-

摘要:

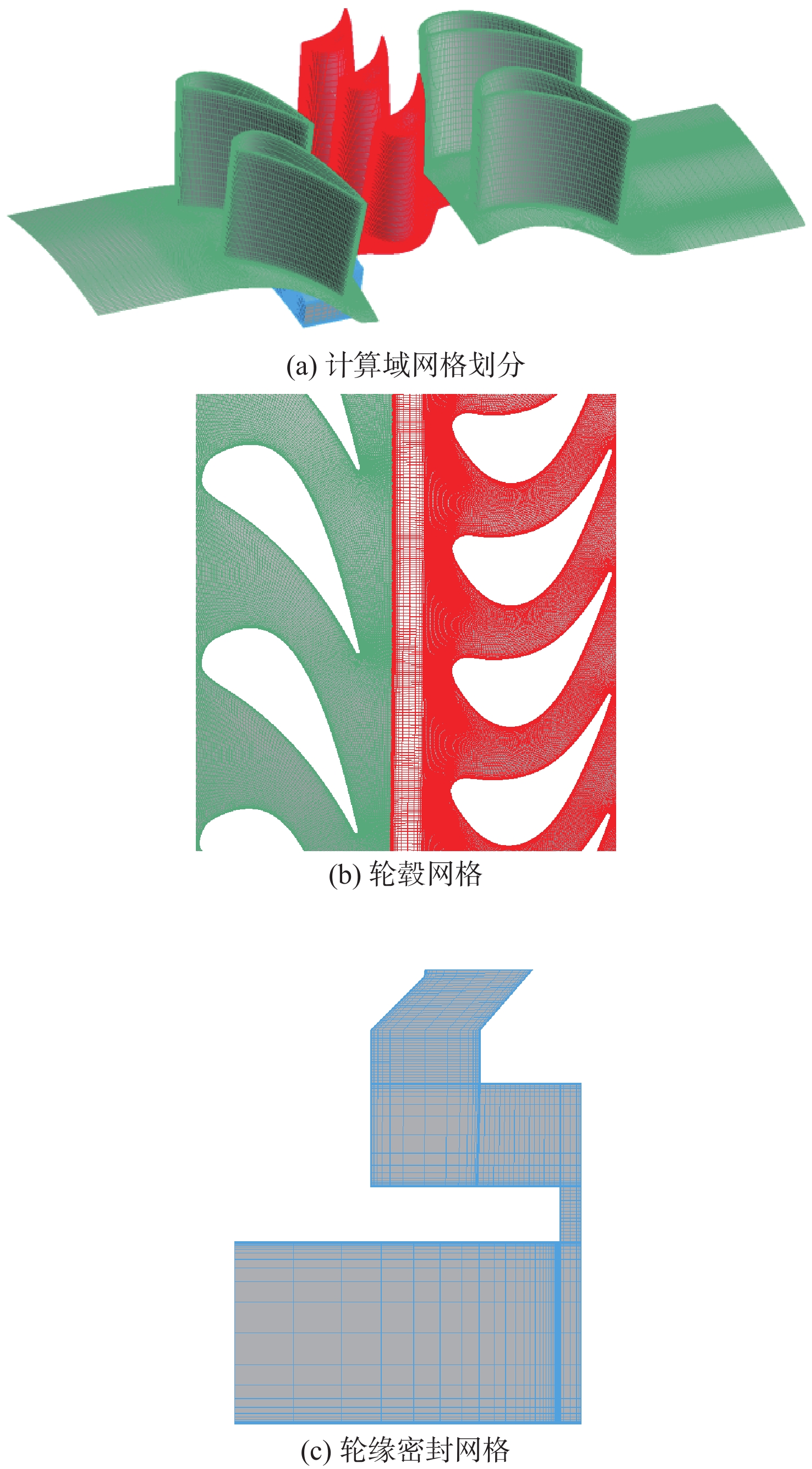

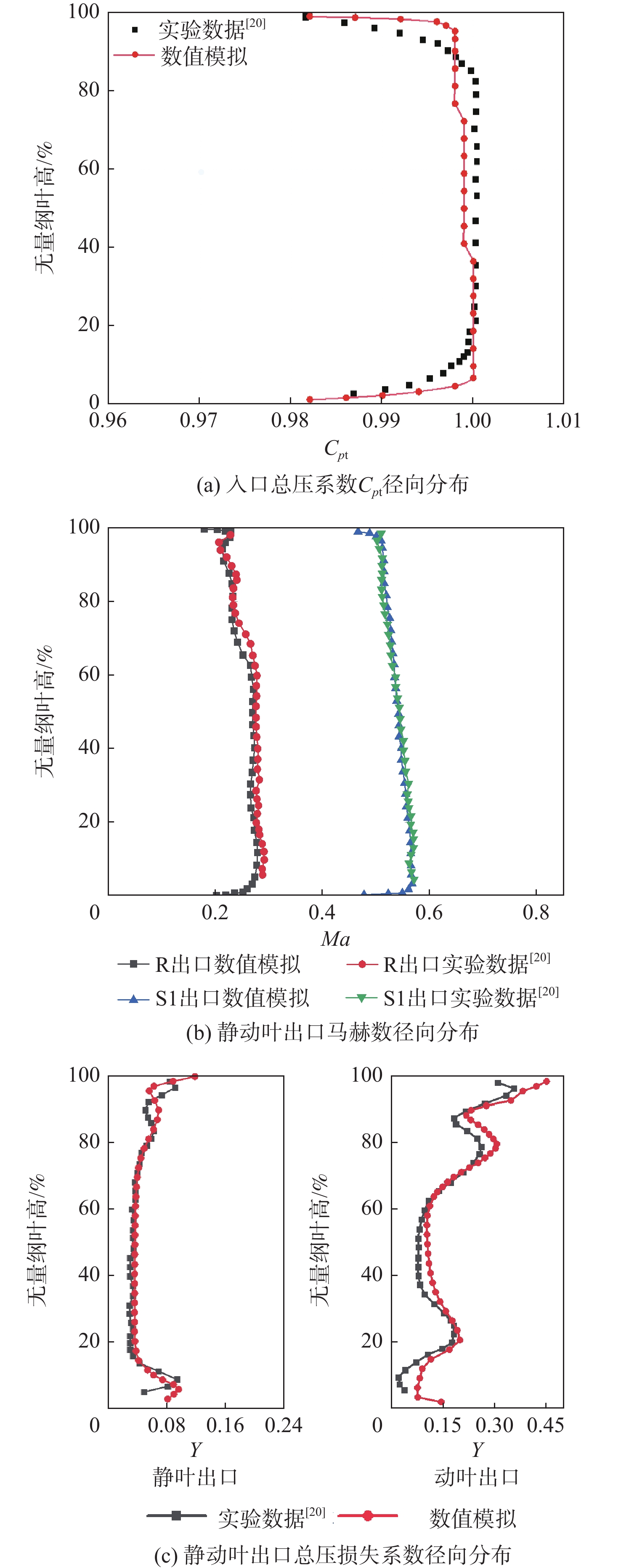

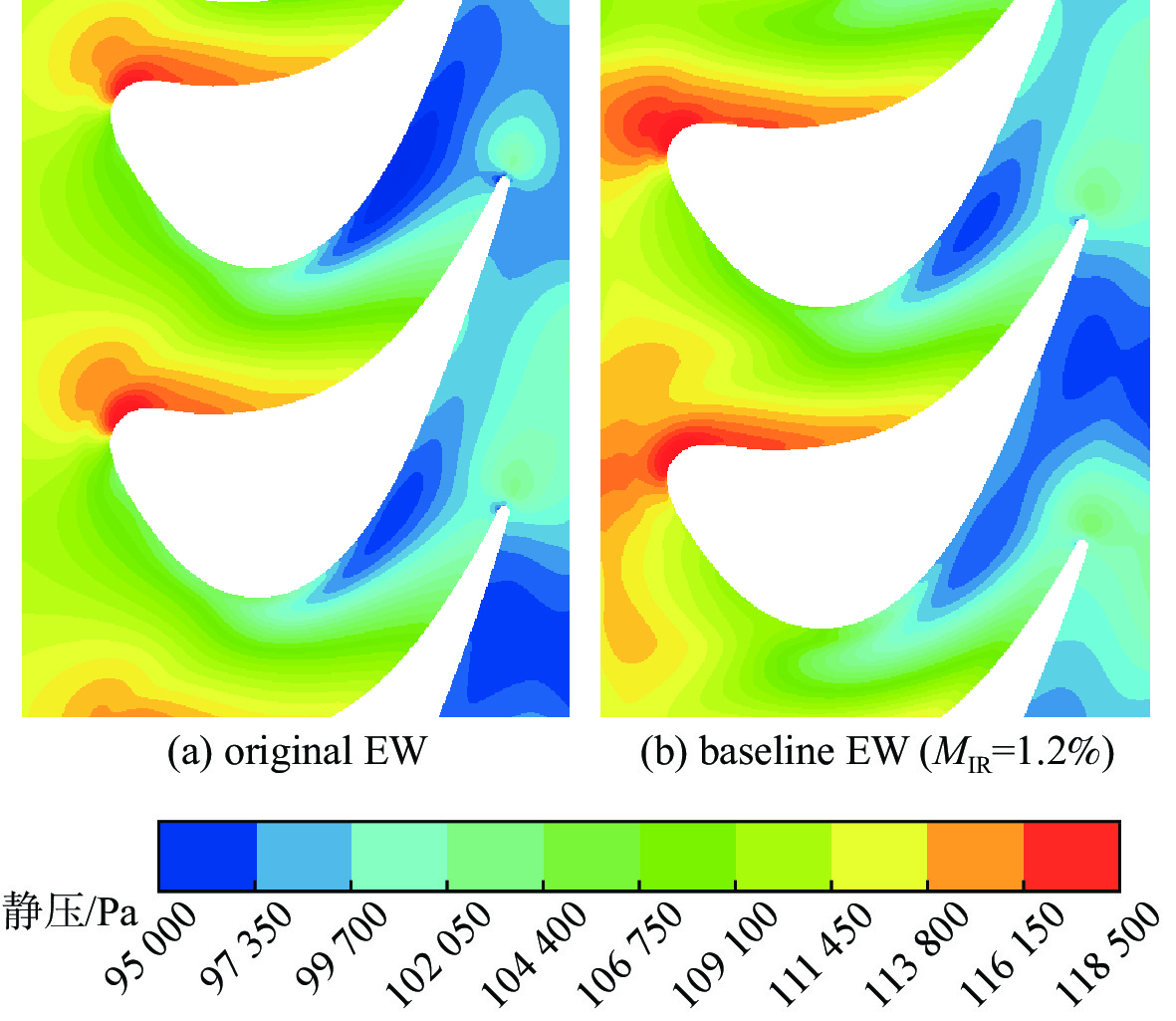

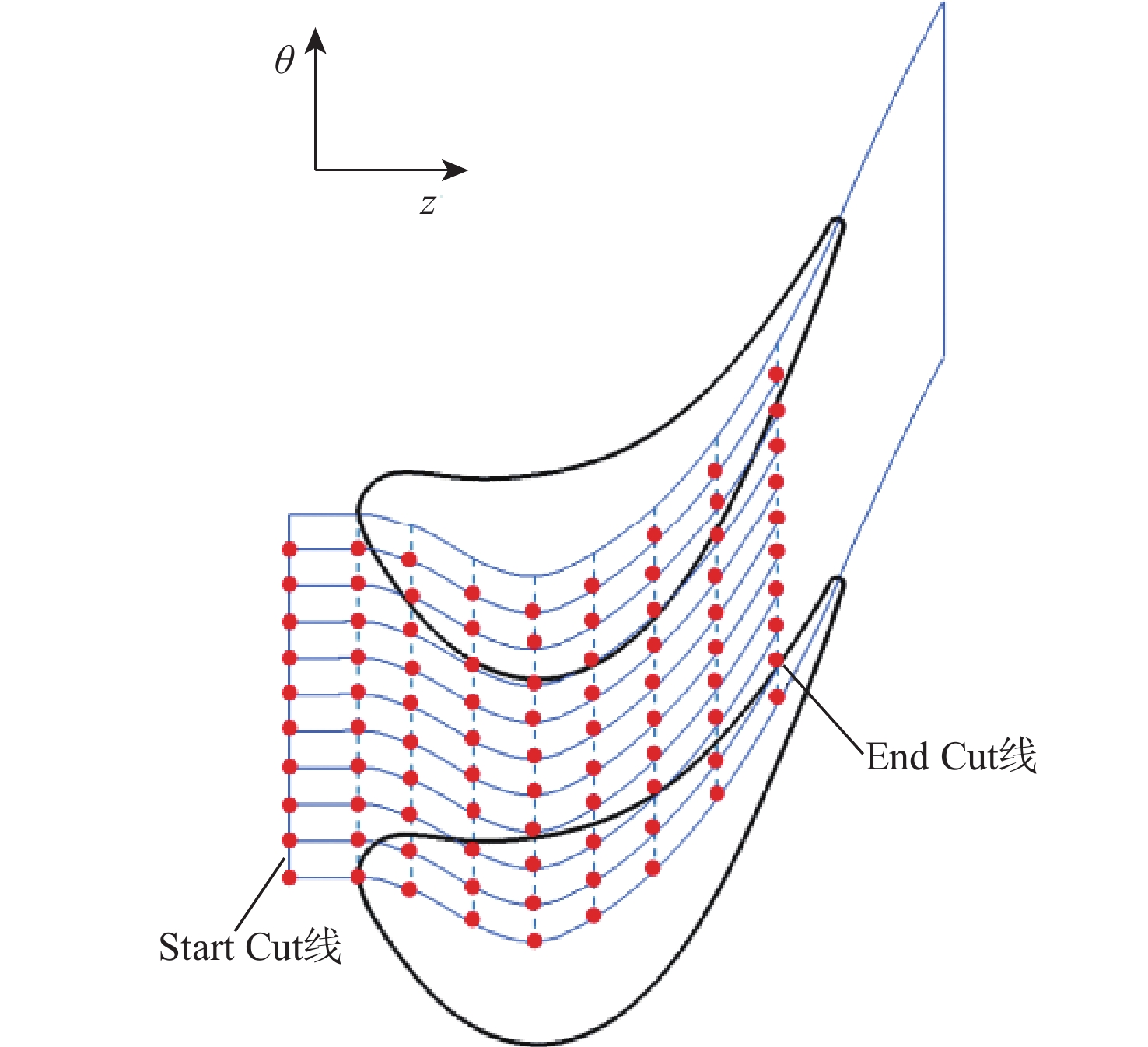

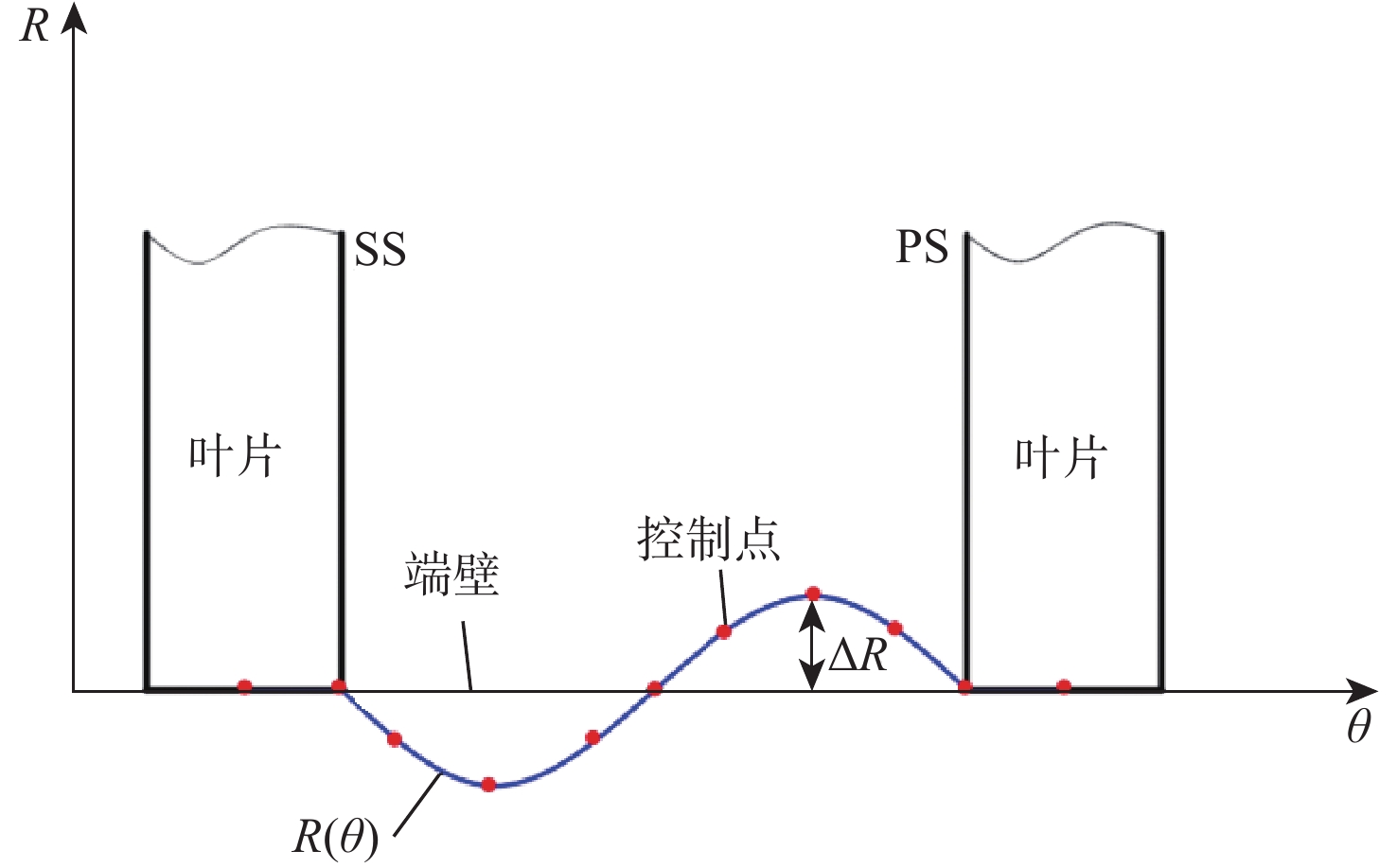

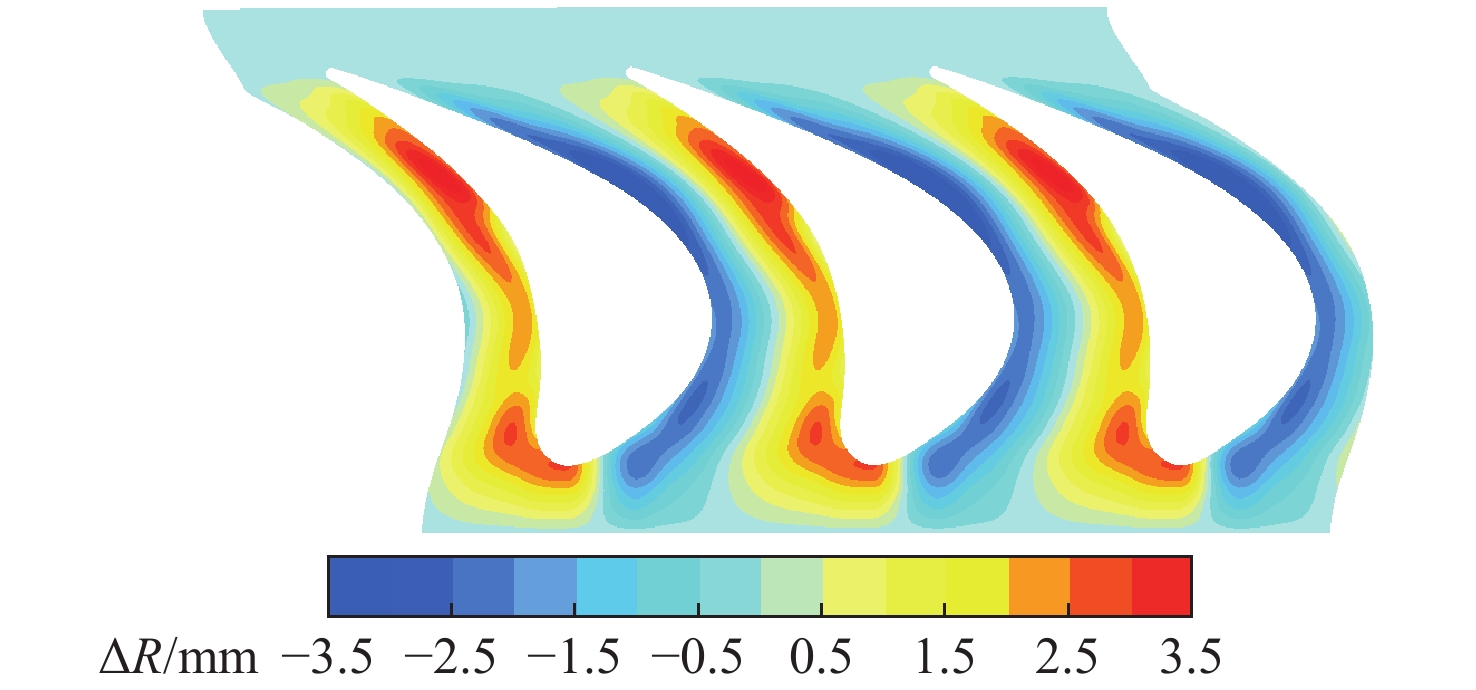

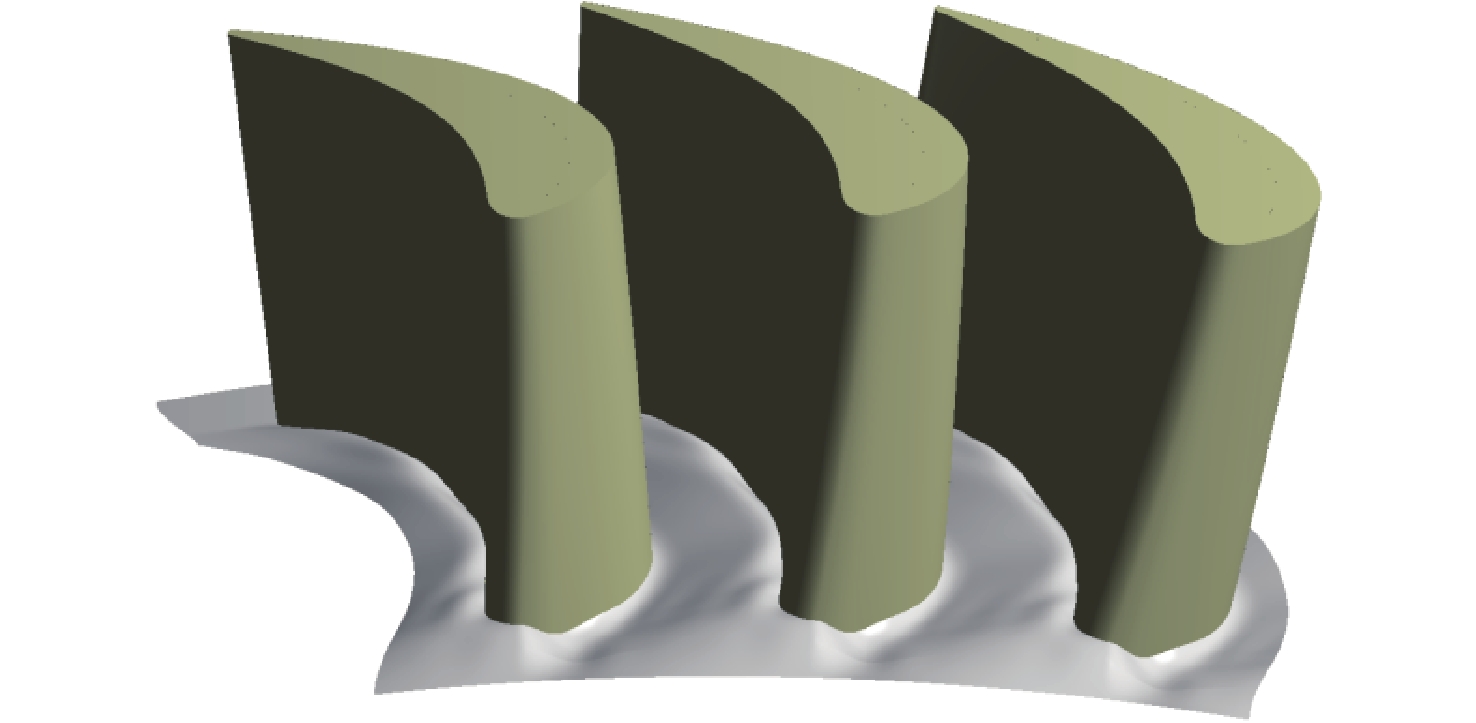

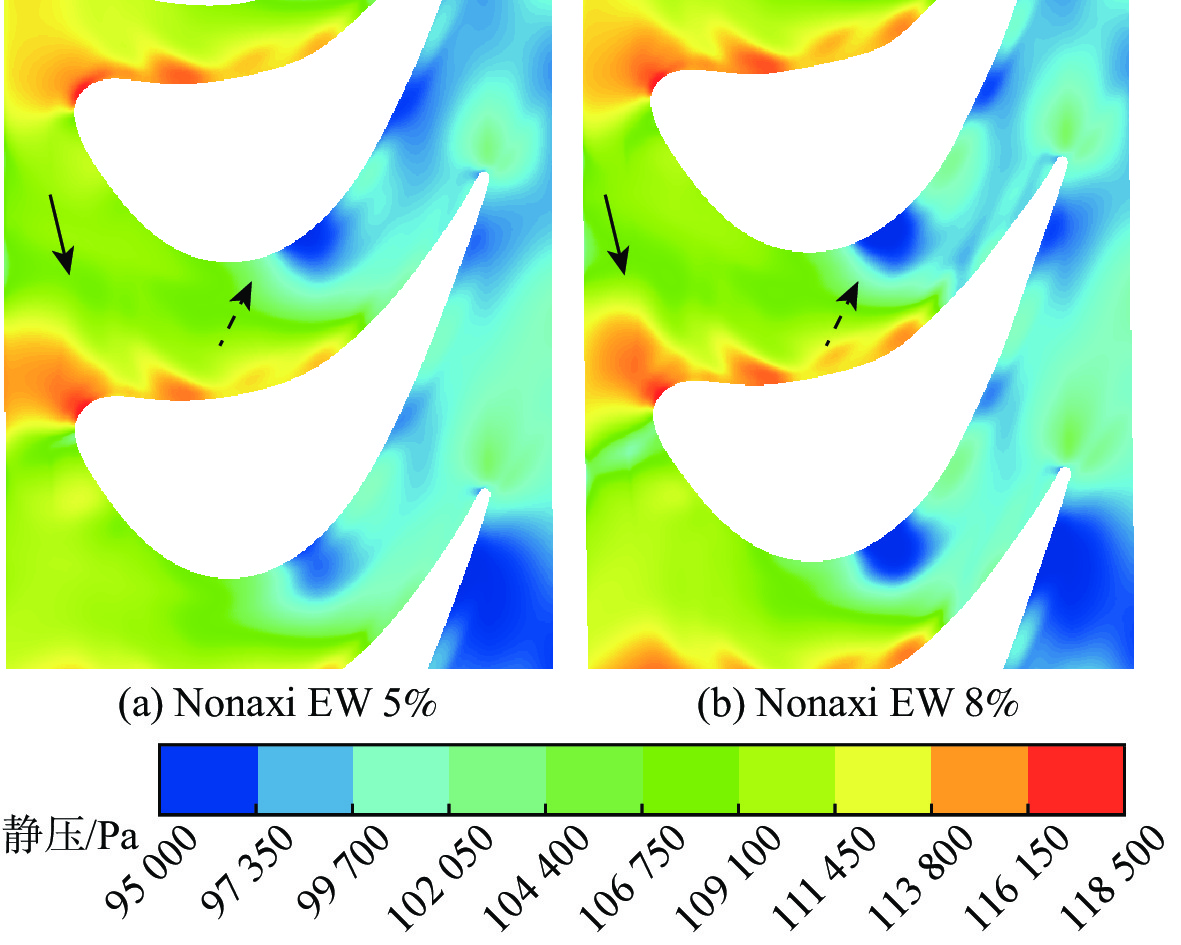

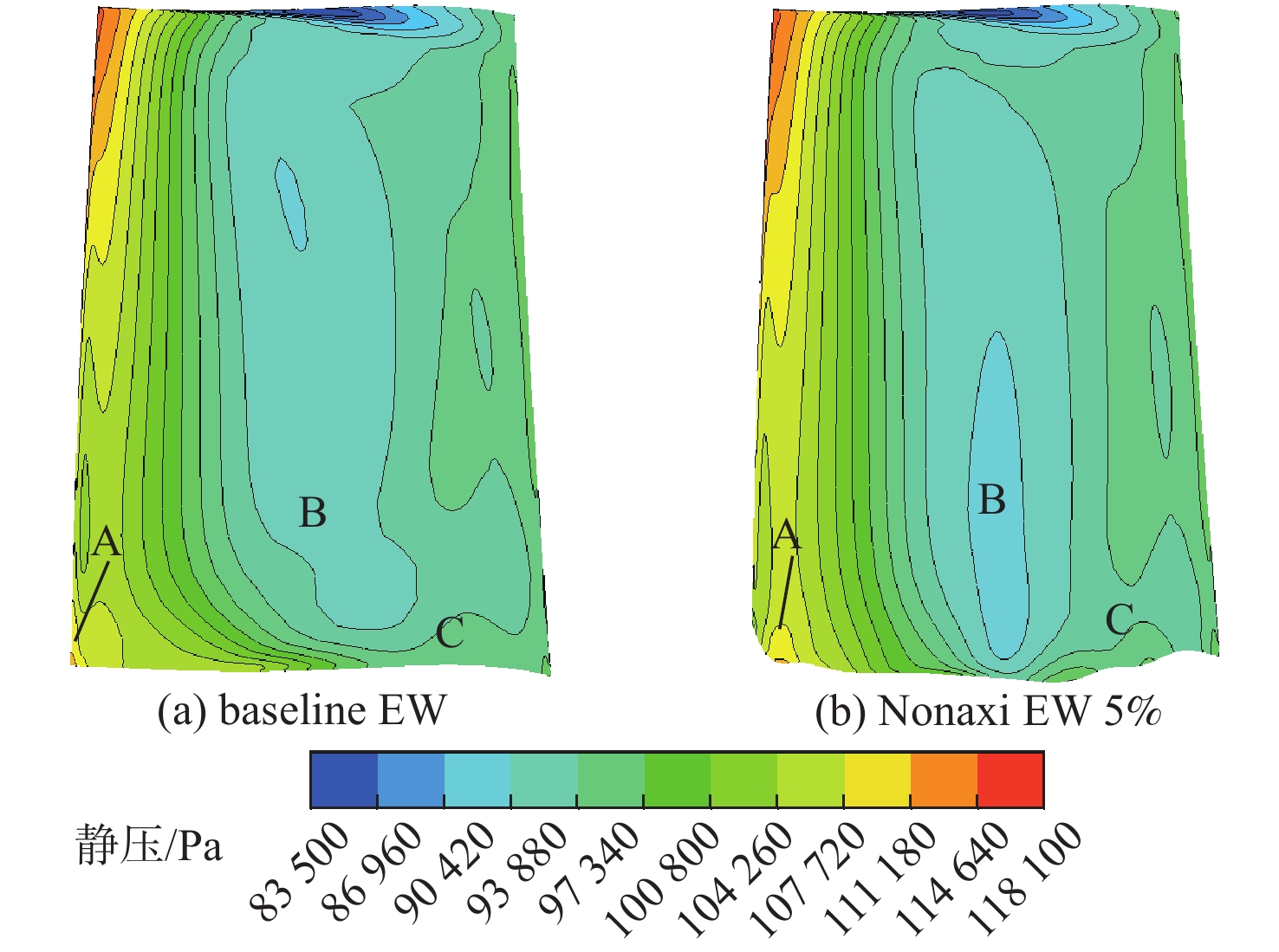

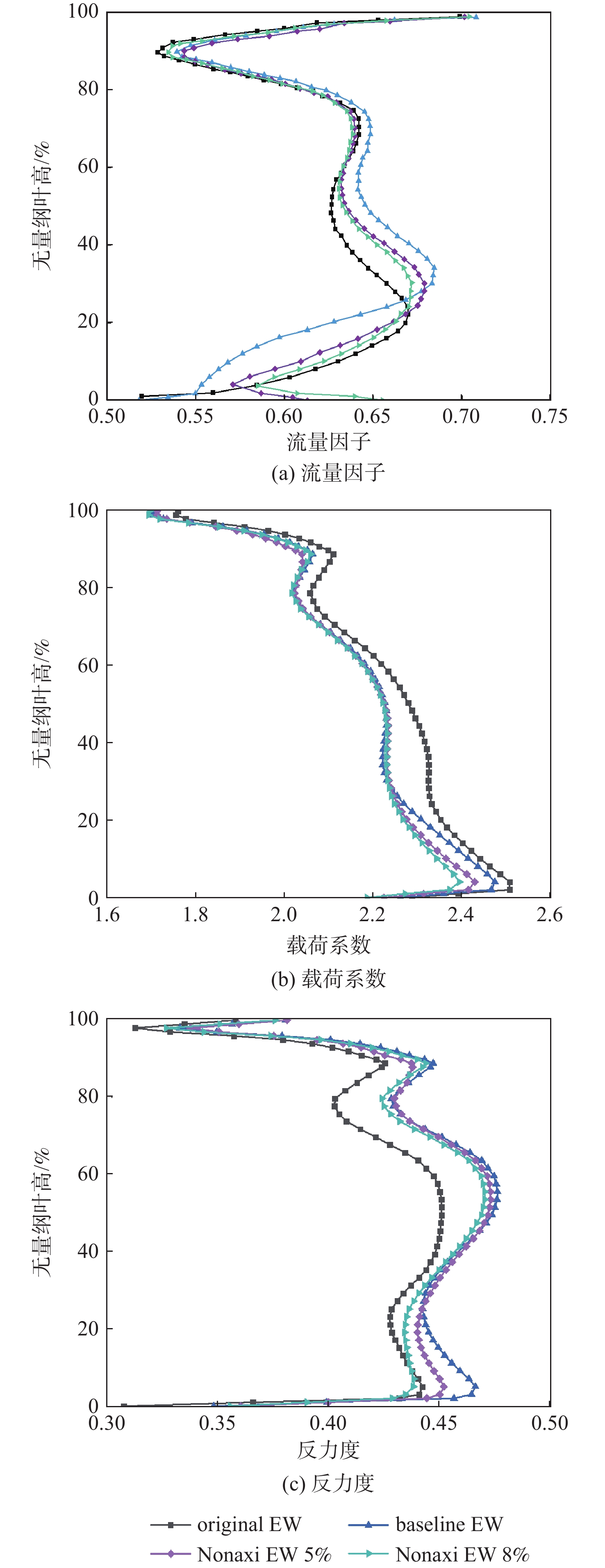

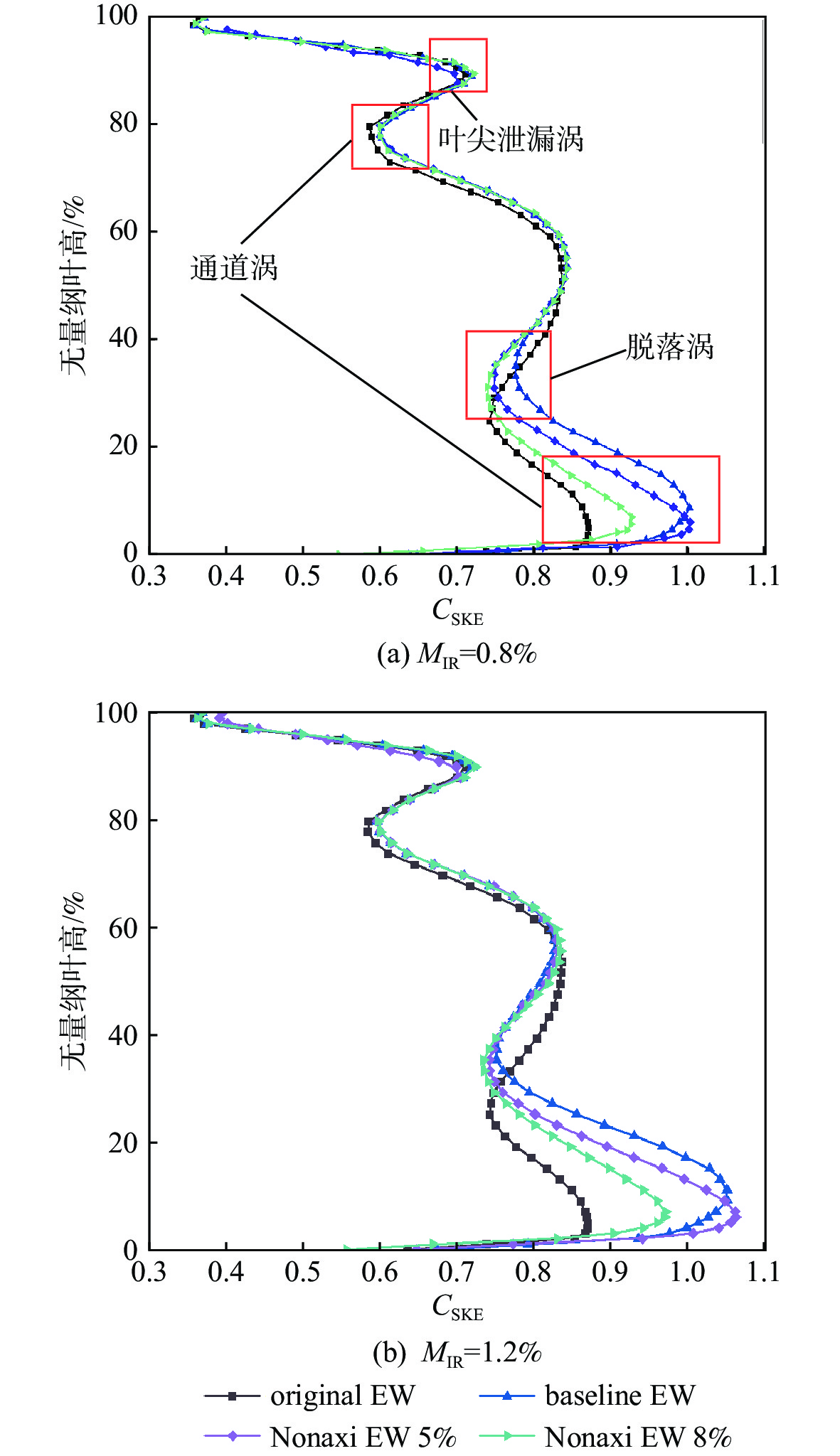

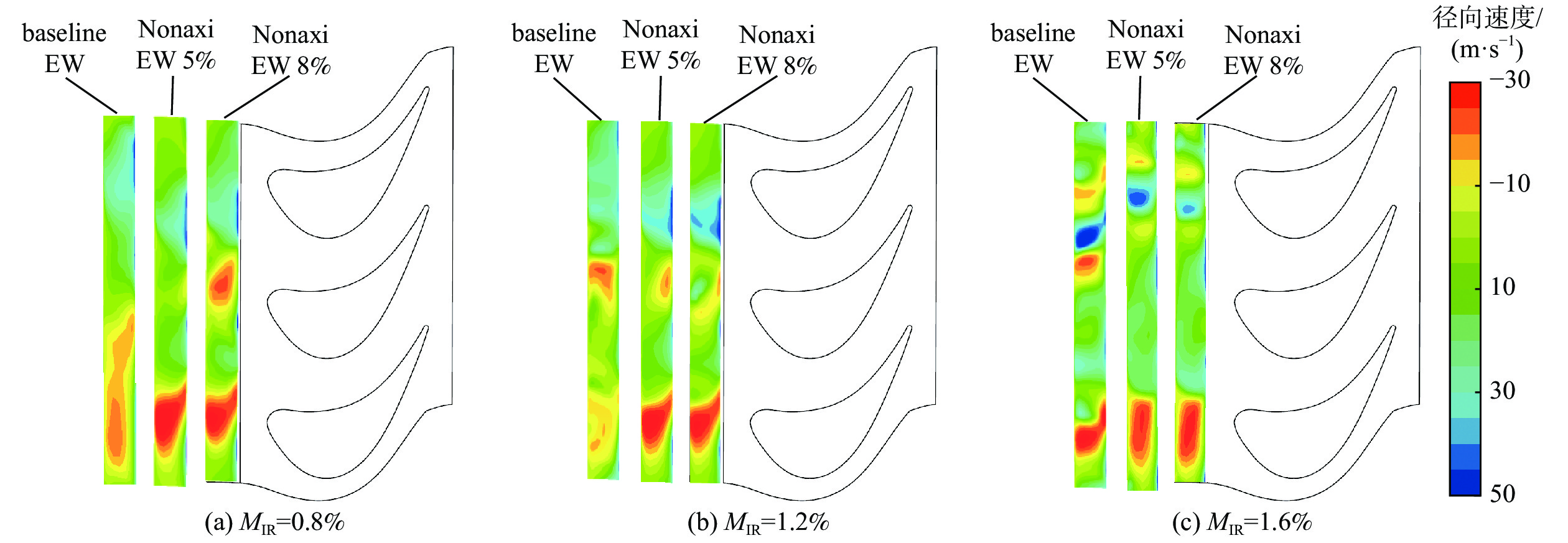

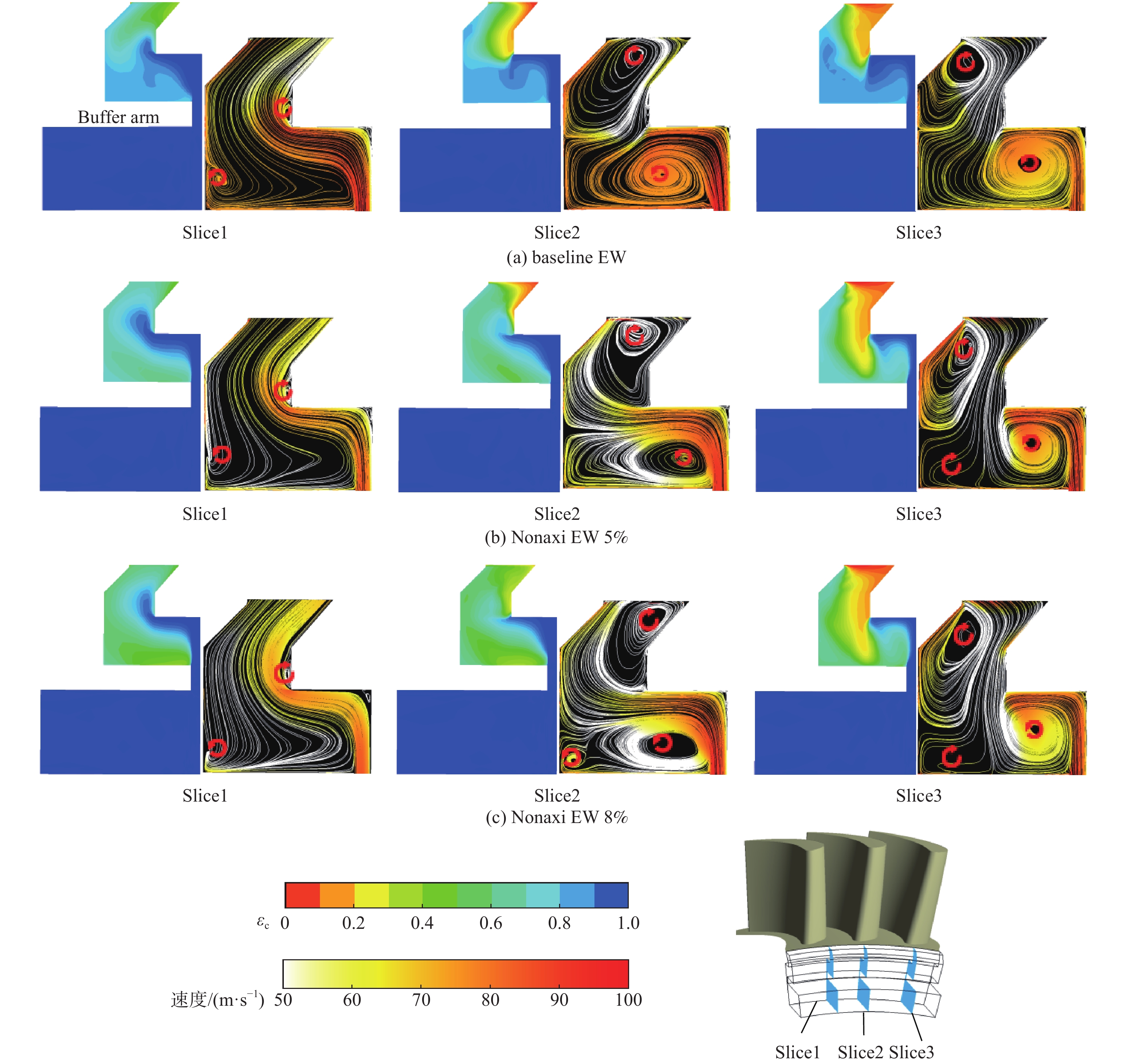

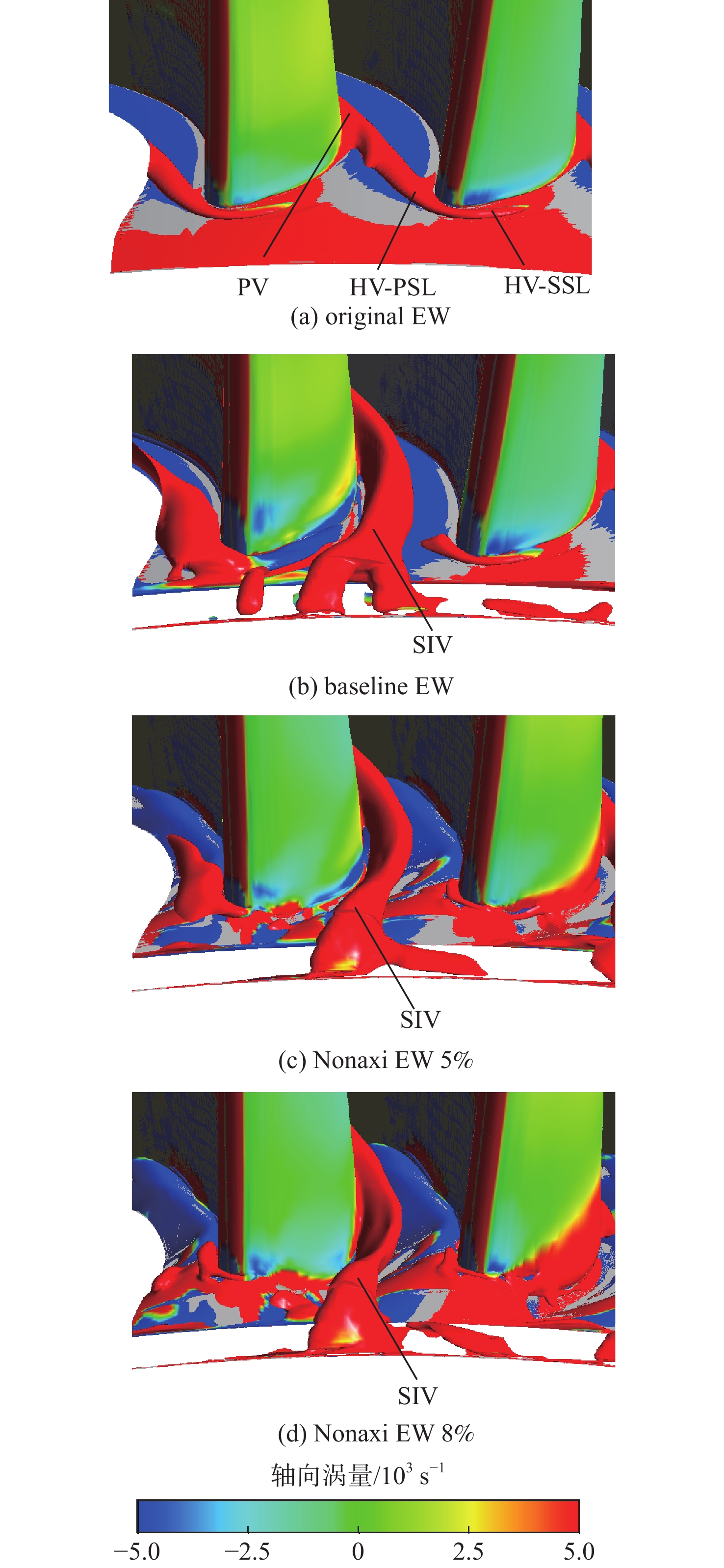

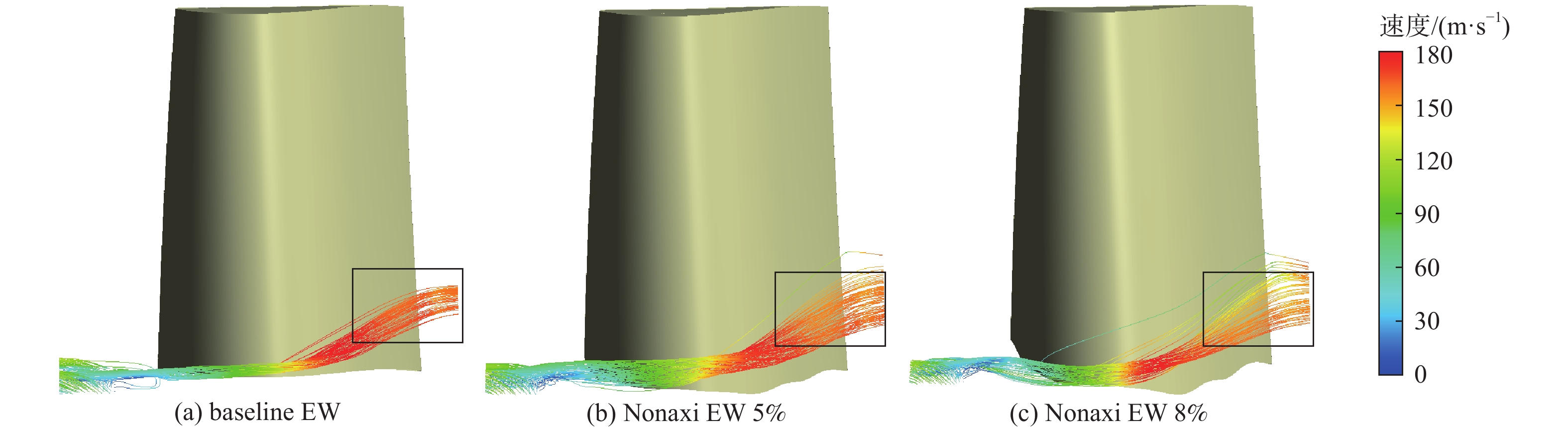

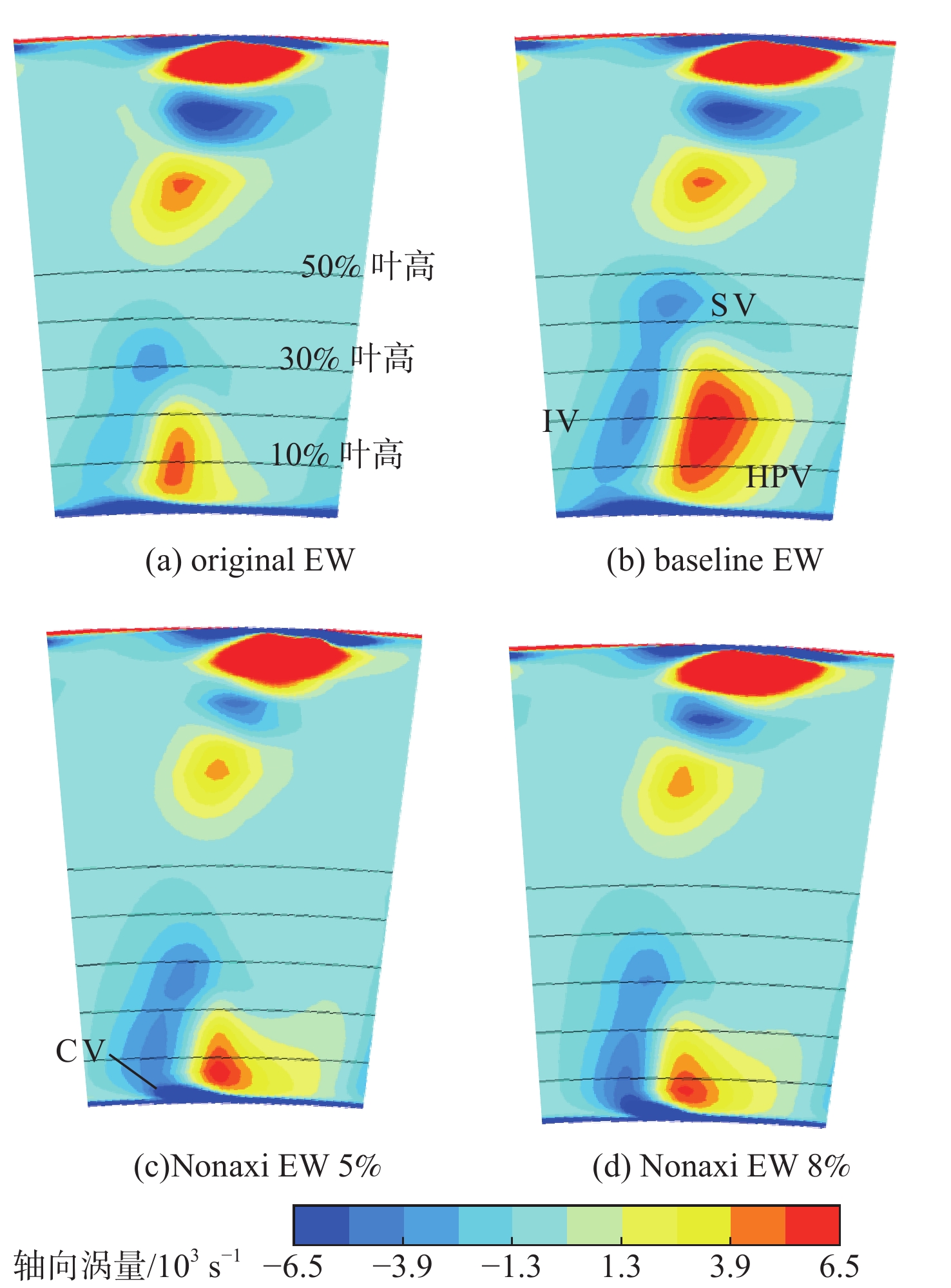

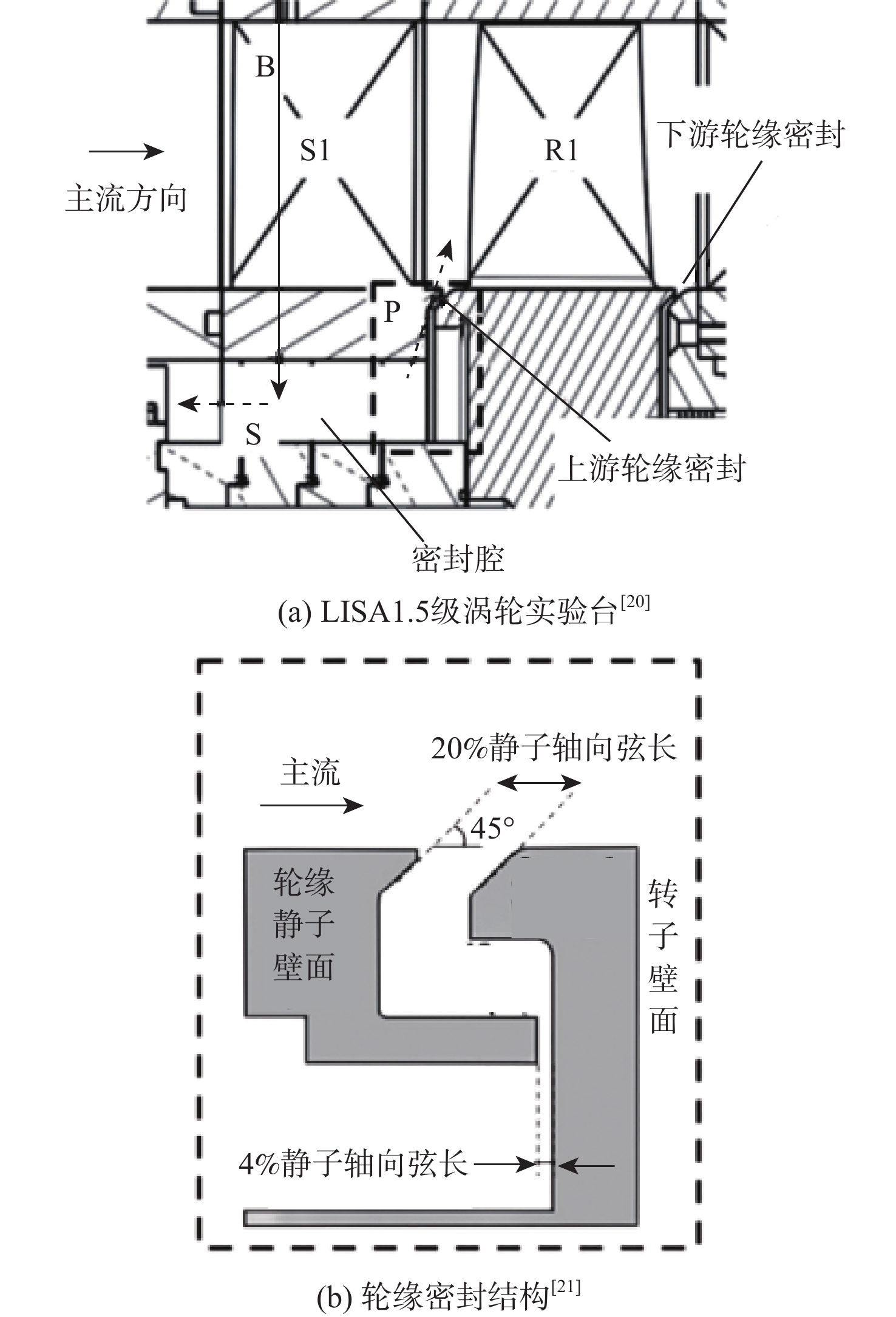

为通过主动端壁控制技术减弱轮缘密封流对主流通道的影响,基于轮毂端壁静压对高压涡轮动叶端壁非轴对称端壁造型,分析了转静间隙密封流与主流相互作用及端壁造型后损失减弱的效果。结果表明:非轴对称端壁造型后密封流对主流通道的堵塞减弱,主流质量流量增加,合理控制端壁造型幅值能够提升涡轮级工作效率;靠近动叶前缘向上凸起的端壁造型增加了轮缘密封腔出口位置的径向压力梯度,增大了燃气入侵与密封出流的强度;主动端壁控制技术降低了主流通道内的横向压力梯度和轮毂二次流结构径向位置,减弱了由密封流引起的二次流损失;密封流质量流量比为1.2%时,造型幅值为5%和8%模型二次流动能分别减少了1.18%和3.76%。

Abstract:To investigate the effect of active endwall control on reducing the influence of rim seal flow on the mainstream passage, this study analyzed the aerodynamic losses of the interaction between the purge flow and the main flow, and the effect of the endwall profiling on the losses reduction, based on the non-axisymmetric endwall profiled by hub static pressure. The results showed that the non-axisymmetric endwall profiling reduces the blockage of the main flow passage by the purge flow, and increases the mass flow rate. The efficiency of the turbine can be increased with a reasonable control of the endwall profiling amplitude. The convex end wall profiling near the leading edge of the blade increases the radial pressure gradient at the exit of the rim seal cavity, and increases the intensity of gas ingestion and purge flow injection. The non-axisymmetric hub endwall profiling reduces the transverse pressure gradient in the main flow passage, lowers the radial position of the hub secondary flow structure and reduces the secondary flow losses caused by the purge flow. The secondary flow kinetic energy is reduced by 1.18% and 3.76% for models with modelling amplitudes of 5% and 8% respectively at the purge flow ratio of 1.2%.

-

Key words:

- non-axisymmetric endwall /

- rim seal /

- gas ingestion /

- sealing effectiveness /

- end zone flow

-

表 1 第1级涡轮效率

Table 1. 1-stage turbine efficiency

计算模型 效率/% 质量流量/(kg·s−1) original EW 90.0092 11.4605 baseline EW, MIR=0.8% 89.6876 11.3727 baseline EW, MIR=1.2% 89.6294 11.3345 baseline EW, MIR=1.6% 89.5801 11.2893 Nonaxi EW 5%, MIR=0.8% 89.6973 11.4271 Nonaxi EW 5%, MIR=1.2% 89.6551 11.3955 Nonaxi EW 5%, MIR=1.6% 89.7288 11.3593 Nonaxi EW 8%, MIR=0.8% 89.2407 11.4333 Nonaxi EW 8%, MIR=1.2% 89.2816 11.3973 Nonaxi EW 8%, MIR=1.6% 89.4151 11.3612 -

[1] SHARMA O P, BUTLER T L. Predictions of end wall losses and secondary flow in axial flow turbine cascades[J]. Journal of Turbomachinery, 1987, 109(2): 229-236. doi: 10.1115/1.3262089 [2] ROSE M G. Non-axisymmetric end wall profiling in the HP NGVs of an axial flow gas turbine: ASME 1994-GT-249[R]. New York: ASME, 1994. [3] HARVEY N W, ROSE M G, TAYLOR M D, et al. Non-axisymmetric turbine endwall design. Part I: Three-dimensional linear design system: ASME 1999 -GT-338[R]. New York: ASME, 1999. [4] HARTLAND J, GREGORY-SMITH D. A design method for the profiling of endwalls in turbines: ASME 2002-GT-30433[R]. New York: ASME, 2002. [5] 李国君, 马晓永, 李军. 非轴对称端壁成型及其对叶栅损失影响的数值研究[J]. 西安交通大学学报, 2005, 39(11): 9-12. doi: 10.3321/j.issn:0253-987X.2005.11.002LI G J, MA X Y, LI J. Non-axisymmetric turbine end wall profiling and numerical investigation of its effect on the turbine cascade loss[J]. Journal of Xi’an Jiao Tong University, 2005, 39(11): 9-12(in Chinese). doi: 10.3321/j.issn:0253-987X.2005.11.002 [6] 郑金, 李国君, 李军, 等. 一种新非轴对称端壁成型方法的数值研究[J]. 航空动力学报, 2007, 22(9): 1487-1491. doi: 10.3969/j.issn.1000-8055.2007.09.015ZHENG J, LI G J, LI J, et al. Numerical research on a new non-axisymmetric endwall profiling method[J]. Journal of Aerospace Power, 2007, 22(9): 1487-1491(in Chinese). doi: 10.3969/j.issn.1000-8055.2007.09.015 [7] 那振喆. 非轴对称端壁造型技术在高压涡轮中应用的机理分析及试验研究[D]. 西安: 西北工业大学, 2017.NA Z Z. Aerodynamic mechanism analysis and experimental research of non-axisymmetric endwall in a high pressure turbine[D]. Xi’an: Northwestern Polytechnical University, 2017(in Chinese). [8] POPOVÍC I, HODSON H P. Improving turbine stage efficiency and sealing effectiveness through modifications of the rim seal geometry[J]. Journal of Turbomachinery, 2013, 135(6): 061016. doi: 10.1115/1.4024872 [9] POPOVIĆ I, HODSON H P, JANKE E, et al. The effects of unsteadiness and compressibility on the interaction between hub leakage and mainstream flows in high-pressure turbines[J]. Journal of Turbomachinery, 2013, 135(6): 061015. doi: 10.1115/1.4024636 [10] POPOVIĆ I, HODSON H P. The effects of a parametric variation of the rim seal geometry on the interaction between hub leakage and mainstream flows in high pressure turbines[J]. Journal of Engineering for Gas Turbines and Power, 2013, 135(11): 112501. doi: 10.1115/1.4024867 [11] POPOVIĆ I, HODSON H P. Aerothermal impact of the interaction between hub leakage and mainstream flows in highly-loaded high pressure turbine blades[J]. Journal of Turbomachinery, 2013, 135(6): 061014. doi: 10.1115/1.4023621 [12] SCHUEPBACH P. Influence of rim seal purge flow on performance of an endwall profiled axial turbine[D]. Lausanne: Swiss Federal Institute of Technology, 2009. [13] REZASOLTANI M, SCHOBEIRI M T, HAN J C. Experimental investigation of the effect of purge flow on film cooling effectiveness on a rotating turbine with nonaxisymmetric end wall contouring[J]. Journal of Turbomachinery, 2014, 136(9): 091009. doi: 10.1115/1.4027196 [14] REGINA K, KALFAS A I, ABHARI R S, et al. Aerodynamic robustness of end wall contouring against rim seal purge flow: ASME 2014-GT-26007[R]. New York: ASME, 2014. [15] 程舒娴, 李志刚, 李军. 端壁造型对轮缘密封流场和密封效率的影响[J]. 西安交通大学学报, 2019, 53(3): 20-27. doi: 10.7652/xjtuxb201903004CHENG S X, LI Z G, LI J. Effects of endwall profiling on the unsteady flow field and sealing efficiency of rim seal[J]. Journal of Xi’an Jiao Tong University, 2019, 53(3): 20-27(in Chinese). doi: 10.7652/xjtuxb201903004 [16] 陶志, 武晓龙, 祝培源, 等. 非轴对称端壁造型对叶片端壁气热性能影响的研究[J]. 推进技术, 2019, 40(8): 1734-1742. doi: 10.13675/j.cnki.tjjs.180513TAO Z, WU X L, ZHU P Y, et al. Research on effects of nonaxisymmetric endwall contouring on blade endwall aerothermal performance[J]. Journal of Propulsion Technology, 2019, 40(8): 1734-1742(in Chinese). doi: 10.13675/j.cnki.tjjs.180513 [17] 姚韵嘉, 祝培源, 陈云, 等. 间隙位置对叶片端壁气膜冷却性能影响的实验研究[J]. 工程热物理学报, 2019, 40(10): 2327-2333.YAO Y J, ZHU P Y, CHEN Y, et al. Experimental study on the effect of the locations of slot jet on film cooling performance of endwall[J]. Journal of Engineering Thermophysics, 2019, 40(10): 2327-2333(in Chinese). [18] 祝培源, 陶志, 姚韵嘉, 等. 非轴对称端壁造型对叶片端壁综合传热特性的影响[J]. 风机技术, 2019, 61(6): 48-55. doi: 10.16492/j.fjjs.2019.06.0009ZHU P Y, TAO Z, YAO Y J, et al. Effects of nonaxisymmetric endwall contouring on blade endwall comprehensive heat transfer characteristics[J]. Chinese Journal of Turbomachinery, 2019, 61(6): 48-55(in Chinese). doi: 10.16492/j.fjjs.2019.06.0009 [19] 张垲垣, 李志刚, 李军. 透平端壁冷却及泛冷却最优的端壁造型设计研究[J]. 西安交通大学学报, 2021, 55(5): 1-9. doi: 10.7652/xjtuxb202105001ZHANG K Y, LI Z G, LI J. Endwall contour design targeting on optimum turbine endwall cooling and phantom cooling effectiveness[J]. Journal of Xi’an Jiao Tong University, 2021, 55(5): 1-9(in Chinese). doi: 10.7652/xjtuxb202105001 [20] BEHR T. Control of rotor tip leakage and secondary flow by casing air injection in unshrouded axial turbines[D]. Dresden: Dresden University of Technology, 2007. [21] REGINA K. High-pressure turbines with novel airfoils and end walls operating under engine representative aero-thermodynamic effects[D]. Lausanne: Swiss Federal Institute of Technology, 2015. 期刊类型引用(0)

其他类型引用(1)

-

下载:

下载: