-

摘要:

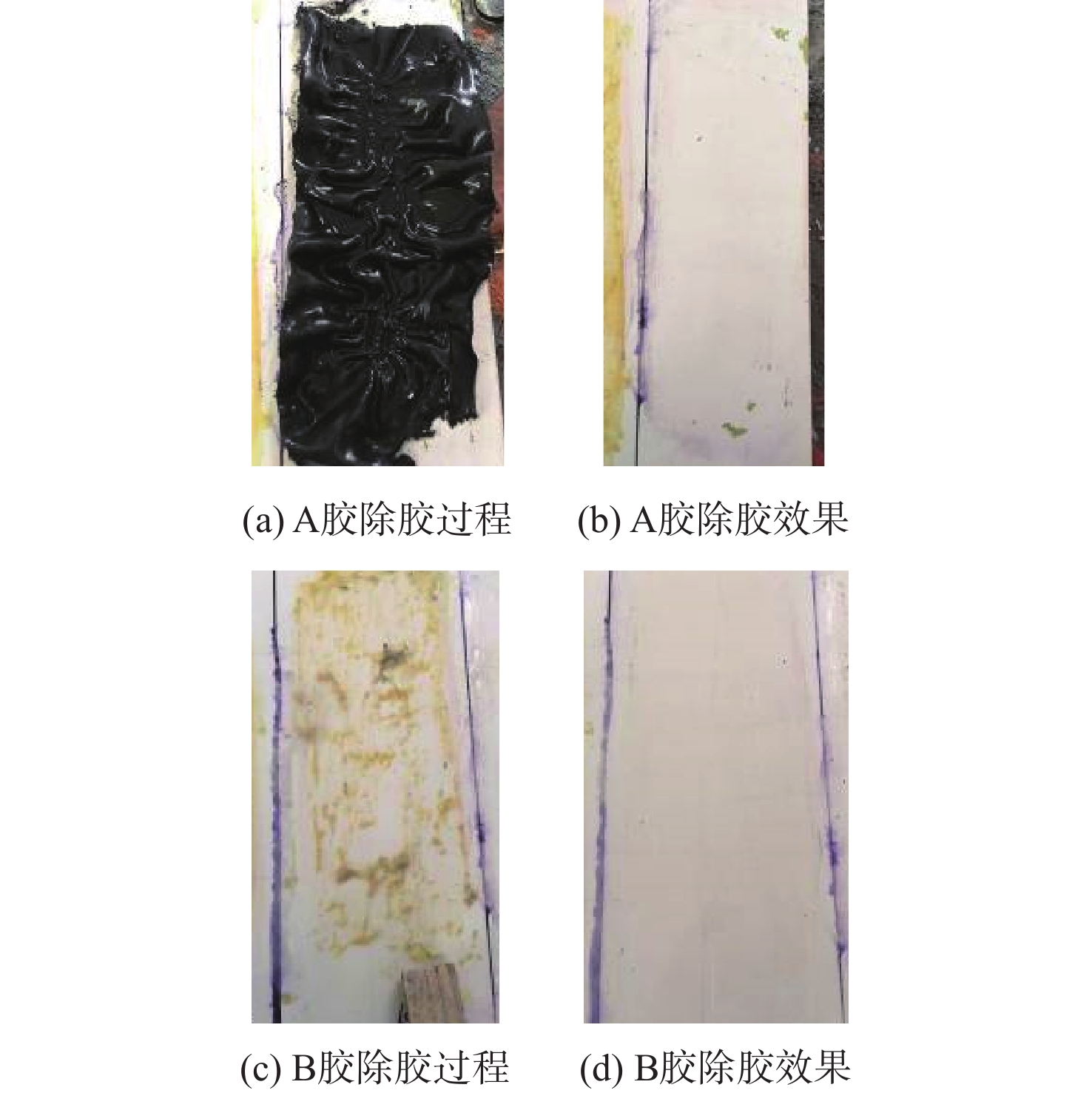

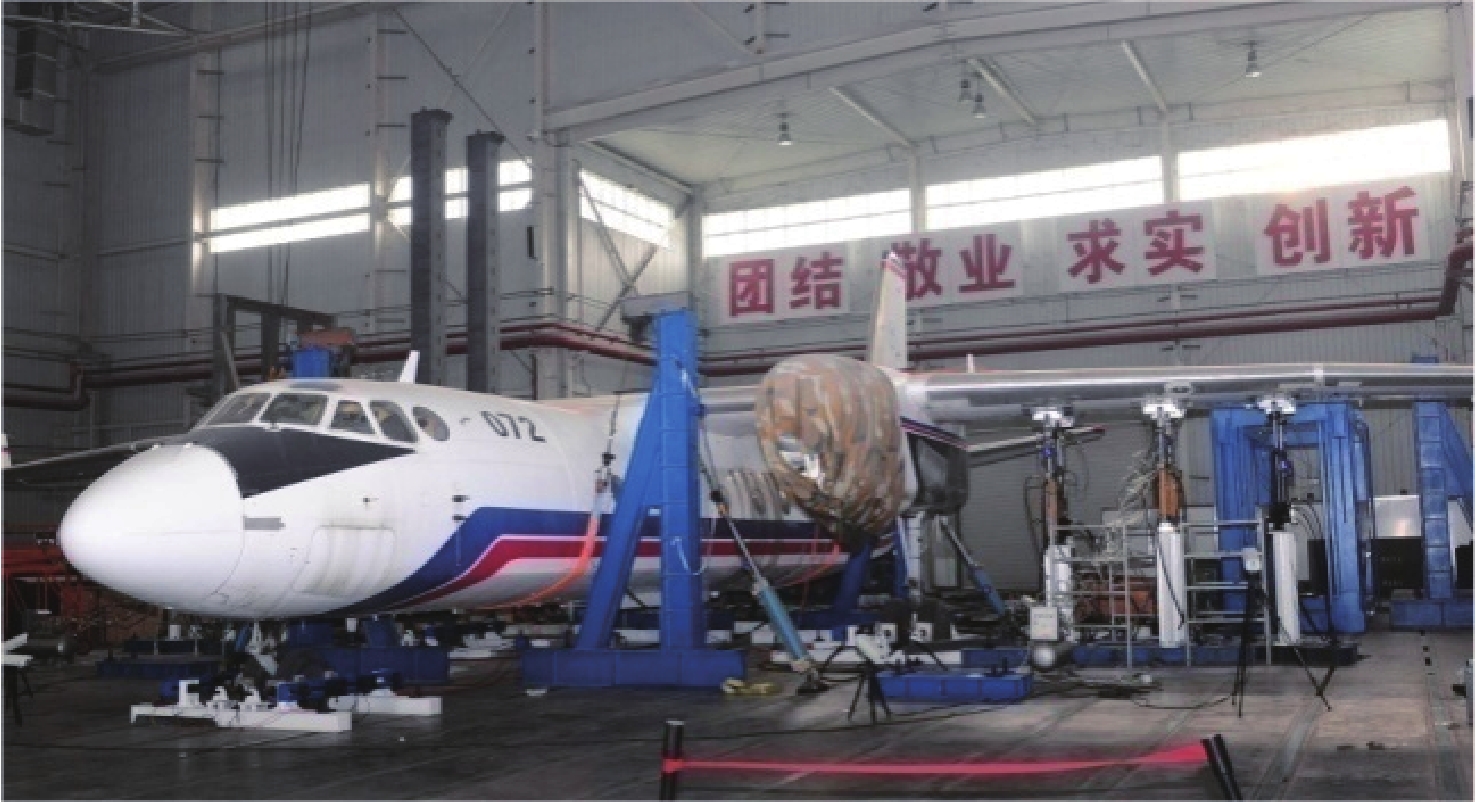

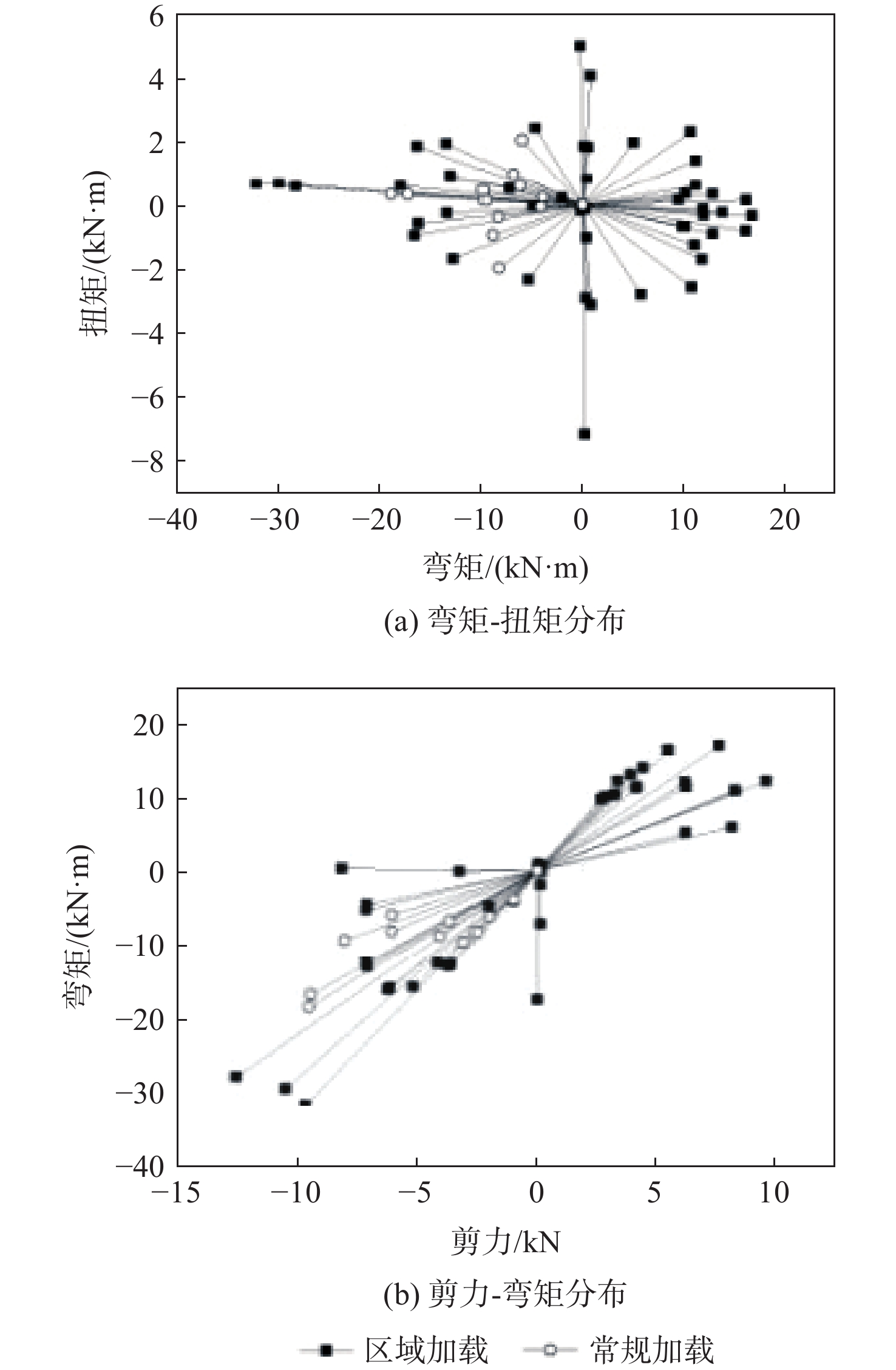

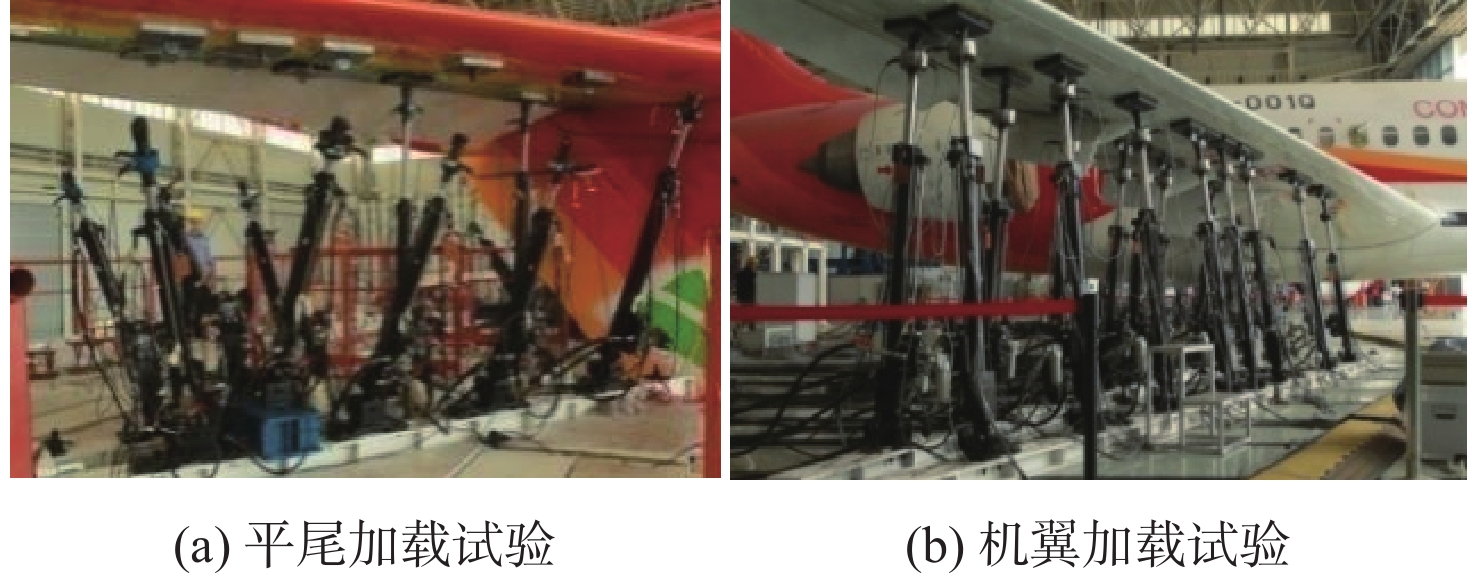

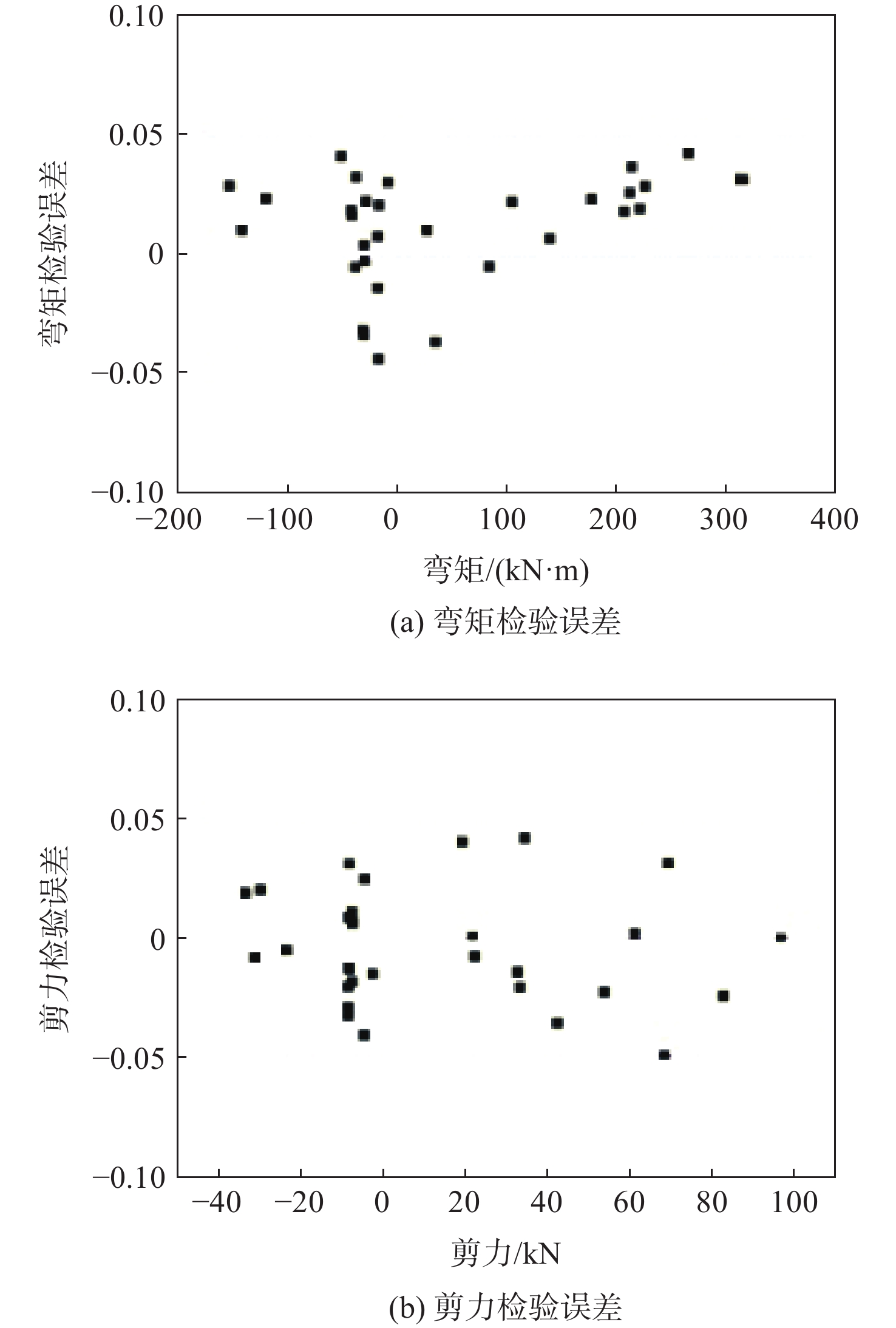

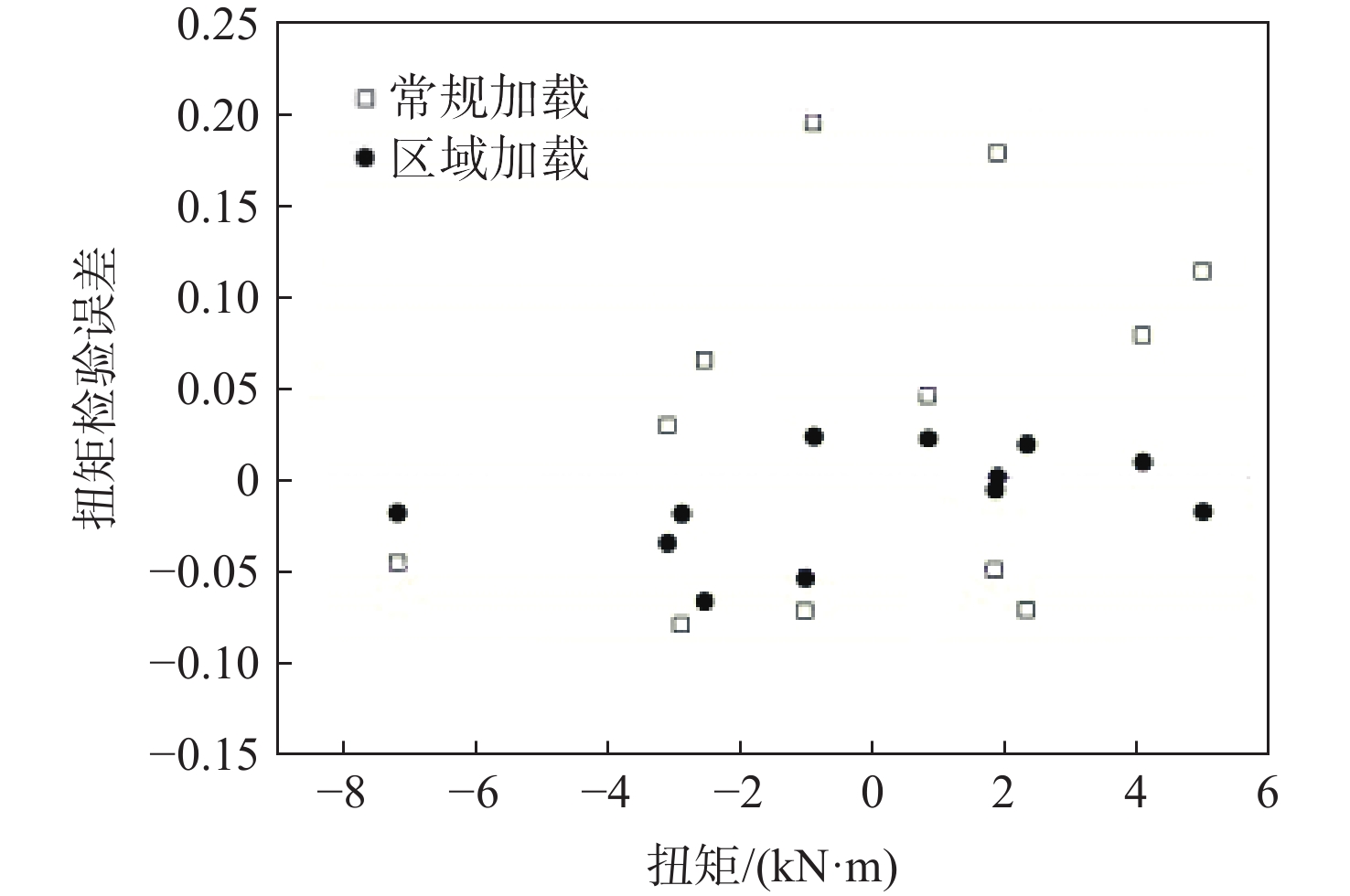

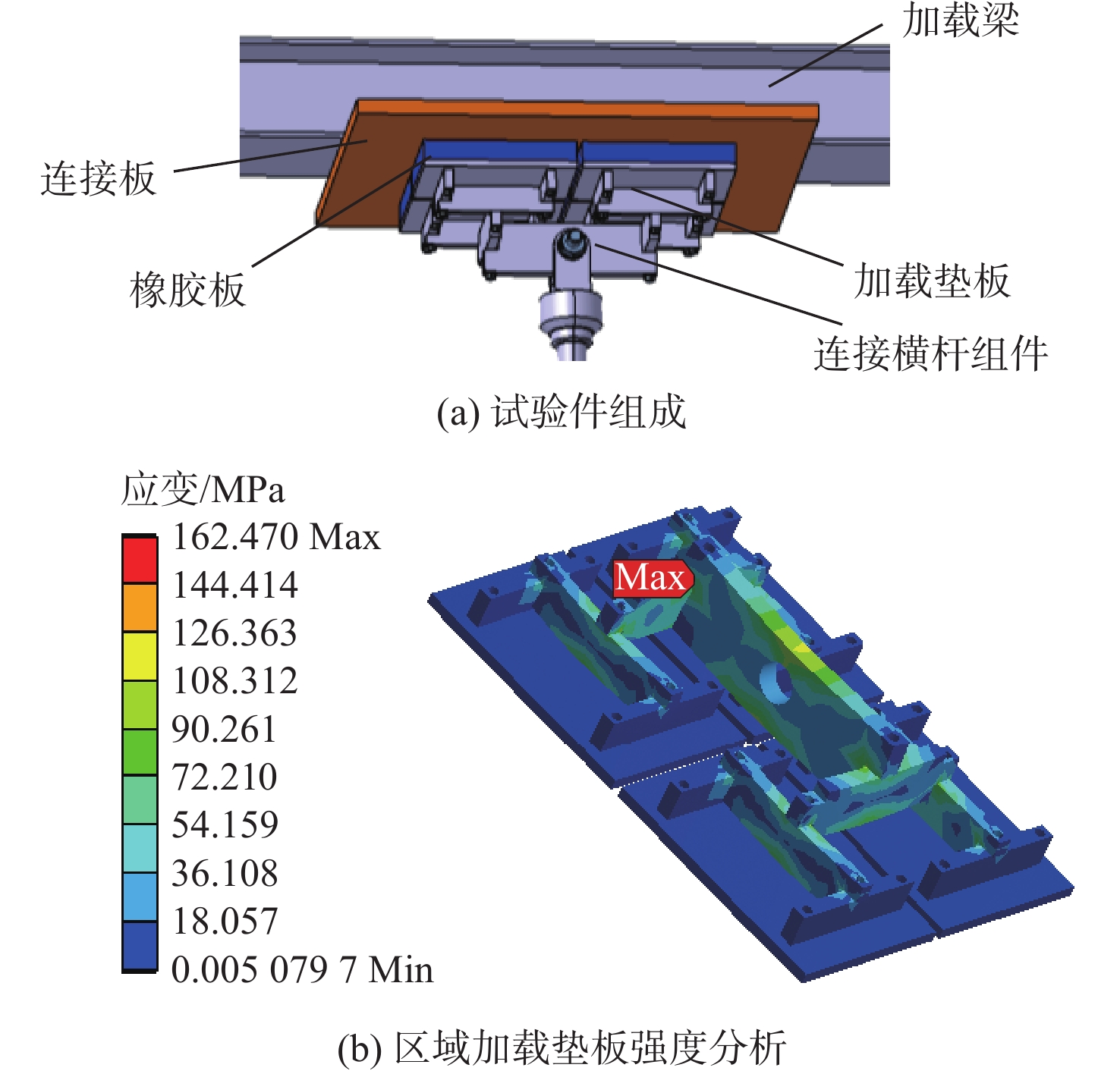

载荷校准试验是飞机飞行载荷测量的关键环节,载荷的施加与翼面真实受载一致或接近,直接决定载荷测量的精度。针对载荷校准试验时载荷量级受局部强度限制难以提高、不能同时实现拉压双向加载、扭矩载荷测量精度不高等问题,开展载荷校准试验区域加载技术研究,通过试验件设计和黏接工艺研究、地面验证试验、机上验证试验等,在飞机载荷校准试验中实现双向同时加载,校准载荷量级大幅提高,并在某型支线飞机载荷校准试验中进行了应用研究,取得了良好的试验结果。

Abstract:The consistency of the applied load with or proximity to the actual load on the wing directly affects the load measurement’s accuracy. Due to local strength restrictions, it is challenging to increase the load level during the load calibration test. Additionally, two-way loading cannot be accomplished at the same time, and the accuracy of the torque load measurement is low.This paper carried out the research on the zone loading technology of the load calibration test. Through test parts design and bonding process research, ground verification test, on-board verification test, etc., for the first time, two-way simultaneous loading was realized in the aircraft load calibration test, and the calibration load level was greatly increased. Applied research has been carried out in the calibration test of a certain type of regional aircraft, and good test results have been obtained.

-

Key words:

- flight test /

- flight loads /

- load calibration test /

- zone loading /

- load measurement

-

表 1 黏接性能试验载荷工况

Table 1. Adhesive performance test load conditions

序号 载荷工况 载荷量级/kN 要求 GK1 拉向 5.3 分10级加载,重复10次 GK2 压向 −21.2 分10级加载,重复10次 GK3 拉压交变 −21.2~5.3 分10级加载,重复30次 GK4 带10°偏度加载 −21.2~5.3 分10级加载,重复5次 GK5 带15°偏度加载 −21.2~5.3 分10级加载,重复5次 表 2 区域加载垫板验证试验载荷工况

Table 2. Zone loading pads verification test load conditions

序号 载荷工况 载荷量级/kN 要求 ZGK1 拉压交变1 −45.12~11.28 分10级加载,重复10次 ZGK2 拉压交变2 −56.4~14.1 分10级加载,重复10次 ZGK3 拉压交变3 −84.6~21.15 分10级加载,重复10次 ZGK4 带偏度10°拉压交变 −84.6~21.15 分10级加载,重复5次 ZGK5 带偏度15°拉压交变 −84.6~21.15 分10级加载,重复5次 -

[1] 中国人民解放军总装备部. 军用飞机结构强度规范 第10部分: 飞行试验: GJB67.10A-2008[S]. 北京: 总装备部军标出版发行部, 2008: 1-10.General Armament Department of the Chinese People’s Liberation Army. Military airplane structural strength specification. Part10: Flight tests: GJB67.10A-2008[S]. Beijing: Army Standards Press of General Armament Department, 2008: 1-10(in Chinese). [2] FAA. Draft AC(J) 25.301 flight loads validation[S]. Washington D.C: FAA, 2002. [3] SKOPINSKI T H, AIKEN W S, HUSTON W B. Calibration of strain-gage installationin aircraft structures for measurement of flight loads, NACA-TR-1178[R]. Washington D.C: NASA, 1954: 505-522. [4] JENKINS J M, DEANGELIS V M. A summary of numerous strain-gage load calibrations on aircraft wings and tails in a technology format: NASA 1997-4804[R]. Washington D.C: NASA, 1997: 90-91. [5] BIRK K, KUEBRICH R. Improved techniques for the calibration and measurement of in-flightloads[C]//Proceedings of the 1st Flight Test Conference. Reston: AIAA, 1981: 2502. [6] LOKOS W, OLNEY C, CHEN T, et al. Strain-gage loads calibration testing of the active aeroelastic wing F/A-18 aircraft[C]//Proceedings of the 22nd AIAA Aerodynamic Measurement Technology and Ground Testing Conference. Reston: AIAA, 2002: 2926. [7] 克利亚奇科M P, 阿尔纳乌托夫E B. 飞机强度飞行试验(静载荷)[M]. 汤吉晨, 译. 西安: 航空航天部《ASST》系统工程办公室, 1992: 1-8.KLIQKO M P, APHAYTOB E B. Aircraft strength flight test (static load)[M]. TANG J C, translated. Xi’an: ASST System Engineering Office of Ministry of Aeronautics and Astronautics, 1992: 1-8(in Chinese). [8] 汤吉晨. 飞机尾翼载荷飞行测量研究[J]. 航空学报, 1989, 10(10): 474-478.TANG J C. Investigation on the determination of airplane tail loads by flight tests[J]. Acta Aeronautica et Astronautica Sinica, 1989, 10(10): 474-478(in Chinese). [9] 曹景涛. 飞机全动式鸭翼载荷飞行测量技术[J]. 航空学报, 2015, 36(4): 1135-1141.CAO J T. Aircraft all movable canard load flight measurement technology[J]. Acta Aeronautica et Astronautica Sinica, 2015, 36(4): 1135-1141(in Chinese). [10] 何发东, 范华飞. 全动平尾带偏度载荷校准试验技术研究[J]. 机械强度, 2014, 36(3): 374-377.HE F D, FAN H F. Stabilator with skewness load calibration test technology research[J]. Journal of Mechanical Strength, 2014, 36(3): 374-377(in Chinese). [11] 曹景涛, 高尚. 液压多点协调加载技术在机翼载荷校准试验中的应用[J]. 航空科学技术, 2015, 26(5): 71-75.CAO J T, GAO S. Application of hydraulic multipoint coordinate loading technology in load calibration test of airfoil[J]. Aeronautical Science & Technology, 2015, 26(5): 71-75(in Chinese). [12] 何乐儒, 贾天娇, 张海涛, 等. 液压协调自动加载系统的多通道协调性研究[J]. 航空科学技术, 2018, 29(3): 40-45.HE L R, JIA T J, ZHANG H T, et al. Study of multi-channel coordination of hydraulic coordination automatic loading system[J]. Aeronautical Science & Technology, 2018, 29(3): 40-45(in Chinese). [13] 何发东. 基于多点协调加载试验的机翼飞行载荷模型研究[J]. 机械科学与技术, 2015, 34(11): 1800-1804.HE F D. Aircraft wing flight load model based on multiple-point coordinated loading calibration test[J]. Mechanical Science and Technology for Aerospace Engineering, 2015, 34(11): 1800-1804(in Chinese). [14] 赵燕. 基于遗传算法与评估模型的飞行载荷实测研究[J]. 航空学报, 2014, 35(9): 2506-2512. doi: 10.7527/S1000-6893.2014.0031ZHAO Y. Flight load measurement based on genetic algorithm and evaluating model[J]. Acta Aeronautica et Astronautica Sinica, 2014, 35(9): 2506-2512(in Chinese). doi: 10.7527/S1000-6893.2014.0031 [15] 吕程, 张辉祥, 夏峰, 等. 大倾角拉压垫加载系统设计与应用[J]. 科学技术与工程, 2018, 18(26): 232-236.LU C, ZHANG H X, XIA F, et al. Design and application of large dip tension/compression pad load system[J]. Science Technology and Engineering, 2018, 18(26): 232-236(in Chinese). [16] 杨家驹. 拉压垫加载技术在飞机结构强度试验中的研究[J]. 科技创新与应用, 2017(6): 80.YANG J J. Research on tension/compression pad loading technology in aircraft structural strength test[J]. Technology Innovation and Application, 2017(6): 80(in Chinese). -

下载:

下载: