-

摘要:

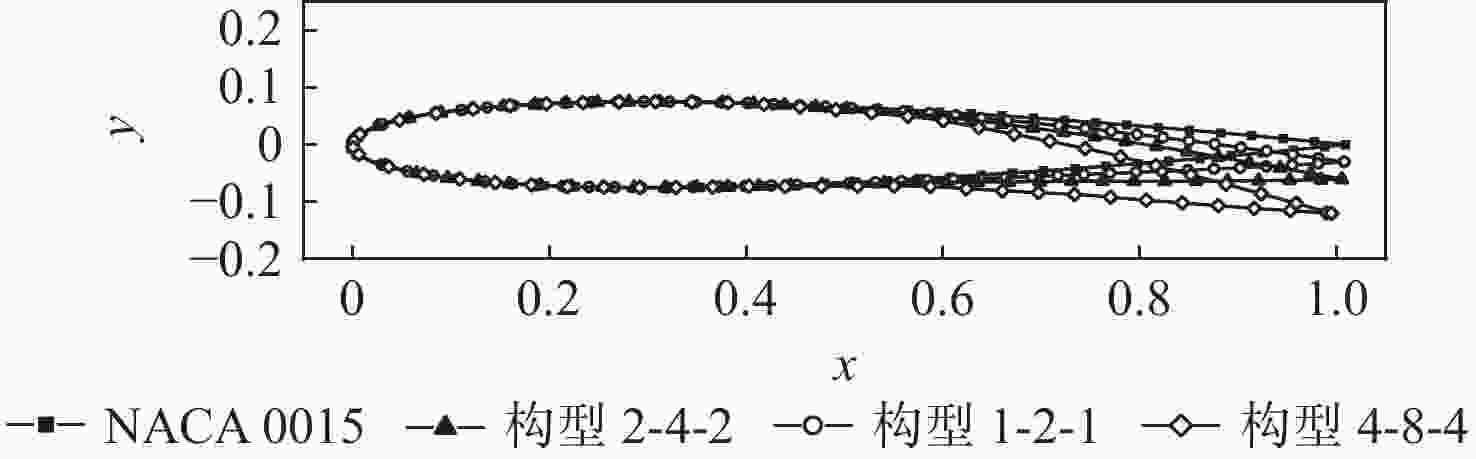

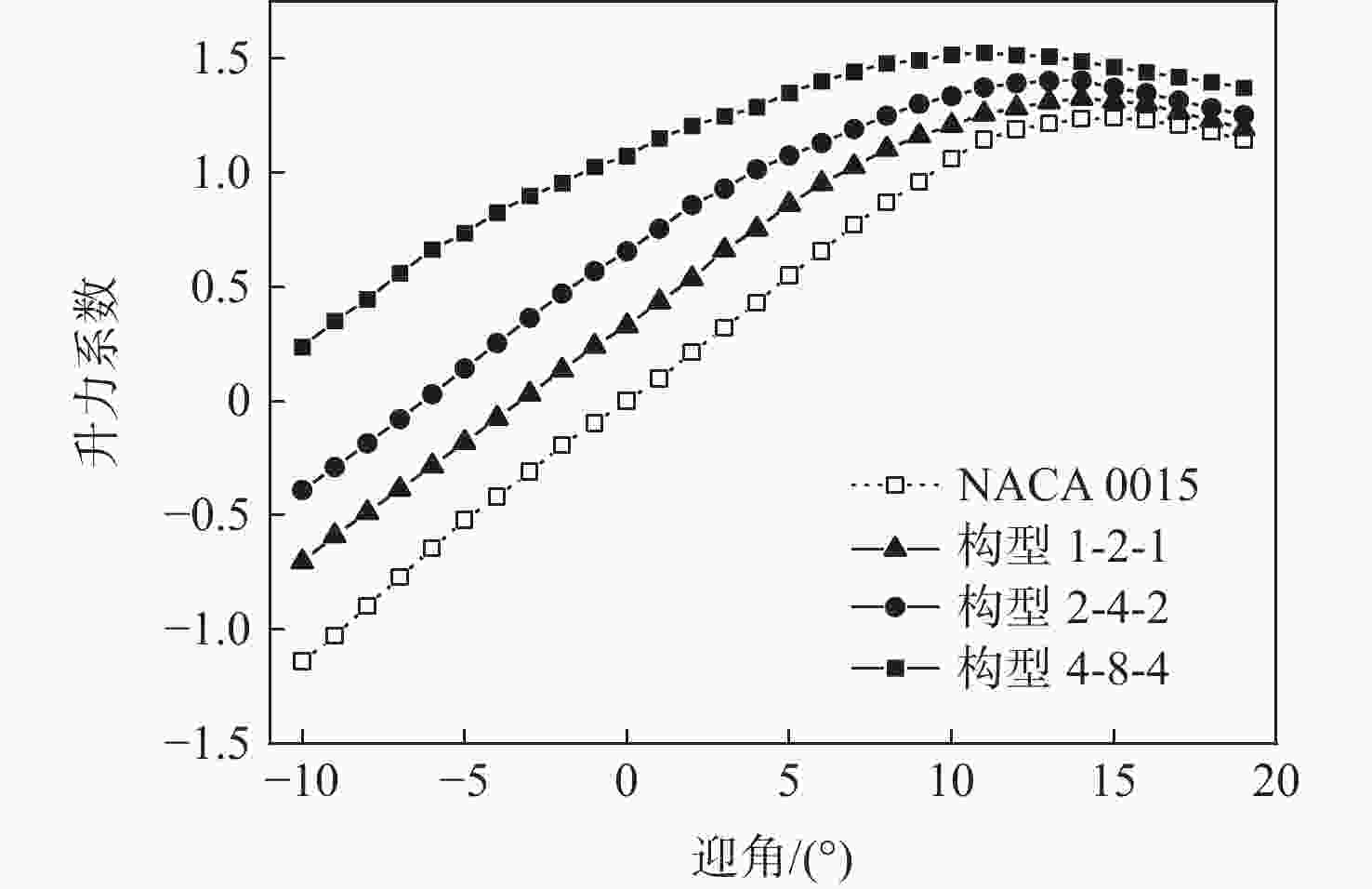

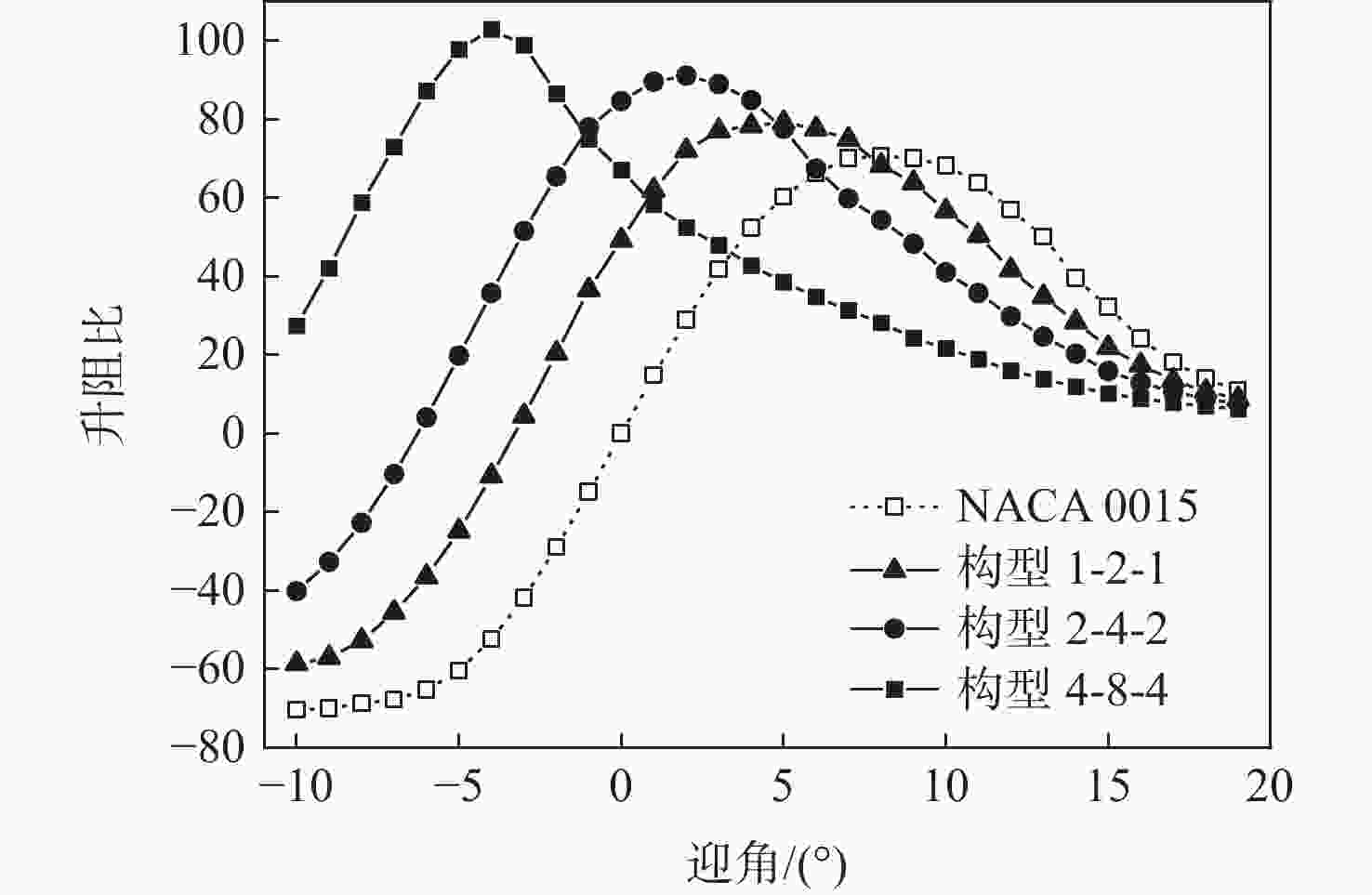

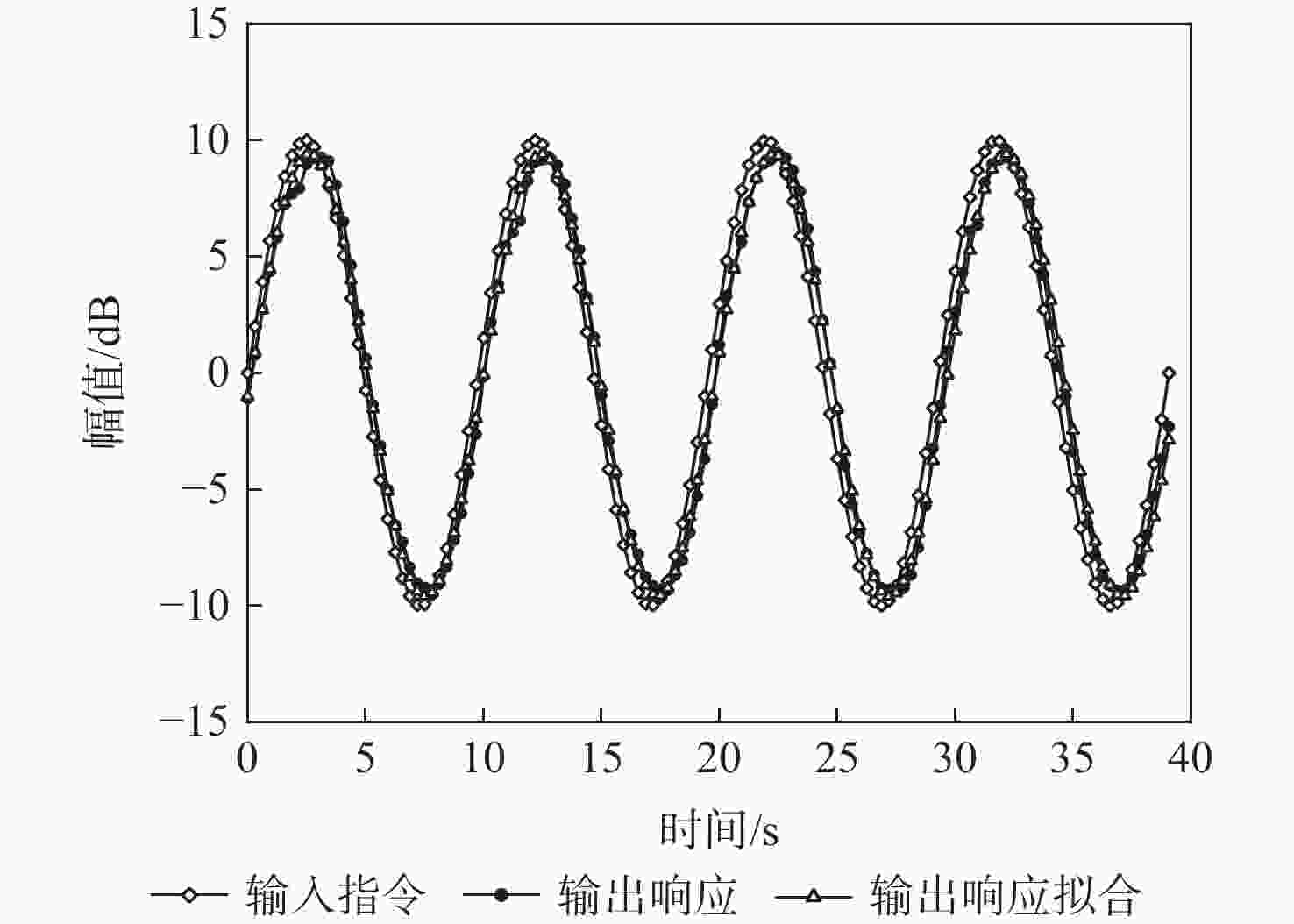

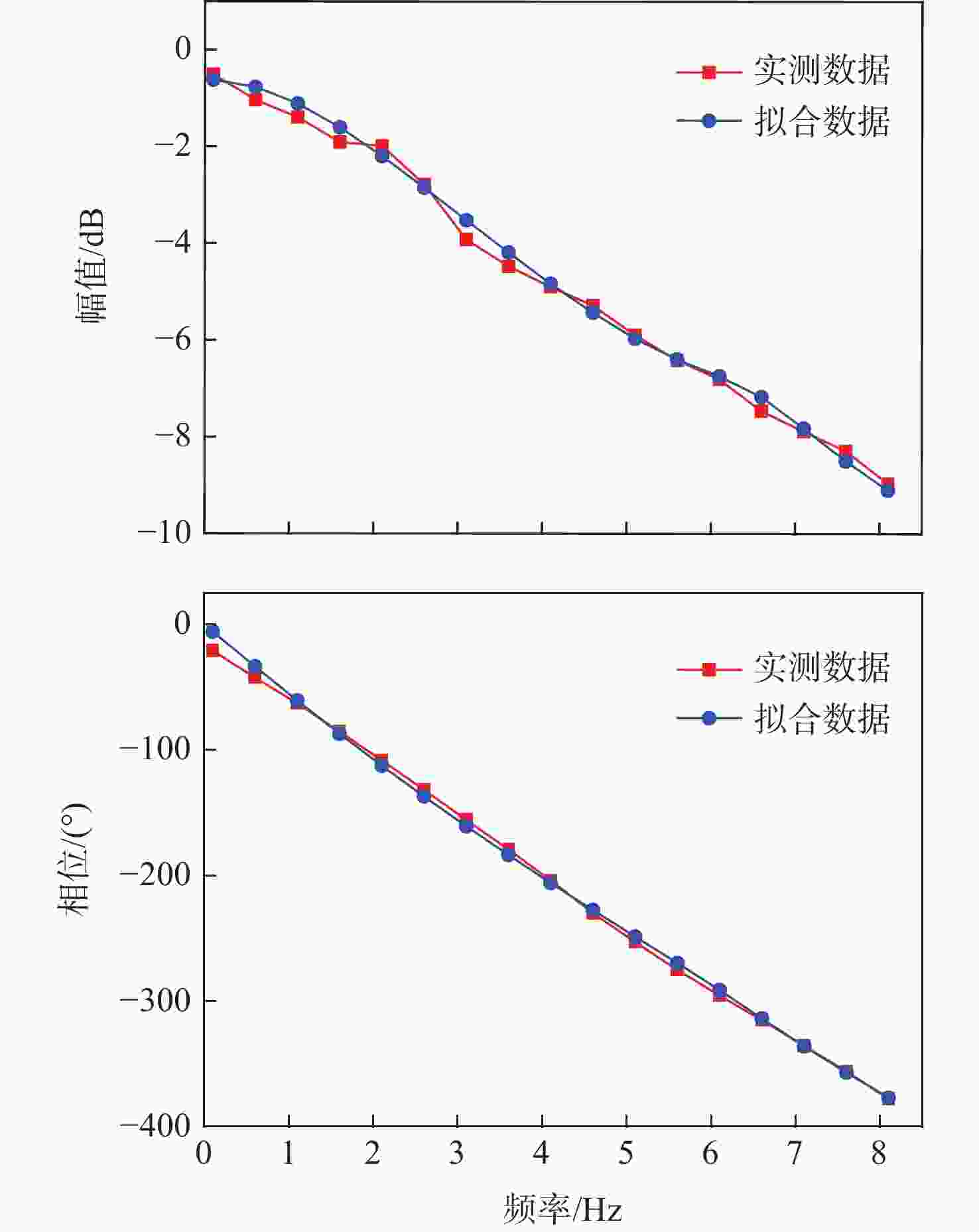

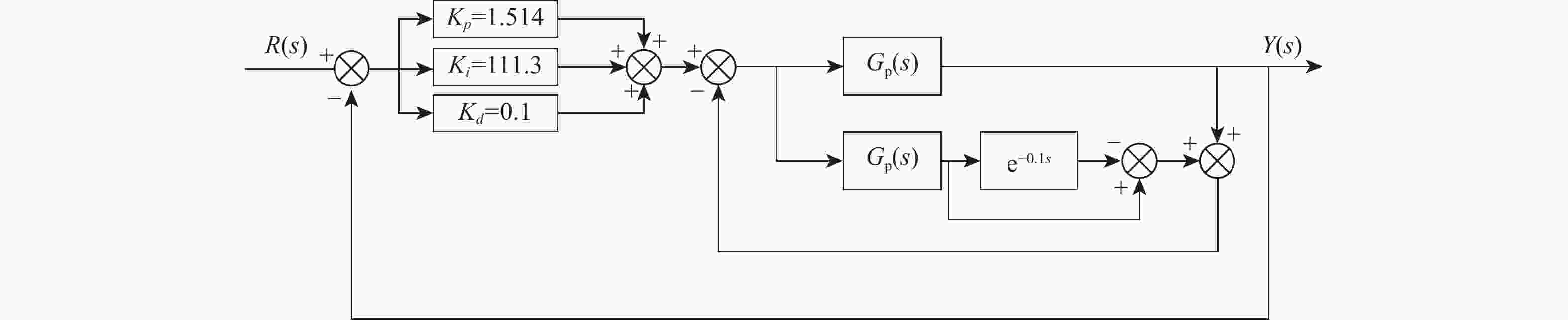

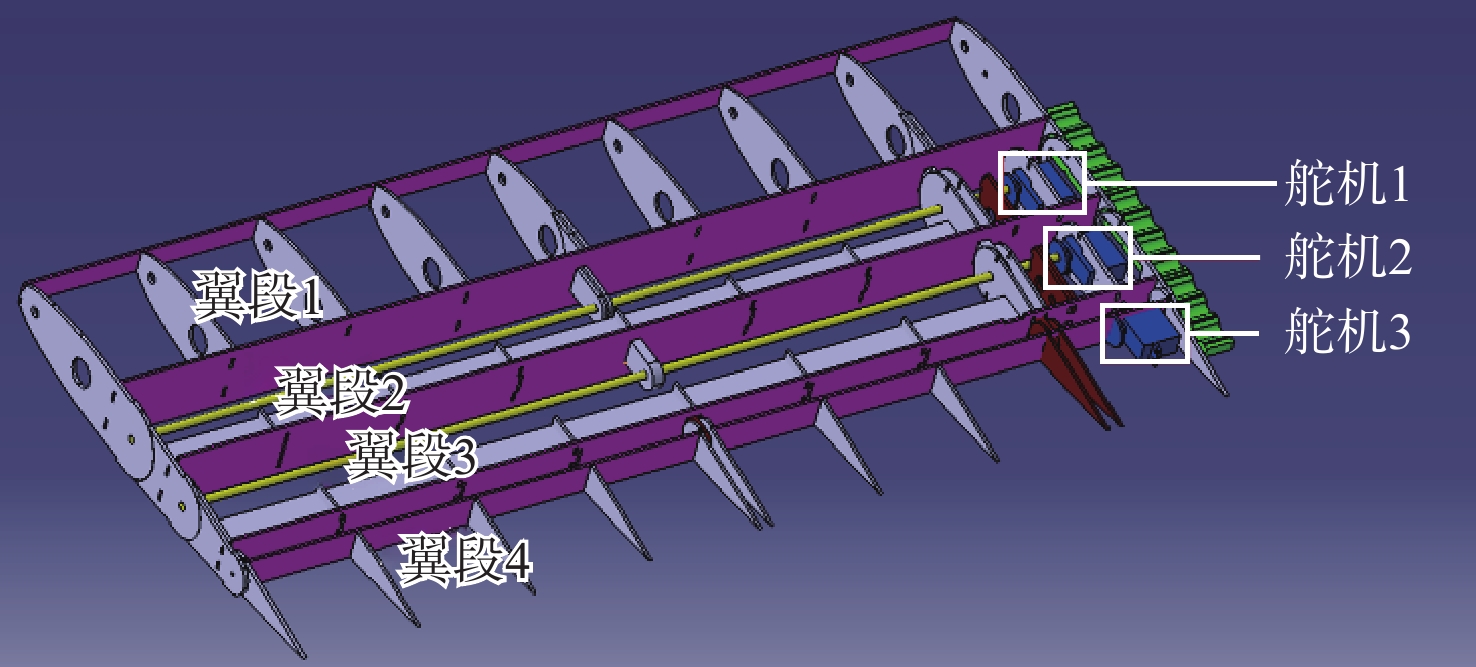

针对固定翼飞行器无法在复杂多变飞行环境中始终处于最优气动构型的缺陷,提出能够根据飞行环境参数自适应变形的机翼设计理念。设计了一款通过刚性翼盒偏转实现变形功能的机翼,通过面元法耦合XFOIL黏性修正器进行气动模型仿真计算,对该机翼的气动特性进行分析;并在此基础上设计变形机翼舵机风洞试验平台,搭建测试采集系统,对航模舵机驱动变形的气动伺服系统进行低速风洞试验,通过子空间辨识法获得了气动伺服系统的数学模型,并通过比例积分微分(PID)控制结合Smith预估控制算法的方式进行舵机补偿控制。最后根据得到的变形机翼气动数据和舵机频响特性,以优化气动性能为目标设计了一款基于舵机补偿的自适应变形机翼反馈控制系统,可以实现在复杂环境中的舵机补偿和自适应变形,对后续变形机翼的设计提供了参考。

Abstract:Aiming at the defect that the fixed-wing aircraft can not always be in the optimal aerodynamic configuration in the complex and changeable flight environment, the wing design concept which can adapt to the deformation according to the flight environment parameters is proposed. A wing is designed in this study to achieve deformation by deflecting the rigid wing box. The aerodynamic characteristics are investigated by the panel method coupling with the XFOIL viscous corrector. A wind tunnel test platform and data acquisition system for the actuators of the morphing wing are built. A low speed wind tunnel test is then carried out on the deformed pneumatic servo system driven by model aircraft actuators, and the mathematical model of the pneumatic servo system is obtained with the subspace identification method. The servo compensation control is carried out by proportion integral differential (PID) control combined with Smith predictive control algorithm. Finally, according to the aerodynamic data of the morphing wing and the frequency response characteristics of these actuators, a feedback control system of the adaptive morphing wing is designed to optimize the aerodynamic performance based on the compensation of actuators. This design could realize the compensation and adaptive deformation of actuators in complex environments, providing a reference for the subsequent design of the morphing wing.

-

-

[1] 崔尔杰, 白鹏, 杨基明. 智能变形飞行器的发展道路[J]. 航空制造技术, 2007, 50(8): 38-41.CUI E J, BAI P, YANG J M. Development path of intelligent morphing aircraft[J]. Aeronautical Manufacturing Technology, 2007, 50(8): 38-41(in Chinese). [2] 张音旋, 陈亮, 吴江鹏, 等. 可变弯度机翼后缘的研究进展及其关键技术[J]. 飞机设计, 2017, 37(6): 34-39.ZHANG Y X, CHEN L, WU J P, et al. Development and key technologies of the variable camber trailing edge[J]. Aircraft Design, 2017, 37(6): 34-39(in Chinese). [3] MAO S, XIE C C, YANG L, et al. Static aeroelastic characteristics of morphing trailing-edge wing using geometrically exact vortex lattice method[J]. International Journal of Aerospace Engineering, 2019, 2019: 1-15. [4] 李军府, 艾俊强, 董海锋. 飞机变形技术发展探究[J]. 航空科学技术, 2009, 20(2): 3-6.LI J F, AI J Q, DONG H F. Research on the development of aircraft morphing technologies[J]. Aeronautical Science and Technology, 2009, 20(2): 3-6(in Chinese). [5] WOODS B K, BILGEN O, FRISWELL M I. Wind tunnel testing of the fish bone active camber morphing concept[J]. Journal of Intelligent Material Systems and Structures, 2014, 25(7): 772-785. doi: 10.1177/1045389X14521700 [6] RAGHAVAN B, PATIL M J. Flight control for flexible, high-aspect-ratio flying wings[J]. Journal of Guidance, Control, and Dynamics, 2010, 33(1): 64-74. doi: 10.2514/1.45471 [7] BARBARINO S, BILGEN O, AJAJ R M, et al. A review of morphing aircraft[J]. Journal of Intelligent Material Systems and Structures, 2011, 22(9): 823-877. doi: 10.1177/1045389X11414084 [8] JHA A K, KUDVA J N. Morphing aircraft concepts, classifications, and challenges[J]. Proceedings of SPIE—The International Society for Optical Engineering, 2004, 5388: 213-224. [9] 冷劲松, 孙健, 刘彦菊. 智能材料和结构在变体飞行器上的应用现状与前景展望[J]. 航空学报, 2014, 35(1): 29-45.LENG J S, SUN J, LIU Y J. Application status and future prospect of smart materials and structures in morphing aircraft[J]. Acta Aeronautica et Astronautica Sinica, 2014, 35(1): 29-45(in Chinese). [10] 孙玉凯, 张仁嘉, 吴志刚, 等. 航模舵机的动态特性测试与系统辨识[J]. 北京航空航天大学学报, 2020, 46(2): 294-303.SUN Y K, ZHANG R J, WU Z G, et al. Dynamic property test and system identification of model aircraft actuators[J]. Journal of Beijing University of Aeronautics and Astronautics, 2020, 46(2): 294-303(in Chinese). [11] CONCILIO A, DIMINO I, PECORA R, et al. Structural design of an adaptive wing trailing edge for enhanced cruise performance[C]// Proceedings of the 24th AIAA/AHS Adaptive Structures Conference. Reston: AIAA, 2016: 1317. [12] 冒森, 杨超, 谢长川, 等. 刚性变弯度机翼设计及低速风洞试验研究[J]. 振动与冲击, 2021, 40(21): 157-167.MAO S, YANG C, XIE C C, et al. Design and low speed wind tunnel tests of a rigid variable camber wing[J]. Journal of Vibration and Shock, 2021, 40(21): 157-167(in Chinese). [13] WHITFIELD D L, SWAFFORD T W, JACOCKS J L. Calculation of turbulent boundary layers with separation and viscous-inviscid interaction[J]. AIAA Journal, 1981, 19(10): 1315-1322. doi: 10.2514/3.60066 [14] 赵志俊, 孟祥喆, 郑浩. 舵机带宽测试系统设计与试验方法研究[J]. 电子测量技术, 2019, 42(1): 63-67.ZHAO Z J, MENG X Z, ZHENG H. Research on design and test method of actuator bandwidth testing system[J]. Electronic Measurement Technology, 2019, 42(1): 63-67(in Chinese). [15] 张少应, 陈明哲. 数字化舵机频率特性测试方法与实现[J]. 测控技术, 2017, 36(7): 30-32. doi: 10.3969/j.issn.1000-8829.2017.07.008ZHANG S Y, CHEN M Z. Method and implementation of frequency characteristic test for digital servo[J]. Measurement & Control Technology, 2017, 36(7): 30-32(in Chinese). doi: 10.3969/j.issn.1000-8829.2017.07.008 [16] 章家保, 刘慧, 贾宏光, 等. 电动舵机伺服系统的模型辨识及其校正[J]. 光学 精密工程, 2008, 16(10): 1971-1976.ZHANG J B, LIU H, JIA H G, et al. Model identification and corrector design for servo system of electromechanical actuator[J]. Optics and Precision Engineering, 2008, 16(10): 1971-1976(in Chinese). [17] 梁春燕, 谢剑英. 大纯滞后系统的自适应补偿控制[J]. 控制理论与应用, 2001, 18(2): 176-180.LIANG C Y, XIE J Y. The adaptive control with compensation for long time delay system[J]. Control Theory & Applications, 2001, 18(2): 176-180(in Chinese). [18] 黄伟, 李芹, 王志萍. 增益和相位补偿的双模Smith预估控制算法[J]. 上海电力学院学报, 2011, 27(6): 603-607.HUANG W, LI Q, WANG Z P. Research on dual-model Smith predictive control with gain and phrase compensation[J]. Journal of Shanghai University of Electric Power, 2011, 27(6): 603-607(in Chinese). [19] MEHTA U, KAYA I. Smith predictor with sliding mode control for processes with large dead times[J]. Journal of Electrical Engineering, 2017, 68(6): 463-469. doi: 10.1515/jee-2017-0081 [20] SAKR A, EL-NAGAR A M, EL-BARDINI M, et al. Improving the performance of networked control systems with time delay and data dropouts based on fuzzy model predictive control[J]. Journal of the Franklin Institute, 2018, 355(15): 7201-7225. doi: 10.1016/j.jfranklin.2018.07.012 -

下载:

下载: