-

摘要:

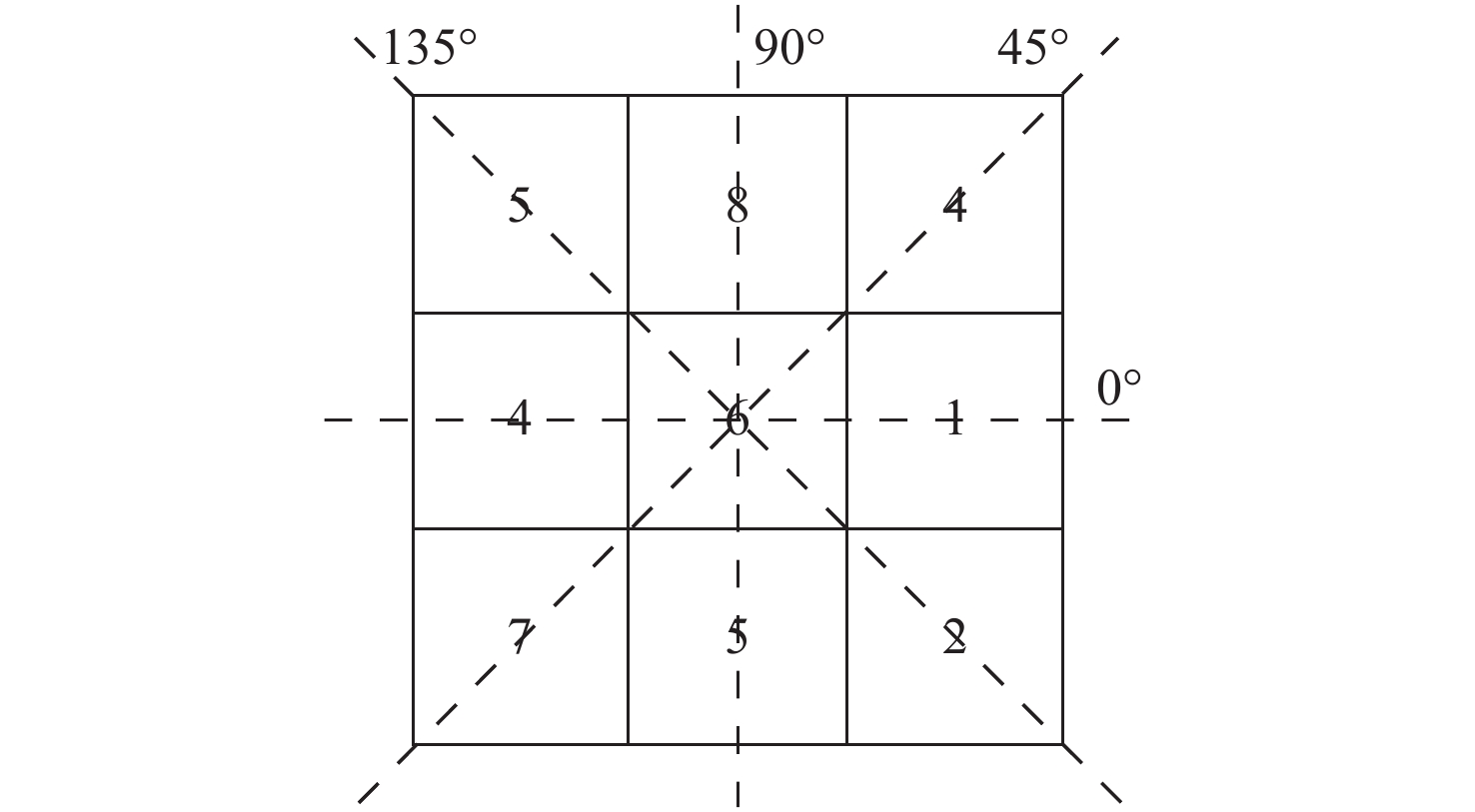

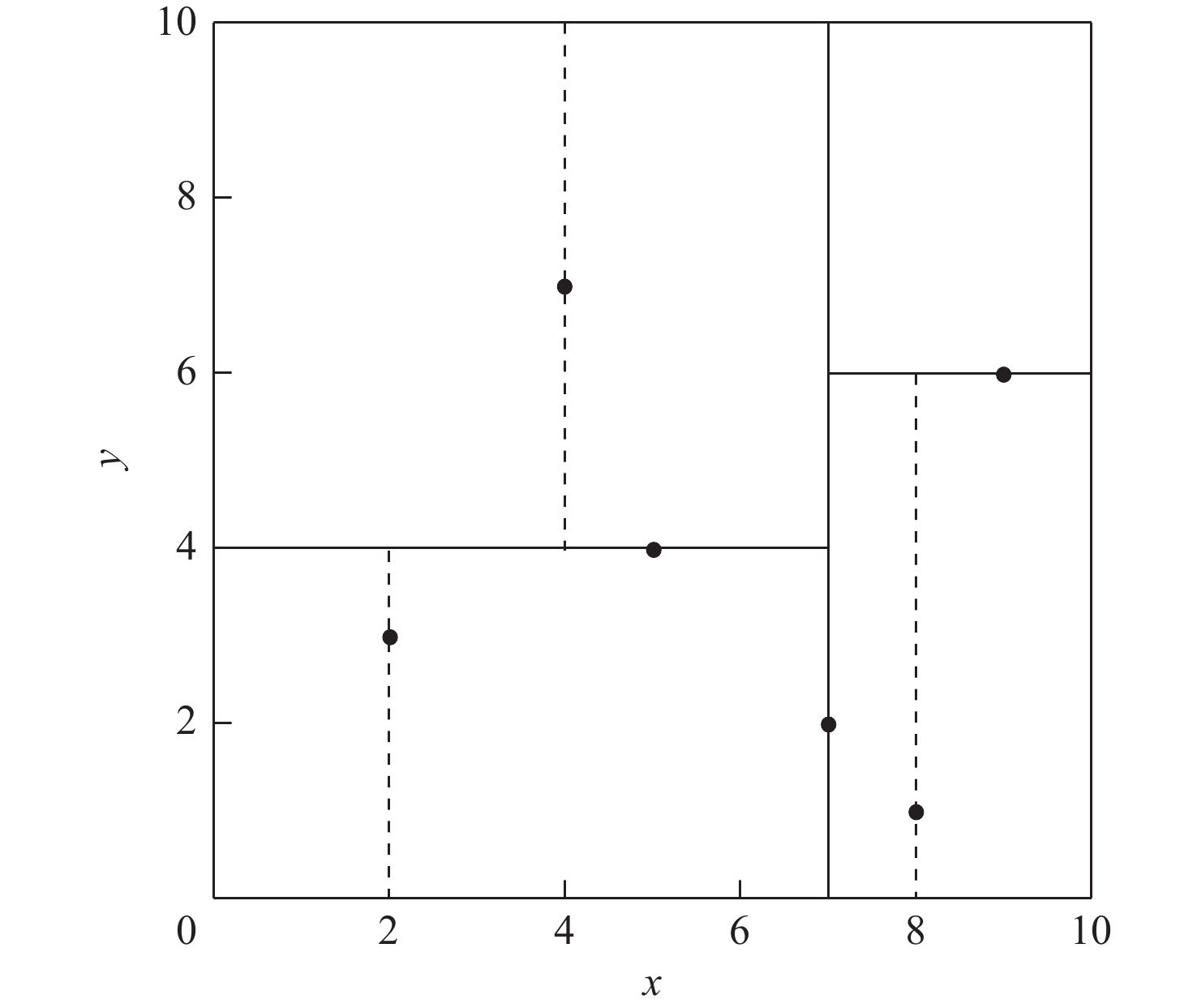

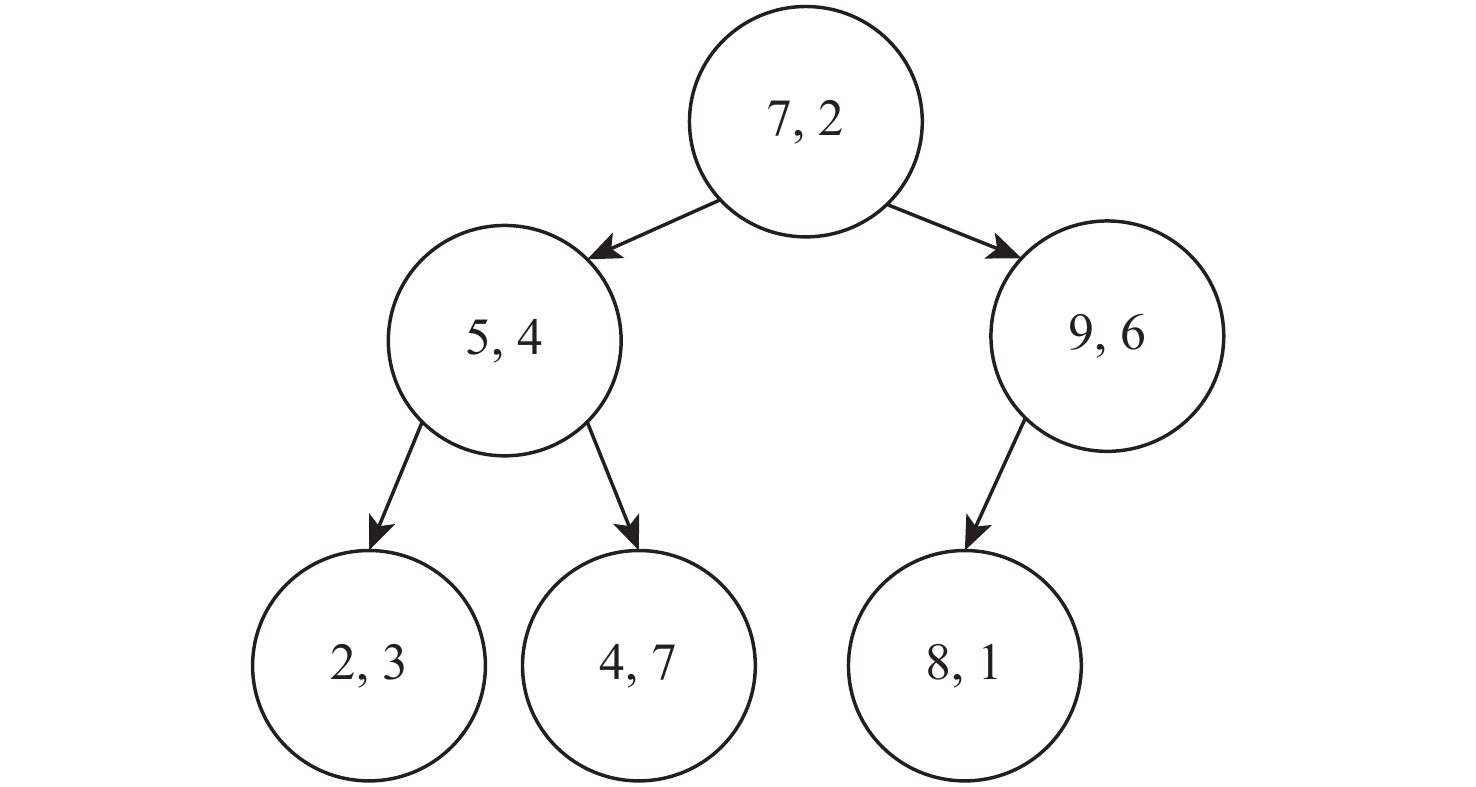

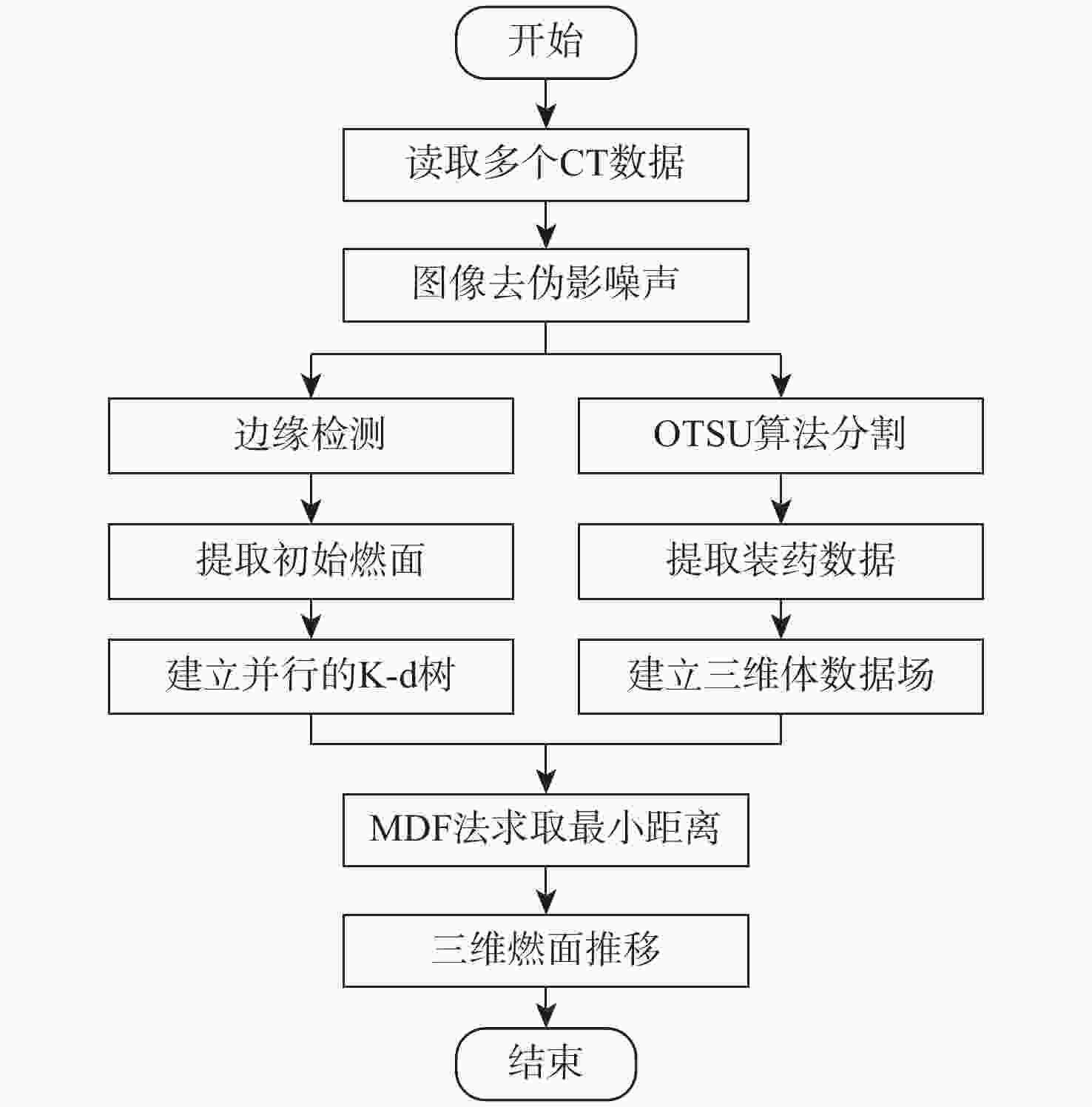

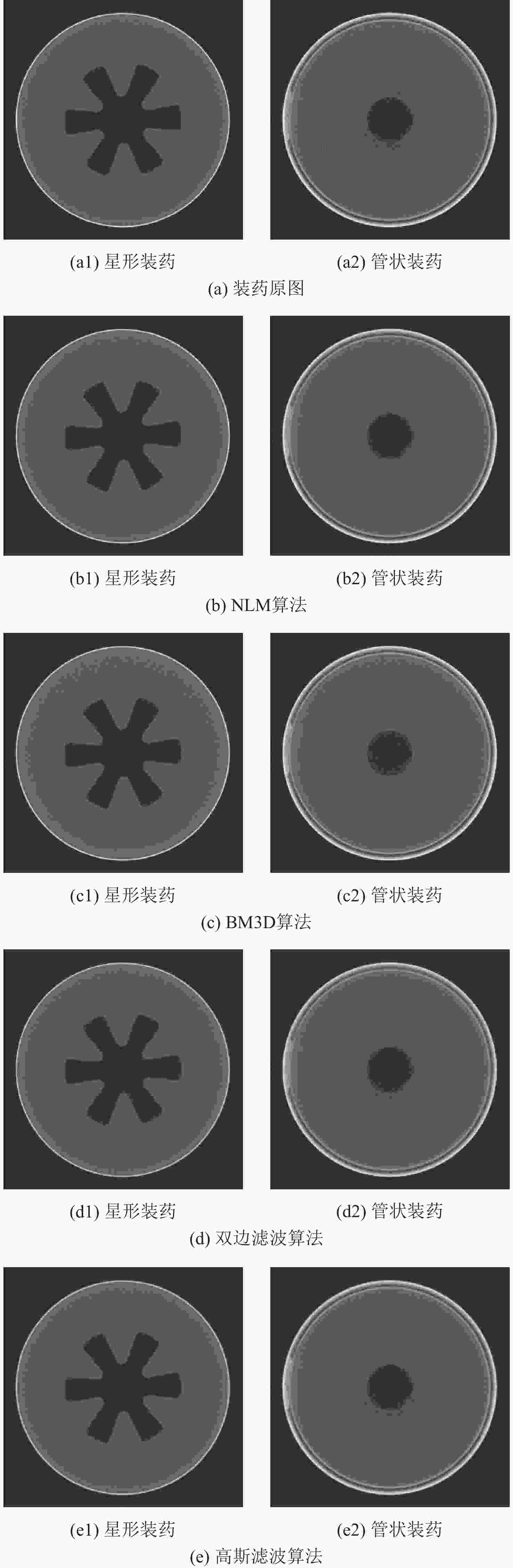

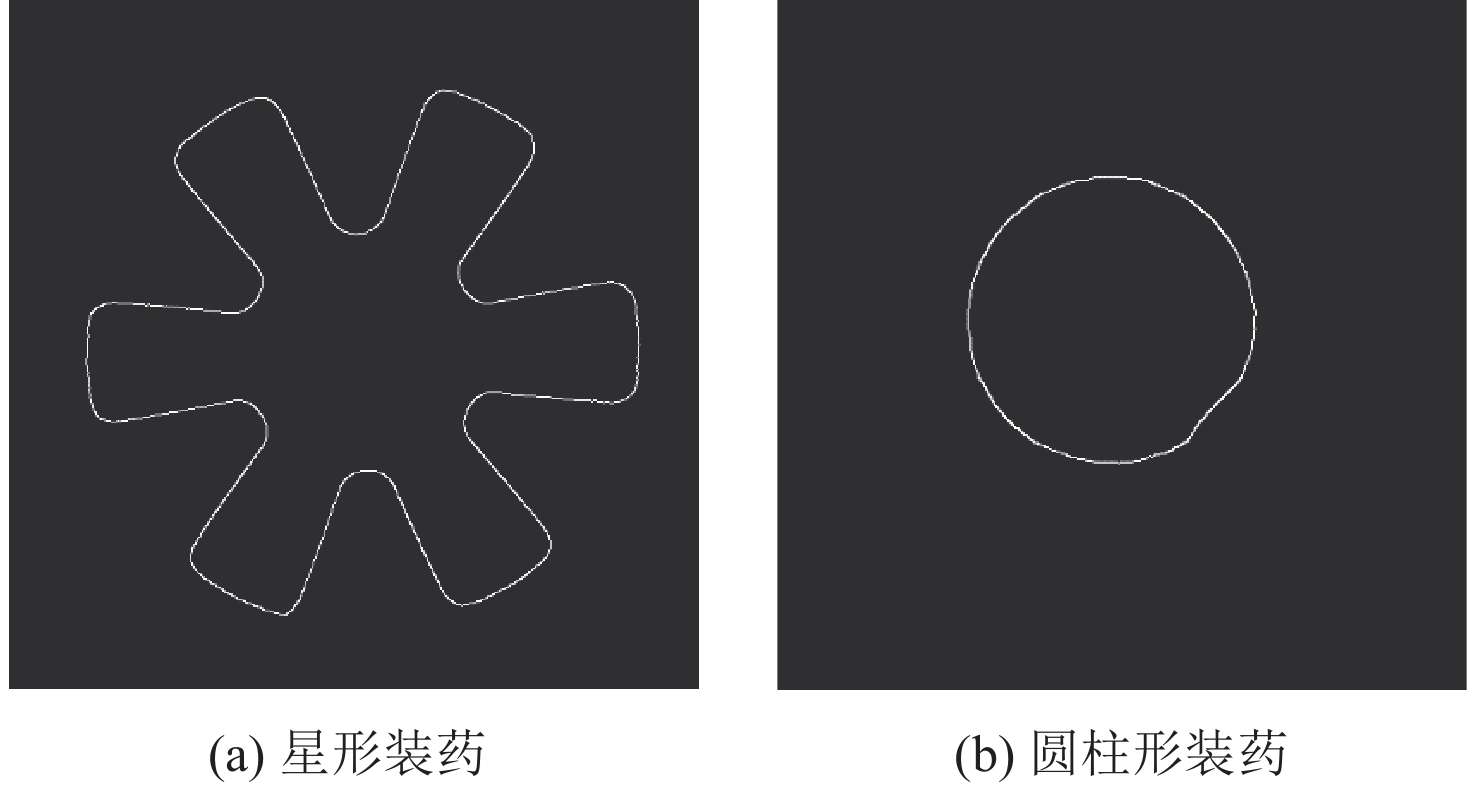

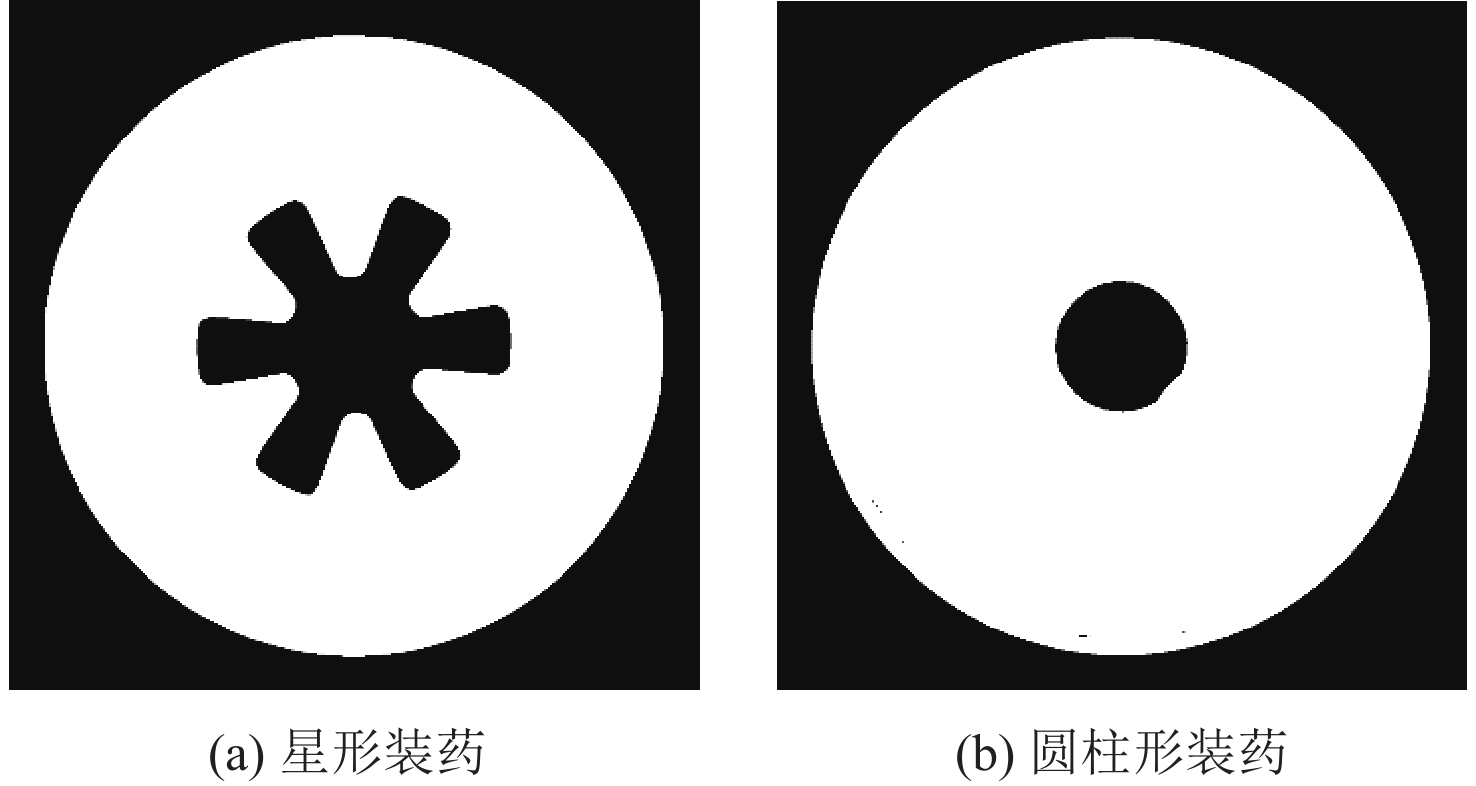

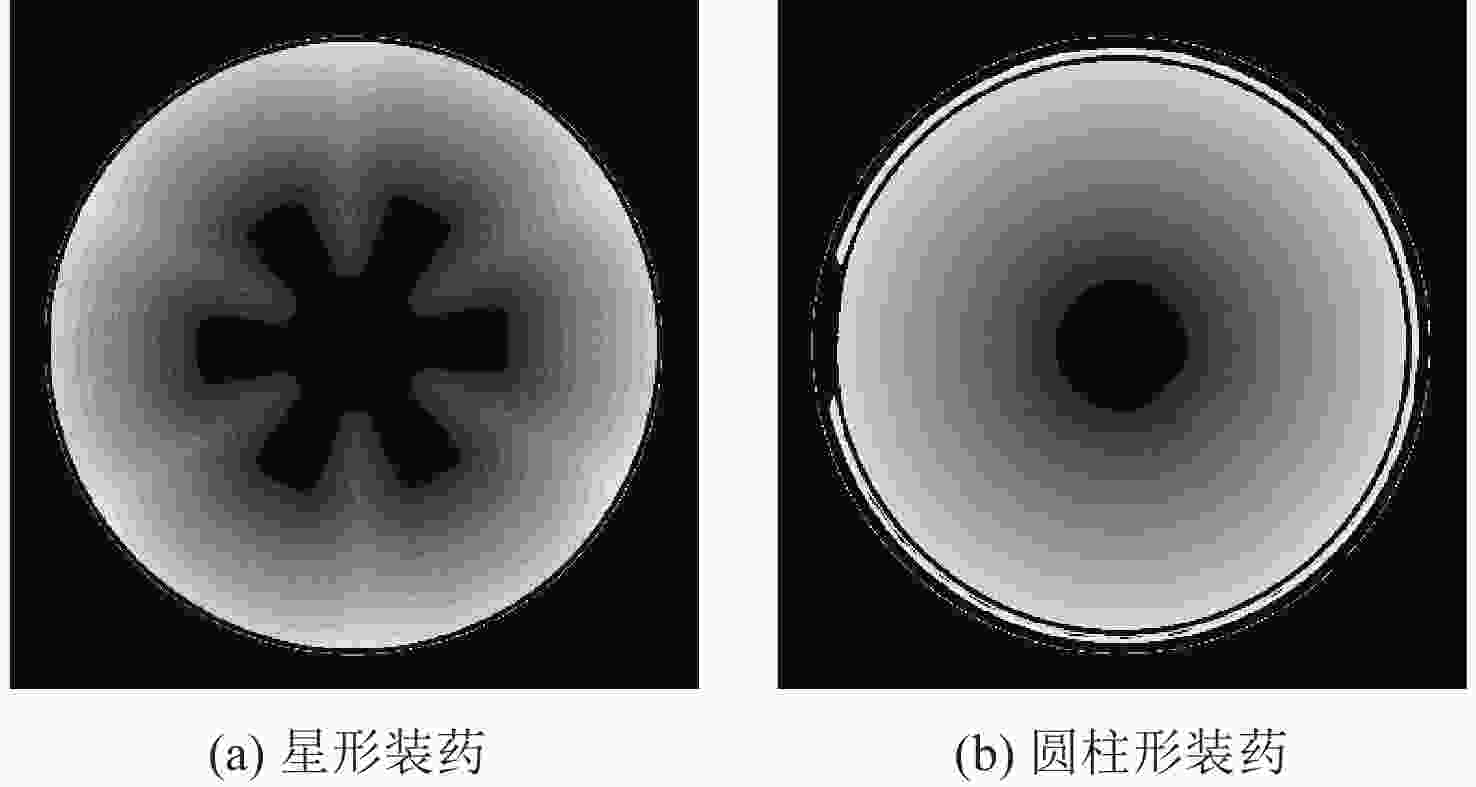

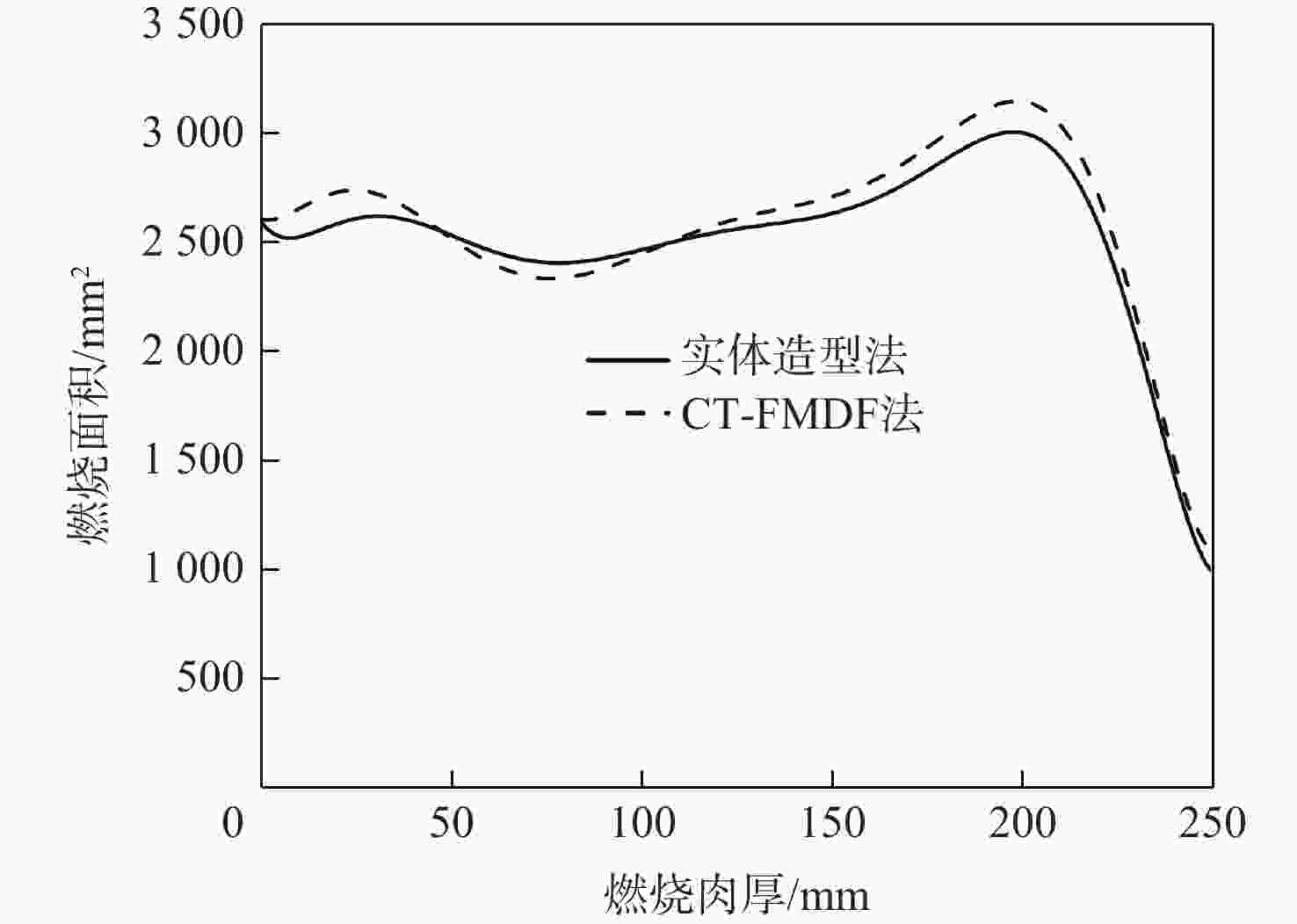

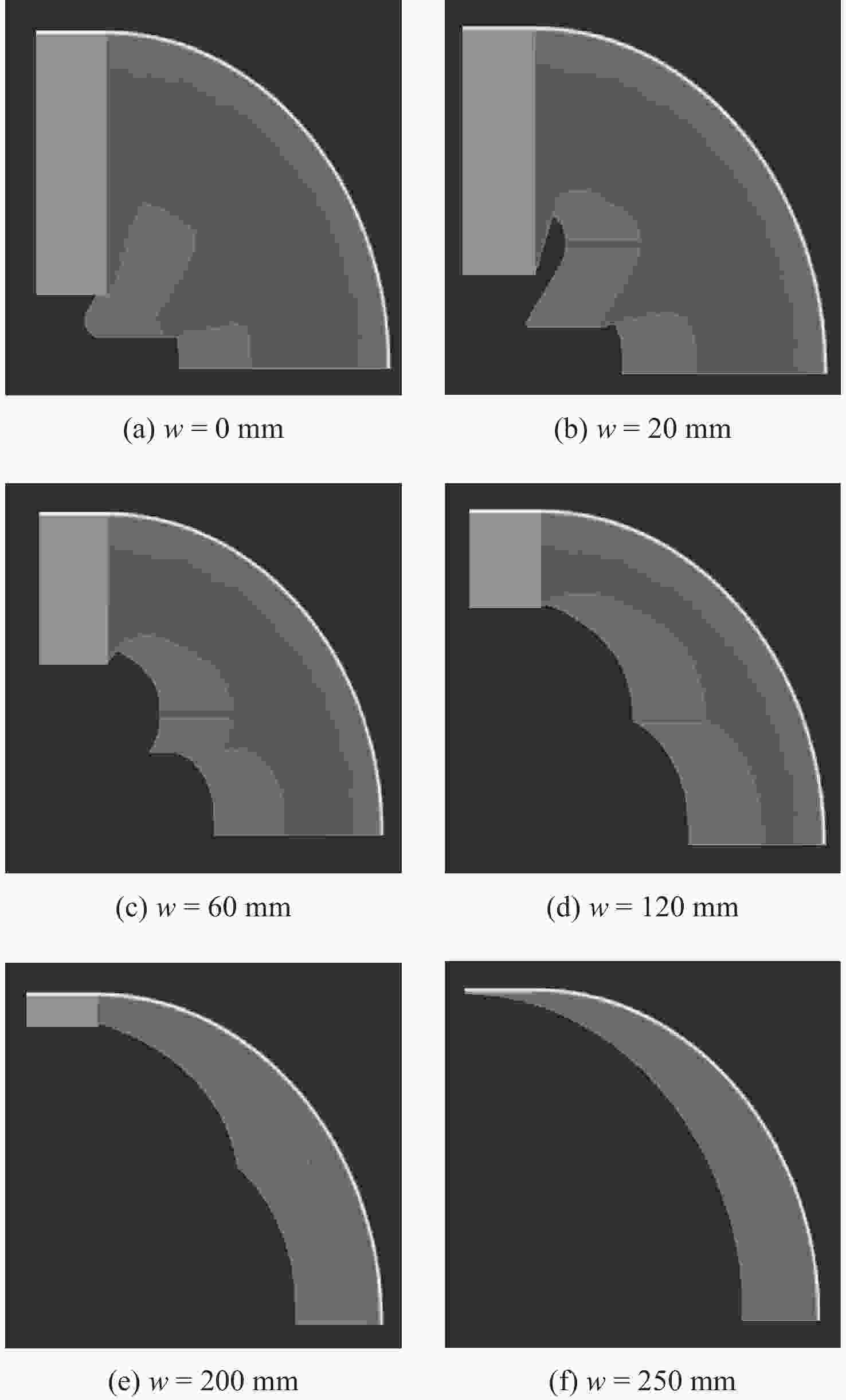

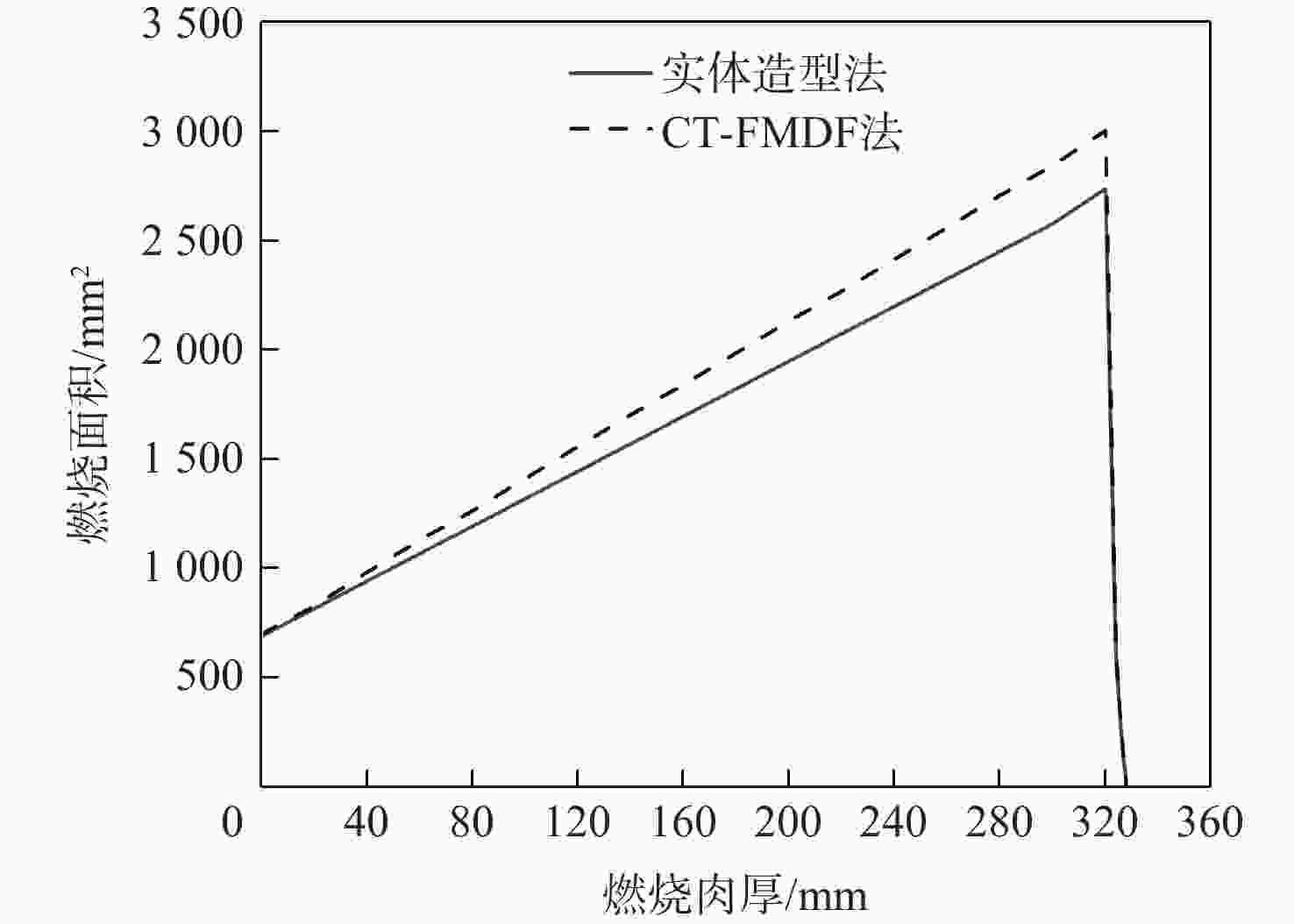

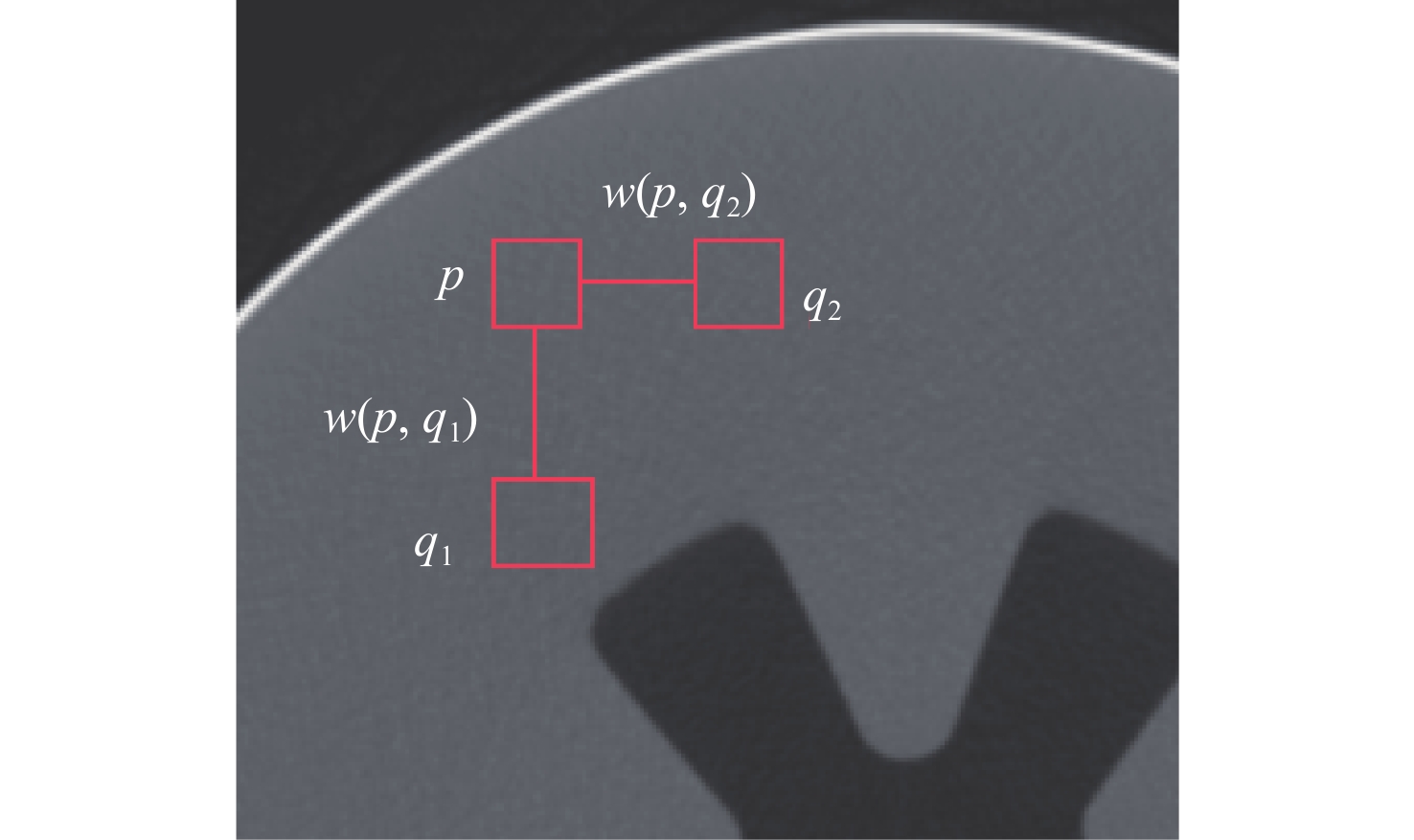

针对固体发动机电子计算机断层扫描(CT)图像数据具有伪影噪声的问题,和实际成型药柱燃面粗糙度大、退移计算难度大的问题,提出一种CT数据的快速最小距离函数(CT-FMDF)法。固体火箭发动机CT图像中存在伪影噪声,采用非均值滤波(NLM)算法对CT图像进行去噪处理,采用Scharr算子对去伪影后的图像进行Canny边缘检测,提取装药燃面。最大类间方差(OTSU)算法将装药分离,并建立三维装药体数据模型,对燃面数据建立多个并行K-d树,快速检索出装药到燃面的最小距离。实验结果证明:对于不同的装药结构,可以完成任意燃去厚度时的燃面位置,且CT-FMDF法运行时间更短。基于CT实测数据,对于带有初始燃面缺陷的装药,可计算出燃烧时缺陷对燃面的影响。

Abstract:A fast minimum distance function method for CT data (CT-FMDF) is proposed to address the artifact noise in CT image data of solid rocket motors, the large combustion surface roughness of actually formed grains, and the difficulty in transition calculation. The non-local means (NLM) filtering algorithm is used to denoise the CT images. Then, the Canny edge detection improved by the Scharr operator is used to extract the initial burning surface of the grains from the de-artifacted image. The maximum between-class variance algorithm (OTSU) separates the grains, establishing a three-dimensional volume data model of grains, and multiple parallel K-dimension trees for the combustion surface data. The minimum distance from the grains to the combustion surface is quickly retrieved. The experimental results show that for different grains structures, the position of a burning surface at any thickness can be achieved and that the algorithm has a shorter running time. For the grains with initial burning surface defects, the effect of the defects on the burning surface during combustion can be calculated based on the actual CT data.

-

Key words:

- solid motor /

- minimum distance function /

- CT image /

- grain burnback /

- K-d tree

-

表 1 K-d树的数据结构

Table 1. K-d tree data structure

域名 数据类型 描述 Node-data 数据矢量 数据集中某个数据点,

是n维矢量(本文就是k维)Range 空间矢量 该节点所代表的空间范围 split 整数 垂直于分割超平面的方向轴序号 Left K-d树 由位于该节点分割超平面左子空间内

所有数据点所构成的K-d树Right K-d树 由位于该节点分割超平面右子空间内

所有数据点所构成的K-d树Parent K-d树 父节点 表 2 去噪声图像质量分析

Table 2. Quality analysis of denoising image

去噪算法 MSE PSNR SSIM NLM(星形) 1.62984 46.0094 0.999048 NLM(圆柱) 6.33753 40.1116 0.997223 BM3D(星形) 2.16834 44.7695 0.998738 BM3D(圆柱) 3.74647 42.3946 0.998386 双边滤波(星形) 5.76638 40.5218 0.996544 双边滤波(圆柱) 10.8642 37.7708 0.995227 高斯滤波(星形) 8.27121 38.9551 0.995228 高斯滤波(圆柱) 7.36916 39.4566 0.996813 表 3 星形装药特征参数

Table 3. Characteristic parameters of star grain

肉厚

w/mm星角

数n星边

夹角θ/(°)星尖角

分数ε星尖导圆

半径f/mm特征

长度l/mm星根尖倒圆

半径r/mm220 6 45 0.7 20 230 20 -

[1] 武丹, 陈文杰, 司学龙, 等. 大型固体火箭发动机发展趋势及关键技术分析[J]. 武汉大学学报(工学版), 2021, 54(2): 102-107.WU D, CHEN W J, SI X L, et al. Research on development trend and key technologies of large solid rocket motor[J]. Engineering Journal of Wuhan University, 2021, 54(2): 102-107(in Chinese). [2] 叶定友, 薛朋飞, 闫大庆. 固体火箭推进技术发展的几点思考[J]. 固体火箭技术, 2021, 44(4): 427-430.YE D Y, XUE P F, YAN D Q. Considerations on development of solid rocket propulsion technology[J]. Journal of Solid Rocket Technology, 2021, 44(4): 427-430(in Chinese). [3] 王世辉, 陆明, 王欢欢, 等. 固体火箭发动机点火试验燃面退移最优重建方法研究[J]. 计算机测量与控制, 2021, 273(6): 245-248.WANG S H, LU M, WANG H H, et al. Research on optimal reconstruction method of combustion surface displacement of SRM ignition test[J]. Computer Measurement & Control, 2021, 273(6): 245-248(in Chinese). [4] 陈庆贵, 卢洪义, 齐强, 等. 固体火箭发动机界面脱粘切向 CT 检测[J]. 固体火箭技术, 2016, 39(3): 347-352.CHEN Q G, LU H Y, QI Q, et al. Tangential CT inspection of interface debonding of SRM[J]. Journal of Solid Rocket Technology, 2016, 39(3): 347-352(in Chinese). [5] 朱敏, 卢洪义, 丛培胜, 等. 固体发动机 CT 检测中的一种缺陷识别方法[J]. 航空动力学报, 2009, 24(1): 230-234.ZHU M, LU H Y, CONG P S, et al. Method of defect recognition in solid motor CT testing[J]. Journal of Aerospace Power, 2009, 24(1): 230-234(in Chinese). [6] 卢洪义, 陈庆贵, 周红梅, 等. 固体火箭发动机CT图像条状伪影校正[J]. 航空动力学报, 2016, 31(10): 2515-2521.LU H Y, CHEN Q G, ZHOU H M, et al. Streak artifacts correction of solid rocket motor's CT image[J]. Journal of Aerospace Power, 2016, 31(10): 2515-2521(in Chinese). [7] 栗飞, 鲜勇, 职世君. 某固体发动机含裂纹药柱地面点火试验及仿真分析[J]. 机械强度, 2021, 43(5): 1233-1238.LI F, XIAN Y, ZHI S J. Simulation analysis and ground test of solid rocket motor grain with surface crack[J]. Journal of Mechanical Strength, 2021, 43(5): 1233-1238(in Chinese). [8] 彭博, 李国盛, 孙婧博, 等. 基于快速最近邻搜索的固体火箭发动机装药燃面计算[J]. 推进技术, 2022, 43(5): 210-220.PENG B, LI G S, SUN J B, et al. Grain burnback analysis of solid rocket motor using fast nearest-neighbor search[J]. Journal of Propulsion Technology, 2022, 43(5): 210-220(in Chinese). [9] WILLCOX M A, BREWSTER M Q, TANG K C, et al. Solid propellant grain design and burnback simulation using a minimum distance function[J]. Journal of Propulsion and Power, 2007, 23(2): 465-475. doi: 10.2514/1.22937 [10] WILLCOX M A, BREWSTER M Q, TANG K C, et al. Solid rocket motor internal ballistics simulation using three-dimensional grain burnback[J]. Journal of Propulsion and Power, 2007, 23(3): 575-584. doi: 10.2514/1.22971 [11] 马长礼. 固体火箭发动机MDF燃面计算方法研究[D]. 长沙: 国防科技大学, 2007.MA C L. Research of MDF burning surface calculation method for solid rocket motor[D]. Changsha: National University of Defense Technology, 2007 ( in Chinese ). [12] 熊文波, 刘宇, 任军学, 等. 基于单元法的三维装药通用燃面计算[J]. 航空学报, 2009, 30(7): 1176-1180.XIONG W B, LIU Y, REN J X, et al. Generalized burning surface calculation of three dimensional propellant based on element method[J]. Acta Aeronautica et Astronautica Sinica, 2009, 30(7): 1176-1180(in Chinese). [13] DIWAKAR M, KUMAR M. A review on CT image noise and its denoising[J]. Biomedical Signal Processing and Control, 2018, 42: 73-88. doi: 10.1016/j.bspc.2018.01.010 [14] BUADES A, COLL B, MOREL J M. A non-local algorithm for image denoising[C]//2005 IEEE Computer Society Conference on Computer Vision and Pattern Recognition (CVPR'05). Piscataway: IEEE Press, 2005: 60-65. [15] KARTSOV S K, KUPRIYANOV D Y, POLYAKOV Y A, et al. Non-local means denoising algorithm based on local binary patterns[C]//Computer Vision in Control Systems-6. Berlin: Springer, 2020: 153-164. [16] SONG R, ZHANG Z, LIU H. Edge connection based Canny edge detection algorithm[J]. Pattern Recognition and Image Analysis, 2017, 27(4): 740-747. doi: 10.1134/S1054661817040162 [17] RONG W, LI Z, ZHANG W, et al. An improved Canny edge detection algorithm[C]//2014 IEEE International Conference on Mechatronics and Automation. Piscataway: IEEE Press, 2014: 577-582. [18] ZHOU K, HOU Q, WANG R, et al. Real-time kd-tree construction on graphics hardware[J]. ACM Transactions on Graphics (TOG), 2008, 27(5): 1-11. [19] BROWN R A. Building a balanced kd tree in o (kn log n) time[J]. Journal of Computer Graphics Techniques, 2015, 4(1):50-68. [20] 曾诚, 宋燕. 改进的OTSU和最大熵结合的迭代图像分割算法[J]. 智能计算机与应用, 2020, 10(12): 121-125.ZENG C, SONG Y. An improved image segmentation algorithm based on Otsu and maximum entropy[J]. Intelligent Computer and Applications, 2020, 10(12): 121-125(in Chinese). [21] REN P F, WANG H B, ZHOU G F, et al. Solid rocket motor propellant grain burnback simulation based on fast minimum distance function calculation and improved marching tetrahedron method[J]. Chinese Journal of Aeronautics, 2021, 34(4): 208-224. doi: 10.1016/j.cja.2020.08.052 [22] 王革, 韩万之, 李冬冬, 等. 基于水平集方法和最小距离函数法的复杂装药燃面退移问题研究[J]. 兵工学报, 2017, 38(2): 280-291.WANG G, HAN W Z, LI D D, et al. Research on grain burning surface regression based on level-set method and minimum distance function[J]. Acta Armamentarii, 2017, 38(2): 280-291(in Chinese). -

下载:

下载: