-

摘要:

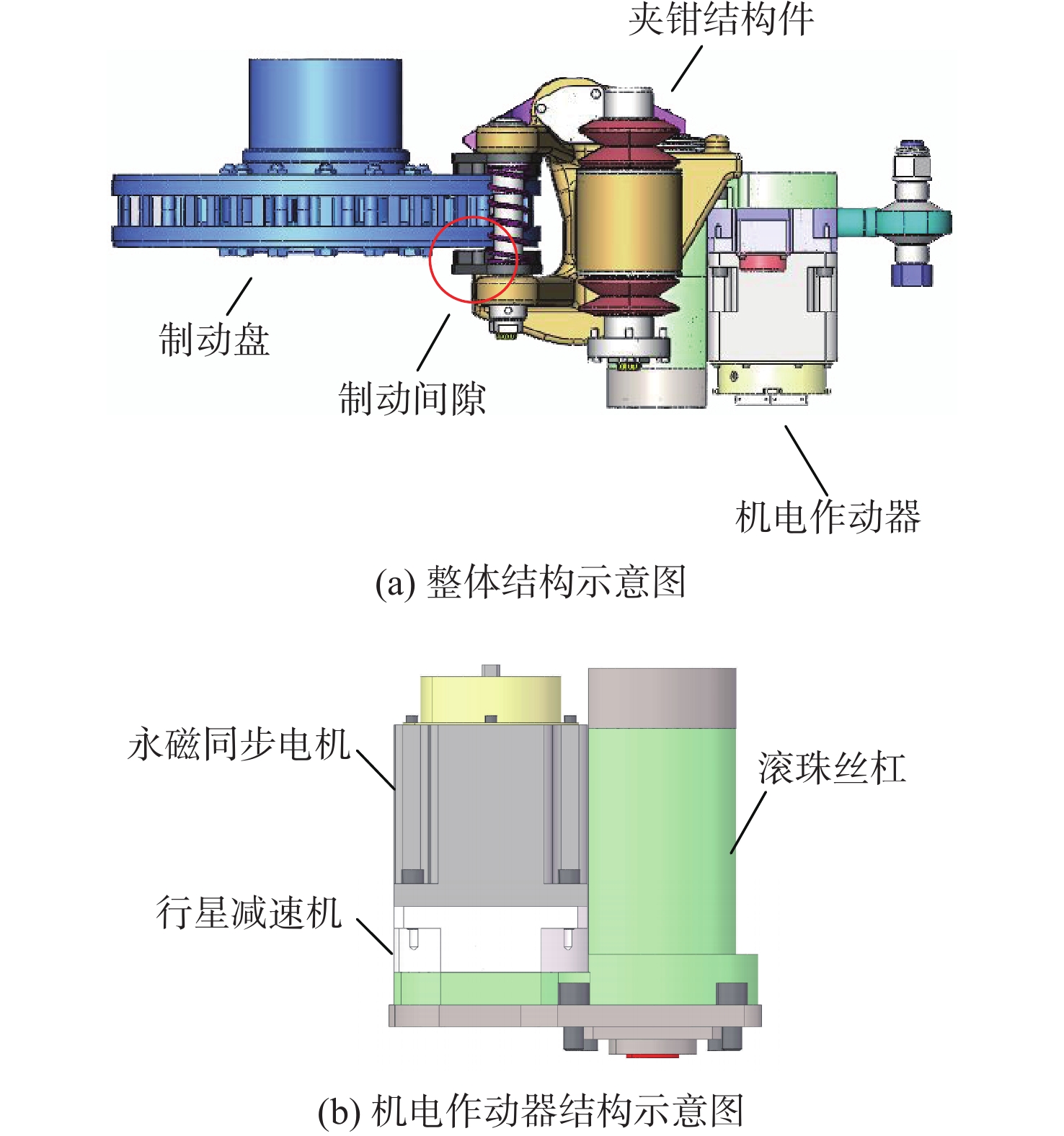

针对低地板有轨电车电子机械制动(EMB)系统压力传感器故障问题,提出一种强耦合条件下的无压力传感器制动力伺服控制策略。基于系统转矩特征曲线,提出一种不依赖于附加机械调节机构及压力检测装置的EMB间隙调整方法。同时,考虑系统制动和缓解过程中存在的“迟滞”特性,在EMB系统刚度特征曲线的基础上,提出一种强耦合条件下的制动力估算策略,与传统方法相比,其可有效地改善制动力的估计精度,能够作为备份制动方案,提高系统的可靠性。在此基础上,设计基于Sigmoid函数的改进型扩张状态观测器(ESO)对系统中的未建模部分与外界扰动进行估计与补偿,并将观测值前馈补偿至积分反步控制器,消除系统的观测误差,提高系统的鲁棒性。通过静态实验平台验证了所提控制策略的有效性。

Abstract:A clamping force sensorless servo control strategy under strong coupling conditions is proposed for low-floor trams with an electromechanical brake (EMB) system. Firstly, based on the torque characteristic curve of the system, an EMB clearance adjustment strategy is proposed, which does not depend on an additional mechanical adjustment mechanism and clamping force detection device. Considering the inherent hysteresis characteristics during braking and mitigation of the system, a braking force estimation method is also proposed under strong coupling conditions based on the stiffness characteristic curve of the EMB system. Compared with traditional control method, the proposed method can effectively improve the estimation accuracy of braking force and be used as a backup braking scheme to enhance the reliability of the system. In addition, an enhanced extended state observer (ESO) based on Sigmoid functions is designed to estimate and compensate the unmodeled parts and external disturbances in the system. The observed values are feedforward compensated to the integral backstepping controller to eliminate the observation errors of the system and improve the robustness of the system. Finally, the effectiveness of the proposed control strategy is verified through a static experimental platform.

-

表 1 刚度模型拟合曲线系数表

Table 1. Coefficient of fitting curve of stiffness model

i $ {a_{5 - i}} $ $ {a_{4 - i}} $ $ {a_{3 - i}} $ $ {a_{2 - i}} $ $ {a_{1 - i}} $ 1 $ 7.49 \times {10^{ - 6}} $ $ - 5.88 \times {10^{ - 4}} $ $ 1.74 \times {10^{ - 2}} $ $ - 2.49 \times {10^{ - 1}} $ 2.49 2 $ - 1.55 \times {10^{ - 6}} $ $ 1.21 \times {10^{ - 4}} $ $ - 2.93 \times {10^{ - 3}} $ $ 4.62 \times {10^{ - 3}} $ 1.32 3 $ 1.44 \times {10^{ - 5}} $ $ - 1.14 \times {10^{ - 3}} $ $ 3.38 \times {10^{ - 2}} $ $ - 4.61 \times {10^{ - 1}} $ 3.51 -

[1] 李繁飙, 黄培铭, 阳春华, 等. 基于非线性干扰观测器的飞机全电刹车系统滑模控制设计[J]. 自动化学报, 2021, 47(11): 2557-2569.LI F B, HUANG P M, YANG C H, et al. Sliding mode control design of aircraft electric brake system based on nonlinear disturbance observer[J]. Acta Automatica Sinica, 2021, 47(11): 2557-2569(in Chinese). [2] WENG J J, TIAN C, WU M L, et al. Coupled rigid-flexible modelling and dynamic characteristic analysis of electromechanical brake (EMB) units on trains[J]. Proceedings of the Institution of Mechanical Engineers, Part F:Journal of Rail and Rapid Transit, 2021, 235(6): 700-712. doi: 10.1177/0954409720957542 [3] 吴萌岭, 雷驰, 陈茂林. 基于列车电机械制动系统夹紧力的控制算法优化[J]. 同济大学学报(自然科学版), 2020, 48(6): 898-903.WU M L, LEI C, CHEN M L. Control algorithm optimization of clamping force based on train electro-mechanical braking system[J]. Journal of Tongji University (Natural Science), 2020, 48(6): 898-903(in Chinese). [4] 吴萌岭, 马天和, 田春, 等. 列车制动技术发展趋势探讨[J]. 中国铁道科学, 2019, 40(1): 134-144.WU M L, MA T H, TIAN C, et al. Discussion on development trend of train braking technology[J]. China Railway Science, 2019, 40(1): 134-144(in Chinese). [5] 夏利红, 邓兆祥. 电子机械制动执行器的摩擦力矩和能耗分析[J]. 湖南大学学报(自然科学版), 2018, 45(4): 48-56.XIA L H, DENG Z X. Calculation and analysis of friction torque and energy dissipation of electromechanical brake actuator[J]. Journal of Hunan University (Natural Sciences), 2018, 45(4): 48-56(in Chinese). [6] BAEK S K, OH H K, KIM S W, et al. A clamping force performance evaluation of the electro mechanical brake using PMSM[J]. Energies, 2018, 11(11): 2876. doi: 10.3390/en11112876 [7] MA R, ZHANG H Y, YUAN M H, et al. Chattering suppression fast terminal sliding mode control for aircraft EMA braking system[J]. IEEE Transactions on Transportation Electrification, 2021, 7(3): 1901-1914. doi: 10.1109/TTE.2021.3054510 [8] 彭晓燕, 何磊, 吕以滨. 基于滑移率的电子机械制动模糊滑模控制[J]. 中南大学学报(自然科学版), 2018, 49(2): 360-370.PENG X Y, HE L, LYU Y B. Fuzzy sliding mode control based on vehicle slip ratio for electro-mechanical braking systems[J]. Journal of Central South University (Science and Technology), 2018, 49(2): 360-370(in Chinese). [9] LI Y J, SHIM T, SHIN D H, et al. Control system design for electromechanical brake system using novel clamping force model and estimator[J]. IEEE Transactions on Vehicular Technology, 2021, 70(9): 8653-8668. doi: 10.1109/TVT.2021.3095900 [10] EUM S, CHOI J, PARK S S, et al. Robust clamping force control of an electro-mechanical brake system for application to commercial city buses[J]. Energies, 2017, 10(2): 220. doi: 10.3390/en10020220 [11] KWON S, LEE S, LEE J, et al. Accurate state estimation for electro-mechanical brake systems[J]. Journal of Electrical Engineering & Technology, 2019, 14(2): 889-896. [12] XU Z, GERADA C. Enhanced force estimation for electromechanical brake actuators in transportation vehicles[J]. IEEE Transactions on Power Electronics, 2021, 36(12): 14329-14339. doi: 10.1109/TPEL.2021.3085996 [13] FU Y F, HU X H, WANG W R, et al. Simulation and experimental study of a new electromechanical brake with automatic wear adjustment function[J]. International Journal of Automotive Technology, 2020, 21(1): 227-238. doi: 10.1007/s12239-020-0022-y [14] JO C, HWANG S, KIM H. Clamping-force control for electromechanical brake[J]. IEEE Transactions on Vehicular Technology, 2010, 59(7): 3205-3212. doi: 10.1109/TVT.2010.2043696 [15] SARIC S, BAB-HADIASHAR A, VAN DER WALT J. Estimating clamp force for brake-by-wire systems: Thermal considerations[J]. Mechatronics, 2009, 19(6): 886-895. doi: 10.1016/j.mechatronics.2009.05.001 [16] 朱进权, 葛琼璇, 孙鹏琨, 等. 基于自抗扰的高速磁浮列车牵引控制策略[J]. 电工技术学报, 2020, 35(5): 1065-1074.ZHU J Q, GE Q X, SUN P K, et al. Traction-system research of high-speed maglev based on active disturbance rejection control[J]. Transactions of China Electrotechnical Society, 2020, 35(5): 1065-1074(in Chinese). [17] 刘华, 汪成文, 郭新平, 等. 电液负载敏感位置伺服系统自抗扰控制方法[J]. 北京航空航天大学学报, 2020, 46(11): 2131-2139.LIU H, WANG C W, GUO X P, et al. Active disturbance rejection control method for position servo system based on electro-hydraulic load sensing[J]. Journal of Beijing University of Aeronautics and Astronautics, 2020, 46(11): 2131-2139(in Chinese). [18] 石嘉, 裴忠才, 唐志勇, 等. 改进型自抗扰四旋翼无人机控制系统设计与实现[J]. 北京航空航天大学学报, 2021, 47(9): 1823-1831.SHI J, PEI Z C, TANG Z Y, et al. Design and realization of an improved active disturbance rejection quadrotor UAV control system[J]. Journal of Beijing University of Aeronautics and Astronautics, 2021, 47(9): 1823-1831(in Chinese). [19] 王伟然, 吴嘉欣, 张懿, 等. 永磁同步电机模糊自整定自适应积分反步控制[J]. 电工技术学报, 2020, 35(4): 724-733.WANG W R, WU J X, ZHANG Y, et al. Fuzzy self-tuning adaptive integral backstepping control for permanent magnet synchronous motor[J]. Transactions of China Electrotechnical Society, 2020, 35(4): 724-733(in Chinese). [20] 赵亚辉, 冯明, 李卫文. 基于SMO的改进型转子位置检测方法[J]. 北京航空航天大学学报, 2020, 46(12): 2329-2338.ZHAO Y H, FENG M, LI W W. Improved rotor position detection method based on SMO[J]. Journal of Beijing University of Aeronautics and Astronautics, 2020, 46(12): 2329-2338(in Chinese). [21] ZHAO Y Y, LIN H, LI B Q. Sliding-mode clamping force control of electromechanical brake system based on enhanced reaching law[J]. IEEE Access, 2021, 9: 19506-19515. doi: 10.1109/ACCESS.2021.3052944 [22] 陈志旺, 张子振, 曹玉洁. 自抗扰fal函数改进及在四旋翼姿态控制中的应用[J]. 控制与决策, 2018, 33(10): 1901-1907.CHEN Z W, ZHANG Z Z, CAO Y J. Fal function improvement of ADRC and its application in quadrotor aircraft attitude control[J]. Control and Decision, 2018, 33(10): 1901-1907(in Chinese). -

下载:

下载: