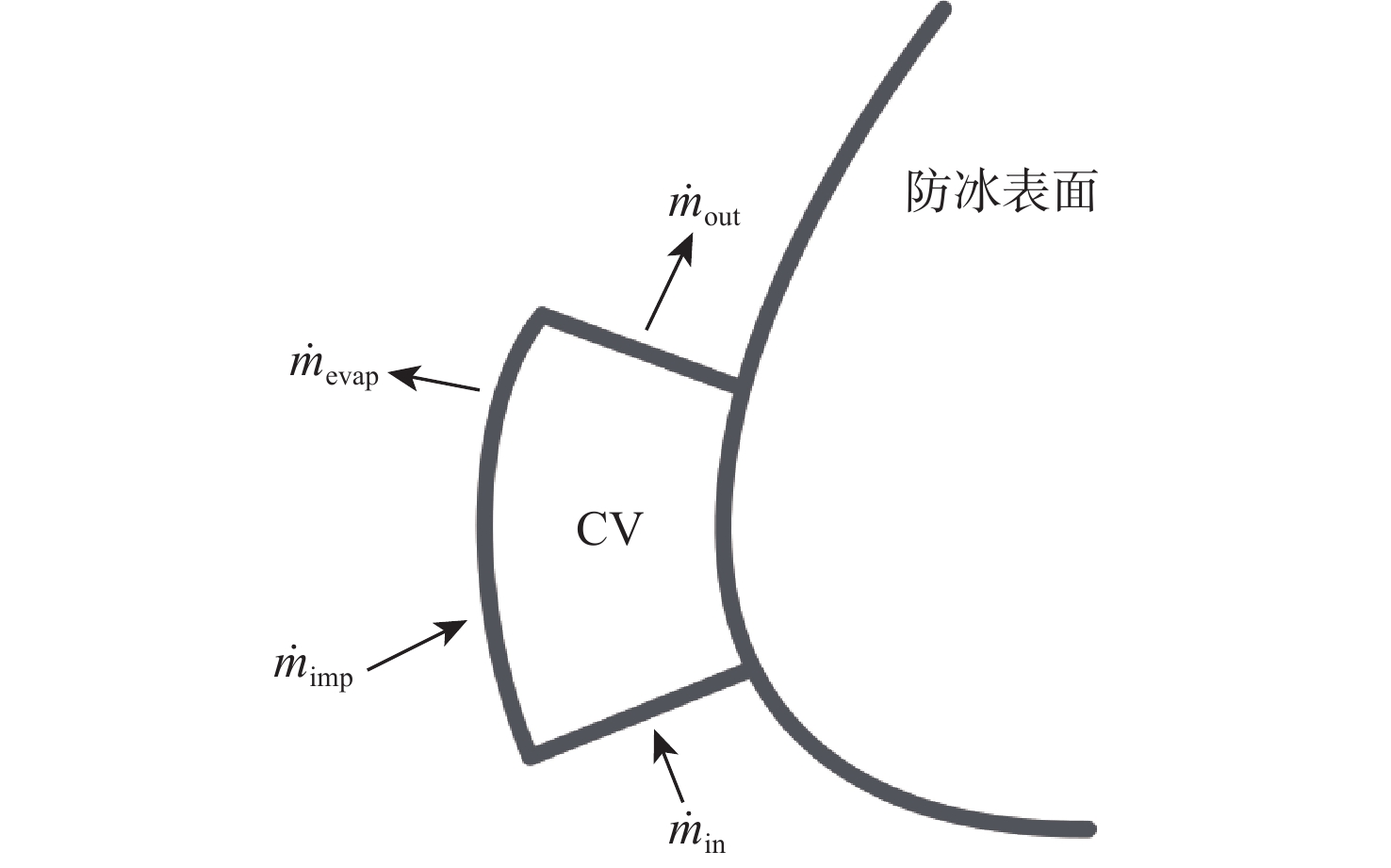

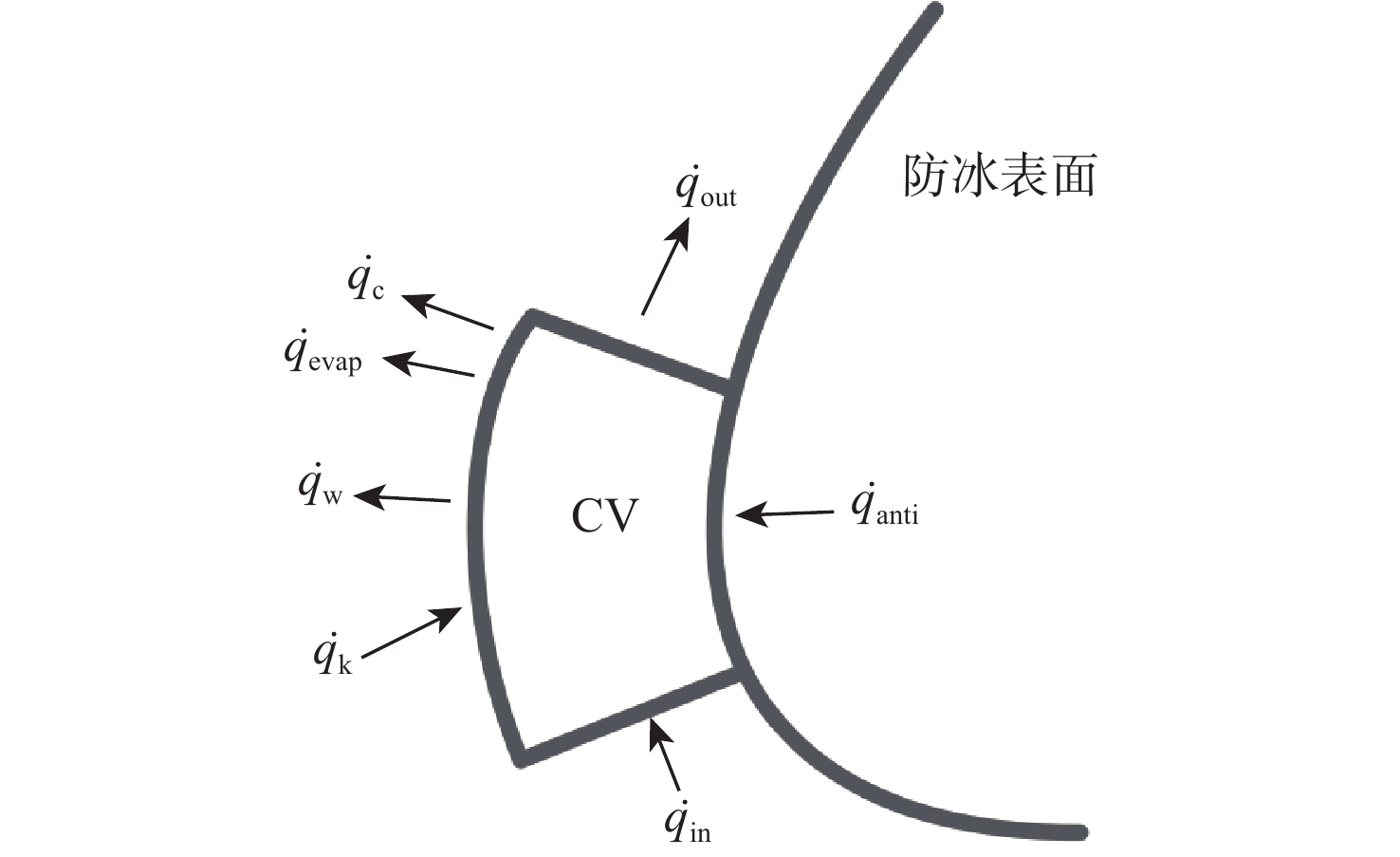

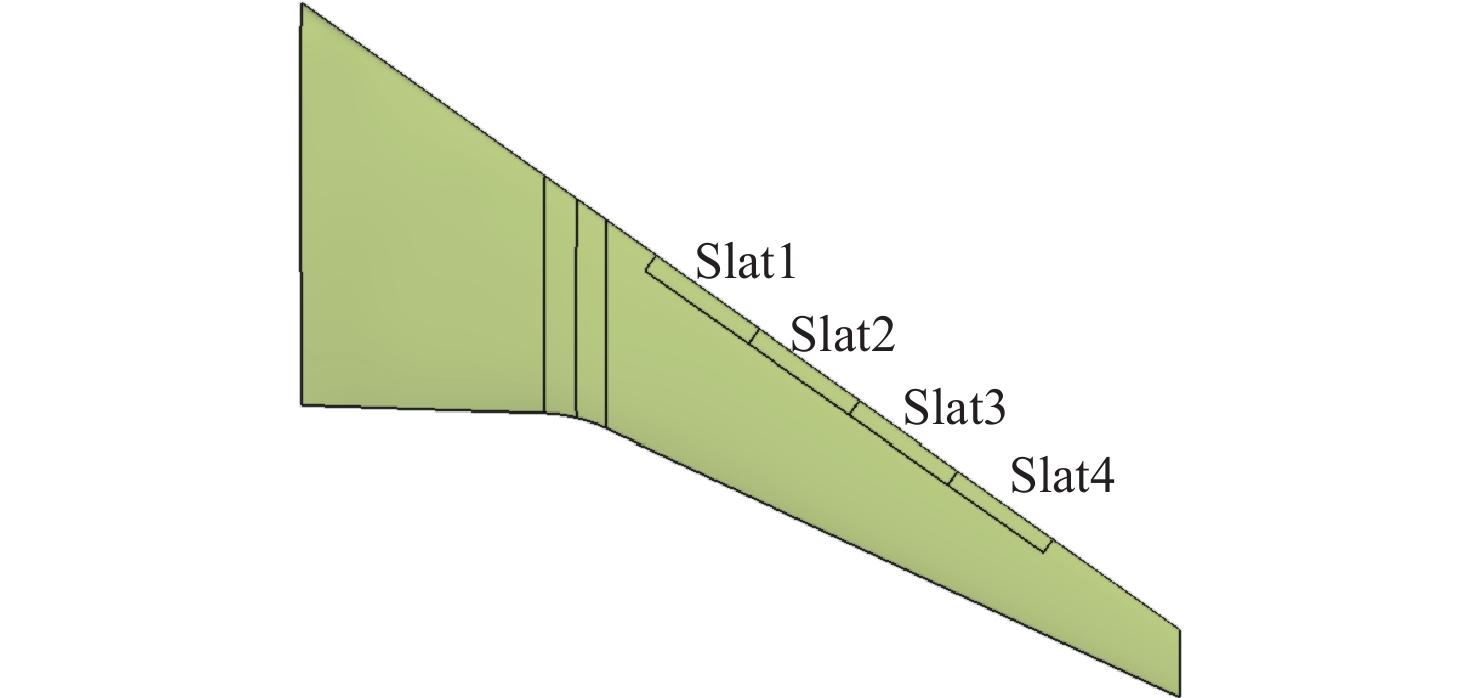

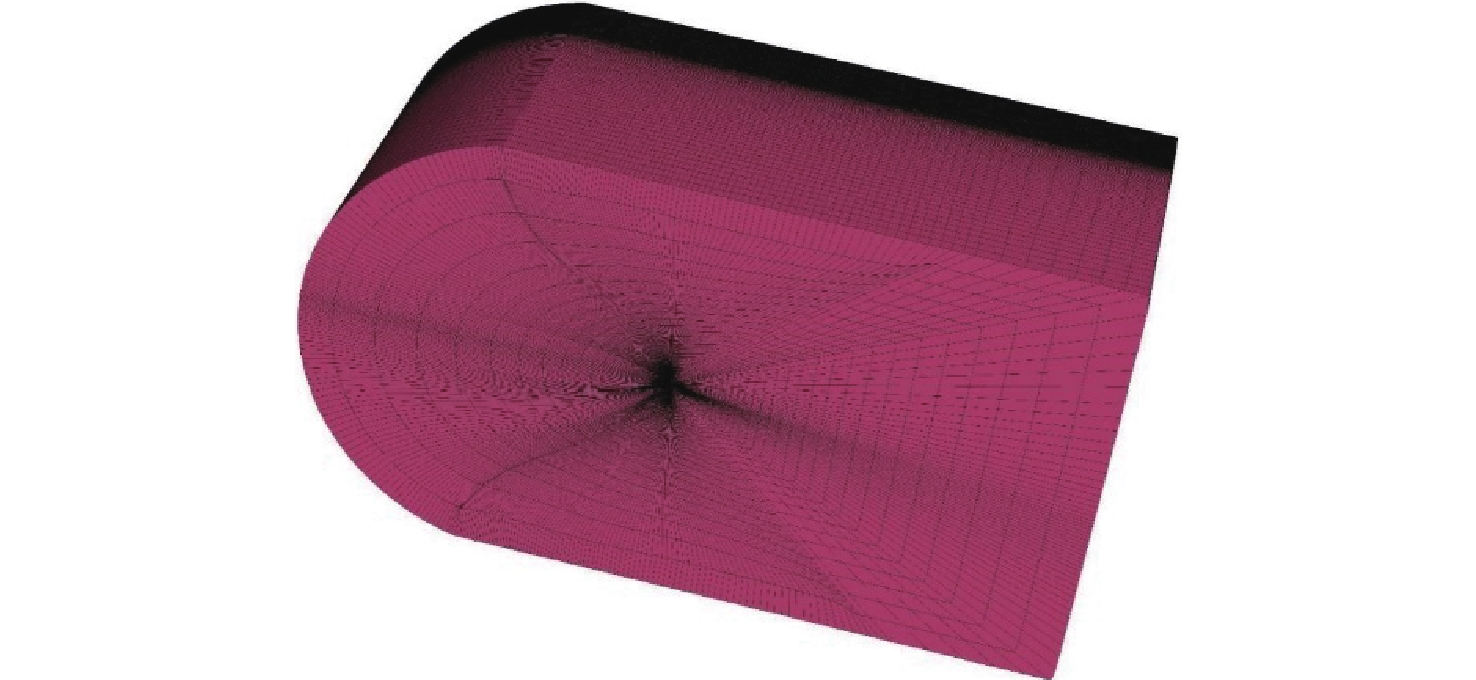

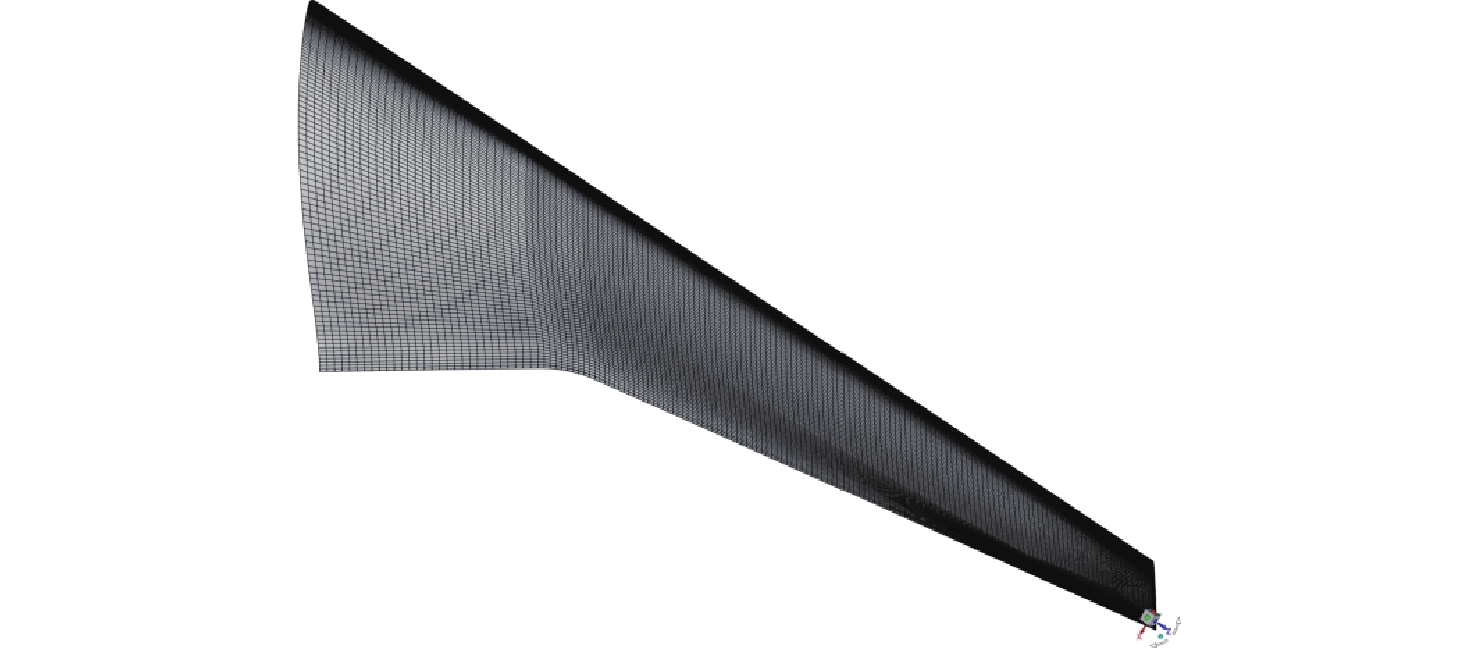

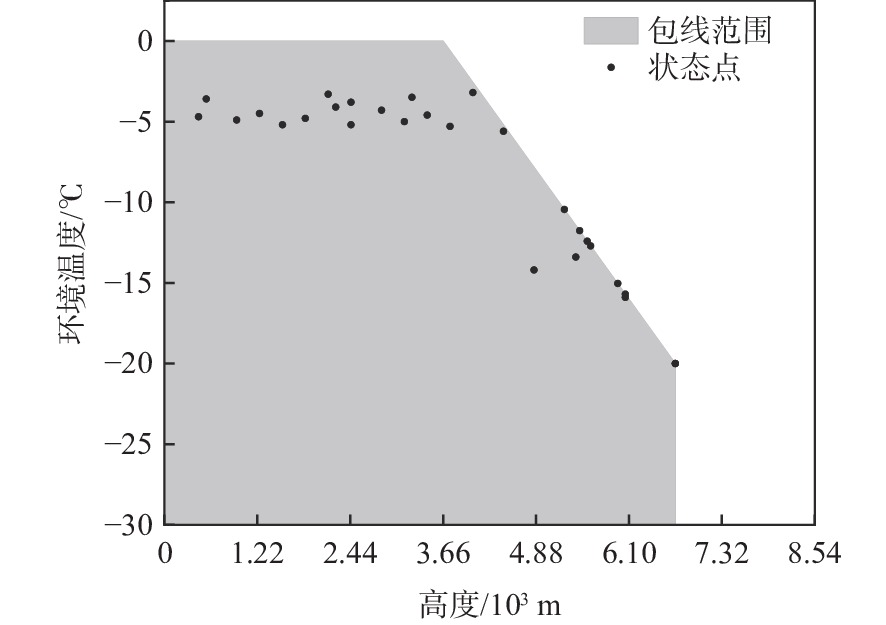

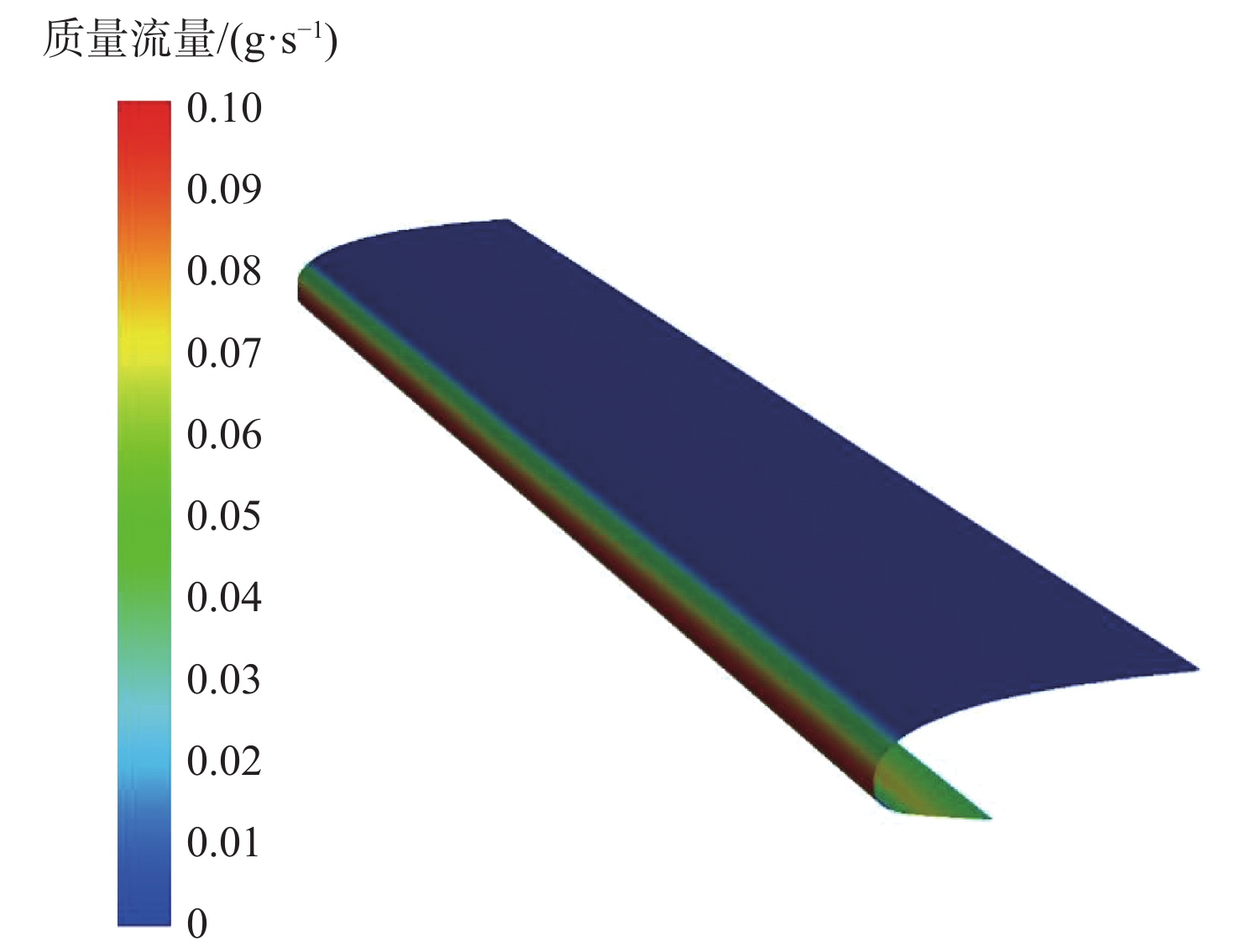

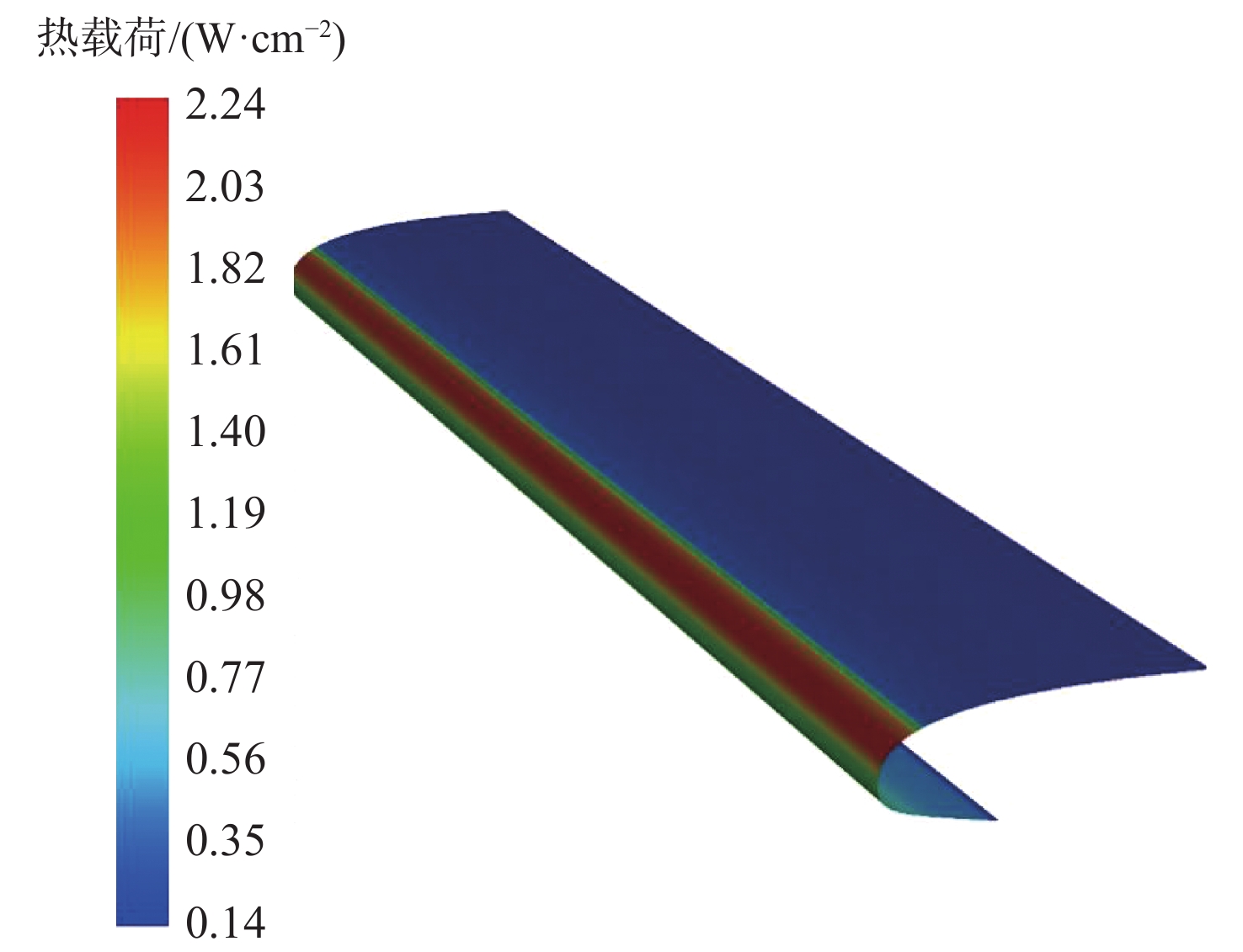

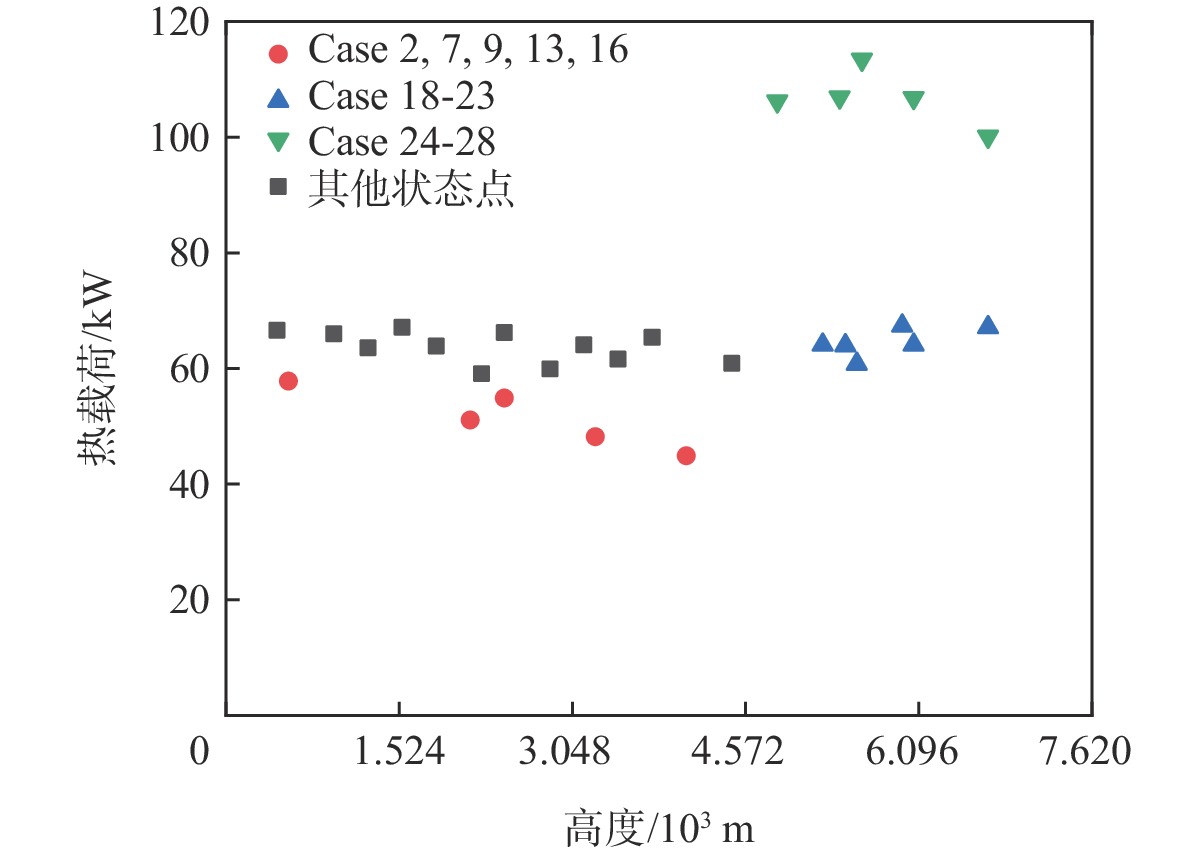

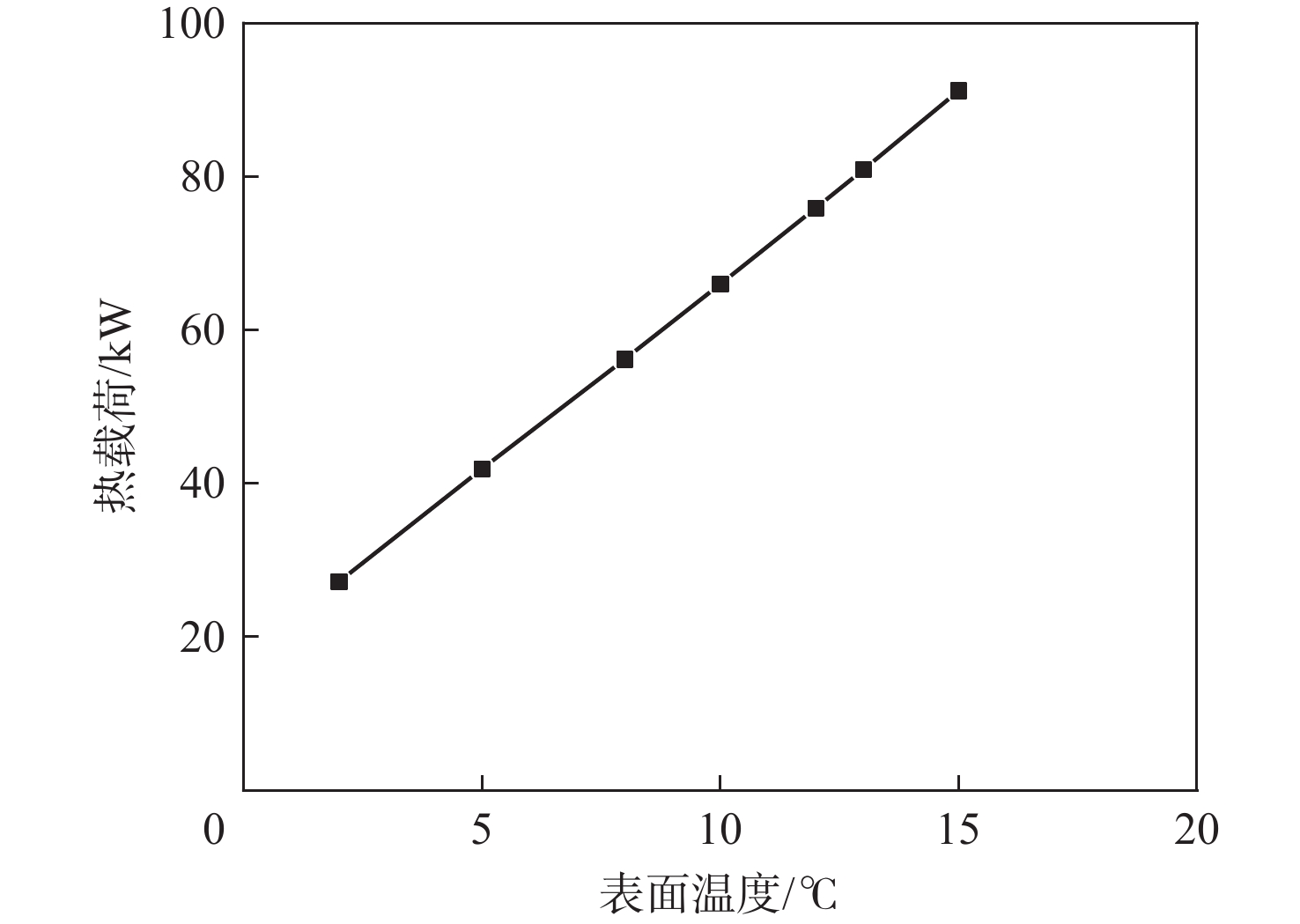

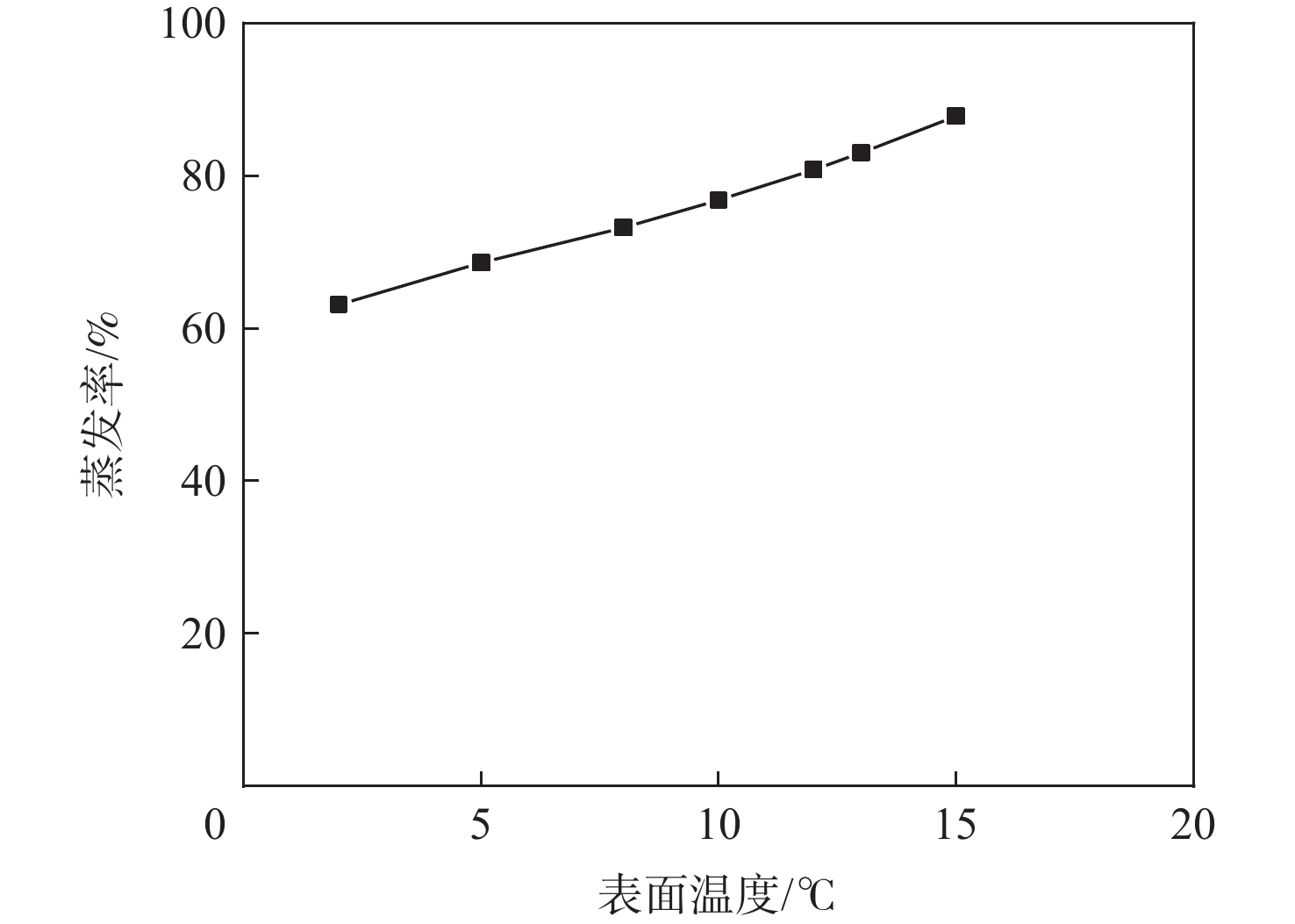

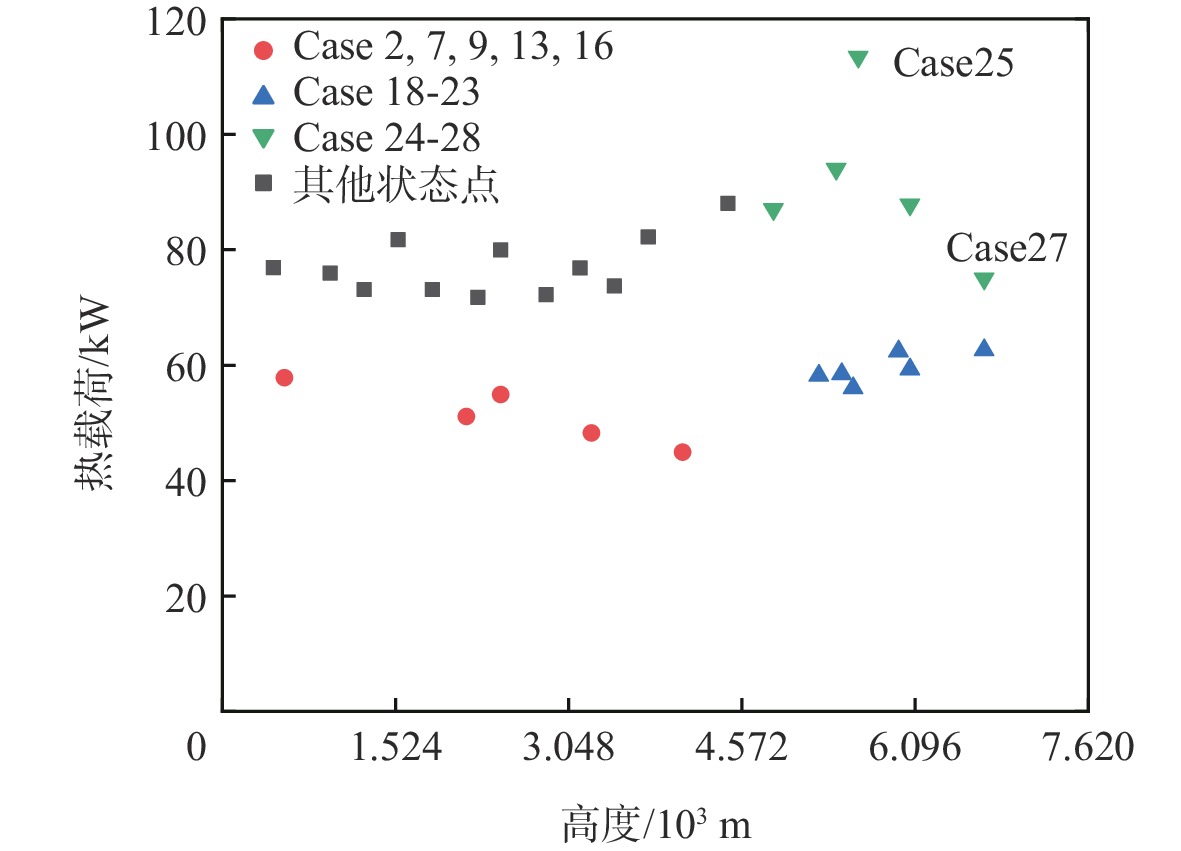

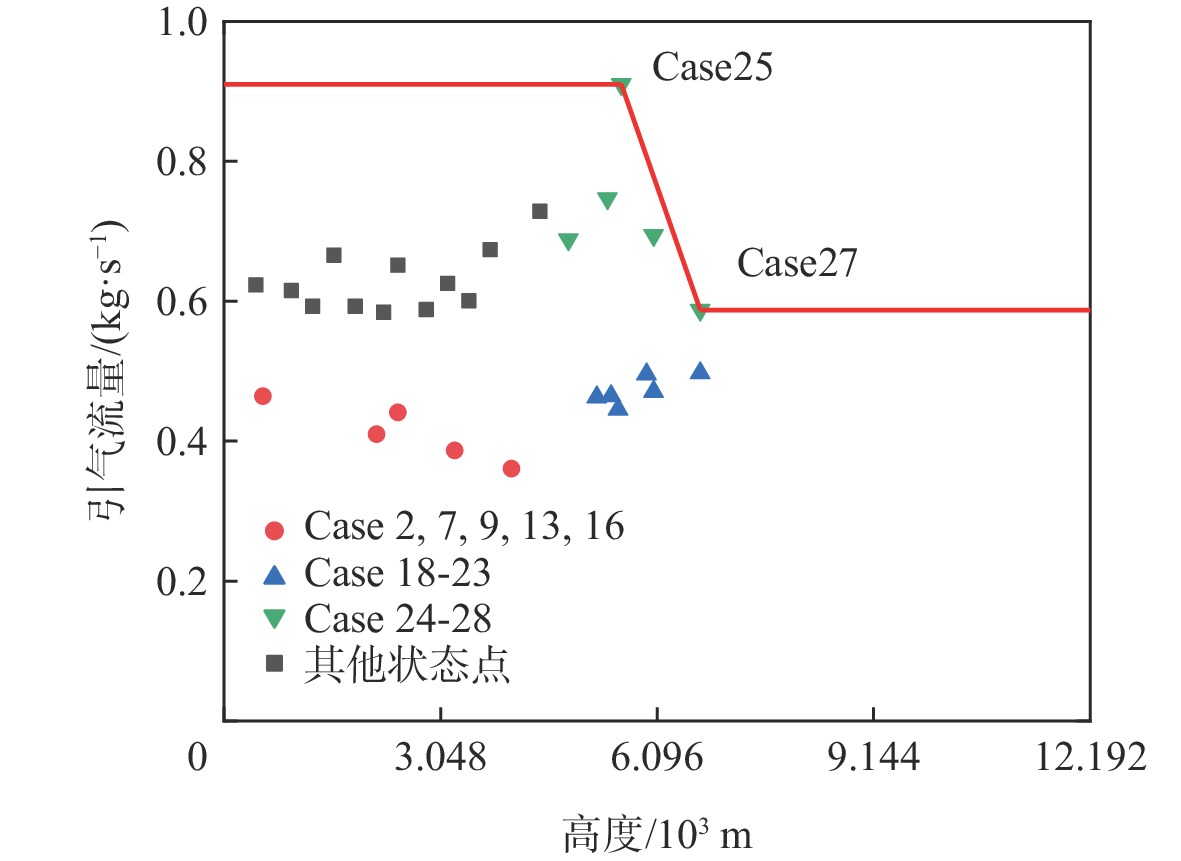

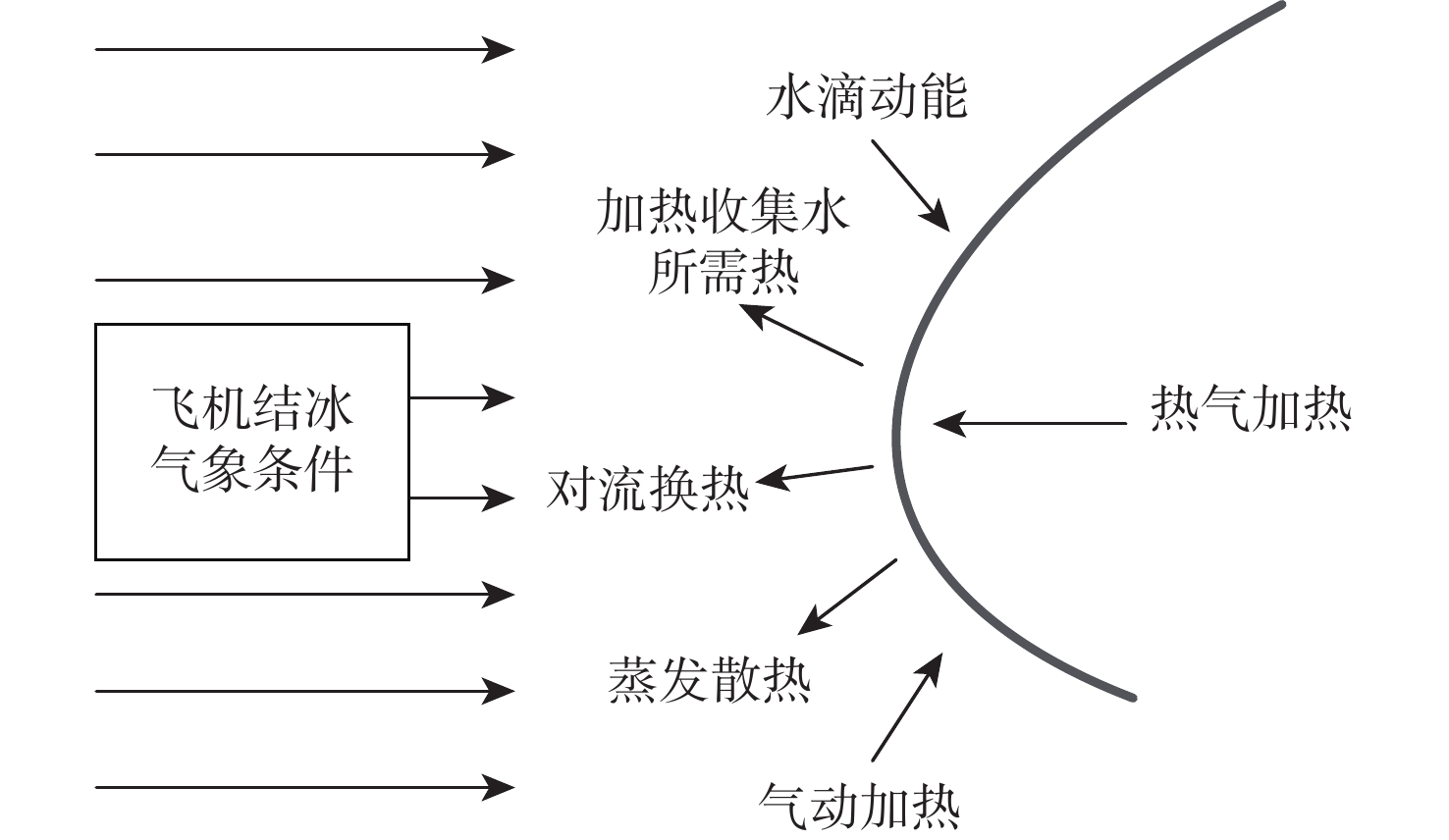

飞机机翼热气防冰系统设计主要包括防冰热载荷计算、笛形管设计、防冰腔设计和防冰系统验证。以某客机机翼为例,在机翼防冰热载荷计算的基础上,分析热载荷及溢流水蒸发率结果,获得防冰引气量需求,进一步提出防冰系统随高度变化的引气流量制度,确定防冰系统严酷状态设计点。采用欧拉-欧拉两相流方法计算水滴运动和表面水滴撞击特性,建立考虑溢流水流动相变的机翼表面的能量平衡方程,计算分析机翼表面的防冰热载荷和溢流水的蒸发率。分析结果表明:同一飞行与结冰气象条件下,在防冰表面温度2~15 ℃范围,热载荷随着表面温度近似以线性增加;为满足防冰要求,高度较低时的状态对应的表面温度设计值较大;引气流量制度随高度变化分为3个阶段:高度小于5594.9 m时,单边流量为0.91 kg/s;高度大于6705.0 m时,单边流量为0.59 kg/s;中间高度对应流量采取两者线性插值方式。研究结果为热气防冰系统的笛行管设计及校核提供支撑。

Abstract:The design of an aircraft wing anti-icing system mainly includes the anti-icing heat load calculation, piccolo tube design, anti-icing cavity design, and anti-icing system verification. This paper introduces the first part of a series study in this respect. With an aircraft wing as an example, the heat load and the runback water evaporation rate are analyzed based on the calculation of the wing anti-icing heat load, and the demand of the bleed air for anti-icing is then obtained. Furthermore, a bleed air schedule for anti-icing varying with altitude is proposed, and severe conditions for the anti-icing system design are determined. The Euler-Euler two-phase flow method is used to calculate the water droplet movement and impingement characteristics on the wing surface. The energy balance equation of the wing surface considering the phase change of runback water is then established, and the anti-icing heat load and evaporation rate of the wing surface are obtained. The results show that the heat load increases approximately linearly with the surface temperature in the range of 2~15 ℃ under the same flight and icing condition. To meet the anti-icing requirements, the design value of the surface temperature corresponding to the lower altitude is increased. The bleed air schedule for anti-icing varying with altitude is divided into three stages: the hot air flow flux is 0.91 kg/s when the altitude is less than 18356 ft, 0.59 kg/s when the altitude is higher than 21998 ft and linearly interpolated when the altitude is in between 18356 and 21998 ft. The results of this study provide valuable insight into the design and verification of the piccolo tube of hot air anti-icing systems.

-

Key words:

- wing /

- hot air anti-icing system /

- heat load /

- design condition /

- bleed air schedule

-

表 1 飞行与结冰条件

Table 1. Flight and icing conditions

编号 高度/m 温度/℃ 迎角/(°) 速度/

(m·s−1)LMVD/

μmSLWC/

(g·m−3)Case1 450 −4.70 4.80 118.10 20 0.54 Case2 550 −3.60 4.90 103.40 20 0.56 Case3 950 −4.90 4.70 121.10 20 0.53 Case4 1250 −4.50 4.80 116.10 20 0.54 Case5 1550 −5.20 4.70 124.60 20 0.53 Case6 1850 −4.80 4.80 119.50 20 0.53 Case7 2150 −3.30 6.30 99.60 20 0.56 Case8 2250 −4.10 4.80 110.50 20 0.55 Case9 2450 −3.80 6.20 106.70 20 0.55 Case10 2450 −5.20 4.70 125.10 20 0.53 Case11 2850 −4.30 4.80 113.90 20 0.54 Case12 3150 −5.00 4.80 121.80 20 0.53 Case13 3250 −3.50 8.00 102.90 20 0.56 Case14 3450 −4.60 4.80 117.50 20 0.54 Case15 3750 −5.30 4.70 125.70 20 0.52 Case16 4050 −3.20 7.80 97.30 20 0.57 Case17 4450 −5.60 4.40 143.00 24 0.42 Case18 5250 −10.45 8.00 116.90 20 0.42 Case19 5450 −11.76 7.80 112.20 20 0.39 Case20 5550 −12.42 7.90 105.00 20 0.38 Case21 5950 −15.04 8.30 118.40 20 0.32 Case22 6050 −15.70 7.80 107.50 20 0.30 Case23 6705 −20.00 9.00 119.10 20 0.21 Case24 4850 −14.20 0.80 206.00 20 0.34 Case25 5595 −12.71 1.10 200.80 22 0.37 Case26 6050 −15.90 0.70 218.00 20 0.30 Case27 6705 −20.00 0.70 225.00 20 0.21 Case28 5400 −13.40 0.80 211.60 21 0.34 注:LMVD为平均水滴尺寸。 表 2 表面温度10℃时热载荷和蒸发率结果

Table 2. Results of thermal load and evaporation rate at surface temperature of 10 ℃

编号 高度/ft 表面温度/℃ 热载荷/kW 蒸发率/% Case1 450 10 66.6 78.5 Case2 550 10 57.8 80.8 Case3 950 10 66.0 76.8 Case4 1250 10 63.6 77.8 Case5 1550 10 67.1 75.6 Case6 1850 10 63.9 76.9 Case7 2150 10 51.1 88.5 Case8 2250 10 59.1 77.7 Case9 2450 10 54.9 86.0 Case10 2450 10 66.2 74.6 Case11 2850 10 59.9 76.7 Case12 3150 10 64.1 75.4 Case13 3250 10 48.2 97.5 Case14 3450 10 61.6 75.6 Case15 3750 10 65.4 73.7 Case16 4050 10 44.9 97.5 Case17 4450 10 60.9 69.5 Case18 5250 10 64.1 97.9 Case19 5450 10 64.0 99.0 Case20 5550 10 60.8 99.5 Case21 5950 10 67.4 99.6 Case22 6050 10 64.1 99.6 Case23 6705 10 67.1 99.8 Case24 4850 10 106.2 87.7 Case25 5595 10 113.4 80.4 Case26 6050 10 106.8 91.0 Case27 6705 10 100.1 99.7 Case28 5400 10 106.9 84.7 注:上表面后缘无溢流水流出。 表 3 不同表面温度时的热载荷和蒸发率结果(Case3)

Table 3. Results of heatload and evaporation rate at different surface temperatures (Case3)

表面温度/℃ 热载荷/kW 蒸发率/% 备注 2 27.2 63.1 上表面有少量溢流水流出 5 41.9 68.6 上表面无溢流水流出 8 56.2 73.2 上表面无溢流水流出 10 66.0 76.8 上表面无溢流水流出 12 75.9 80.8 上表面无溢流水流出 13 80.9 83.0 上表面无溢流水流出 15 91.2 87.8 上表面无溢流水流出 表 4 满足防冰需求的表面温度设计值

Table 4. Design value of surface temperature to meet anti-icing requirements

编号 高度/m 表面温度/℃ 热载荷/kW 蒸发率/% Case1 450 12 76.9 82.8 Case2 550 10 57.8 80.8 Case3 950 12 75.9 80.8 Case4 1250 12 73.1 81.9 Case5 1550 13 81.7 81.4 Case6 1850 12 73.1 80.8 Case7 2150 10 51.1 88.5 Case8 2250 13 71.7 83.9 Case9 2450 10 54.9 86.0 Case10 2450 13 79.9 80.2 Case11 2850 13 72.2 82.7 Case12 3150 13 76.8 80.9 Case13 3250 10 48.2 97.5 Case14 3450 13 73.7 81.2 Case15 3750 14 82.2 81.1 Case16 4050 10 44.9 97.5 Case17 4450 16 88.0 82.4 Case18 5250 8 58.2 95.8 Case19 5450 8 58.5 97.2 Case20 5550 8 56.0 99.4 Case21 5950 8 62.4 99.4 Case22 6050 8 59.3 99.6 Case23 6705 8 62.6 99.8 Case24 4850 7 87.0 81.0 Case25 5595 10 113.4 80.4 Case26 6050 7 87.8 83.6 Case27 6705 5 75.0 91.1 Case28 5400 8 94.0 80.5 -

[1] 裘燮纲, 韩凤华. 飞机防冰系统[M]. 北京: 航空专业教材编审组, 1985.QIU X G, HAN F H. Aircraft anti-icing system [M]. Beijing: Editing Group of Aviation Teaching Materials, 1985(in Chinese). [2] DU Y X, GUI Y W, XIAO C H, et al. Investigation on heat transfer characteristics of aircraft icing including runback water[J]. International Journal of Heat and Mass Transfer, 2010, 53(19-20): 3702-3707. doi: 10.1016/j.ijheatmasstransfer.2010.04.021 [3] OLSEN W, SHAW R, NEWTON J. Ice shapes and the resulting drag increase for a NACA 0012 airfoil[C]//Proceedings of the 22nd Aerospace Sciences Meeting. Reston: AIAA, 1984. [4] CORTINAS J V Jr, BERNSTEIN B C, ROBBINS C C, et al. An analysis of freezing rain, freezing drizzle, and ice pellets across the United States and Canada: 1976–90[J]. Weather and Forecasting, 2004, 19(2): 377-390. doi: 10.1175/1520-0434(2004)019<0377:AAOFRF>2.0.CO;2 [5] JONES S, REVELEY M, EVANS J K, et al. Subsonic aircraft safety icing study: NASA/TM-2008-215107 [R]. Washington, D. C.: NASA, 2008 [6] 郁嘉, 卜雪琴, 林贵平, 等. 非结冰气象条件下机翼热气防冰系统数值模拟[J]. 空气动力学学报, 2016, 34(5): 562-567.YU J, BU X Q, LIN G P, et al. Numerical simulation of a wing hot air anti-icing system in dry air conditions[J]. Acta Aerodynamica Sinica, 2016, 34(5): 562-567(in Chinese). [7] PAPADAKIS M, WONG S H, YEONG H W, et al. Icing tests of a wing model with a hot-air ice protection system[C]//Proceedings of the AIAA Atmospheric and Space Environments Conference. Reston: AIAA, 2010. [8] 卜雪琴, 郁嘉, 林贵平, 等. 机翼热气防冰系统设计[J]. 北京航空航天大学学报, 2010, 36(8): 927-930.BU X Q, YU J, LIN G P, et al. Investigation of the design of wing hot-air anti-icing system[J]. Journal of Beijing University of Aeronautics and Astronautics, 2010, 36(8): 927-930(in Chinese). [9] ROSERO J A, ORTEGA J A, ALDABAS E, et al. Moving towards a more electric aircraft[J]. IEEE Aerospace and Electronic Systems Magazine, 2007, 22(3): 3-9. doi: 10.1109/MAES.2007.340500 [10] DOMINGOS R, PAPADAKIS M, ZAMORA A. Computational methodology for bleed air ice protection system parametric analysis[C]//Proceedings of the AIAA Atmospheric and Space Environments Conference. Reston: AIAA, 2010. [11] 倪章松, 刘森云, 张军, 等. 环境参数对飞机防冰热载荷的影响规律[J]. 航空动力学报, 2021, 36(1): 8-14.NI Z S, LIU S Y, ZHANG J, et al. Influnce of environment parameters on anti-icing heat load for aircraft[J]. Journal of Aerospace Power, 2021, 36(1): 8-14(in Chinese). [12] 管宁. 三维机翼防冰热载荷的数值模拟[D]. 南京: 南京航空航天大学, 2007.GUAN N. Numerical simulation of anti-icing thermal loads on a 3D airfoil[D]. Nanjing: Nanjing University of Aeronautics and Astronautics, 2007 (in Chinese). [13] 卜雪琴, 郁嘉, 林贵平. 一种热气防冰系统的数值仿真[J]. 计算机仿真, 2010, 27(9): 40-43.BU X Q, YU J, LIN G P. Numerical simulation of an airfoil hot-air anti-icing system[J]. Computer Simulation, 2010, 27(9): 40-43(in Chinese). [14] 赵勇, 杨新亮. 飞机水平尾翼水滴撞击特性及防冰热载荷计算[J]. 航空动力学报, 2012, 27(11): 2401-2407.ZHAO Y, YANG X L. Impingement characteristics and anti-icing heat load calculation of certain tailplane[J]. Journal of Aerospace Power, 2012, 27(11): 2401-2407(in Chinese). [15] 林贵平, 卜雪琴, 申晓斌. 飞机结冰与防冰技术[M]. 北京: 北京航空航天大学出版社, 2016.LIN G P, BU X Q, SHEN X B. Aircraft icing and anti-icing technology[M]. Beijing: Beijing University of Aeronautics & Astronautics Press, 2016 (in Chinese). [16] MESSINGER B L. Equilibrium temperature of an unheated icing surface as a function of air speed[J]. Journal of the Aeronautical Sciences, 1953, 20(1): 29-42. doi: 10.2514/8.2520 -

下载:

下载: