Design and parameter optimization method of compaction admittance controller for automated fiber placement

-

摘要:

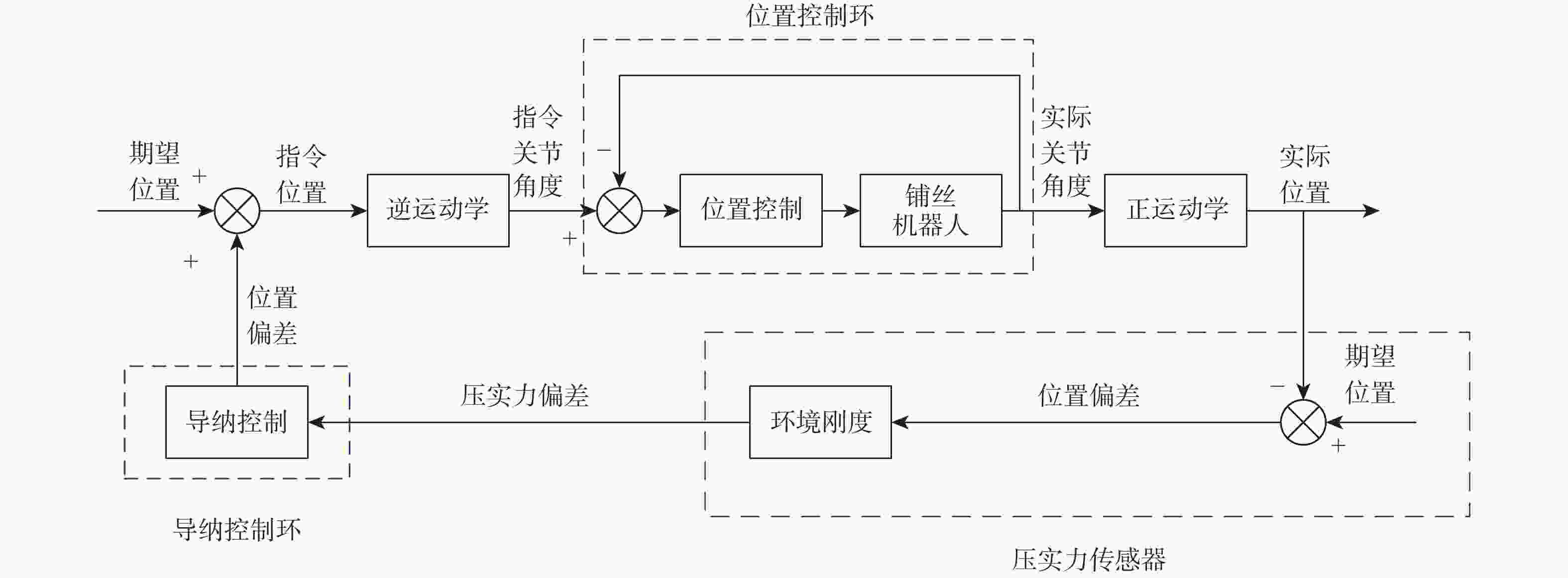

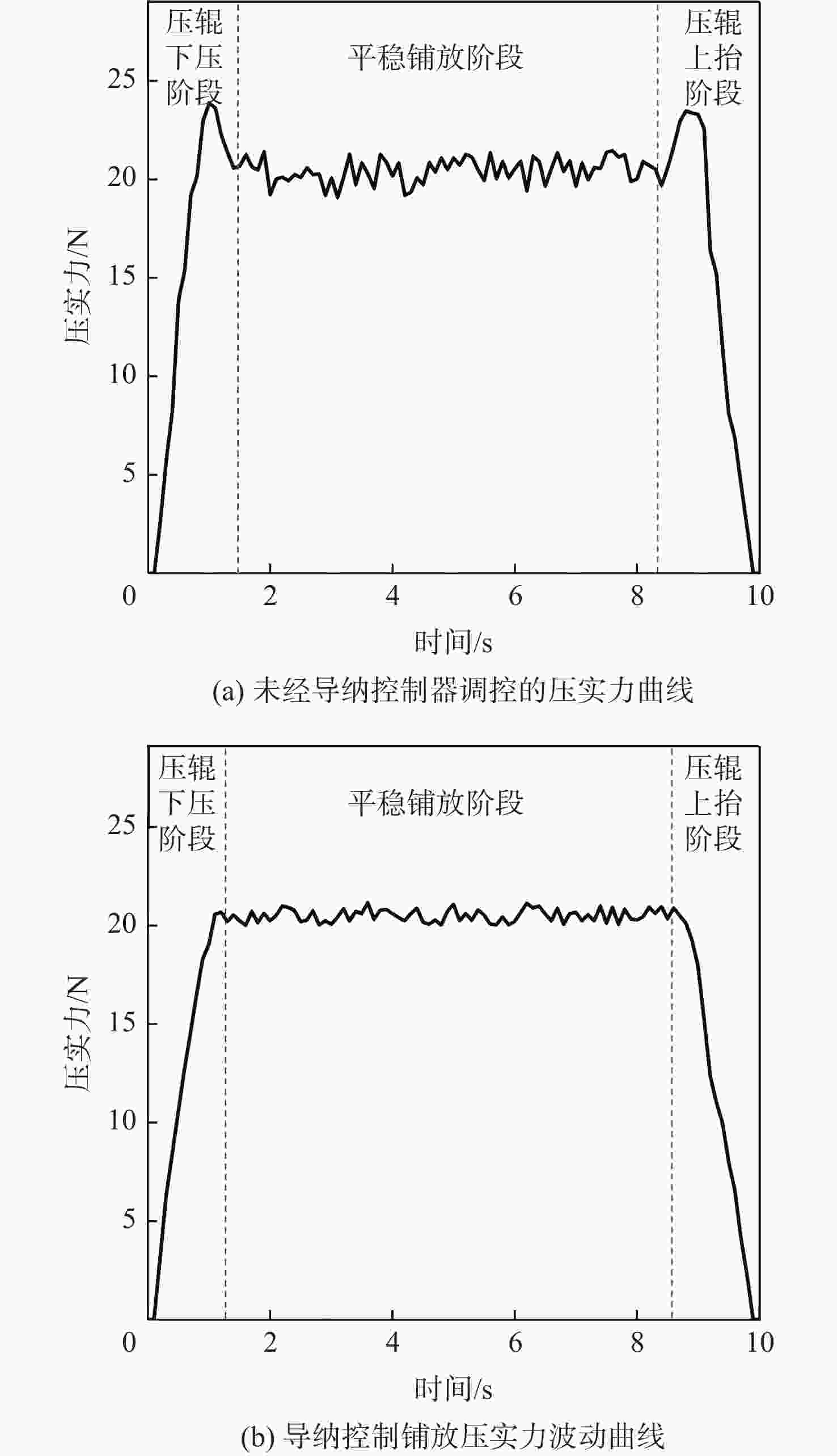

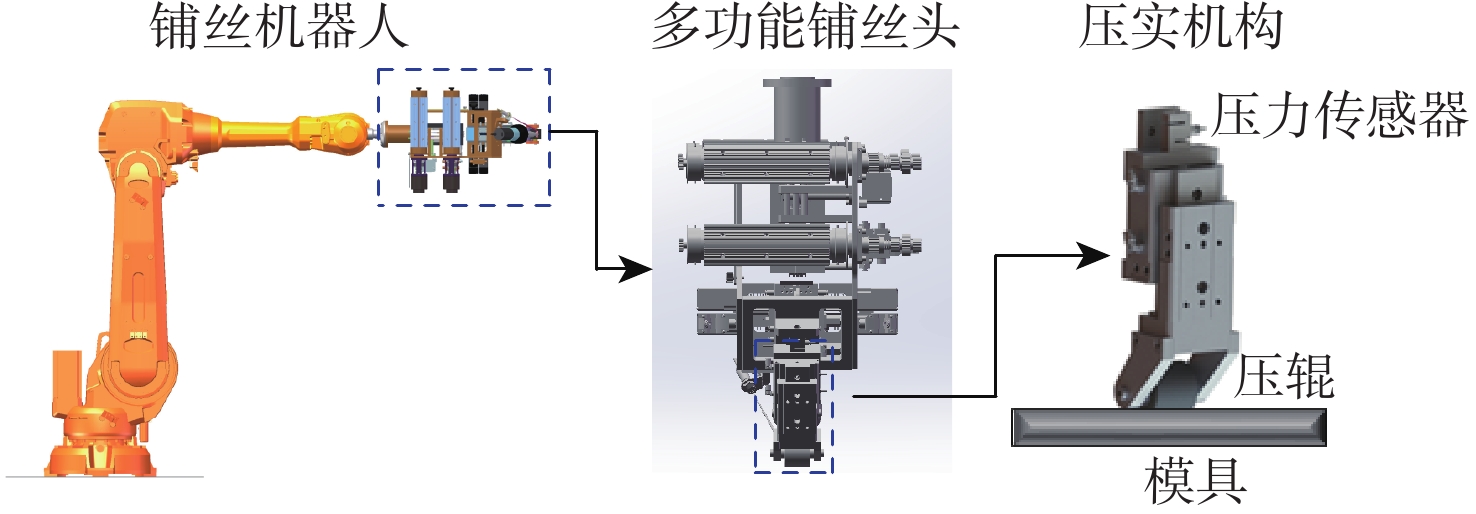

铺放压实力是连续纤维复合材料结构自动铺放成型的关键工艺参数之一。由于多数铺丝设备刚性高且位控精度不足,往往容易导致压实力波动较大,严重影响成型质量。因此,面向纤维预浸料自动铺放成型过程中压实力的柔顺控制要求,构建铺丝设备压实机构与成型模具间的二阶等效模型,设计一种基于导纳控制原理的铺放压实力控制器,采用烟花群体智能算法对控制器的惯性参数、阻尼参数及刚度参数进行优化求解,并通过建模仿真与铺放试验验证铺放压实力导纳控制器的有效性。

Abstract:Compaction pressure is one of the crucial manufacturing process parameters of continuous fiber composite structures fabricated by automated fiber placement. Due to the high rigidity and insufficient position control accuracy of most automated fiber placements, compaction pressure fluctuates drastically which results in poor forming quality. In order to satisfy the compliance control requirements of pressure regulation, the second-order equivalent model between the compaction mechanism and the forming mould was constructed, a pressure controller based on admittance control principle was proposed. Further, the inertia parameter, damping parameter and stiffness parameter of the controller were optimized by using fireworks swarm intelligence algorithm, and the effectiveness of the controller was demonstrated by modeling and simulation, and practical layup experiment.

-

表 1 烟花算法及优化目标主要参数

Table 1. Main parameters of fireworks algorithm and optimization objective

参数 设定值 烟花阵列数量 50 变量维数 3 惯性参数空间 (0,10) 阻尼参数空间 (100,300) 刚度参数空间 (0,10) 高斯变异火花数量 3 爆炸火花数目常数 5 爆炸半径常数 5 迭代次数 300 ITAE权重ω1 0.01 稳态误差权重ω2 0.1 -

[1] SOUTIS C. Carbon fiber reinforced plastics in aircraft construction[J]. Materials Science and Engineering:A, 2005, 412(1-2): 171-176. doi: 10.1016/j.msea.2005.08.064 [2] OROMIEHIE E, PRUSTY B G, COMPSTON P, et al. Automated fibre placement based composite structures: Review on the defects, impacts and inspections techniques[J]. Composite Structures, 2019, 224: 110987. doi: 10.1016/j.compstruct.2019.110987 [3] SHIRINZADEH B, ALICI G, FOONG C W, et al. Fabrication process of open surfaces by robotic fibre placement[J]. Robotics and Computer-Integrated Manufacturing, 2004, 20(1): 17-28. doi: 10.1016/S0736-5845(03)00050-4 [4] AIZED T, SHIRINZADEH B. Robotic fiber placement process analysis and optimization using response surface method[J]. The International Journal of Advanced Manufacturing Technology, 2011, 55(1): 393-404. [5] CHEN M J, WU B L, CHEN Y, et al. Design of tension control system for automated fibre placement[C]// Proceedings of the 5th International Conference on Mechanical Engineering, Materials and Energy. Paris: Atlantis Press, 2016. [6] DI FRANCESCO M, VELDENZ L, DELL'ANNO G, et al. Heater power control for multi-material, variable speed automated fibre placement[J]. Composites Part A:Applied Science and Manufacturing, 2017, 101: 408-421. doi: 10.1016/j.compositesa.2017.06.015 [7] JIANG J X, HE Y X, WANG H, et al. Modeling and experimental validation of compaction pressure distribution for automated fiber placement[J]. Composite Structures, 2021, 256: 113101. doi: 10.1016/j.compstruct.2020.113101 [8] DUBOIS O, LE CAM J B, BÉAKOU A. Experimental analysis of prepreg tack[J]. Experimental Mechanics, 2010, 50(5): 599-606. doi: 10.1007/s11340-009-9236-7 [9] DE JESUS G O I, PATROUIX O, AOUSTIN Y. Pressure based approach for automated fiber placement (AFP) with sensor based feedback loop and flexible component in the effector[J]. IFAC-PapersOnLine, 2017, 50(1): 794-799. doi: 10.1016/j.ifacol.2017.08.511 [10] 段玉岗, 刘芬芬, 陈耀, 等. 纤维铺放压紧力及预浸带加热温度对复合材料力学性能的影响[J]. 复合材料学报, 2012, 29(4): 148-156. doi: 10.13801/j.cnki.fhclxb.2012.04.025DUAN Y G, LIU F F, CHEN Y, et al. Effects of compaction force and heating temperature of prepreg on composite mechanical properties during fiber placement process[J]. Acta Materiae Compositae Sinica, 2012, 29(4): 148-156(in Chinese). doi: 10.13801/j.cnki.fhclxb.2012.04.025 [11] 马志涛, 李初晔, 冯长征, 等. 铺放压力和铺放压辊对丝束铺放质量影响的研究[J]. 航空制造技术, 2018, 61(20): 88-91. doi: 10.16080/j.issn1671-833x.2018.20.088MA Z T, LI C Y, FENG C Z, et al. Effect of placement pressure and placement roller on quality of tows placement[J]. Aeronautical Manufacturing Technology, 2018, 61(20): 88-91(in Chinese). doi: 10.16080/j.issn1671-833x.2018.20.088 [12] HOGAN N. Impedance control: An approach to manipulation: Part I—theory, implementation and applications[J]. Journal of Dynamic Systems, Measurement, and Control, 1985, 107(1): 1-24. [13] MO Y, GAO S, JIANG Z H, et al. Impedance control with force signal compensation on space manipulator-assisted docking mission[C]//2014 IEEE International Conference on Information and Automation. Piscataway: IEEE Press, 2014: 1239-1243. [14] SAYYAADI H, SHARIFI M. Adaptive impedance control of UAVs interacting with environment using a robot manipulator[C]//2014 Second RSI/ISM International Conference on Robotics and Mechatronics. Piscataway: IEEE Press, 2014: 636-641. [15] 喻洋, 王耀兵, 魏世民, 等. 基于柔顺控制的机器人装配技术[J]. 北京邮电大学学报, 2020, 43(4): 1-6. doi: 10.13190/j.jbupt.2019-227YU Y, WANG Y B, WEI S M, et al. Robot assembly technology based on compliance control[J]. Journal of Beijing University of Posts and Telecommunications, 2020, 43(4): 1-6(in Chinese). doi: 10.13190/j.jbupt.2019-227 [16] LASKY T A, HSIA T C. On force-tracking impedance control of robot manipulators[C]//Proceedings of 1991 IEEE International Conference on Robotics and Automation. Piscataway: IEEE Press, 1991: 274-280. [17] JIN M H, ZHANG Z J, NI F L, et al. Cartesian Space Synchronous Impedance Control of Two 7-DOF robot arm manipulators[C]// 2014 IEEE/RSJ International Conference on Intelligent Robots and Systems. Piscataway: IEEE Press, 2014: 4750-4756. [18] 李正义. 机器人与环境间力/位置控制技术研究与应用[D]. 武汉: 华中科技大学, 2011.LI Z Y. Research and application of robot force position control methods for robot-environment interaction[D]. Wuhan: Huazhong University of Science and Technology, 2011 (in Chinese). [19] TAN Y, YU C, ZHENG S Q, et al. Introduction to fireworks algorithm[J]. International Journal of Swarm Intelligence Research, 2013, 4(4): 39-70. doi: 10.4018/ijsir.2013100103 [20] 谭营, 郑少秋. 烟花算法研究进展[J]. 智能系统学报, 2014, 9(5): 515-528. doi: 10.3969/j.issn.1673-4785.201409010TAN Y, ZHENG S Q. Recent advances in fireworks algorithm[J]. CAAI Transactions on Intelligent Systems, 2014, 9(5): 515-528(in Chinese). doi: 10.3969/j.issn.1673-4785.201409010 [21] XUE J J, WANG Y, LI H, et al. Advanced fireworks algorithm and its application research in PID parameters tuning[J]. Mathematical Problems in Engineering, 2016, 2016: 1-9. -

下载:

下载: