-

摘要:

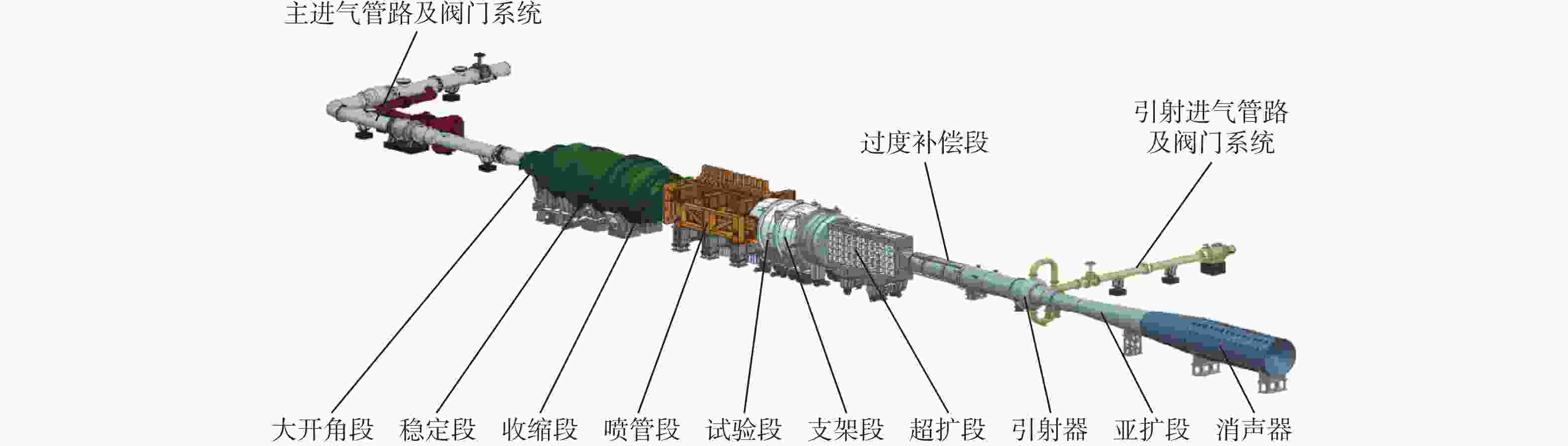

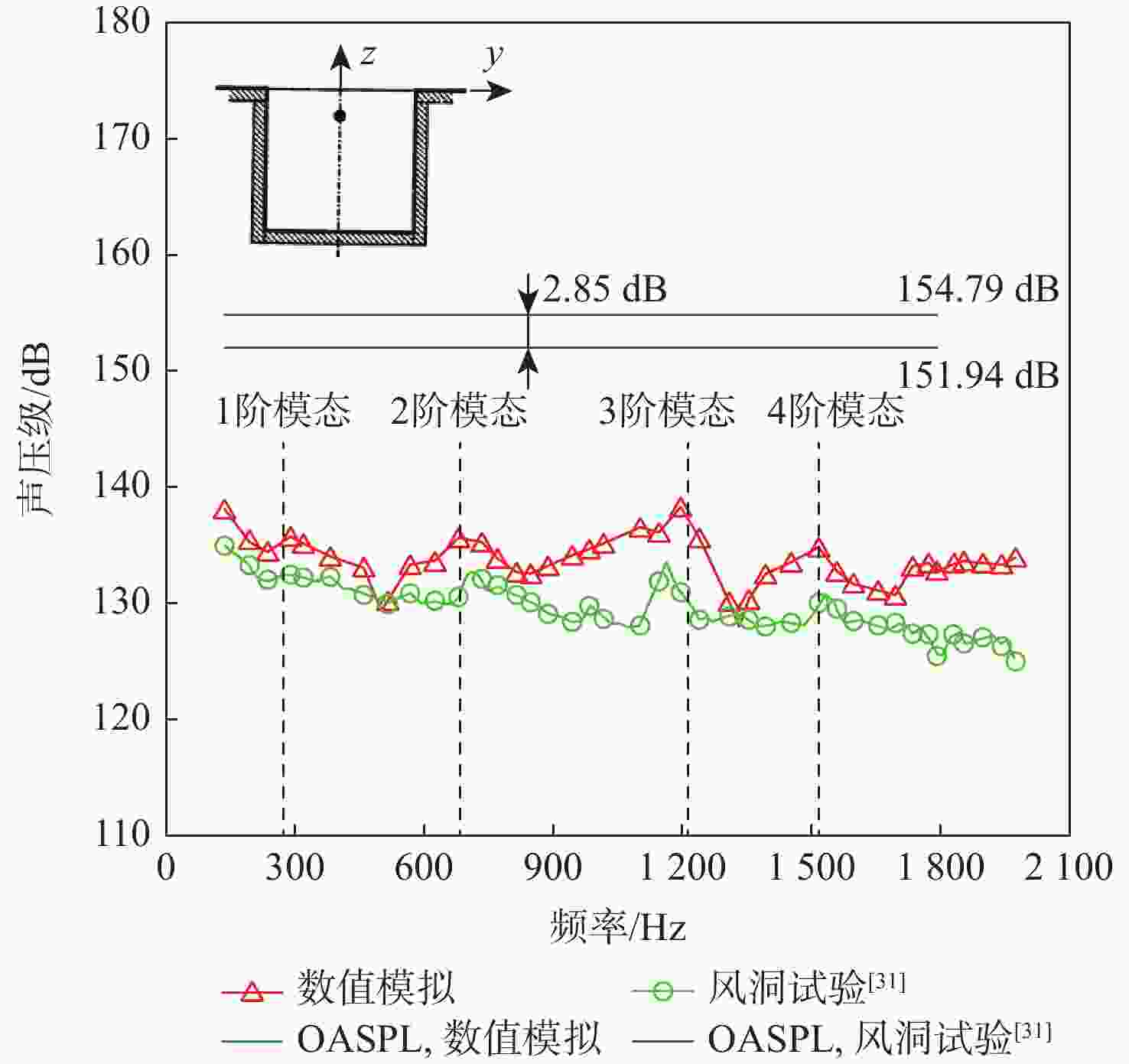

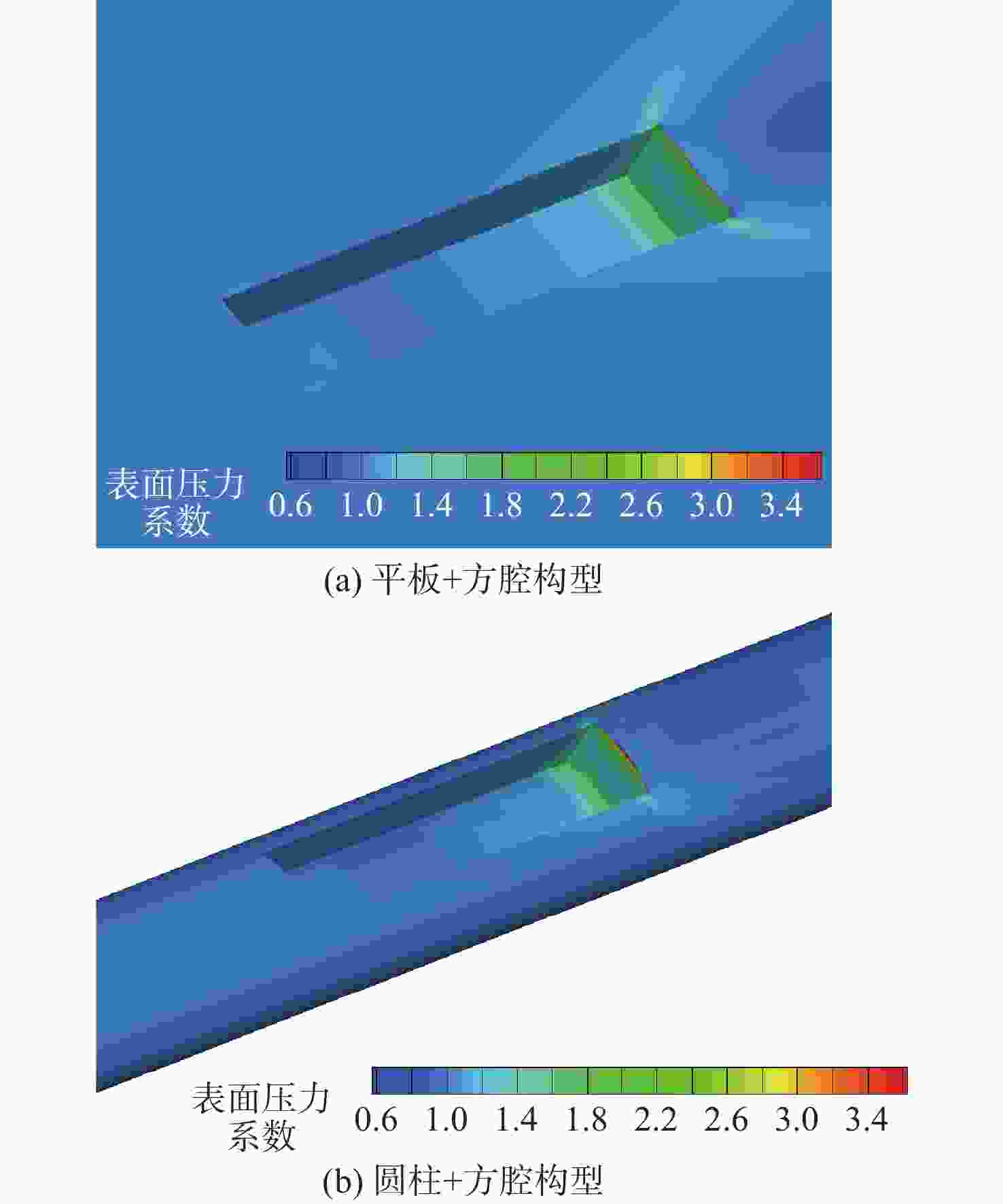

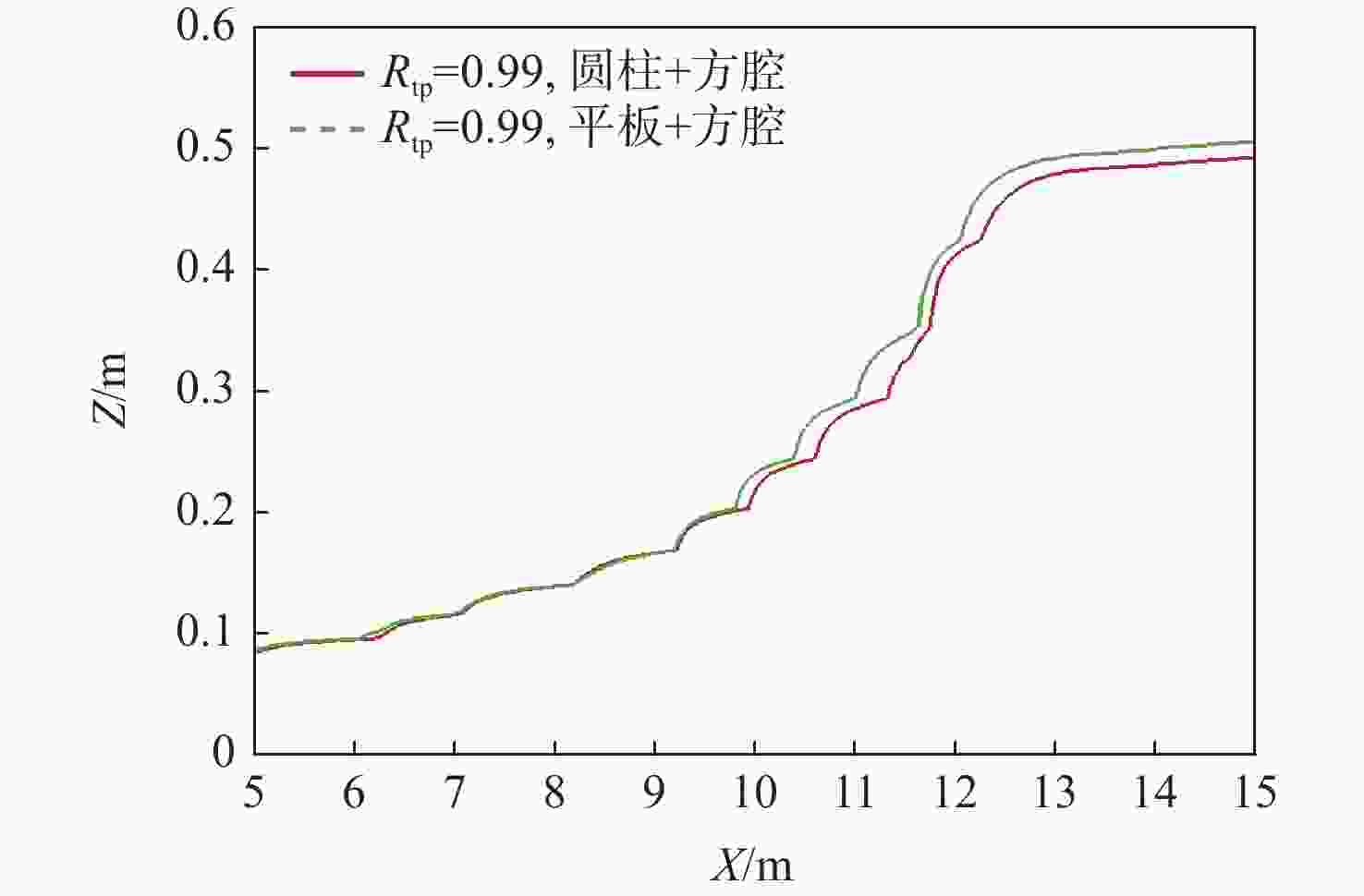

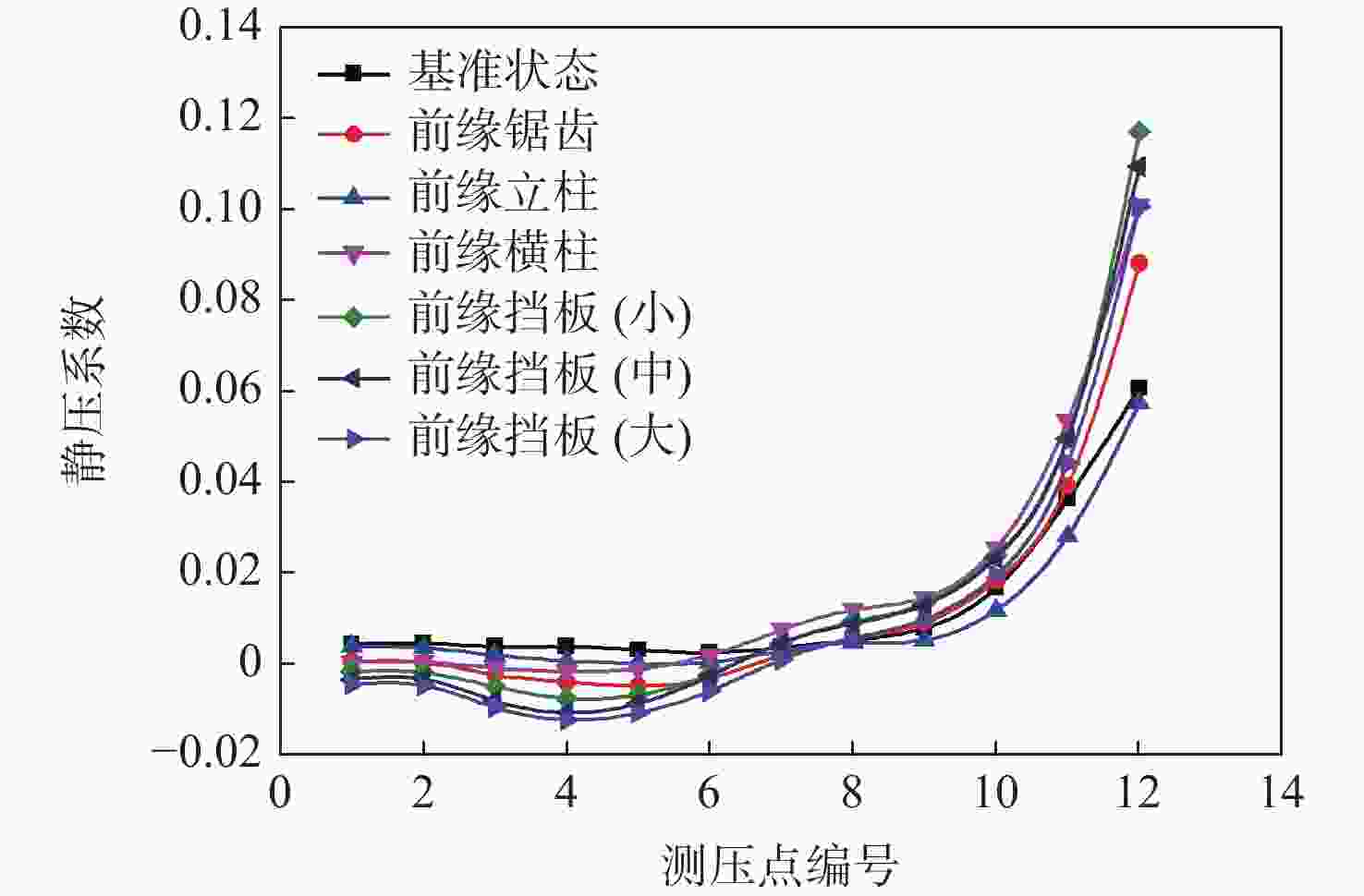

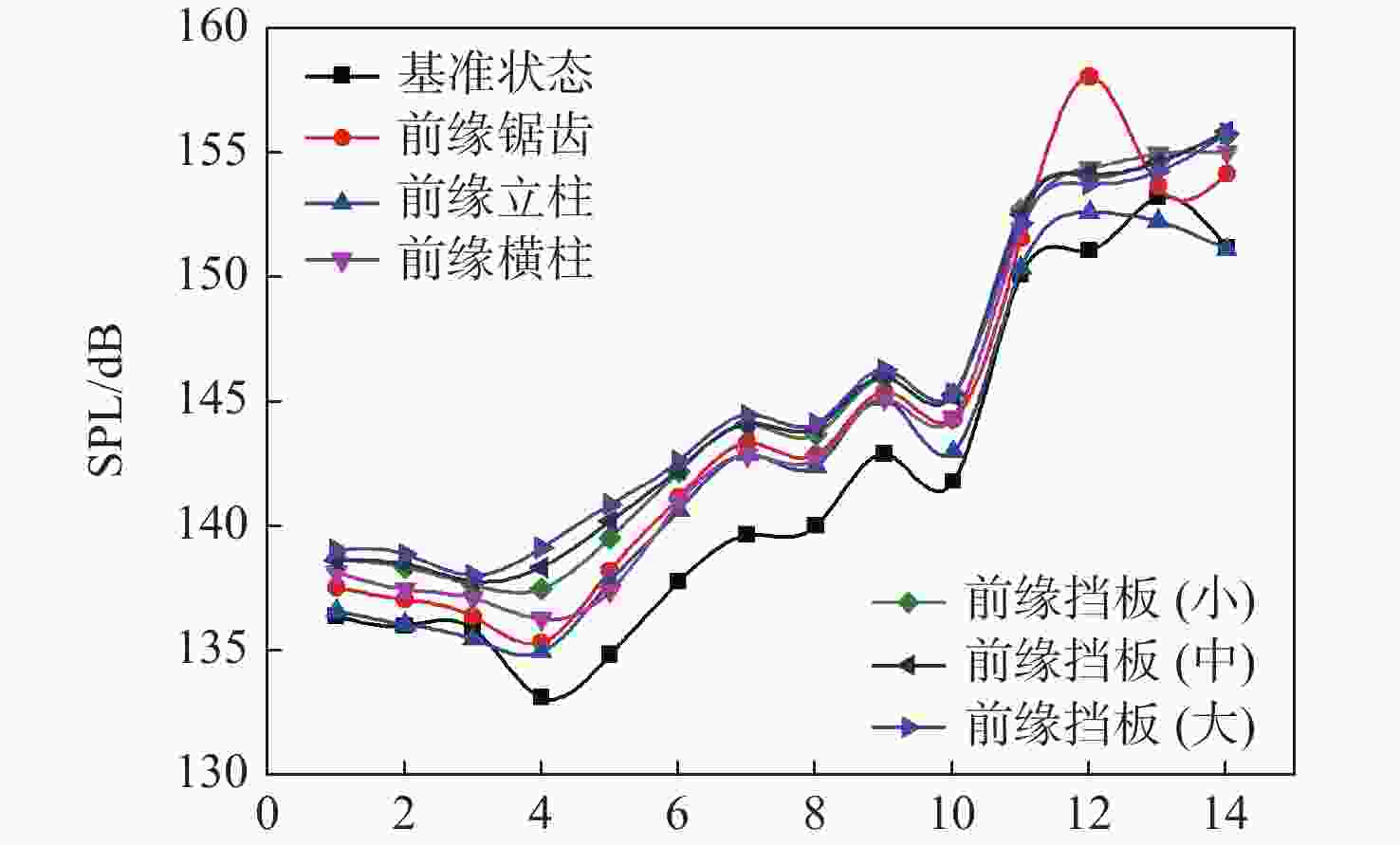

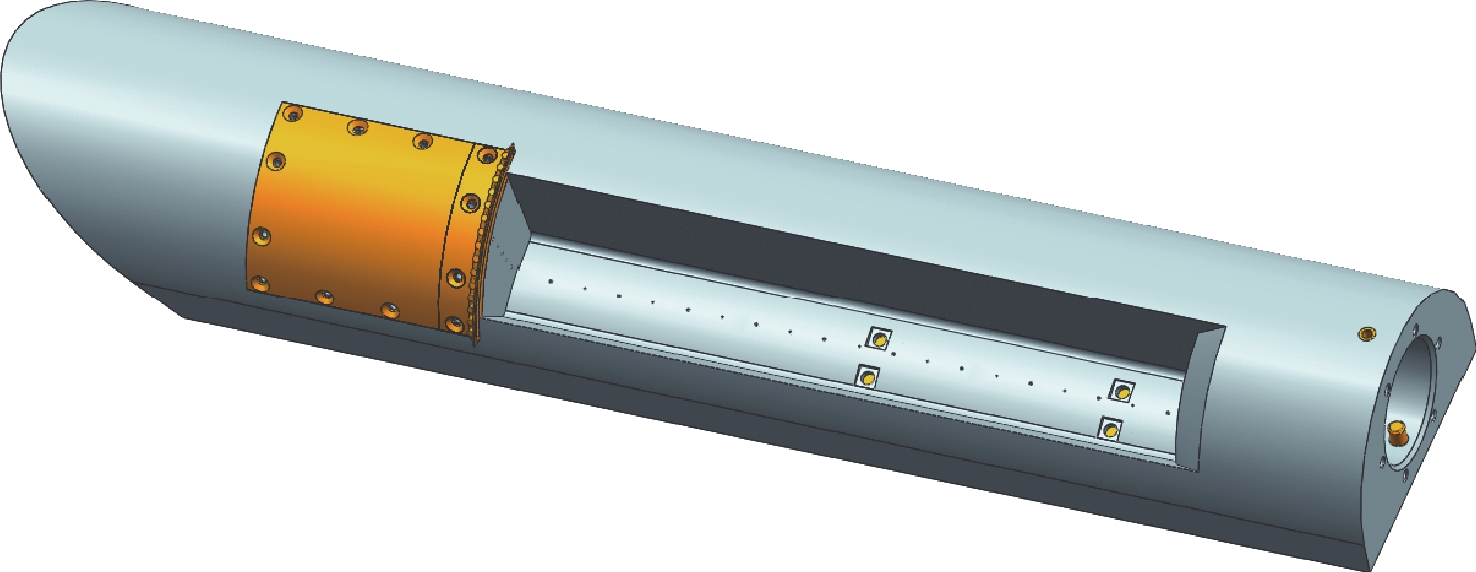

高马赫数(

Ma >2)武器舱剪切层更强、更稳定,其噪声产生机制与通常的亚、跨、超声速武器舱流动不同,导致用来抑制空腔噪声的流动控制措施也不同。分别采用数值模拟和风洞试验2种手段,研究了圆柱形机身和马赫数对空腔流动特性的影响,以及前缘锯齿、前缘立柱、前缘横柱、前缘挡板等不同被动流动控制措施对高马赫数武器舱声压级特性的影响,为高马赫数武器舱的流动控制措施设计和研究提供参考。研究表明:圆柱形机身对空腔底部的压力分布会产生影响,压力分布的不均匀性增大,后壁附近的压力峰值增大;对通常的亚、跨、超声速武器舱流动较为有效的被动流动控制措施,对高马赫数空腔流动效果不明显,甚至会加大武器舱内的噪声等级,需要开展更为深入的研究,以设计更为有效的流动控制措施。Abstract:The noise generation mechanism of weapon bays at a high Mach number (

Ma >2) is different from that of the subsonic, transonic, and supersonic weapon bay flow because of the stronger and more stable shear layer. This discrepancy may also lead to different flow control measures for cavity noise suppression. Using numerical simulations and wind tunnel tests, this study examines the effects of the cylindrical fuselage and Mach number on cavity flow characteristics, and of different passive flow control measures such as leading edge serrations, leading edge columns, leading edge transverse columns and leading edge baffles on the sound pressure level of a weapon bay at a high Mach number. This study provides a reference for the design and research of flow control measures for a high Mach number weapon bay. The results show that the cylindrical fuselage has an impact on the pressure distribution at the cavity bottom, that the unevenness of the pressure distribution increases, and that the pressure peak near the rear wall increases. The passive flow control measures, which are more effective for the subsonic, transonic and supersonic weapon bay flow, are not effective for the high Mach number cavity flow, and even increase the noise level in the weapon bay. Further research is needed to design more effective flow control measures.-

Key words:

- weapon bay /

- numerical simulation /

- wind tunnel test /

- flow control /

- sound pressure level

-

-

[1] LAWSON S J, BARAKOS G N. Review of numerical simulations for high-speed, turbulent cavity flows[J]. Progress in Aerospace Sciences, 2011, 47(3): 186-216. doi: 10.1016/j.paerosci.2010.11.002 [2] MAULL D J, EAST L F. Three-dimensional flow in cavities[J]. Journal of Fluid Mechanics, 1963, 16(4): 620-632. doi: 10.1017/S0022112063001014 [3] DIX R E, BAUER R C. Experimental and theoretical study of cavity acoustics: AEDC-TR-99-4[R]. Arnold AFB: Arnold Engineering Development Center, 2000. [4] ZHUANG N, ALVI F S, ALKISLAR M B, et al. Supersonic cavity flows and their control[J]. AIAA Journal, 2006, 44(9): 2118-2128. doi: 10.2514/1.14879 [5] TAKEDA K, SHIEH C M. Cavity tones by computational aeroacoustics[J]. International Journal of Computational Fluid Dynamics, 2004, 18(6): 439-454. doi: 10.1080/10618560410001673461 [6] CATTAFESTA L N, SONG Q, WILLIAMS D R, et al. Review of active control of flow-induced cavity resonance: AIAA-2003-3567[R]. Reston: AIAA, 2003. [7] SHAW L. Active control for cavity acoustics: AIAA-1998-2347[R]. Reston: AIAA, 1998. [8] KIM B H. Modeling pulsed blowing systems for active flow control [D]. Chicago: Illinois Institute of Technology, 2003. [9] SMITH B, WELTERLEN T, MAINES B, et al. Weapons bay acoustic suppression from rod spoilers: AIAA-2002-0662[R]. Reston: AIAA, 2002. [10] NORTON D. Investigation of B47 bomb bay buffet: D12675[R]. Chicago: Boeing Airplane Co. , 1952. [11] ROSSITER J. The effects of cavities on the buffetting of aircraft: AERO. 754[R]. Bedfordshire: Royal Aircraft Establishment, 1962. [12] ROSSITER J, KURN A. Wind tunnel measurements of the unsteady pressures in and behind a bomb bay (T.S.R.2): AERO. 2677[R]. Bedfordshire: Royal Aircraft Establishment, 1963. [13] SHAW L, CLARK R, TALMADGE D. F-111 generic weapons bay acoustic environment[J]. Journal of Aircraft, 1988, 25(2): 147-153. doi: 10.2514/3.45555 [14] UKEILEY L S, PONTON M K, SEINER J M. Suppression of pressure loads in cavity flows[J]. AIAA Journal, 2004, 42(1): 70-79. doi: 10.2514/1.9032 [15] SADDINGTON A J, THANGAMANI V, KNOWLES K. Comparison of passive flow control methods for a cavity in transonic flow[J]. Journal of Aircraft, 2016, 53(5): 1439-1447. doi: 10.2514/1.C033365 [16] ROSS J, PETO J. The effect of cavity shaping, front spoilers and ceiling bleed on loads acting on stores, and on the unsteady environment within weapon bays: DERA/AS/HWA/CR97010/1[R]. Bedfordshire: Royal Aircraft Establishment, 1997. [17] BAYSAL O, YEN G W, FOULADI K. Navier-Stokes computations of cavity aero-acoustics with suppression devices[J]. Journal of Vibration and Acoustics, 1994, 116(1): 105-112. doi: 10.1115/1.2930385 [18] LAWSON S J, BARAKOS G N. Assessment of passive flow control for transonic cavity flow using detached-eddy simulation[J]. Journal of Aircraft, 2009, 46(3): 1009-1029. doi: 10.2514/1.39894 [19] ASHWORTH R. DES of a cavity with spoiler[C]//Proceedings of the 2nd Symposium on Hybrid RANS-LES Methods. Berlin: Springer, 2008: 162-171. [20] TIPTON A G, SHAW L L. Weapon bay cavity noise environments data correlation and prediction for the B-1 aircraft: AFW AL-TR-0-3060[R]. Los Angeles: Rockwell International Corporation, 1980. [21] CENKO A, SESLANDES R, DILLENIUS M, et al. Unsteady weapon bay aerodynamics—Urban legend or flight clearance nightmare[C]//Proceedings of the 46th AIAA Aerospace Sciences Meeting and Exhibit. Reston: AIAA, 2008. [22] 吴继飞, 徐来武, 范召林, 等. 开式空腔气动声学特性及其流动控制方法[J]. 航空学报, 2015, 36(7): 2155-2165.WU J F, XU L W, FAN Z L, et al. Aeroacoustic characteristics and flow control method of open cavity flow[J]. Acta Aeronautica et Astronautica Sinica, 2015, 36(7): 2155-2165(in Chinese). [23] 杨党国. 内埋武器舱气动声学特性与噪声抑制研究[D]. 绵阳: 中国空气动力研究与发展中心研究生部, 2010.YANG D G. Studies on aeroacoustic characteristics and noise suppressions for internal weapon bays[D]. Mianyang: Graduate Faculty of China Aerodynamics Research and Development Center, 2010(in Chinese). [24] LUO B H, HU Z W, DAI C H. Experimental study of high subsonic cavity flow oscillation and its suppression by acoustic excitation[J]. Chinese Journal of Aeronautics, 1998, 11(3): 161-164. [25] 谢露, 张彦军, 侯银珠, 等. 亚声速武器舱空腔流动压力特性及其控制方法[J]. 航空学报, 2020, 41(11): 123961.XIE L, ZHANG Y J, HOU Y Z, et al. Cavity flow pressure characteristics and flow control methods of subsonic weapon bay[J]. Acta Aerodynamic et Astronautica Sinica, 2020, 41(11): 123961(in Chinese). [26] 冯强, 崔晓春. 飞翼布局飞机武器舱综合流动控制技术[J]. 航空学报, 2012, 33(5): 781-787.FENG Q, CUI X C. Study on integrated flow control for weapons bay of flying wing configuration aircraft[J]. Acta Aerodynamic et Astronautica Sinica, 2012, 33(5): 781-787(in Chinese). [27] 周方奇, 杨党国, 王显圣, 等. 前缘直板扰流对高速空腔的降噪效果分析[J]. 航空学报, 2018, 39(4): 21812. doi: 10.7527/S1000-6893.2017.21812ZHOU F Q, YANG D G, WANG X S, et al. The effect of leading edge plate on high speed cavity noise controlling[J]. Acta Aeronautica et Astronautica Sinica, 2018, 39(4): 21812(in Chinese). doi: 10.7527/S1000-6893.2017.21812 [28] 刘瑜, 童明波, HU Z W, 等. 基于DDES 算法的有扰流片腔体气动噪声分析[J]. 空气动力学学报, 2015, 33(5): 643-648. doi: 10.7638/kqdlxxb-2014.0025LIU Y, TONG M B, HU Z W, et al. DDES of aeroacoustic over an open cavity with and without a spoiler[J]. Acta Aerodynamica Sinica, 2015, 33(5): 643-648(in Chinese). doi: 10.7638/kqdlxxb-2014.0025 [29] TRAVIN A K, SHUR M L, SPALART P R, et al. Improvement of delayed detached-eddy simulation for LES with wall modelling[C]//Proceedings of the European Conference on Computational Fluid Dynamics. Lisbon: ECCOMAS, 2006: 32-410. [30] 国防科学技术工业委员会. 高速风洞和低速风洞流场品质规范: GJB 1179—91[S]. 北京: 国防科学技术工业委员会, 1991.Commission of Science, Technology and Industry For National Defense. Specification for flow quality of high and low speed wind tunnels: GJB 1179—91[S]. Beijing: Commission of Science, Technology and Industry for National Defense, 1991(in Chinese). [31] BAUER R C, DIX R E. Engineering model of unsteady flow in a cavity: AEDC-TR-91-17[R]. Arnold AFB: Arnold Engineering Development Center, 1991. -

下载:

下载: